Corrugated paper preparing process and device

A preparation process and technology of corrugated paper, applied in papermaking, pulp dewatering, textiles and papermaking, etc., can solve the problems of poor uniformity, decreased quality of finished paper, large loss, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

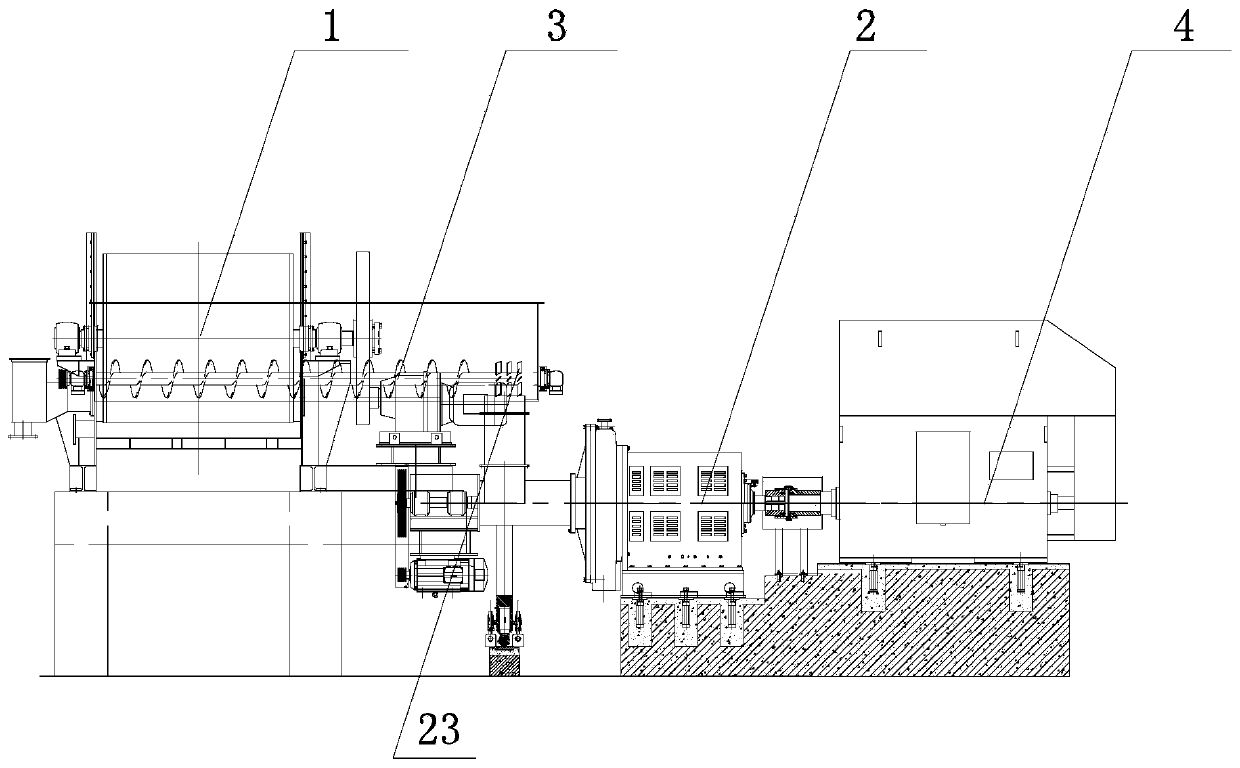

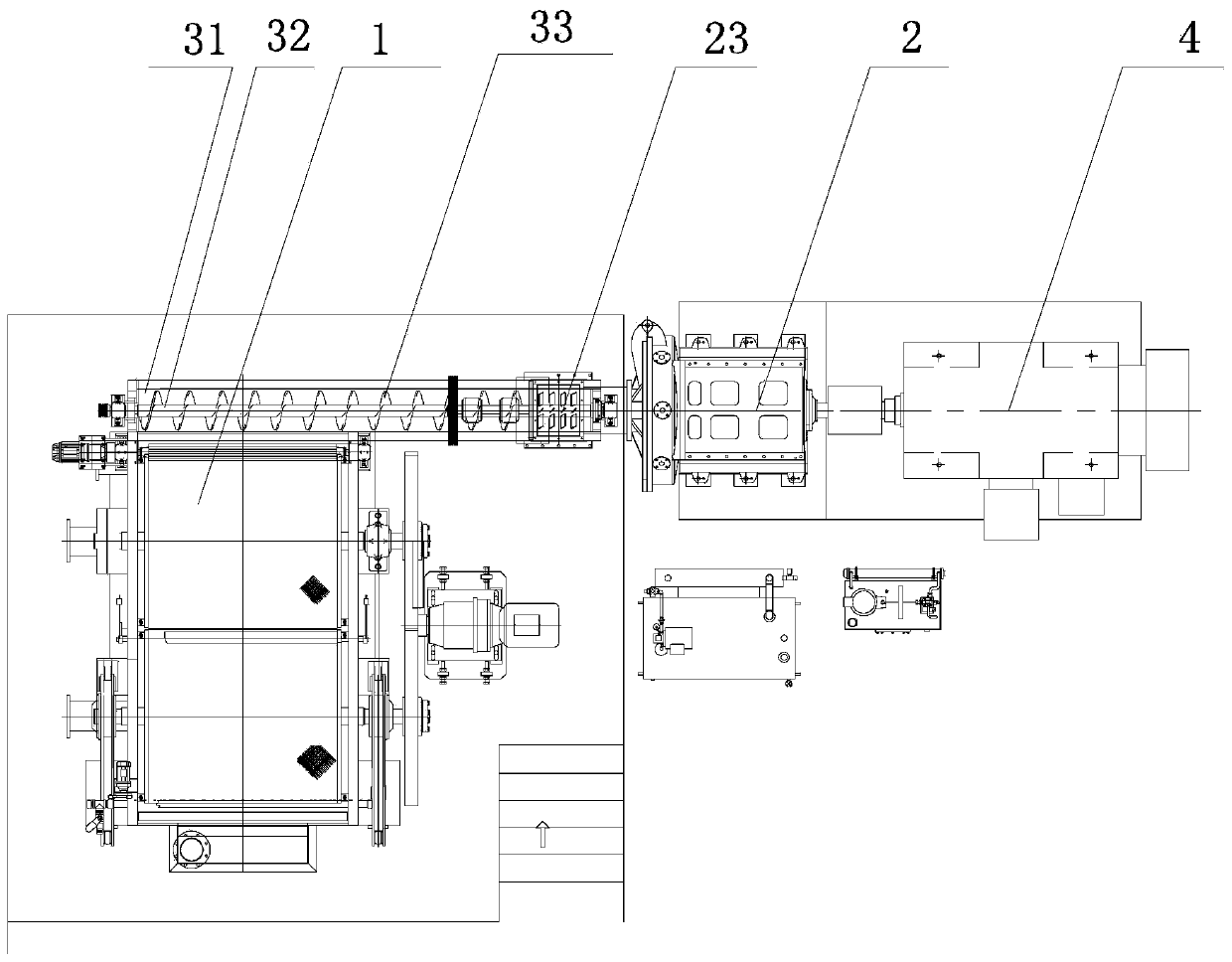

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

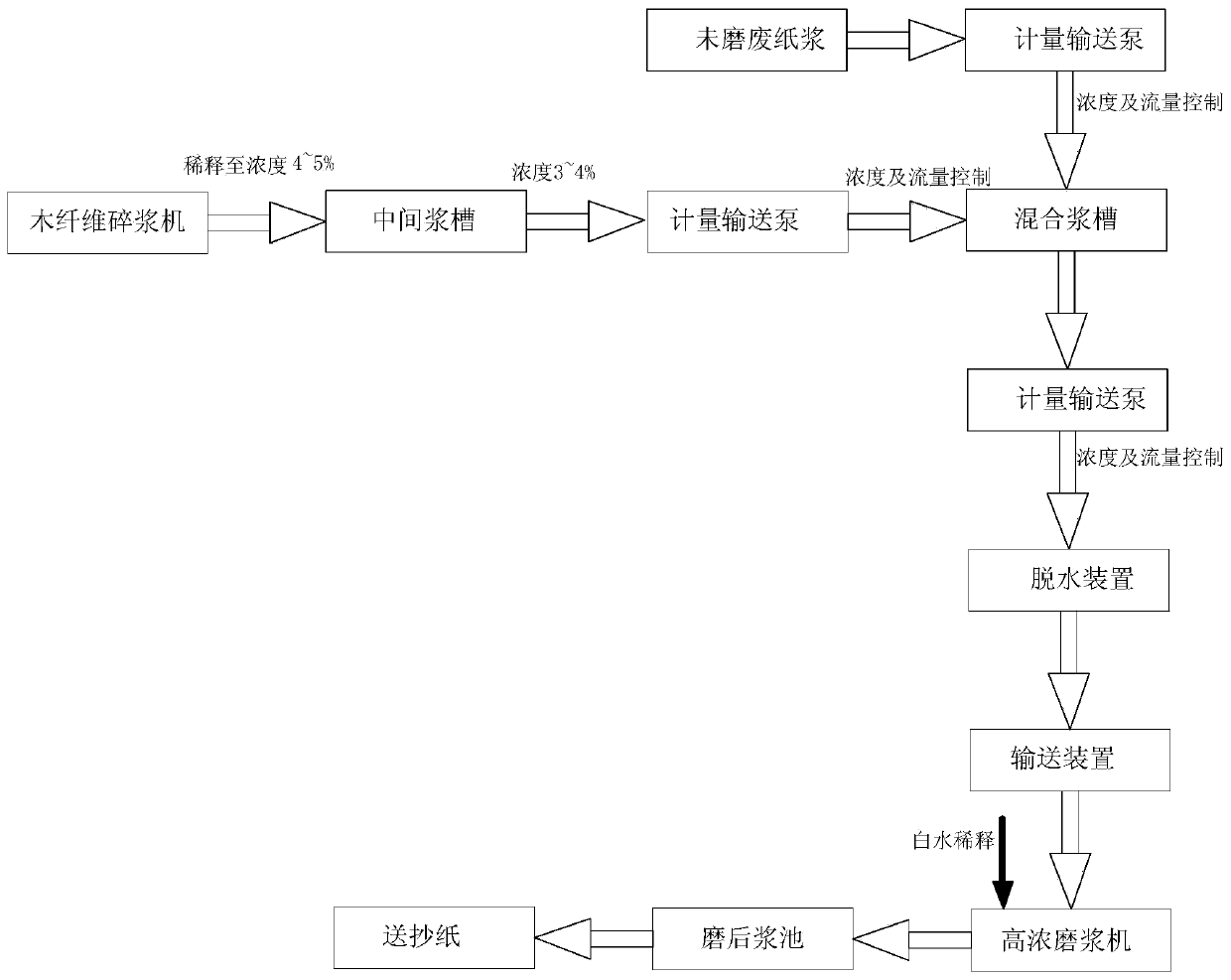

[0028] Figure 1 to Figure 3 An embodiment of the present invention is shown. The corrugated paper preparation process of this embodiment includes the following steps:

[0029] S1. Raw material treatment: waste paper is processed separately into pulp, and MDF fiber filaments and / or MDF waste are put into a separate pulper to decompose to obtain MDF pulp, and then diluted to 4% to 5%. It is transported to the middle tank by the pump for standby;

[0030] S2, slurry mixing: the pulp and MDF slurry are evenly mixed;

[0031] S3, dehydration: the mixed slurry is dehydrated by a dehydrator to a mass concentration of 18% to 25%;

[0032] S4. Refining: the dehydrated pulp is transported to the refiner for refining;

[0033] S5. The ground slurry is sent to the paper machine to make finished corrugated paper.

[0034] In the corrugated p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com