A kind of photocuring coating, ultraviolet light curing hydrophobic anti-adhesion film surface and preparation method thereof

A light-curing coating and ultraviolet light technology, which is applied in polyether coatings, antifouling/underwater coatings, polyurea/polyurethane coatings, etc., can solve the problems of dirty film surface, decreased hydrophobicity, and adsorption together, and achieve Enhanced hydrophobicity, no reduction in water contact angle, and cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

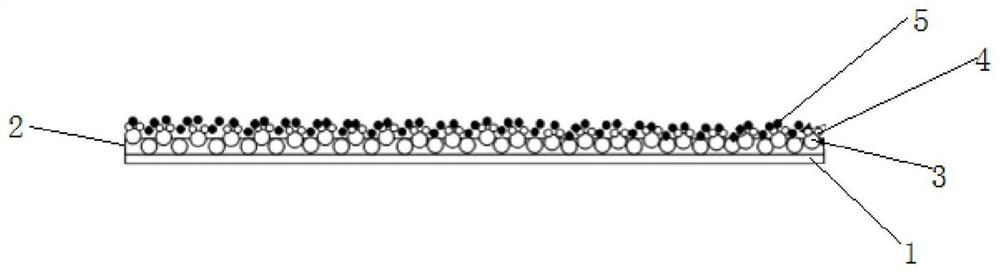

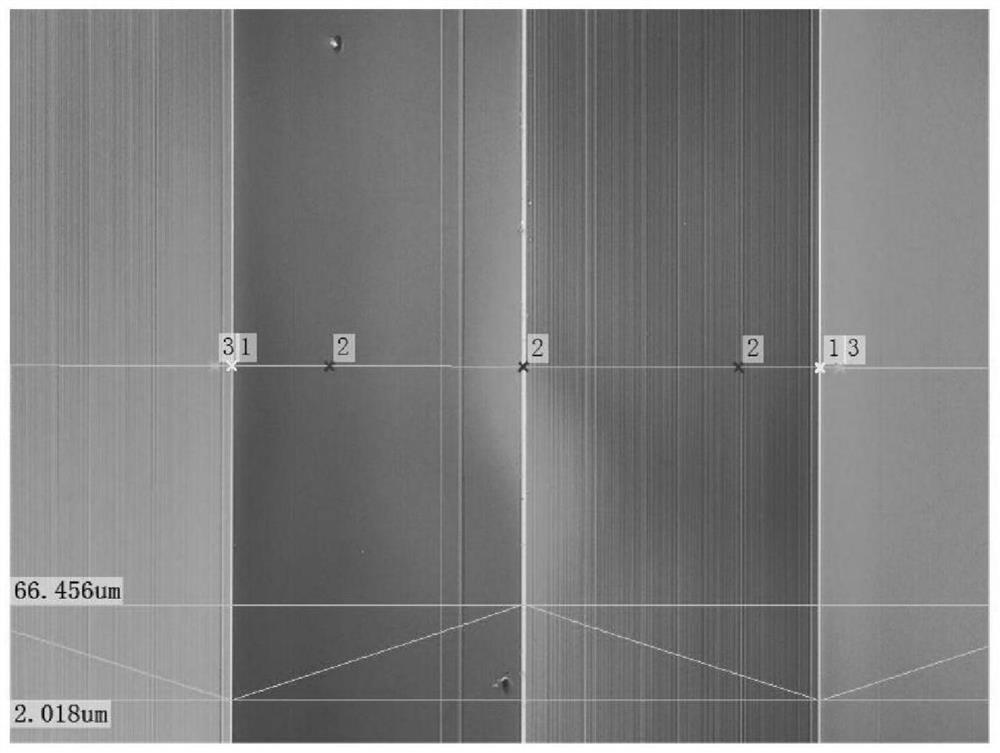

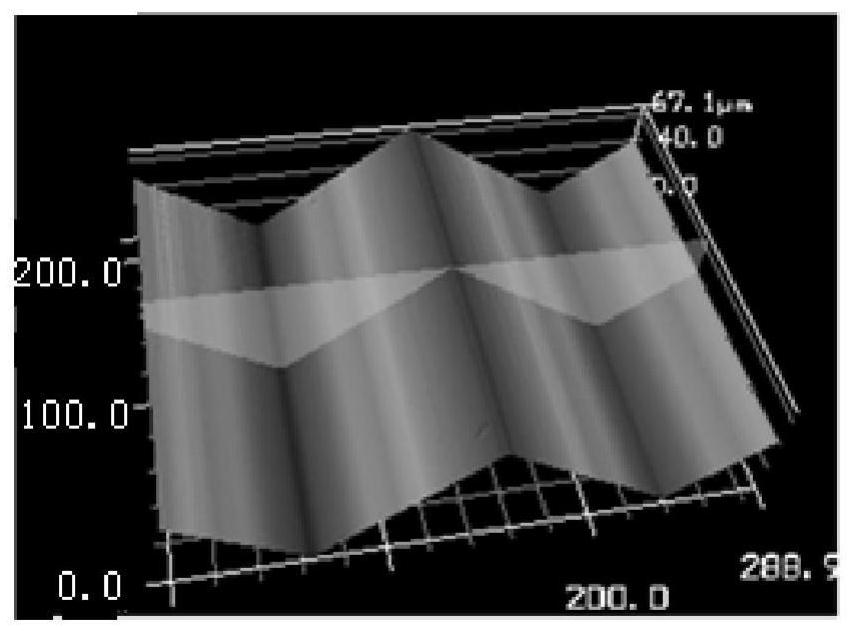

Image

Examples

Embodiment 1

[0074] In this embodiment, a photocurable coating is provided, and the photocurable coating includes the following components by weight:

[0075] 15 parts of polyurethane acrylate, 30 parts of nanoparticles, 15 parts of perfluoropolyether, 3 parts of photoinitiator, 8 parts of perfluoro-modified long-chain alkyl silane, and 30 parts of solvent. Among them, the polyurethane acrylate is Cytec EBECRYL8415, the nanoparticles are nano-zinc oxide, the particle size of the nanoparticles is 50-150nm, and the photoinitiator is 2-methyl-1-[-4-methylthio)phenyl]-2 -Morpholinyl-1-acetone, perfluoropolyether is DAC-HP, and perfluoromodified long-chain alkylsilane is tridecafluorooctyltrimethoxysilane.

[0076] The preparation method of described photocuring coating comprises the following steps:

[0077] (1) Add solvent and perfluoropolyether to the reactor, stir for 20min at a stirring rate of 800r / min, add photoinitiator and polyurethane acrylate to the mixture in step A, stir and disso...

Embodiment 2

[0087] In this embodiment, a photocurable coating is provided, and the photocurable coating includes the following components by weight: 15 parts of polyurethane acrylate, 10 parts of nanoparticles, 3 parts of perfluoropolyether, 3 parts of photoinitiator, 15 parts of perfluorinated modified long-chain alkyl silane, 30 parts of solvent. Among them, the polyurethane acrylate is Cytec EBECRYL8602, the nanoparticles are nano-silicon oxide, the particle size of the nanoparticles is 50-200nm, and the photoinitiator is 2,4,6-trimethylbenzoyl-diphenylphosphine oxide. The fluoropolyether is RS-90, and the perfluoromodified long-chain alkylsilane is tridecafluorooctyltriethoxysilane.

[0088] The preparation method of described photocuring coating comprises the following steps:

[0089] (1) Add solvent and perfluoropolyether to the reactor, stir at a stirring rate of 600r / min for 30min, add photoinitiator and polyurethane acrylate to the mixture in step A, stir and dissolve, keep stir...

Embodiment 3

[0096] In this embodiment, a photocurable coating is provided, and the photocurable coating includes the following components by weight: 15 parts of polyurethane acrylate, 30 parts of nanoparticles, 10 parts of perfluoropolyether, 3 parts of photoinitiator, 5 parts of perfluorinated modified long-chain alkyl silane, 30 parts of solvent. Among them, the polyurethane acrylate is Sartomer CN9013NS, the nanoparticles are nano-silicon oxide, the particle size of the nanoparticles is 50-250nm, and the photoinitiator is 2-hydroxy-2-methyl-1-phenyl-1-acetone. The fluoropolyether is KY-1203, and the perfluoromodified long-chain alkylsilane is tridecafluorooctyltriethoxysilane.

[0097] The preparation method of described photocuring coating comprises the following steps:

[0098] (1) Add solvent and perfluoropolyether to the reactor, stir for 50min at a stirring rate of 700r / min, add photoinitiator and polyurethane acrylate to the mixture in step A, stir and dissolve, keep stirring fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com