Method for removing mercury and mercury-containing compounds from oxygen-enriched combustion flue gas, and adsorbent and preparation method thereof

A technology of combustion flue gas and oxygen-enriched combustion, which is applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of high production cost and transportation cost of active gas, achieve low N content, simple process, and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

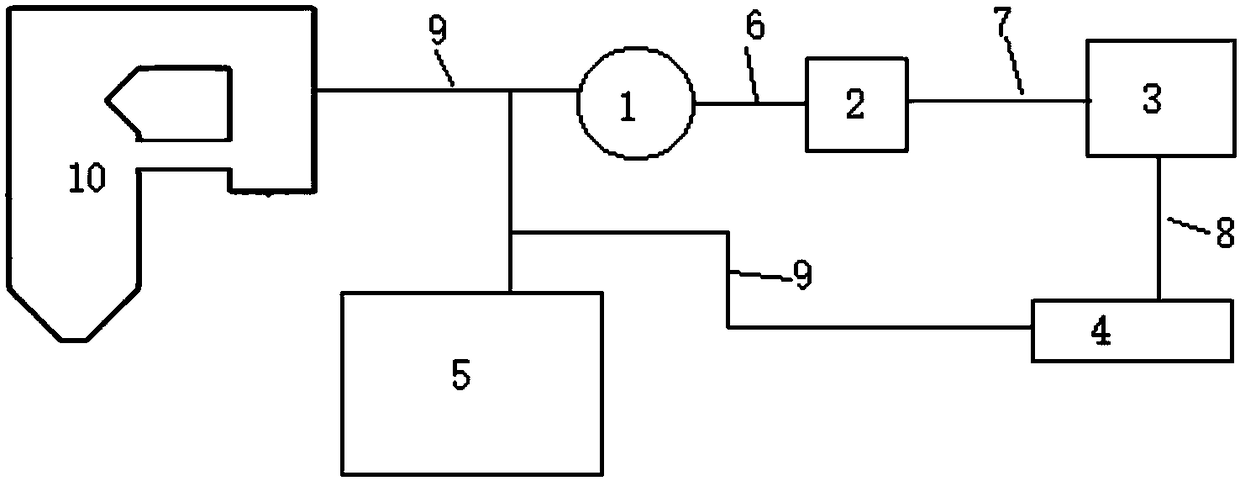

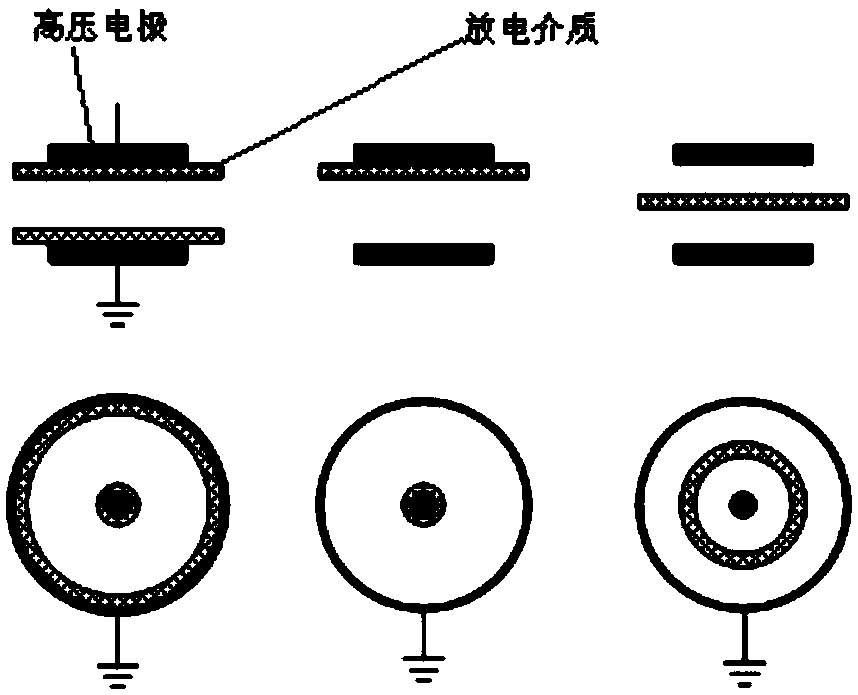

Method used

Image

Examples

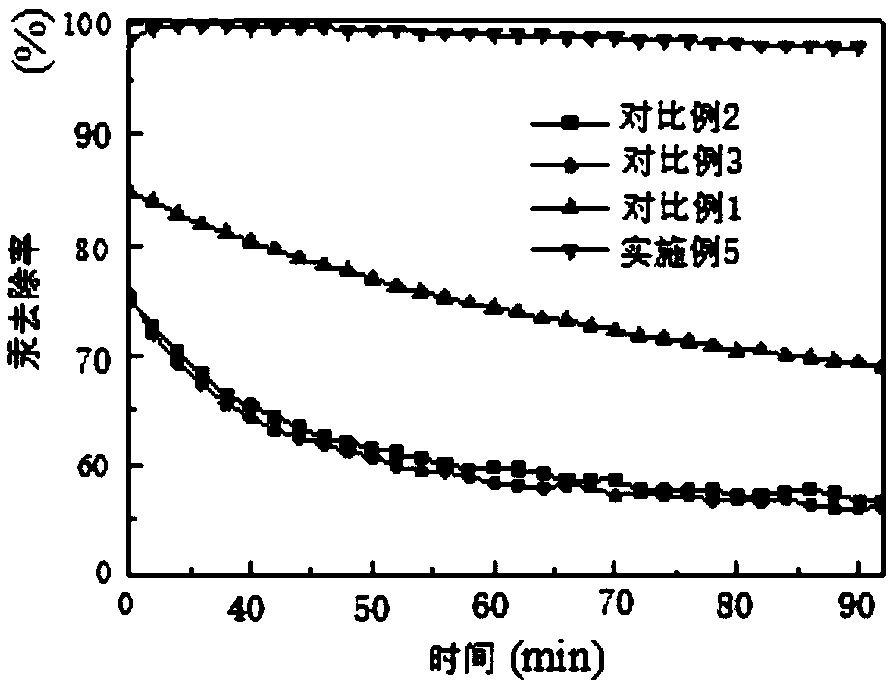

Embodiment 1

[0044] Example 1: Prepare simulated flue gas according to the main flue gas components of oxy-fuel combustion cycle flue gas, the specific flue gas composition is 95% CO 2 , 3%H 2 O, 0.15% SO 2 , 0.002% HCl, the rest is O 2 , the flue gas temperature is 200°C. Adjust the flow rate of the carrier gas, and the time for the activated carbon powder to pass through the plasma reactor is 0.1 second. The plasma generator output voltage was set to 40kV. The mercury adsorption test was carried out on a fixed bed, and the effect of the adsorbent obtained by the above method was tested. The test results show that in the first 30 minutes of the adsorption test, the adsorption efficiency continued at 93%, and after 30 minutes of the adsorption test, the adsorption efficiency dropped sharply, and the adsorption efficiency dropped to 50% at the 60th minute.

Embodiment 2

[0045] Example 2: Prepare simulated flue gas according to the main flue gas components of oxygen-enriched combustion cycle flue gas, the specific flue gas composition is 95% CO 2 , 3%H 2 O, 0.15% SO 2 , 0.002% HCl, the rest is O 2 , the flue gas temperature is 200°C. Adjust the flow rate of the carrier gas, and the time for the activated carbon powder to pass through the plasma reactor is 0.1 second. The plasma generator output voltage was set to 35kV. The modified activated carbon powder was collected at the outlet of the plasma reactor with a bag filter. The mercury adsorption test was carried out on a fixed bed, and the effect of the adsorbent obtained by the above method was tested. The test results showed that the adsorption efficiency continued at 95% in the first 30 minutes of the adsorption test, and slowly decreased to 90% between the 30th and 60th minutes of the adsorption test.

Embodiment 3

[0046] Example 3: Prepare simulated flue gas according to the main flue gas components of oxy-fuel combustion cycle flue gas, the specific flue gas composition is 95% CO 2 , 3%H 2 O, 0.15% SO 2 , 0.002% HCl, the rest is O 2 , the flue gas temperature is 200°C. Adjust the flow rate of the carrier gas, and the time for the activated carbon powder to pass through the plasma reactor is 0.1 second. The plasma generator output voltage was set to 30kV. The modified activated carbon powder was collected at the outlet of the plasma reactor with a bag filter. The mercury adsorption test was carried out on a fixed bed, and the effect of the adsorbent obtained by the above method was tested. The test results showed that the adsorption efficiency continued at 96% in the first 60 minutes of the adsorption test, and gradually decreased to 92% between the 60th minute and the 120th minute of the adsorption test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com