Metal producing method and producing device by molten salt electrolysis

A molten salt electrolysis, molten salt technology, applied in the field of manufacturing equipment, manufacturing titanium metal, can solve problems such as difficulty, low recovery efficiency, increased cost, etc., to achieve the effect of inhibiting the reverse reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

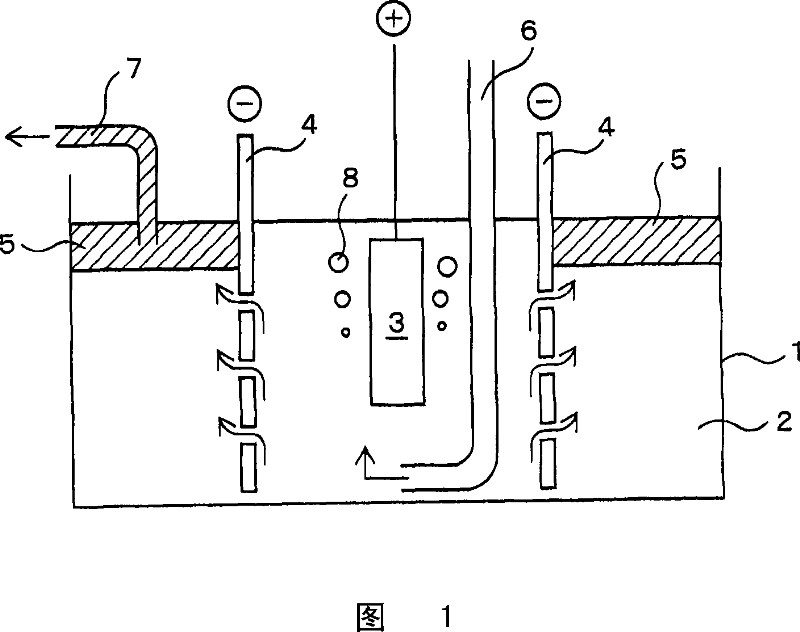

[0073] The molten salt electrolysis of calcium chloride was performed in the electrolytic cell shown in FIG. The temperature of the electrolytic bath composed of calcium chloride is kept at 850±5°C, and the ring-shaped cathode 4 is not particularly cooled, but is kept at 850±5°C.

[0074] Through the bath supply pipe 6, the raw material molten calcium chloride is continuously supplied to the inside of the cathode, and at the same time, the metal calcium concentration layer is drawn out of the system through a drawing pipe immersed outside the cathode. The metallic calcium extracted to the outside of the system is supplied to the reduction reaction of titanium oxide. On the other hand, the chlorine gas generated by the anode is supplied to the chlorination reaction of titanium ore. It is possible to produce metallic calcium equivalent to 80% of the theoretical weight calculated from the amount of electricity supplied to the anode and cathode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com