Polyacrylonitrile suspension with high solid content and low viscosity, preparation method and application thereof, and preparation method of polyacrylonitrile-based carbon fiber

A technology of polyacrylonitrile and high solid content, which is applied in the field of carbon fiber and can solve problems such as poor process continuity, high viscosity of the polymerization system, and difficulty in mass and heat transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

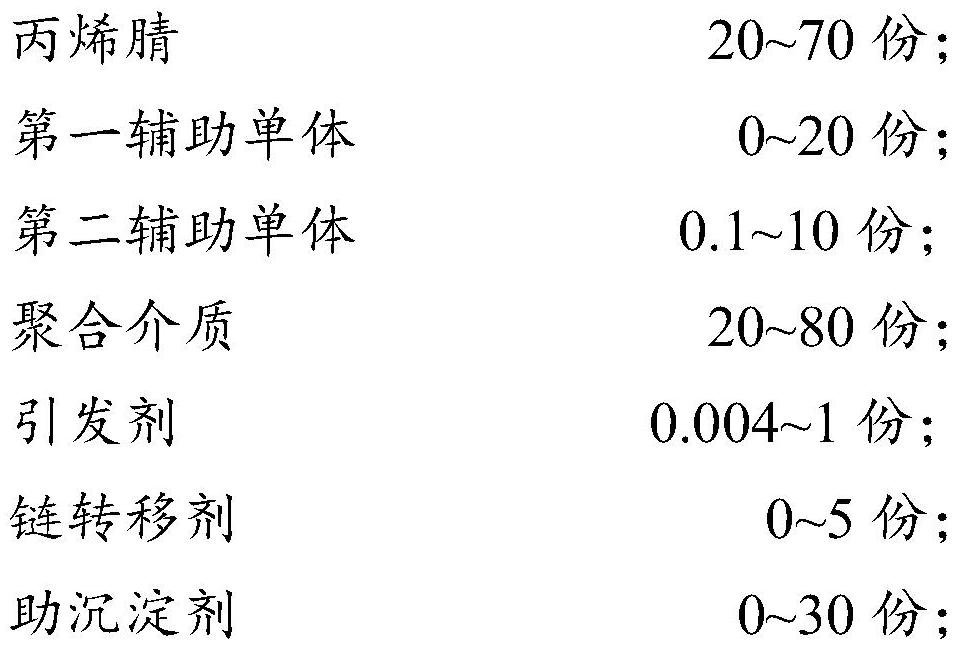

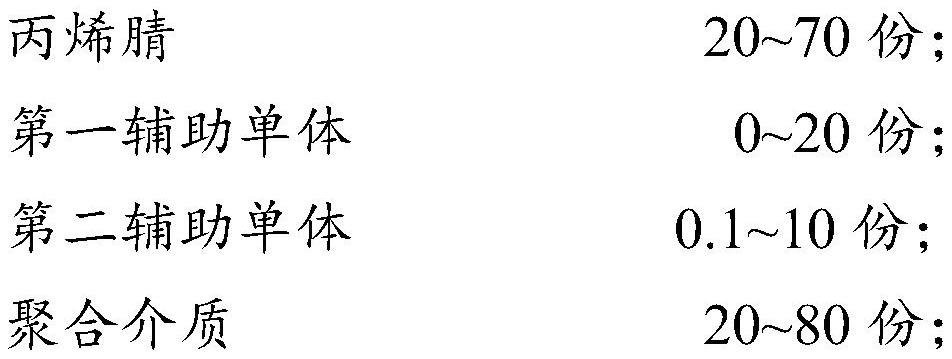

[0056] The present invention also provides a preparation method for the polyacrylonitrile suspension described in the above technical scheme, comprising the following steps:

[0057] mixing the preparation raw materials to obtain the mixed raw materials;

[0058] performing a polymerization reaction on the mixed raw materials to obtain the polyacrylonitrile suspension with high solid content and low viscosity;

[0059] The temperature of the polymerization reaction is 30-100° C., and the time is 0.5-24 hours; after the polymerization reaction, the total conversion rate of acrylonitrile, the first auxiliary monomer and the second auxiliary monomer is 15-90%.

[0060] The invention mixes the preparation raw materials to obtain the mixed raw materials. In the present invention, the mixing preferably includes the following steps:

[0061] mixing the initiator and part of the polymerization medium to obtain an initiator solution;

[0062] Mixing the preparation raw materials excep...

Embodiment 1

[0103] 38.8 parts of acrylonitrile, 0.4 part of itaconic acid, 0.8 part of methyl acrylate and 55 parts of N,N-dimethylacetamide were stirred for 5 minutes under nitrogen protection and a rotating speed of 150r / min to obtain primary mixed raw materials; 0.04 parts of azobisisobutyronitrile and 4.98 parts of N,N-dimethylacetamide were mixed to obtain an initiator solution; Stir for 2min to obtain mixed raw materials;

[0104] The mixed raw material is under the protection of nitrogen, the rotating speed is 150r / min, the temperature is 65°C, and the relative pressure is 0MPa, and the polymerization reaction is carried out for 4h (the total mass conversion rate of the polymerized monomer is 70%), and the solid content is obtained. 31.8%, a polyacrylonitrile suspension with a viscosity of 30 Pa s (the number average molecular weight of polyacrylonitrile is 13 × 10 4 g / mol).

Embodiment 2

[0106] The polyacrylonitrile suspension was prepared according to the method of Example 1 (solid content was 25%, the total mass conversion rate of polymerized monomers was 50%, the viscosity was 26 Pa s, and the number average molecular weight of polyacrylonitrile was 17 × 10 4 g / mol), the difference is that the initiator is adjusted to azobisisoheptanonitrile, and the polymerization temperature is limited to 55°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com