Production technology for high-viscosity CPP self-sticking protection film

A self-adhesive protective film, production process technology, applied in layered products, lamination devices, lamination, etc., can solve the poor control of cast film shrinkage, fish eyes, crystal points, black spots, impurities can not be obtained Effectively suppress and other problems to achieve the effect of improving product transparency, product quality stability, and high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

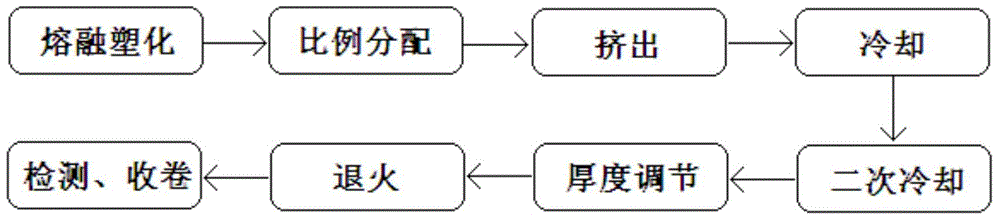

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0020] This case provides the production process of the high-viscosity CPP self-adhesive protective film of an embodiment. The high-viscosity CPP self-adhesive protective film is a three-layer co-extruded cast film, including an anti-adhesive layer, a base layer and an adhesive layer. The high-viscosity CPP The preparation principle of self-adhesive protective film is relatively mature, and the principles adopted by various manufacturers are similar, but "able to manufacture" does not mean that the quality of the film produced by each company must be very good, and it can produce top-level optical equipment that can be used There are very few manufacturers of films, and the final reason is that the improvement of the raw material formula is not enough, and the production proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com