Method for reducing specific surface area BET (Brunauer Emmet Teller) of white carbon black prepared by using sulfuric acid precipitation method

A sulfuric acid precipitation method and a technology of specific surface area, applied in the direction of silicon oxide, etc., can solve the problem of research, to clarify and other problems, and achieve the effect of simple operation, accurate control and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

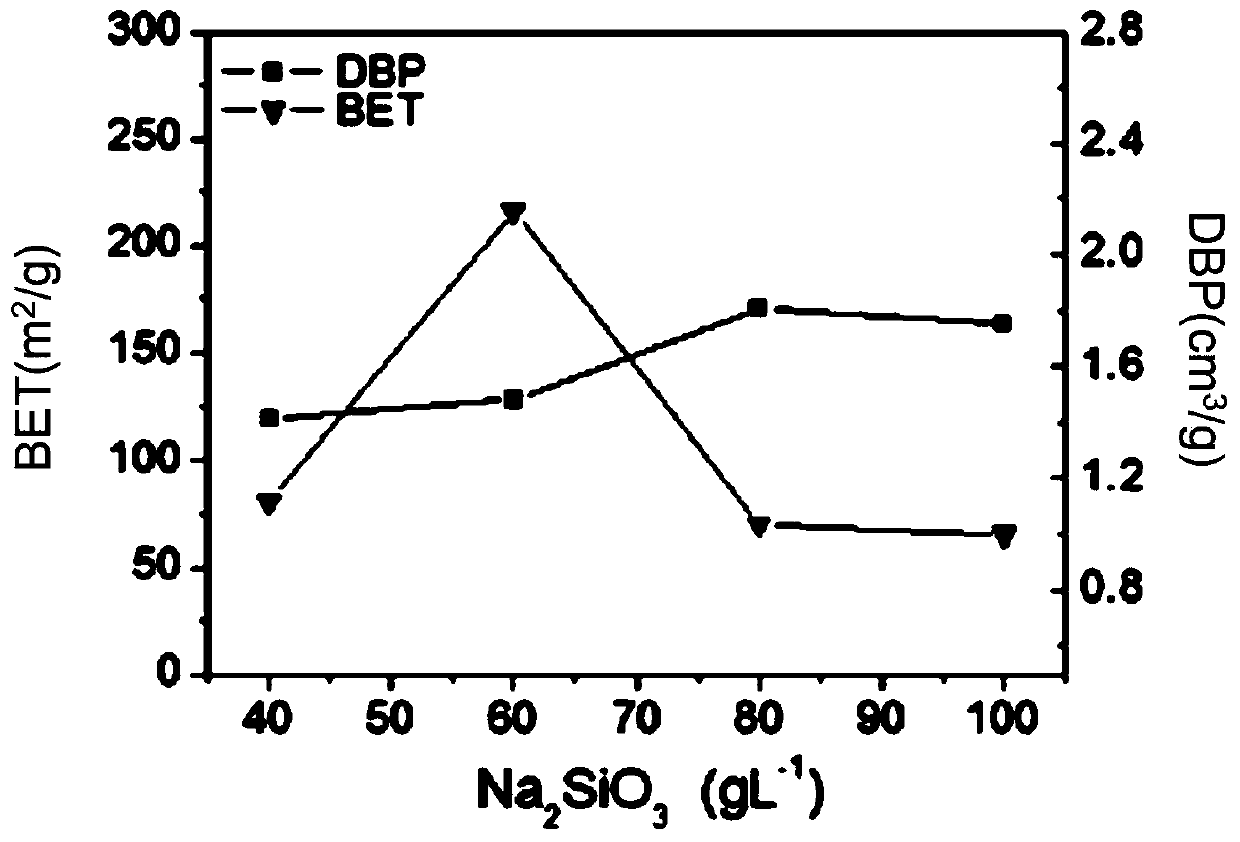

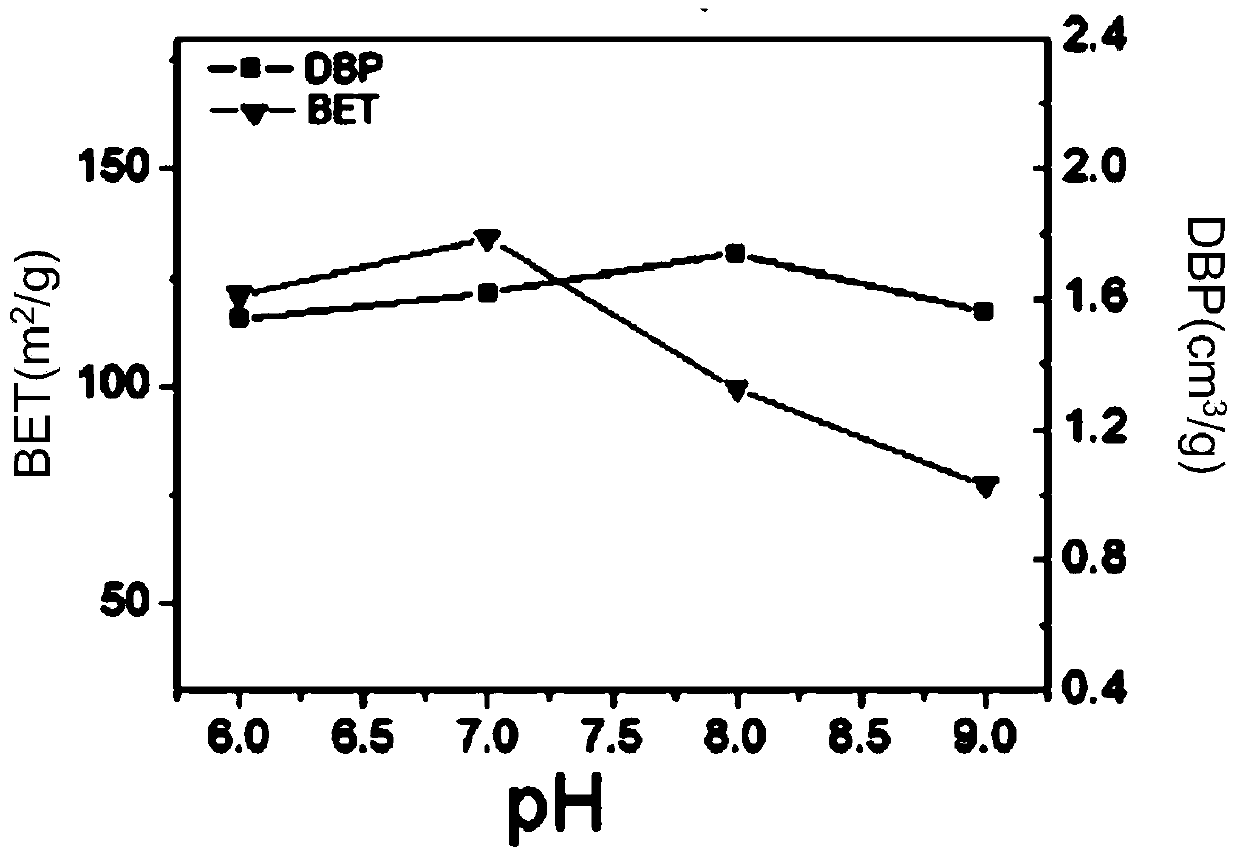

[0062] Example 1 Research on the Effects of Process Parameters on the Specific Surface Area BET and Oil Absorption Value DBP of Silica

[0063] In this experiment, L 16 (4 5 ) Orthogonally studied the influence of the five factors of sodium silicate (water glass) concentration, reaction pH, reaction temperature, sodium chloride concentration and aging pH on the specific surface area BET and oil absorption value DBP of silica, and obtained through data analysis Detailed conclusion.

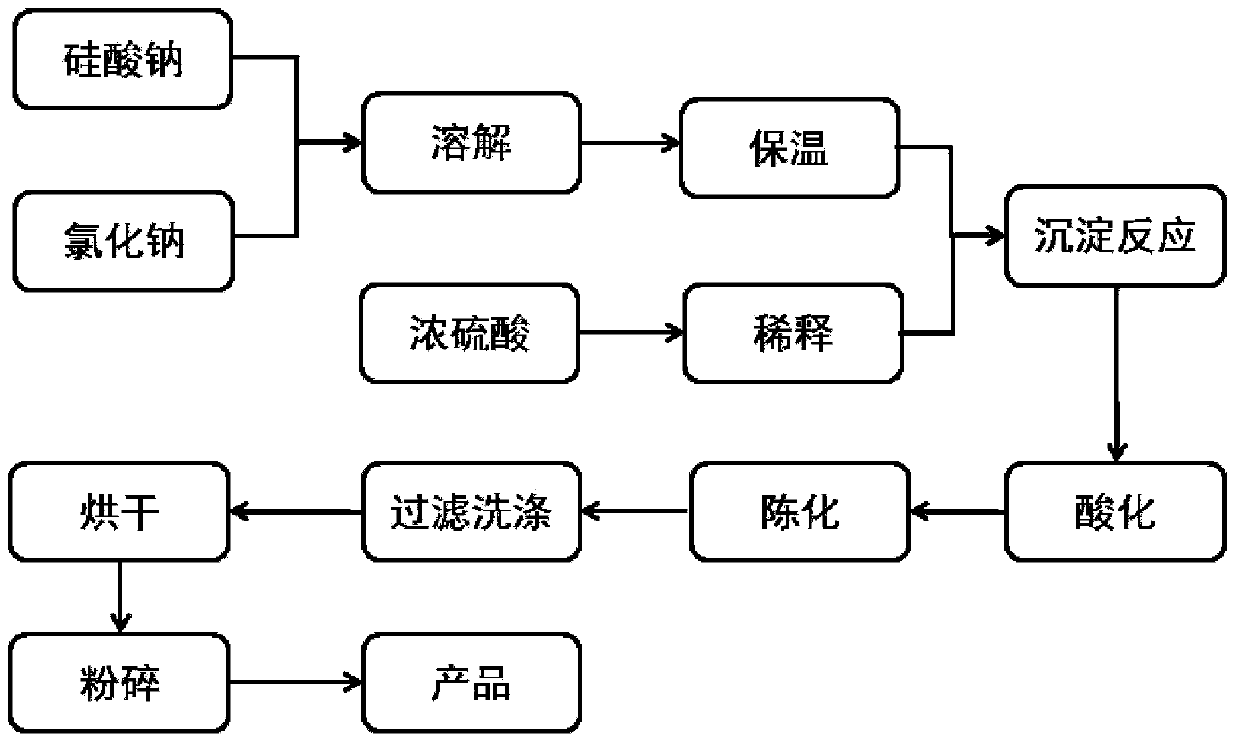

[0064] The specific experimental process is roughly as follows:

[0065] (1) Prepare 200mL of sodium silicate solution with a certain concentration (sodium silicate concentration in Table 1), pour it into a 500mL three-necked flask, add a certain amount (NaCl concentration in Table 1) of NaCl solid; dilute concentrated sulfuric acid to 40% concentration.

[0066] (2) Heat the bottom liquid of the reaction liquid to a certain temperature (the reaction temperature in Table 1), add sulfuric acid d...

Embodiment 2

[0088] Example 2 BET is 117m 2 / g of silica production

[0089] (1) Add solid water glass and water into the dissolving kettle, feed steam with a pressure greater than 0.7Mpa into the dissolving kettle until the pressure in the dissolving kettle is 0.5-0.6Mpa, then turn off the steam, keep warm for 2-3 hours, and dissolve to a mass concentration It is more than 35% liquid water glass;

[0090] (2) adding water to the dissolved liquid water glass in a water glass adjustment tank, and diluting it into a water glass solution with a mass concentration of 22%;

[0091] (3) Mix the water glass solution and sulfuric acid solution in a reaction kettle, and react for 60 minutes at pH 10 and temperature 94°C;

[0092] (4) Adjust the pH of the reaction solution to 6, and age it for 60 minutes at a temperature of 94°C to obtain a slurry;

[0093] (5) Adjust the pH of the slurry to 3; press filter through a filter press, and then wash to filter out part of the water and wash away sodium...

Embodiment 3

[0095] Example 3 BET is 110m 2 / g of silica production

[0096] (1) Add solid water glass and water into the dissolving kettle, feed steam with a pressure greater than 0.7Mpa into the dissolving kettle until the pressure in the dissolving kettle is 0.5-0.6Mpa, then turn off the steam, keep warm for 2-3 hours, and dissolve to a mass concentration It is more than 35% liquid water glass;

[0097] (2) adding water to the dissolved liquid water glass in a water glass adjustment tank, and diluting it into a water glass solution with a mass concentration of 20%;

[0098] (3) Mix the water glass solution and sulfuric acid solution in a reaction kettle, and react for 60 minutes at pH 10 and temperature 94°C;

[0099] (4) Adjust the pH of the reaction solution to 7, and age it for 60 minutes at a temperature of 94°C to obtain a slurry;

[0100] (5) Adjust the pH of the slurry to 3; press filter through a filter press, and then wash to filter out part of the water and wash away sodium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com