Reaction rectification device and method for preparing cyclohexanol by hydrating cyclohexene

A cyclohexene water and reactive rectification technology is applied in the field of reactive rectification devices for preparing cyclohexanol by hydration of cyclohexene, and can solve the problems of accelerating cyclohexene hydration reaction speed, slow hydration reaction speed, poor mechanical strength and the like , to improve the one-way conversion rate and solve the effect of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

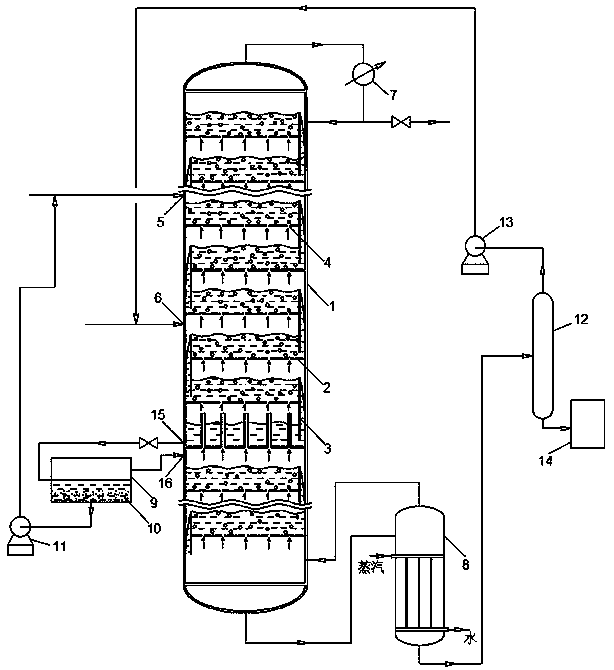

[0038] (1) The diameter of the reactive distillation column is 450mm, the column height is 14500mm, and the total number of plates is 29; (2) The process conditions in the reactive distillation column: the flow rate of cyclohexene is 80kmol / h, the flow rate of ethylene glycol ether 80kmol / h, water flow rate 320kmol / h, ZSM-5 molecular sieve catalyst mass concentration 30%, reaction temperature 120°C, reaction pressure 0.5MPa; (3) water and catalyst enter from the 6th tray The feed port is added to the reactive distillation tower, and water and catalyst flow between the sieve plates of the reactive distillation tower in a slurry state; (4) cyclohexene and ethylene glycol ether are fed from the feed port at the 17th tray Added to the reactive distillation tower, it turns into steam at high temperature, enters the slurry through the sieve holes on the sieve plate, contacts the slurry in reverse, and under the catalysis of the catalyst, cyclohexene reacts with water to form cyclohex...

Embodiment 2

[0041] (1) The diameter of the reactive distillation column is 450mm, the column height is 14500mm, and the total number of plates is 29; (2) The process conditions in the reactive distillation column: the flow rate of cyclohexene is 70kmol / h, and the flow rate of propylene glycol methyl ether is 42kmol / h, water flow rate is 70kmol / h, ZSM-5 molecular sieve catalyst mass concentration is 10%, reaction temperature is 110°C, reaction pressure is 0.3MPa; (3) Water and catalyst feed from the sixth tray (4) Cyclohexene and propylene glycol methyl ether are fed into the reactive distillation tower from the inlet of the 17th tray. In the reactive distillation tower, it turns into steam at high temperature, enters the slurry through the sieve holes on the sieve plate, contacts the slurry in reverse, and under the catalysis of the catalyst, cyclohexene reacts with water to form cyclohexanol; (5) unreacted cyclohexene Hexene, propylene glycol methyl ether and water vapor enter the conden...

Embodiment 3

[0044] (1) The diameter of the reactive distillation column is 450mm, the column height is 14500mm, and the total number of plates is 29; (2) The technological conditions in the reactive distillation column: the flow rate of cyclohexene is 60kmol / h, and the flow rate of dimethylformamide The flow rate is 48kmol / h, the water flow rate is 120kmol / h, the mass concentration of ZSM-5 molecular sieve catalyst is 15%, the reaction temperature is 130°C, and the reaction pressure is 0.4MPa; The feed inlet is added to the reactive distillation tower, and water and catalyst flow between the sieve plates of the reactive distillation tower in a slurry state; (4) cyclohexene and dimethylformamide are fed from the 17th tray The feed port is added to the reactive distillation tower, which turns into steam at high temperature, enters the slurry through the sieve holes on the sieve plate, and contacts the slurry in reverse, and under the catalysis of the catalyst, cyclohexene reacts with water t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com