Preparation method, prepared ketene compound and application of compound

A technology for compounds and ketenes, applied in the field of compound preparation, can solve the problems of complex cracking products, reduced reaction conversion rate, low single-pass yield, etc., to improve the cracking reaction conversion rate, improve the reaction selectivity, and inhibit the cracking reverse reaction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

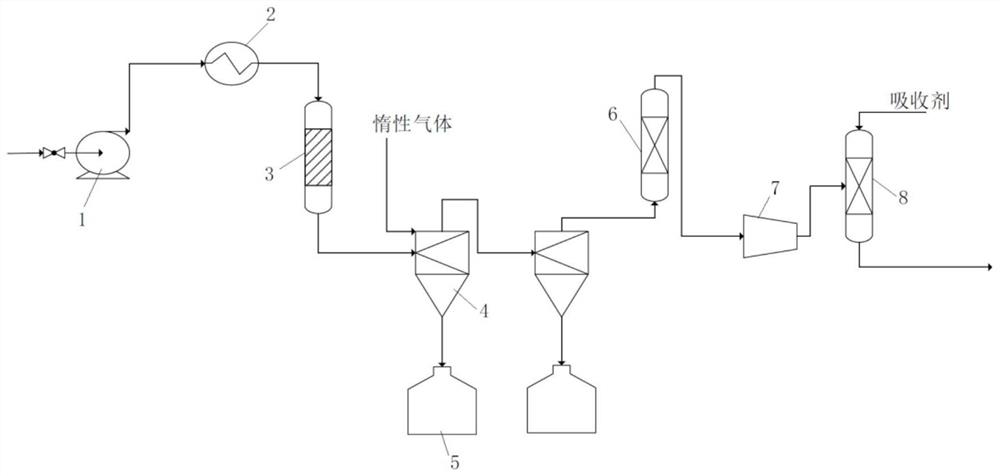

Embodiment 1

[0050] Isobutyric anhydride (purity 99%) is passed through feed pump 1 ( figure 1 shown) enters the preheater 2 at a rate of 4.46g / min, and the preheating temperature is 350°C. After the raw material is preheated and gasified, it enters the pyrolysis reactor 3 with a reaction temperature of 400°C and a reaction pressure of 10kPa. The high-temperature cracked gas is successively passed through two series-connected cyclone separators 4 with a wall temperature of 30° C., and nitrogen gas with a precooling temperature of 40° C. is passed into the cyclone separators at a rate of 3.2 L / min (the total moles of nitrogen are The amount is 5 times of the molar amount of the raw material), the liquid coming out from the cyclone separator is collected by the separation liquid storage tank 5, and the gas phase is sent to the washing tower 6, and reverse spray washing is carried out with cyclohexane as the washing agent. The gas phase coming out from the washing tower enters the collection...

Embodiment 2

[0053] Isobutyric anhydride (purity 99%) enters the preheater 2 at a rate of 29.1 g / min through the feed pump 1, and the preheating temperature is 300°C. After the raw material is preheated and gasified, it enters the pyrolysis reactor 3 with a reaction temperature of 500°C and a reaction pressure of 20kPa. The high-temperature cracked gas is successively passed through two series-connected cyclone separators 4 with a wall temperature of 25° C., and nitrogen gas with a precooling temperature of 25° C. The amount is 2 times of the molar amount of the raw material), the liquid coming out from the cyclone separator is collected by the separation liquid storage tank 5, and the gas phase is sent into the washing tower 6, and the reverse spray washing is carried out with n-hexane as the washing agent. The gas phase coming out of the washing tower enters the collection device 8, and the product DMK is collected with n-nonane as an absorbent to obtain a DMK solution with a mass concen...

Embodiment 3

[0056] Isobutyric anhydride (purity 99%) enters the preheater 2 at a rate of 3.7 g / min through the feed pump 1, and the preheating temperature is 310° C. After the raw material is preheated and gasified, it enters the pyrolysis reactor 3 with a reaction temperature of 460°C and a reaction pressure of 12kPa. The high-temperature cracked gas is successively passed through two series-connected cyclone separators 4 with a wall temperature of 35° C., and nitrogen gas with a precooling temperature of 30° C. is passed into the cyclone separators at a rate of 1.6 L / min (the total moles of nitrogen are The amount is 3 times of the molar amount of the raw material), the liquid coming out from the cyclone separator is collected by the separation liquid storage tank 5, and the gas phase is sent into the washing tower 6, and reverse spray washing is carried out with cyclohexane as the washing agent. The gas phase coming out of the washing tower enters the collection device 8, and the produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com