A kind of synthetic method of nitrogen-enriched Schiff base polymer

A nitrogen-enriched Schiff base and a synthesis method technology are applied in the synthesis field of nitrogen-enriched Schiff base polymers, and can solve the problems of difficulty in control and low safety, and achieve the effects of reduced dosage, uniform particle size distribution and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

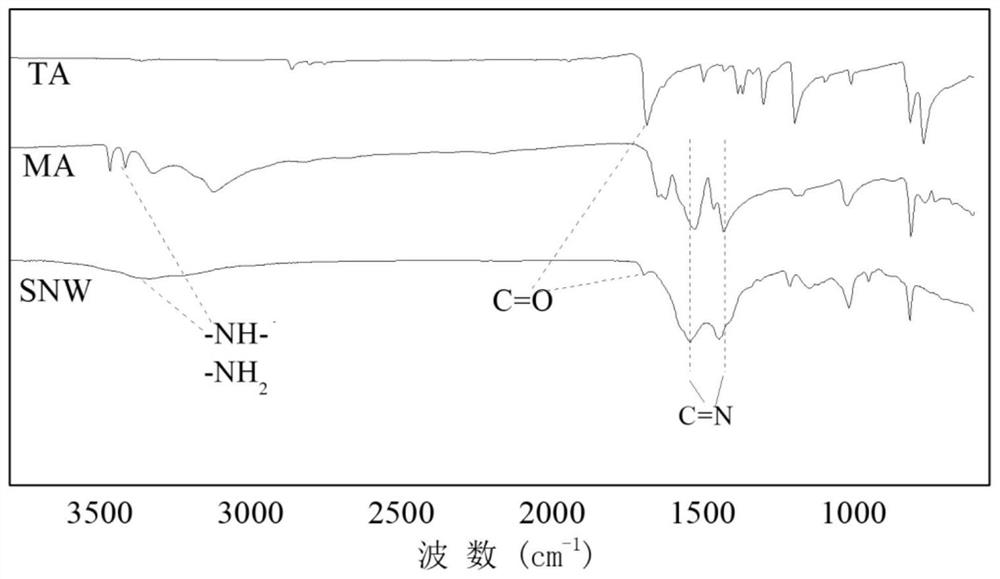

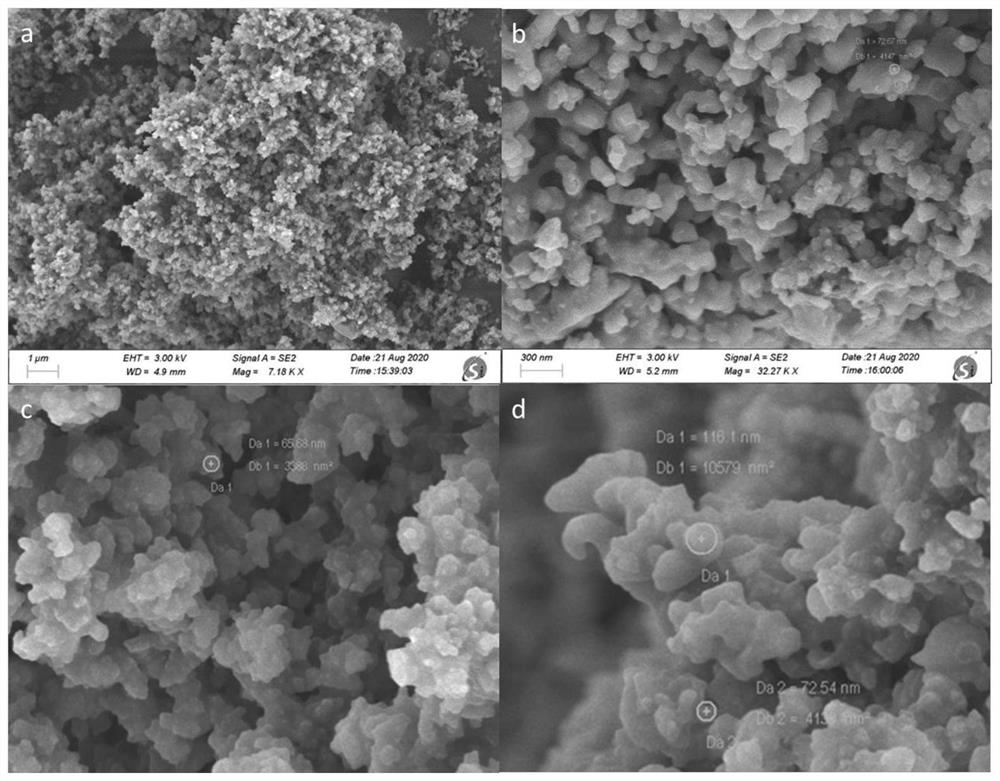

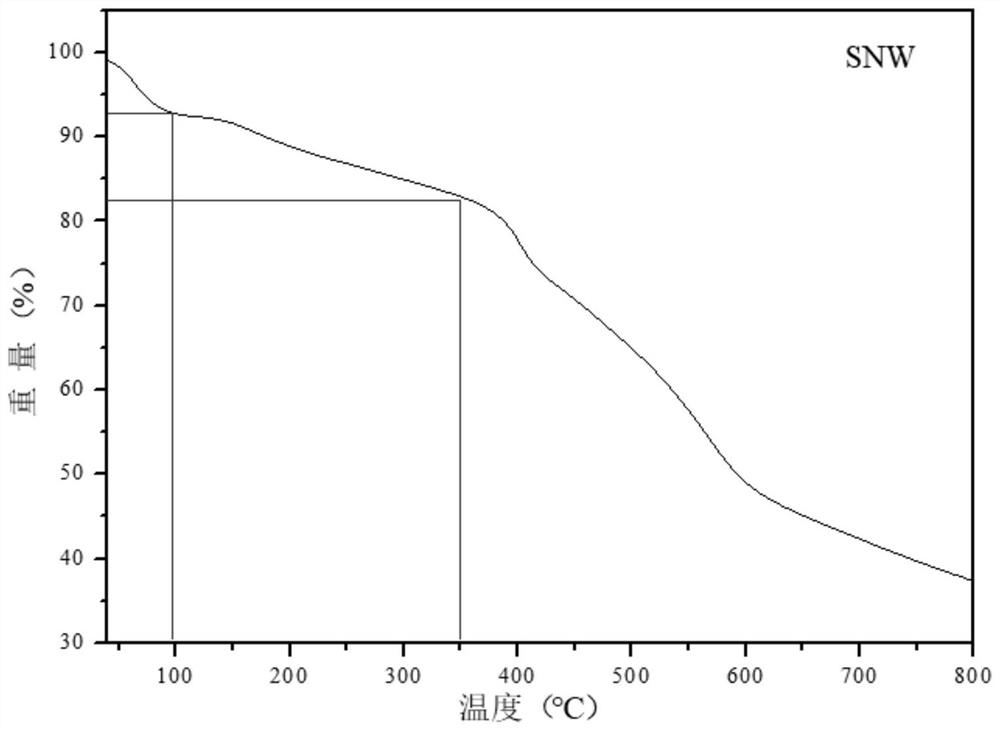

[0031] Add 15mmol of terephthalaldehyde (TA) and 20mmol of melamine (MA) into a double-necked round-bottomed flask, add 35ml of dimethyl sulfoxide, 10ml of xylene and 10ml of toluene, connect a water separator and a condenser, and condense The end of the tube is connected to a bubbler, magnetically stirred and inert gas is used for ventilation. During the reaction, ventilation is continued for protection. The temperature of the oil bath is set at 120 °C, stirred and refluxed for 2 h, and the temperature is raised to 150 °C after the reflux is completed. The water is refluxed until anhydrous is formed, and the reaction time is about 6h. After the reaction is completed, the heating is stopped, and the ventilation is stopped after the reaction is lowered to room temperature, and the solid material is filtered out. Using water as a solvent, the solid substance was extracted by Soxhlet extraction method for 4 hours, and the product was dried in a vacuum drying oven at 80°C for 24 ho...

Embodiment 2

[0041]Add 15mmol of terephthalaldehyde (TA) and 20mmol of melamine (MA) into a double-necked round-bottomed flask, add 35ml of dimethyl sulfoxide, 15m of toluene and 5ml of xylene, connect a water separator and a condenser, and condense The end of the tube was connected to a bubbler, magnetically stirred and inert gas was used for ventilation. During the reaction, ventilation was continued for protection. The temperature of the oil bath was set at 120 °C, and the temperature was stirred and refluxed for 2 h. After the reflux, the temperature was raised to 150 °C for reaction. The water is refluxed until anhydrous is formed, and the reaction time is about 6h. After the reaction is completed, the heating is stopped, and the ventilation is stopped after the reaction is lowered to room temperature, and the solid material is filtered out. Using water as a solvent, the solid substance was extracted by Soxhlet extraction method for 4 hours, and the product was placed in a vacuum dryin...

Embodiment 3

[0043] Add 10mmol of terephthalaldehyde (TA) and 20mmol of melamine (MA) into a double-necked round-bottomed flask, add 35ml of dimethyl sulfoxide, 10ml of xylene and 10ml of toluene, connect a water separator and a condenser, and condense The end of the tube is connected to a bubbler, magnetically stirred and inert gas is used for ventilation. During the reaction, ventilation is continued for protection. The temperature of the oil bath is set at 130 °C, and the temperature is stirred and refluxed for 2 h. After the reflux is completed, the temperature is raised to 150 °C for reaction. The water is refluxed until anhydrous is formed, and the reaction time is about 6h. After the reaction is completed, the heating is stopped, and the ventilation is stopped after the reaction is lowered to room temperature, and the solid material is filtered out. Using water as a solvent, the solid substance was extracted by Soxhlet extraction method for 4 hours. The product was placed in a vacuum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com