Bimetallic core-shell catalyst for electro-catalysis synergistic hydrogen production as well as preparation method and application of bimetallic core-shell catalyst

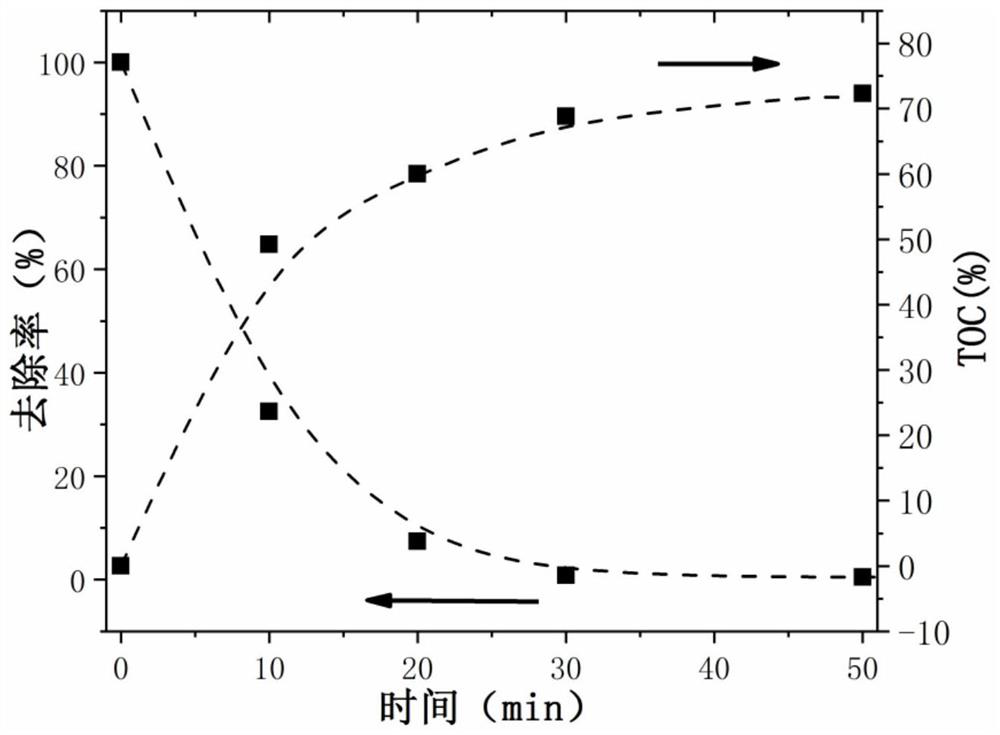

A core-shell catalyst, electrocatalysis technology, applied in physical/chemical process catalysts, chemical instruments and methods, electrodes, etc., can solve the problems of long reaction process time, increased processing time, weak superoxide radical activity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for preparing a core-shell catalyst for electrocatalytic synergistic hydrogen production, comprising the steps of:

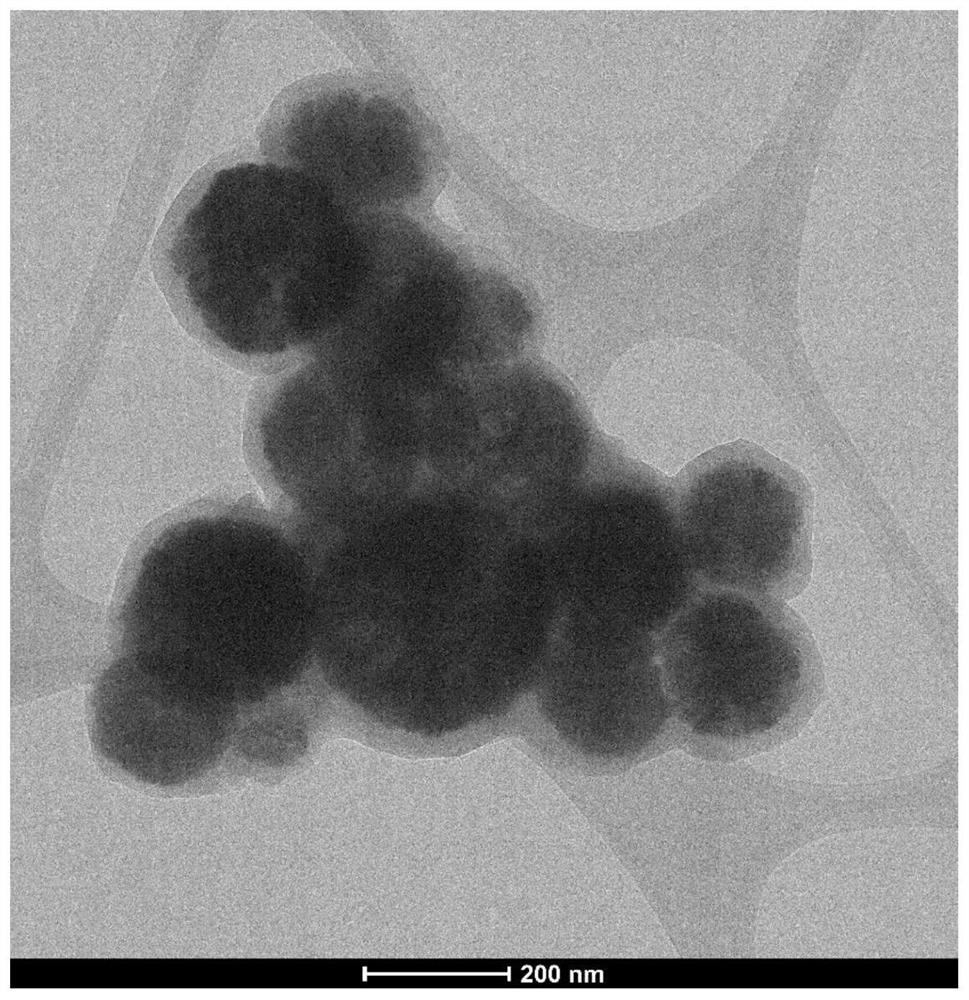

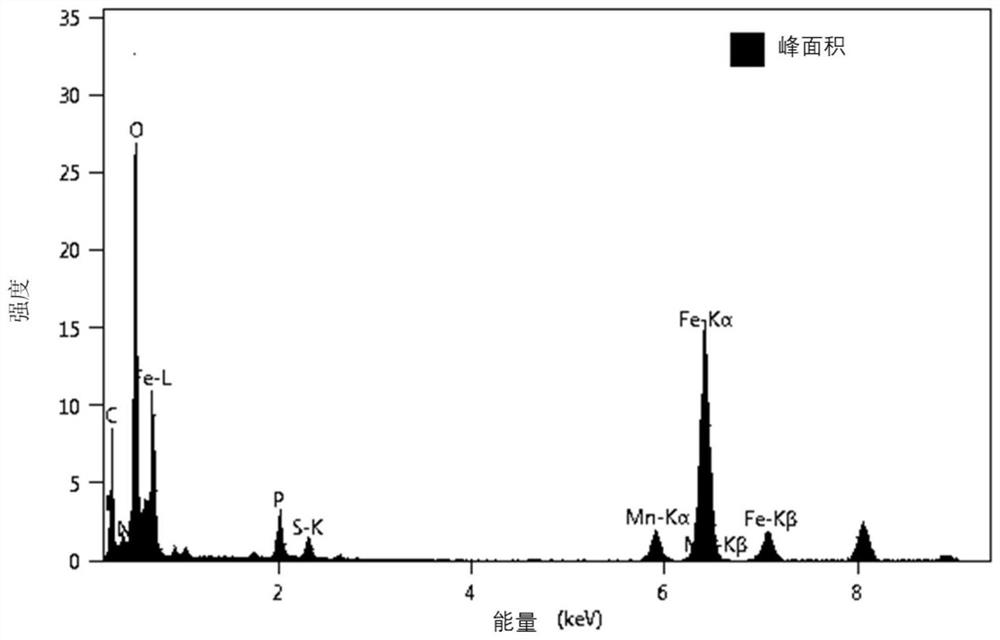

[0044] 1) Add 1.35g FeCl to a 50mL beaker 3 ·6H 2 O, 0.124MnCl 2 4H 2 O and 40mL ethylene glycol, stir vigorously to turn bright yellow, add 3.6gNaAC, stir well, add 10mL ethylenediamine to obtain a dark green solution, pour it into a 50mL polytetrafluoroethylene reactor, and react at a temperature of 200°C for 12h , washed with ethanol three times after cooling and dried in vacuum to obtain the bimetallic MnFe 3 o 4 nanospheres.

[0045] 2) Using 10 mg of hexachlorocyclotriphosphazene as the source of N and P, 22.5 mg of thioacetamide as the source of S, adding 50 mg of the bimetallic MnFe 3 o 4 Add 15 mL of ethanol and tetrahydrofuran at a mass ratio of 1:1 to the nanospheres as a solvent, and ultrasonicate for 5 min at an ultrasonic frequency of 50 Hz until the reactants are completely dissolved and uniformly dispersed. Then seal it wi...

Embodiment 2

[0056] A method for preparing a core-shell catalyst for electrocatalytic synergistic hydrogen production, comprising the steps of:

[0057] 1) Add 0.628g FeCl to a 50mL beaker 3 ·6H 2 O, 1.0g MnCl 2 4H 2 O and 40mL ethylene glycol, stir vigorously to turn bright yellow, add 3.6gNaAC, stir well, add 10mL ethylene glycol to obtain a dark green solution, pour it into a 50mL polytetrafluoroethylene reactor at 200°C for 12h, wash with ethanol for 3 times and vacuum Dry to obtain bimetallic MnFe 3 o 4 nanospheres.

[0058] 2) The heteroatom shell uses 20mg of hexachlorocyclotriphosphazene as the N source and P source, 45mg of thiourea as the S source, and 50mg of the above-mentioned bimetallic MnFe 3 o 4 Nano-microspheres, 15mL of ethanol and tetrahydrofuran with a mass ratio of 1:1 as a solvent, ultrasonic (50Hz) 5min completely dissolved and uniformly dispersed. Then seal it with a polyethylene film, and quickly inject 3 mL of triethylamine as an acid-binding agent with a ...

Embodiment 3

[0062] A method for preparing a multi-component heterogeneous nodule shell catalyst suitable for electric Fenton, comprising the steps of:

[0063] 1) Add 0.675g FeCl to a 50mL beaker 3 ·6H 2 O, 0.248g MnCl 2 4H 2 O and 40mL polyvinyl alcohol, stir vigorously to turn bright yellow, add 3.6gKAC, stir well, add 10mL ethylenediamine to obtain a dark green solution, pour it into a 50mL polytetrafluoroethylene reactor, react at 200°C for 24h, and ethanol after cooling After washing 3 times and drying in vacuum, the metal microsphere core (MnFe 3 o 4 ).

[0064] 2) Adopt 50mg hexachlorocyclotriphosphazene as N and P source, 112.5mg sulfonyldiphenol as S source, 250mg above-mentioned solvothermal method preparation diameter is the metal microsphere core of 50x50 ± 10nm, 30mL mass ratio is 1: 1 ethanol and tetrahydrofuran as solvents, ultrasonic (100Hz) 5min completely dissolved and uniformly dispersed. Then seal it with plastic wrap, and quickly inject 2 mL of trimethylamine a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com