Device and method for recycling low-concentration organic solvent

A technology for organic solvents and recovery devices, which is applied in organic chemistry methods, chemical instruments and methods, organic chemistry, etc., can solve the problems of low purity of organic solvents and high energy consumption, and achieve reduced dehydration burden, low energy consumption, and improved economy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

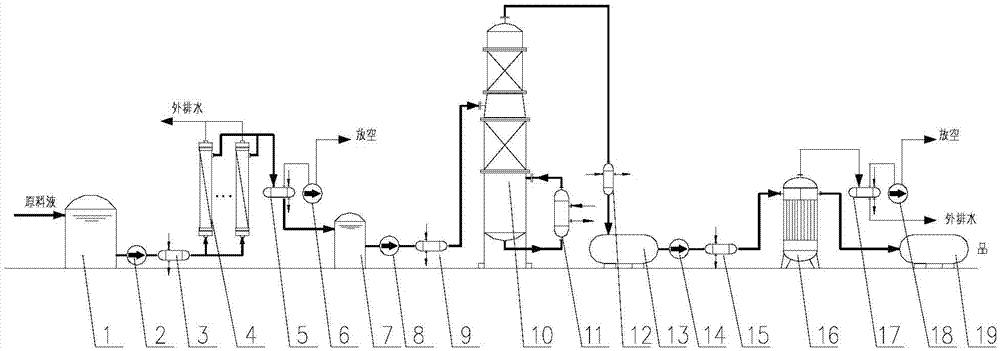

Embodiment 1

[0043] The raw material liquid in the raw material liquid tank 1 is an ethanol aqueous solution with a mass concentration of 0.1% ethanol and 99.9% water. After being heated by the first heater 3 through the first delivery pump 2, it enters the pervaporation membrane module 4 for organic solvent separation and pervaporation The membrane module 4 is evacuated by the first vacuum pump 6, the permeated liquid is evacuated by the first condenser 5, the temperature of the first heater heating 3 is 40°C, the operating pressure of the first vacuum pump 6 is 800 Pa, and the permeated liquid has a mass concentration of 10 % of the ethanol aqueous solution and enter the separation liquid tank 7; the second delivery pump 8 beats the ethanol aqueous solution into the distillation tower 10 after being heated by the second heater 9 to carry out distillation and enrichment, the operating pressure of the distillation tower 10 is normal pressure, and the distillation temperature Control at 90°C...

Embodiment 2

[0045] The raw material liquid in the raw material liquid tank 1 is an acetone aqueous solution with a mass concentration of 10% acetone and 90% water. After being heated by the first heater 3 through the first delivery pump 2, it enters the pervaporation membrane module 4 for organic solvent separation and pervaporation. The membrane module 4 is evacuated by the first vacuum pump 6, the permeated liquid is evacuated by the first condenser 5, the temperature of the first heater heating 3 is 50°C, the operating pressure of the first vacuum pump 6 is 500 Pa, and the permeated liquid has a mass concentration of 40 % of the acetone aqueous solution and enter the separating liquid tank 7; the second delivery pump 8 beats the acetone aqueous solution into the distillation tower 10 after being heated by the second heater 9 to carry out distillation and enrichment, the operating pressure of the distillation tower 10 is normal pressure, and the distillation temperature Control at 99°C t...

Embodiment 3

[0047] The raw material liquid in the raw material liquid tank 1 is an aqueous solution of isopropanol with a mass concentration of 6.5% isopropanol and 93.5% water. After being heated by the first heater 3, it enters the pervaporation membrane module 4 for organic solvent Separation, pervaporation membrane module 4 is evacuated by the first vacuum pump 6, the permeated liquid is evacuated by the first condenser 5 condenser, the temperature of the first heater heating 3 is 45 °C, the operating pressure of the first vacuum pump 6 is 500 Pa, and the permeated liquid It is the isopropanol aqueous solution of mass concentration 30% and enters separation liquid tank 7; The second conveying pump 8 beats the acetone aqueous solution through the second heater 9 heating in the distillation tower 10 and carry out distillation enrichment, the operating pressure of the distillation tower 10 At normal pressure, the distillation temperature is controlled at 99°C to obtain an isopropanol conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com