Micro-adhesion protection film, preparation method and applications thereof

A protective film and micro-adhesive technology, applied in adhesives, pressure-sensitive films/sheets, film/sheet-shaped adhesives, etc., can solve problems such as large viscosity climb, interference of electronic components, residual glue, etc., and achieve stable viscosity , The effect of small change in peeling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

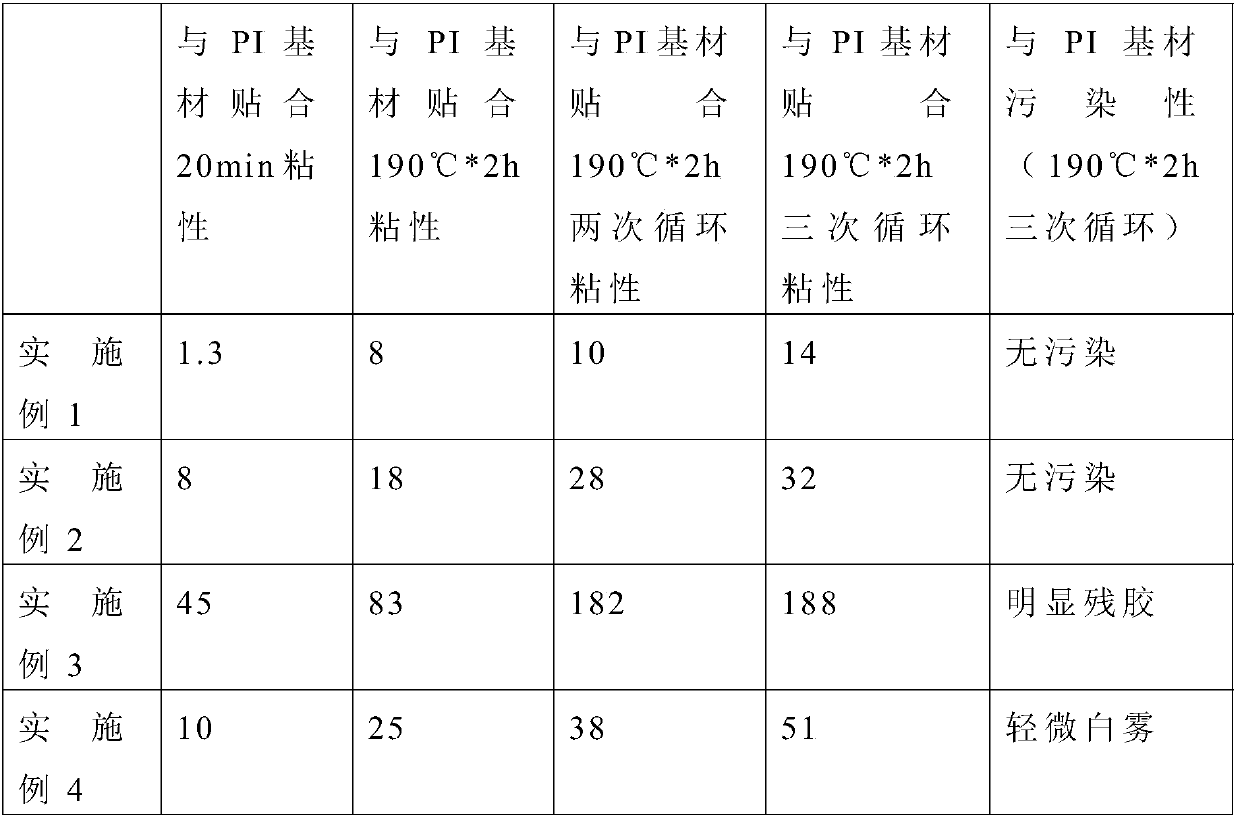

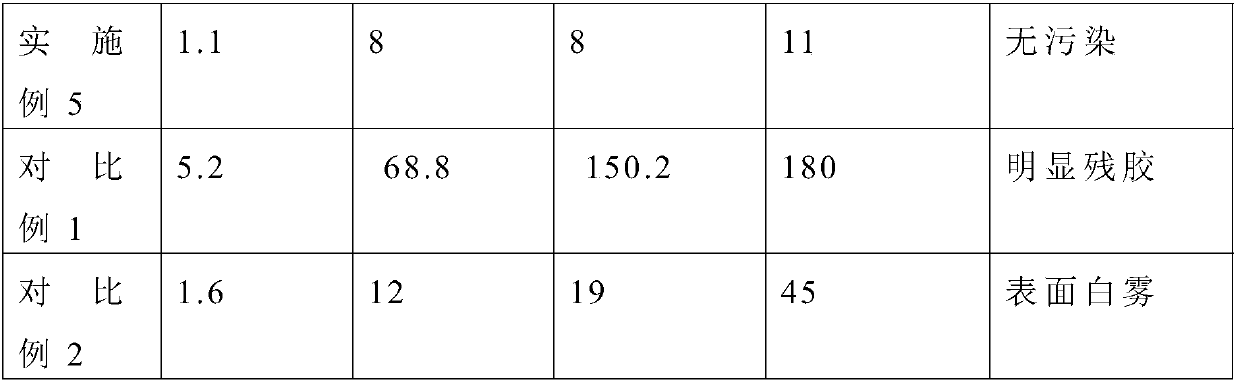

Embodiment 1

[0029] Such as figure 1 As shown, this embodiment is a kind of slightly sticky protective film, which consists of a base material layer, an adhesive layer and a release layer from top to bottom. The substrate layer is a 12.5 μm PI film, the thickness of the adhesive layer is 15 μm, and the release layer is a silicone release film with a thickness of 25 μm.

[0030] The preparation method of slightly sticky protective film comprises the steps:

[0031] S1: Preparation of high-temperature-resistant acrylic masterbatch: Methyl methacrylate: butyl acrylate: ethyl acrylate: acrylic acid: acrylamide with a mass ratio of 32:52:10:2:4, and ethyl acetate to make 30% Masterbatch with solid content;

[0032] S2: Take 100g of the masterbatch prepared in step S1, add 1.8g of hexamethylene diisocyanate curing agent (wherein the solvent is mainly ethyl acetate) with a solid content of 75%, stir for 20min to prepare a mixed solution, add the Leveling agent 1.5g, antioxidant 10101.5g, after...

Embodiment 2

[0035] Basically the same as Example 1, except that the mass ratio of methyl methacrylate: butyl acrylate: ethyl acrylate: acrylic acid: acrylamide is 22:62:10:2:4.

Embodiment 3

[0037] Basically the same as Example 1, except that the mass ratio of methyl methacrylate: butyl acrylate: ethyl acrylate: acrylic acid is 32:52:10:2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com