Carrier tape for 5G chip PVD process and manufacturing method thereof

A manufacturing method and chip technology, applied in the direction of film/flaky adhesives, coatings, adhesive additives, etc., can solve the problems of unstable carrier tape viscosity, low process yield, easy chip drop, etc., to achieve good Antistatic ability, high process yield, and long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] Further, the preparation method of described composite acrylic glue comprises the following steps:

[0038] S11, put acrylic glue, inorganic filler, anti-aging agent, antibacterial and antifungal agent, coupling agent and plasticizer into the temperature-controllable reaction kettle, raise the temperature to 75°C, start the stirrer to stir for 35min-40min, and the stirring speed is 155r / min~160r / min, the mixture A is prepared at this time;

[0039] S12, send the carbon nanotubes and lithium sulfate into the reaction kettle, adjust the stirring speed to 310r / min-350r / min, and obtain the composite acrylic glue after stirring evenly.

[0040] Further, the plasticizer is an epoxy plasticizer.

[0041]Further, the specific steps of defoaming casting technology in S2 are as follows: coating the polyamic acid added with nano aggregates on the carrier, sending it into a tunnel oven, raising the temperature in stages, at 345°C to 250°C , heated for 35min-40min, and then reacte...

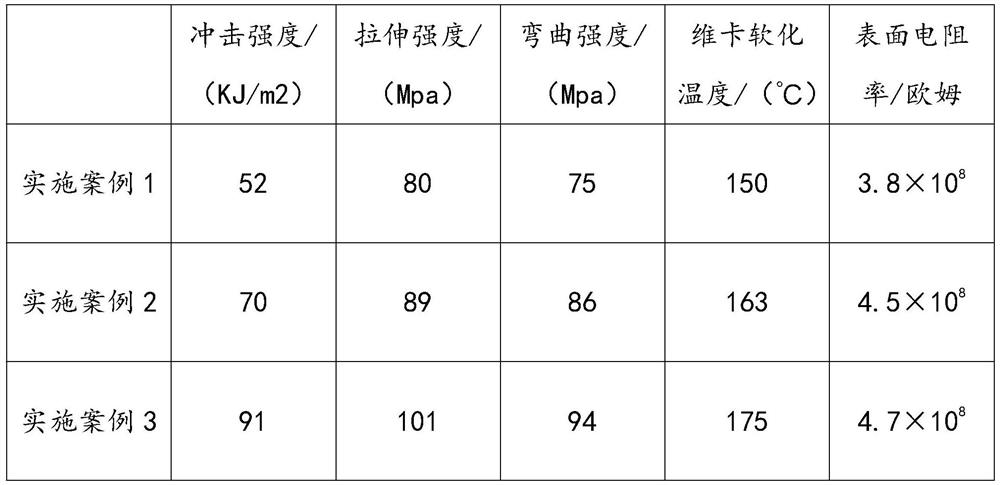

Embodiment example 1

[0046] Weigh 55 parts of acrylic glue, 35 parts of inorganic filler, 1 part of anti-aging agent, 0.2 part of antibacterial and antifungal agent, 12 parts of coupling agent, 10 parts of plasticizer, 5 parts of carbon nanotubes and 10 parts of lithium sulfate. Put glue, inorganic filler, anti-aging agent, antibacterial and antifungal agent, coupling agent and plasticizer into the temperature-controllable reaction kettle, raise the temperature to 75°C, start the stirrer to stir for 40min, and the stirring speed is 160r / min. Prepare mixture A, send carbon nanotubes and lithium sulfate into the reaction kettle, adjust the stirring speed to 350r / min, and obtain the composite acrylic glue after stirring evenly;

[0047] Weigh 70 parts of pyromellitic dianhydride, 60 parts of dimethyl acetyl, 5 parts of composite nanoparticles, 90 parts of organosol, 40 parts of p-phenylenediamine, 25 parts of polyethylene glycol, 25 parts of ethanol, antistatic liquid 45 parts and 30 parts of composi...

Embodiment example 2

[0052] Weigh 55 parts of acrylic glue, 35 parts of inorganic filler, 1 part of anti-aging agent, 0.2 part of antibacterial and antifungal agent, 12 parts of coupling agent, 10 parts of plasticizer, 6 parts of carbon nanotubes and 11 parts of lithium sulfate. Put glue, inorganic filler, anti-aging agent, antibacterial and antifungal agent, coupling agent and plasticizer into the temperature-controllable reaction kettle, raise the temperature to 75°C, start the stirrer to stir for 40min, and the stirring speed is 160r / min. Prepare mixture A, send carbon nanotubes and lithium sulfate into the reaction kettle, adjust the stirring speed to 350r / min, and obtain the composite acrylic glue after stirring evenly;

[0053] Weigh 70 parts of pyromellitic dianhydride, 60 parts of dimethyl acetyl, 10 parts of composite nanoparticles, 90 parts of organosol, 40 parts of p-phenylenediamine, 25 parts of polyethylene glycol, 25 parts of ethanol, antistatic liquid 45 parts and 30 parts of compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com