Online lamination protection film of light guide plate and preparation process of online lamination protection film

A preparation process and technology of protective film, which are applied in the field of protective film for on-line lamination of light guide plates and its preparation process, can solve the problems of inconvenient operation, poor temperature resistance, small tearing strength, etc. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the drawings and embodiments:

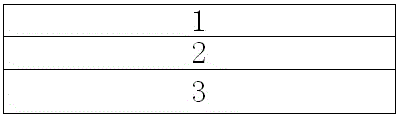

[0042] Such as figure 1 As shown, a light guide plate is laminated with a protective film on-line and includes a substrate surface layer 1, a core layer 2 and an elastomer layer 3 from the inside out. The core layer 2 is provided between the substrate surface layer 1 and the elastomer layer 3. The elastomer layer 3 is bonded to the board,

[0043] The surface layer 1, the core layer 2 and the elastomer layer 3 of the base material are formed into one body through a co-extrusion process.

[0044] The thickness of the protective film is 50-150 microns, and the surface layer 1 of the substrate plays a role of temperature resistance. The protective film is attached to the board and does not deform, shrink, or bubble in an environment of 90 degrees. The thickness of the core layer 2 is 30-40 microns, and the core layer 2 acts as a protective film to increase stiffness and bri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com