Method and device for photocatalytic reaction

A photocatalytic reaction and photocatalyst technology, applied in the field of photocatalytic reaction, can solve the problems of low light utilization rate and inability to effectively suppress the reverse reaction, and achieve the effect of improving the light utilization rate, increasing the scattering probability, and increasing the gas-liquid interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment is used to illustrate the application of the photocatalytic reaction method and device of the present invention in the photocatalytic water splitting reaction.

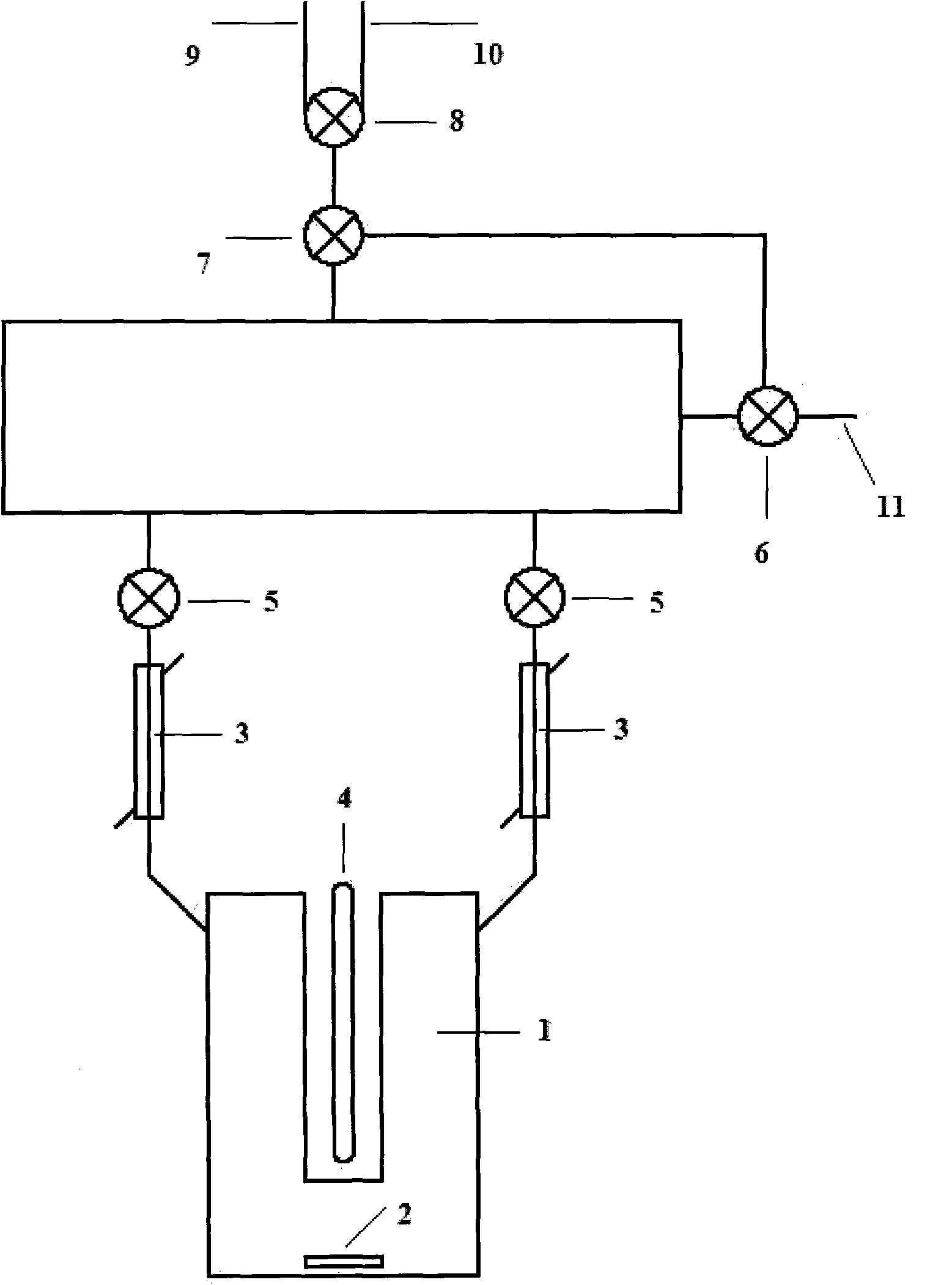

[0038] The device used in this example is figure 1 As shown, the device includes 1 reaction vessel, 2 ultrasonic nebulizers, 3 condenser sleeves, 4 light sources, 5-7 three-way valves, 8 four-way valves, 9-10 gas chromatography interfaces, 11 vacuum pump interfaces (5 -10 collectively referred to as the "sampling section"). Among them, the two adjacent branches of the four-way valve 8 are connected, and form a quantitative sampling loop with the glass tube between the three-way valve 7, and the other two adjacent branches of the four-way valve 8 are connected through the gas chromatography interface 9 and 10 are connected to a gas chromatograph. Turning the four-way valve 8 can connect or disconnect the quantitative sampling loop with the chromatogram. When it is in the disconnected state, op...

Embodiment 2

[0055] This embodiment is used to illustrate the application of the photocatalytic reaction method and device of the present invention in the photocatalytic degradation of organic pollutants.

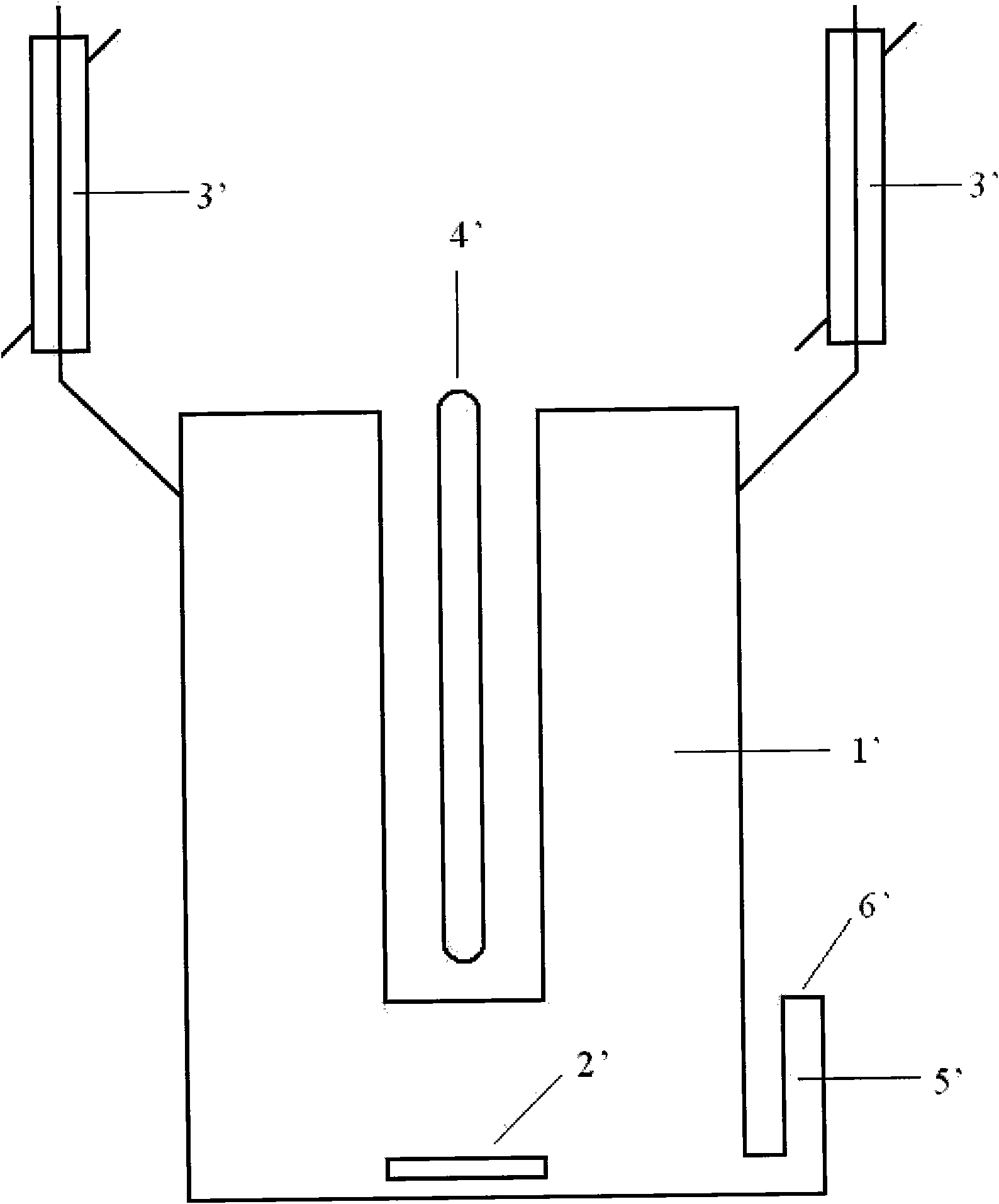

[0056] The device used in this example is figure 2 As shown, the device includes 1' reaction vessel, 2' ultrasonic nebulizer, 3' condensation sleeve, 4' light source, 5' sampling part and 6' sampling part cover. Among them, the reaction vessel 1' is connected to the atmosphere through the condensation sleeve 3' to supplement the oxygen needed in the reaction process; a sampling part cover 6' is added to the sampling part 5' to prevent the escape of atomized droplets . Wherein the reaction vessel 1' is a quartz glass material.

[0057] The specific operation steps are as follows:

[0058] 1) 25mg TiO 2 and 50ml 2×10 -5 m / l rhodamine B solution was added to figure 2 In the shown reaction vessel 1 ';

[0059] 2) Install the 150W mercury lamp on figure 2 In the position of the power...

Embodiment 3

[0071] This embodiment is used to illustrate the application of the photocatalytic reaction method and device of the present invention in the photocatalytic water splitting reaction.

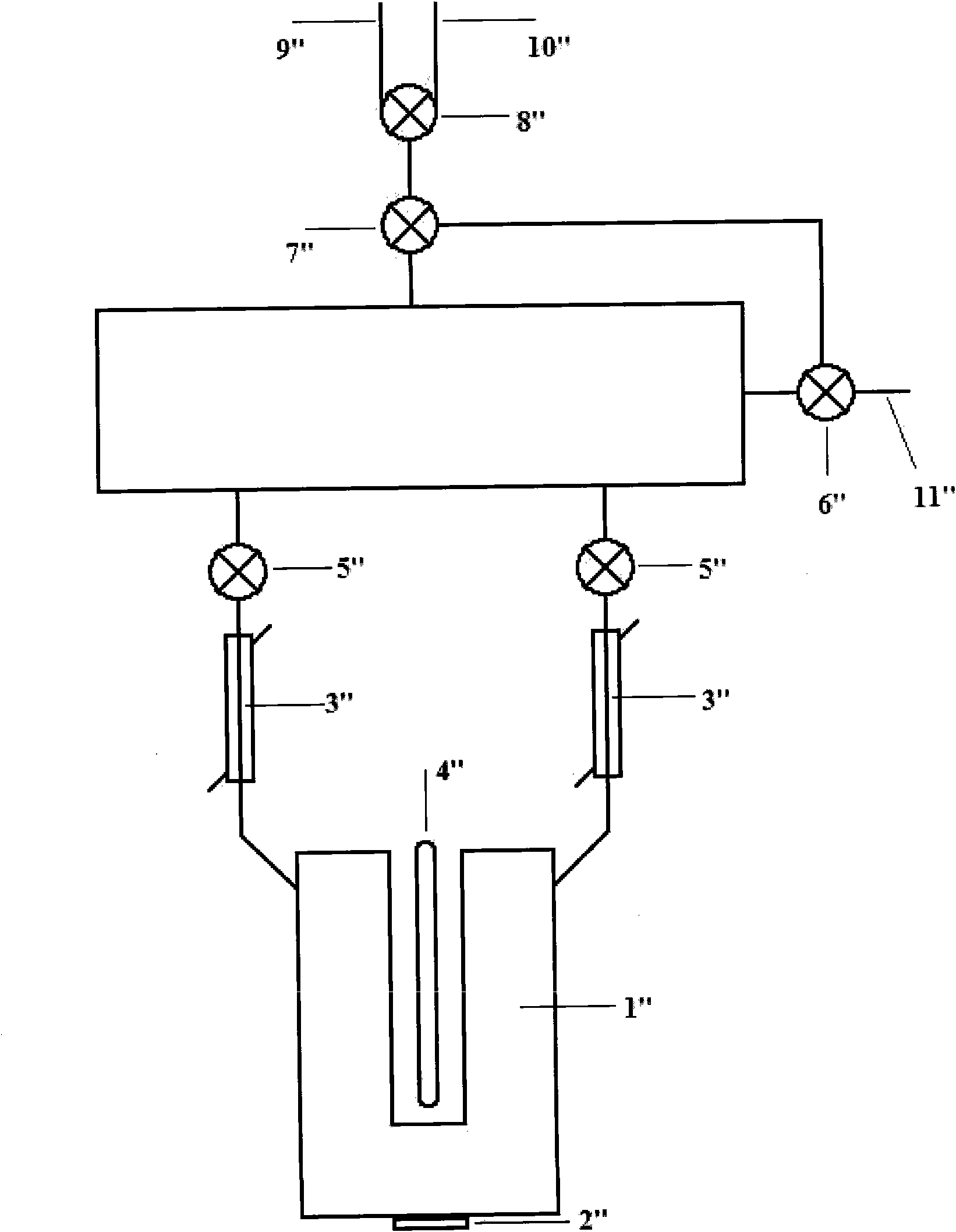

[0072] The device used in this example is image 3 As shown, the device includes 1" reaction vessel, 2" ultrasonic nebulizer, 3" condensation sleeve, 4" light source, 5"-7" three-way valve, 8" four-way valve, 9"-10" gas chromatograph Interface, 11" vacuum pump interface (5"-10" can be collectively referred to as "sampling part"). Among them, the ultrasonic atomizer 2" is in contact with the outer bottom surface of the reaction vessel 1"; the two adjacent branches of the four-way valve 8" are connected, and form a quantitative sampling loop with the glass tube between the three-way valve 7". , the other two adjacent branches of the four-way valve 8" are connected to the gas chromatograph through 9" and 10". Turning the four-way valve 8" can make the quantitative sampling loop connected or discon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com