Cobalt-base alloy welding wire, hook claw using welding wire, connection rod and surfacing method

A cobalt-based alloy and welding wire technology, which is applied in the direction of connecting rods, connecting rod bearings, welding media, etc., can solve the problems of poor process stability, no engineering application value, and low yield, and achieve the effect of hardness and nondestructive testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0037] The cobalt-based alloy welding wire shown in Table 1 is used, the sum of the mass percentages of each component in the welding wire is 100%, and the diameter is φ2.7mm.

[0038] Table 1 Chemical composition of cobalt-based alloy welding wire (Wt%)

[0039]

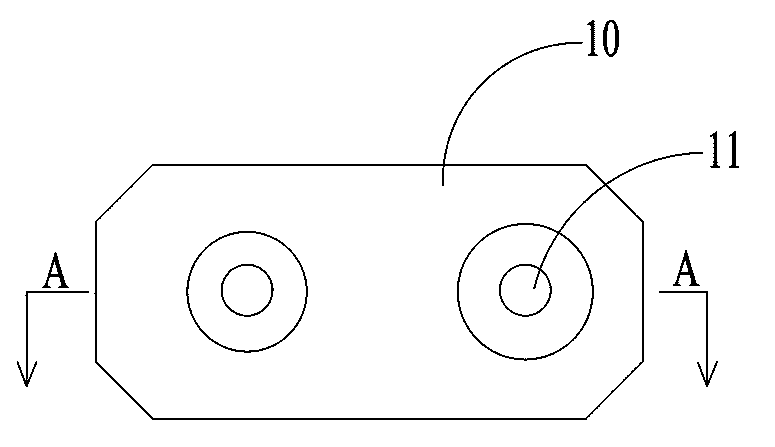

[0040] The base material of the claw and the connecting rod is made of 00Cr18Ni10N austenitic stainless steel.

[0041] Pretreatment: Before surfacing, remove the burrs on the surfaces to be surfacing of hooks and connecting rods and other defects that may affect the quality of surfacing, and clean the surfaces to be surfacing.

[0042] Preheating: Preheat the claws and connecting rods to be surfacing, and the preheating temperature is higher than 260°C.

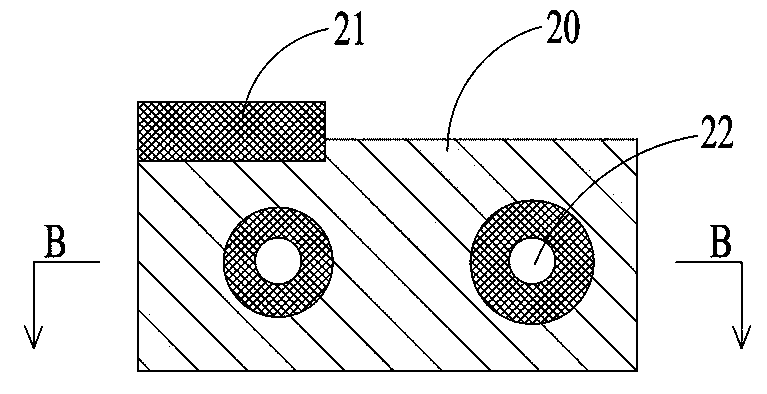

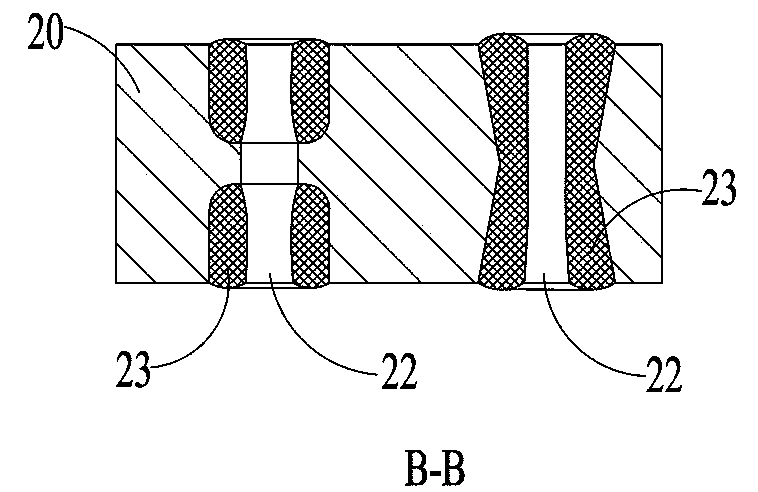

[0043] Overlay welding on the tooth surface of the hook and claw: oxyacetylene flame welding is used, such as Figure 5 As shown, ignite, adjust the flame to be a carbonization flame, and adjust the length of the inner flame L2 to be 2-2.5 times of the flame ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com