A Catalytic Membrane Reactor with Built-in Spoiler Structure

A catalytic membrane and reactor technology, applied in the field of heterogeneous catalytic reactions, can solve the problems of increasing late-stage reactants, product separation costs, and reduced catalytic conversion efficiency, and achieve the effects of promoting high-efficiency utilization, simple structure, and preventing transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

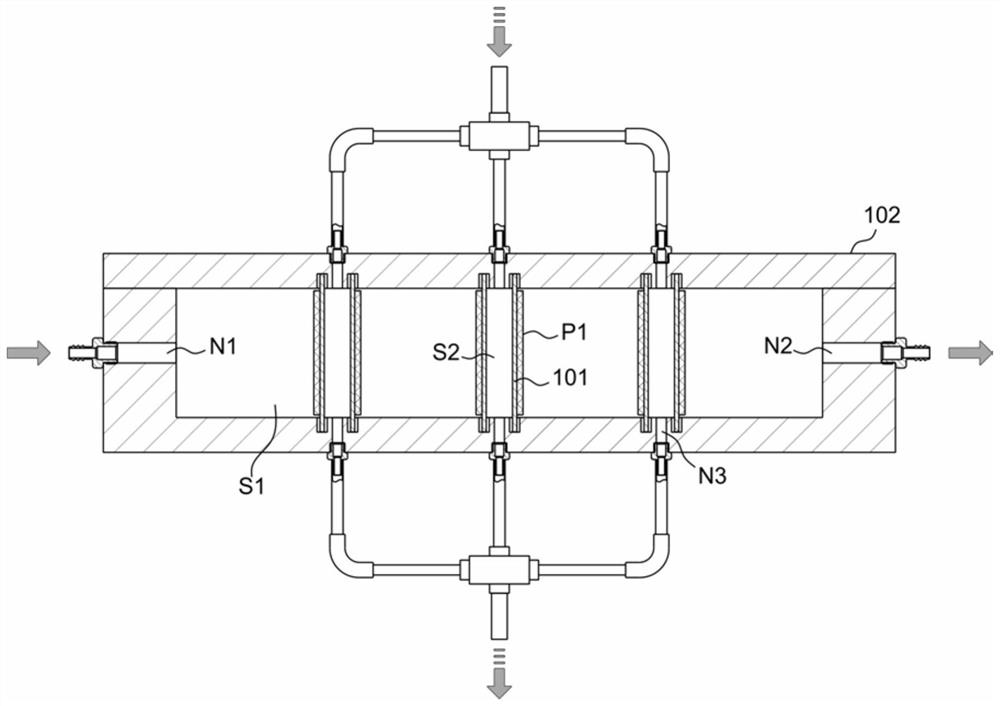

[0041] refer to figure 1 , is the first embodiment of the present invention, which provides a catalytic membrane reactor with a built-in spoiler structure, including a one-phase flow channel S1 and a two-phase flow channel S2, the first phase of the reaction is in the one-phase flow channel Flow through S1, and the second phase of the reaction flows through the two-phase flow channel S2. This invention is mainly used for the heterogeneous catalytic reaction of gas phase reactants and liquid phase reactants. The first phase of the reaction can be gas phase or liquid phase. , correspondingly, if the first reaction phase is a gas phase, then the second reaction phase is a liquid phase; if the first reaction phase is a liquid phase, then the second reaction phase is a gas phase; Refers to liquid-phase reactants, and the second phase of the reaction specifically refers to gas-phase reactants.

[0042] The two-phase flow channel S2 and the one-phase flow channel S1 are separated fr...

Embodiment 2

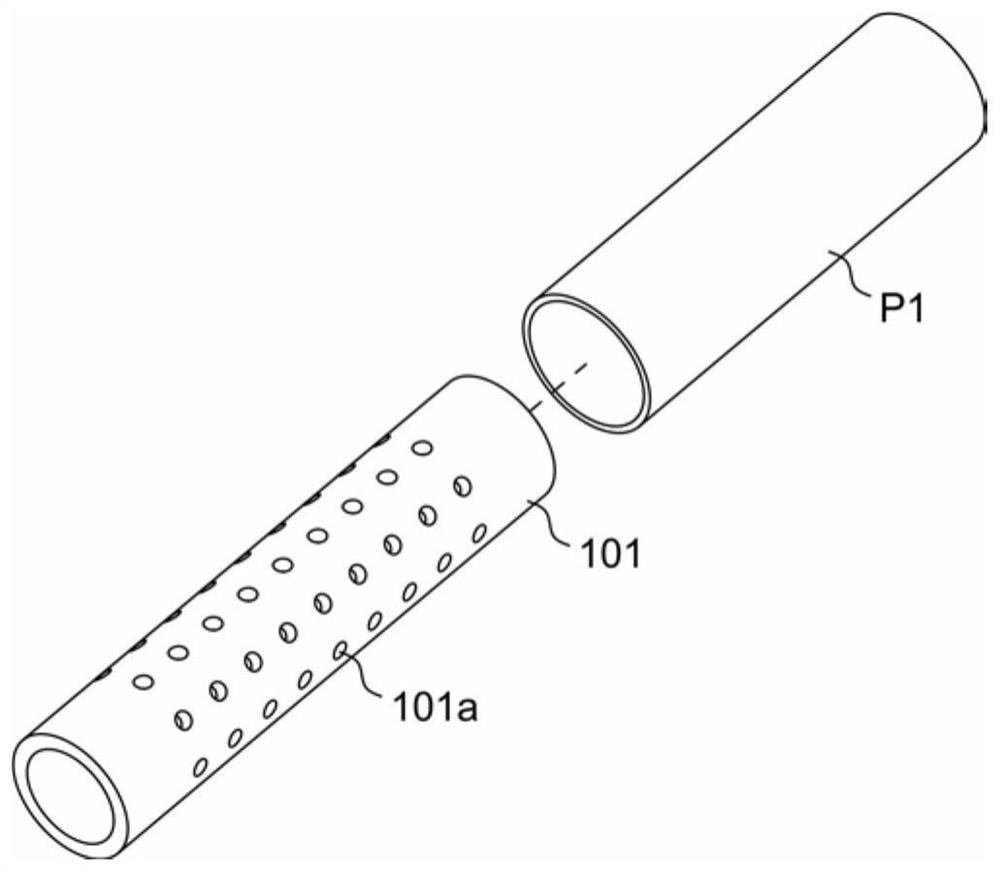

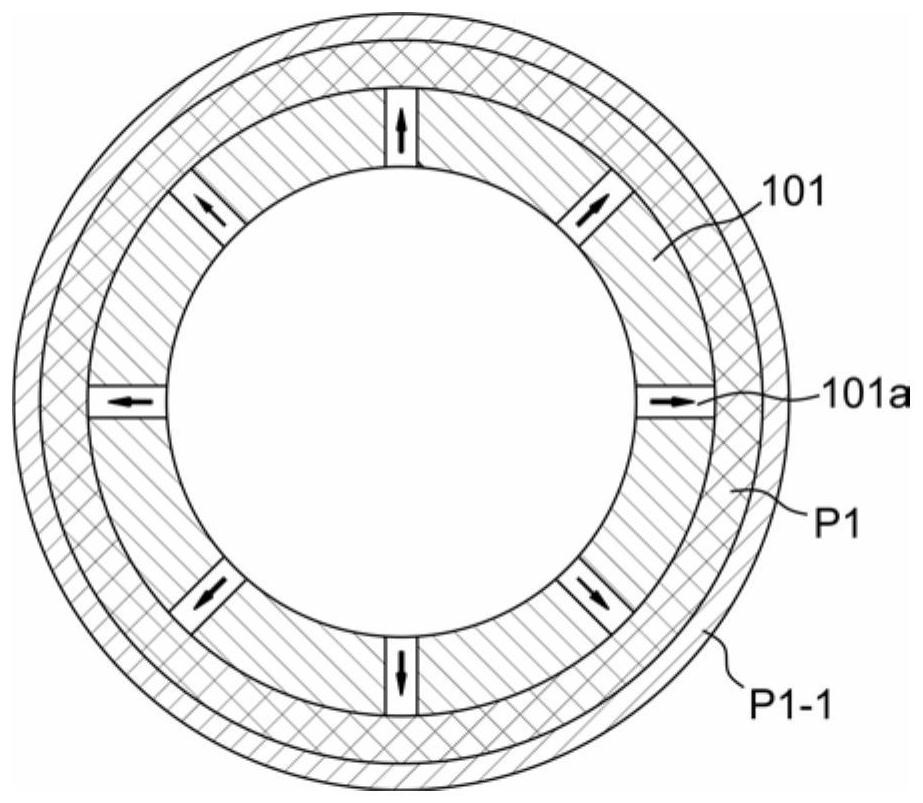

[0045] refer to Figure 1 to Figure 4 , this embodiment is different from the first embodiment in that: the two-phase channel S2 is formed by the pipe 101, and the reaction second phase flows from one end of the pipe 101 to the other end, the side wall of the pipe 101 has a gas-permeable structure, and the pipe 101 Both ends are hollow and the wall surface is breathable. The pipe wall breathable structure of the pipe fitting 101 can be realized by processing the air holes 101a or adopting a porous structure pipe wall.

[0046] It should be noted that the single-phase permeable membrane P1 covers the air-permeable structure, and the single-phase permeable membrane P1 can provide a transmission path for the gas-phase reactant diffused from the air-vent hole 101a on the side wall of the pipe 101, and completely dissipate the gas-phase reactant diffused from the air-vent hole 101a The substances are transferred to the surface of the catalyst P1-1, and react with the liquid-phase r...

Embodiment 3

[0053] refer to figure 1 , 5 , 6, 7, this embodiment is different from the above-mentioned embodiment in that: the one-phase flow channel S1 is formed by the chamber of the carrier 102, and the first reaction phase flows through from the inlet N1 to the outlet N2 of the chamber; the one-phase flow channel S1 Defined by the chamber, the liquid-phase reactant flows through the limited space; the pipe 101 is placed in the chamber, the liquid-phase reactant will contact the pipe 101 in the flow direction, and the pipe 101 constitutes a flow-disturbing structure, and the existence of the pipe 101 will Destroy the concentration boundary layer caused by the reaction when the liquid-phase reactant flows through the one-phase flow channel S1, thereby strengthening the transfer process of the reactant and promoting the follow-up of the reaction; at the same time, the vortex street formed after the liquid-phase reactant flows through the spoiler tube is also It helps to strengthen the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com