A kind of oil-based drilling cuttings breaking stabilizer and preparation method thereof

An oil-based drilling cuttings and destabilization technology, which is used in chemical dehydration/demulsification, treatment of hydrocarbon oil, petroleum industry, etc. Simple, good effect, good effect of breaking stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation raw materials of the oil-based drilling cuttings breaking agent provided by the invention include basic compounds. In the present invention, the basic compound is preferably a sodium-containing basic compound, more preferably sodium carbonate and / or sodium hydroxide.

[0027] The preparation raw materials of the oil-based drilling cuttings breaking agent provided by the present invention include organic matter, and the organic matter includes amide compounds and / or polybasic organic acids. In the present invention, the amide compound is preferably carbonamide. In the present invention, the polybasic organic acid is preferably 2-hydroxypropane-1,2,3-tricarboxylic acid and / or oxalic acid.

[0028] The raw materials for the preparation of the oil-based drilling cuttings breaking agent provided by the invention include water. The present invention has no special restrictions on the water, and industrial water commonly used by those skilled in the art can b...

Embodiment 1

[0049] Under the condition that the stirring speed is 100rpm, add sodium carbonate, carbonamide and water in sequence, the weight ratio of sodium carbonate, carbonamide and water is 13:14:73, keep stirring for 5min, and cool to room temperature to obtain oil-based drill cuttings Stabilizer.

[0050] At a stirring speed of 100rpm, add 100 parts by weight of oil-based cuttings to 100 parts by weight of the oil-based cuttings breaking agent obtained above, and stir for 5 minutes to obtain a solid-liquid mixture; Under these conditions, centrifuge for 3 minutes and let stand to obtain a base oil phase, an aqueous phase and a solid phase.

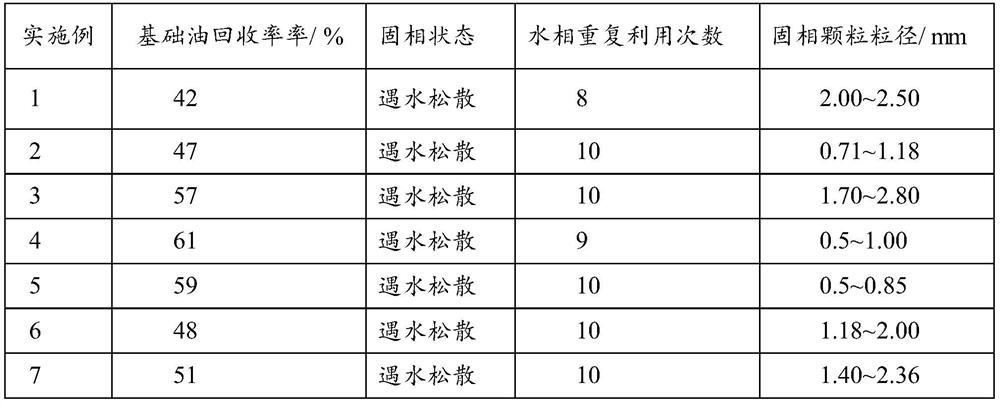

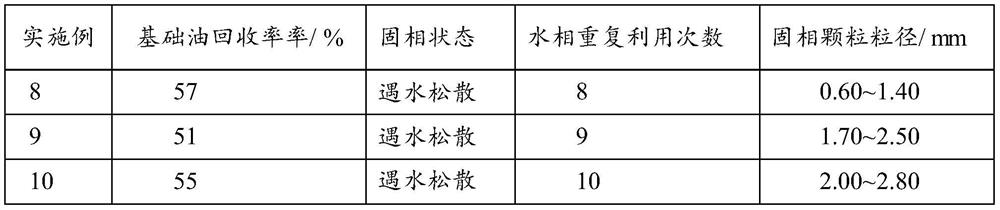

[0051] According to the method described in the above technical scheme, the oil content, state, particle size and base oil recovery rate in the solid phase after the separation are tested, and the test results are shown in Table 1, which is the oil base prepared by the embodiment of the present invention. Breaking effect data of cuttings breaki...

Embodiment 2

[0055] Under the condition that the stirring rate is 200rpm, sodium carbonate, oxalic acid and water are sequentially added, the weight ratio of the sodium carbonate, oxalic acid and water is 20:20:60, the stirring is kept for 15min, cooled to room temperature, and the oily base Drill cutting stabilizer.

[0056] At a stirring speed of 200rpm, add 100 parts by weight of oil-based cuttings to 200 parts by weight of the oil-based cuttings breaking agent prepared above, and stir for 15 minutes to obtain a solid-liquid mixture; Under the condition of 3000rpm, centrifuge for 4min and let stand to obtain base oil phase, water phase and solid phase.

[0057] According to the method described in the above-mentioned technical scheme, test the oil content, state, particle size and base oil recovery rate in the solid phase after separation, and the test results are shown in Table 1.

[0058] The above separated water phase can be directly used as an oil-based drill cuttings breaking age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com