Synthesis, Catalyst and Application of Bismuth Vanadate Photocatalyst with Controlled Facet Ratio

A photocatalyst, bismuth vanadate technology, applied in vanadium compound, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of low quantum efficiency of photocatalyst and controllable synthesis of photocatalyst. It has been developed and other issues to achieve the effect of inhibiting the occurrence of reverse reactions, cheap materials, and improving reaction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

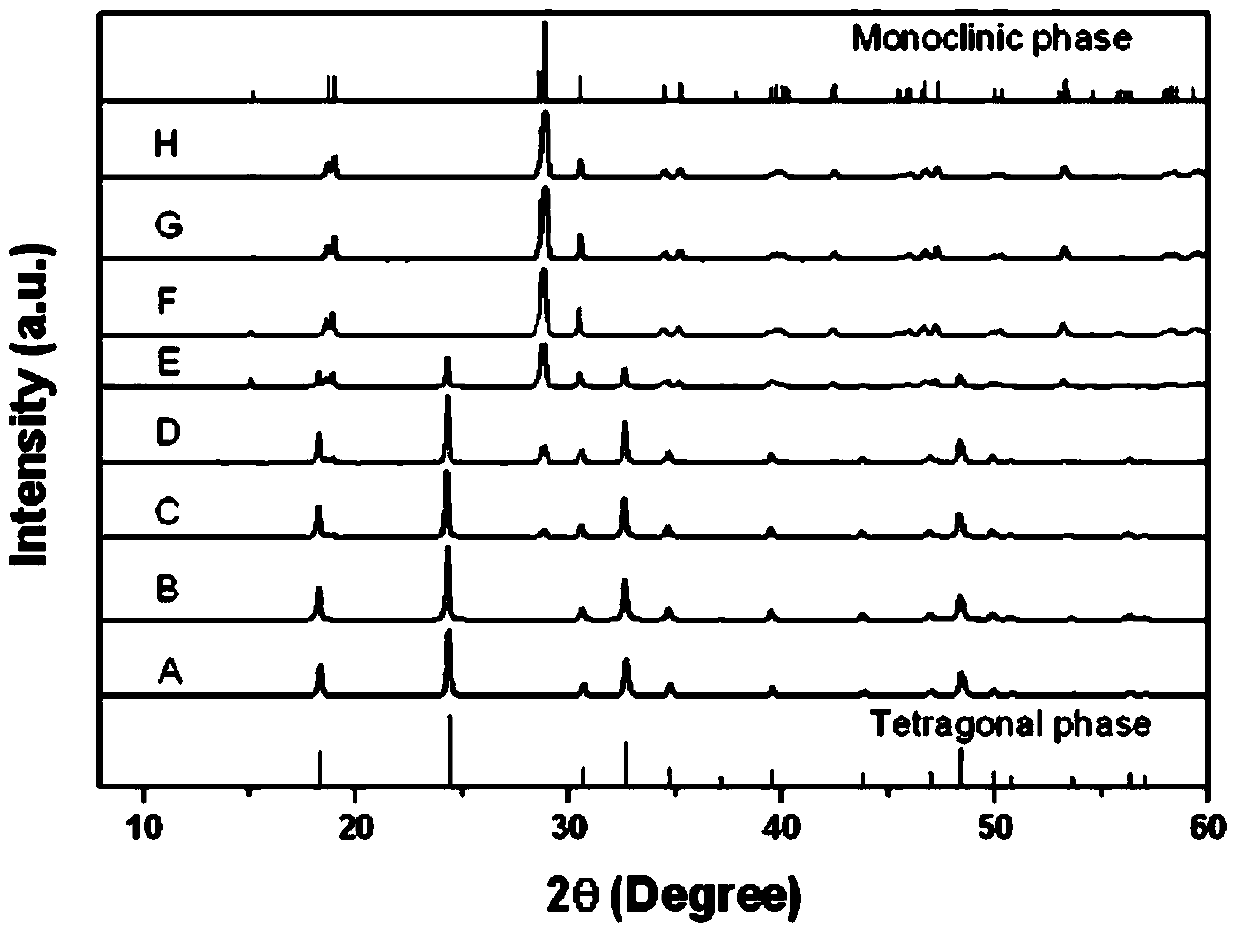

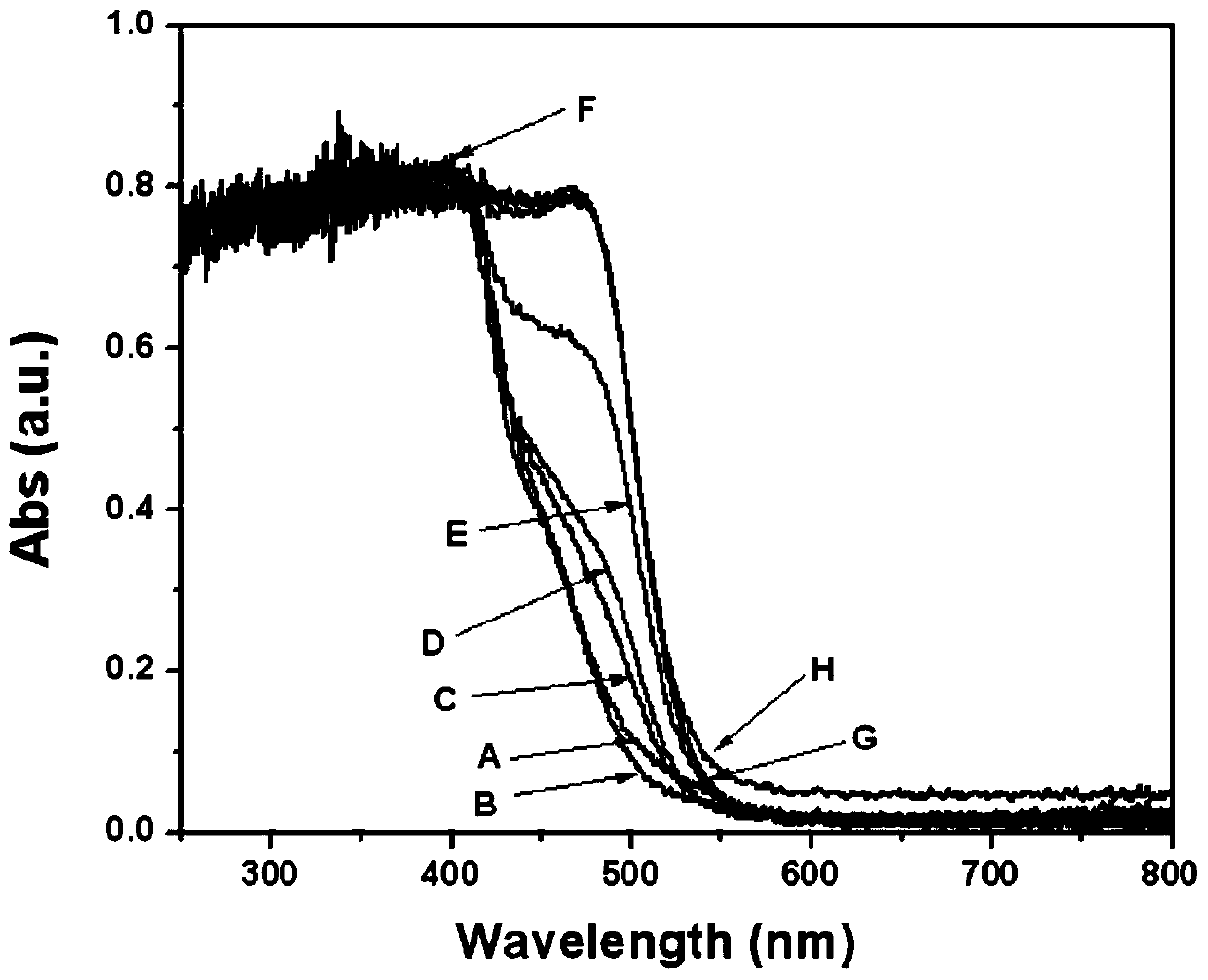

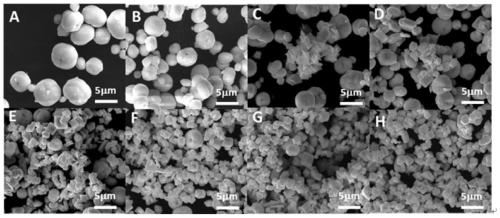

[0032] Preparation of BiVO with different crystal phases and morphologies by hydrothermal method 4 catalyst of light:

[0033] The preparation process of the precursor is: 0.04mol of bismuth nitrate and 0.04mol of ammonium metavanitate are respectively dissolved in 300mL of 2mol / L nitric acid solution. Adjust the pH value of the solution to pH=0.4 with ammonia water (mass concentration 25%-28%) to obtain a yellow suspension, and continue stirring for 2 hours to obtain the bismuth vanadate precursor;

[0034] Hydrothermal treatment process: The prepared bismuth vanadate precursor suspension was transferred to eight 100mL hydrothermal reaction kettles with a volume of 70mL, and then placed in an oven at 200°C for hydrothermal reaction for different times. After the reaction was completed, the solution was cooled to room temperature, centrifuged, washed three times with secondary water, and dried in an oven at 80° C. for 8 hours. That is, different crystal phases and morphologi...

Embodiment 2

[0037] Preparation of BiVO with different crystal phases and morphologies by oil bath method under atmospheric pressure 4 catalyst of light:

[0038] The preparation process of the precursor is as follows: 0.02mol of bismuth nitrate and 0.02mol of ammonium metavanitate are respectively dissolved in 70mL of 2mol / L nitric acid solution. Adjust the pH value of the solution to pH=0.4 with ammonia water (with a mass concentration of 25%-28%) to obtain a yellow suspension, and continue stirring for 2 hours to obtain a bismuth vanadate precursor;

[0039] Oil bath process under normal pressure: transfer the prepared bismuth vanadate precursor suspension into a 250mL round-bottomed flask, fill the volume of the solution to 60% of the volume of the container, and then place it in an oil bath at 80°C for reflux and stirring. Sampling at different reaction times. After the reaction was completed, the solution was cooled to room temperature, centrifuged, washed three times with secondar...

Embodiment 3

[0042] Preparation of decahedral BiVO with different facet ratios by hydrothermal method 4 catalyst of light:

[0043] The preparation process of the precursor is as follows: 0.04mol of bismuth nitrate and 0.04mol of ammonium metavanitate are respectively dissolved in 120mL of 2mol / L nitric acid solution. Adjust the pH value of the solution to pH=0.25, 0.50, 0.75, 1.00 with ammonia water (mass concentration 25%-28%) to obtain a yellow suspension, and continue stirring for 2 hours to obtain a bismuth vanadate precursor.

[0044] Hydrothermal treatment process: The prepared bismuth vanadate precursor suspension was transferred to four 100mL hydrothermal reaction kettles with a volume of 70mL, and then placed in an oven for hydrothermal reaction at 200°C for 12h. After the reaction was completed, the solution was cooled to room temperature, centrifuged, washed three times with secondary water, and dried in an oven at 80° C. for 8 hours. That is, different crystal phases and mor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com