Sensible heat recycling method and device in xylose production process

A production process and sensible heat recovery technology, applied in the production of sugar, sugar production, glucose production, etc., can solve the problems of flash gas entry, environmental pollution, heat loss, etc., to reduce energy consumption, save consumption, save The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

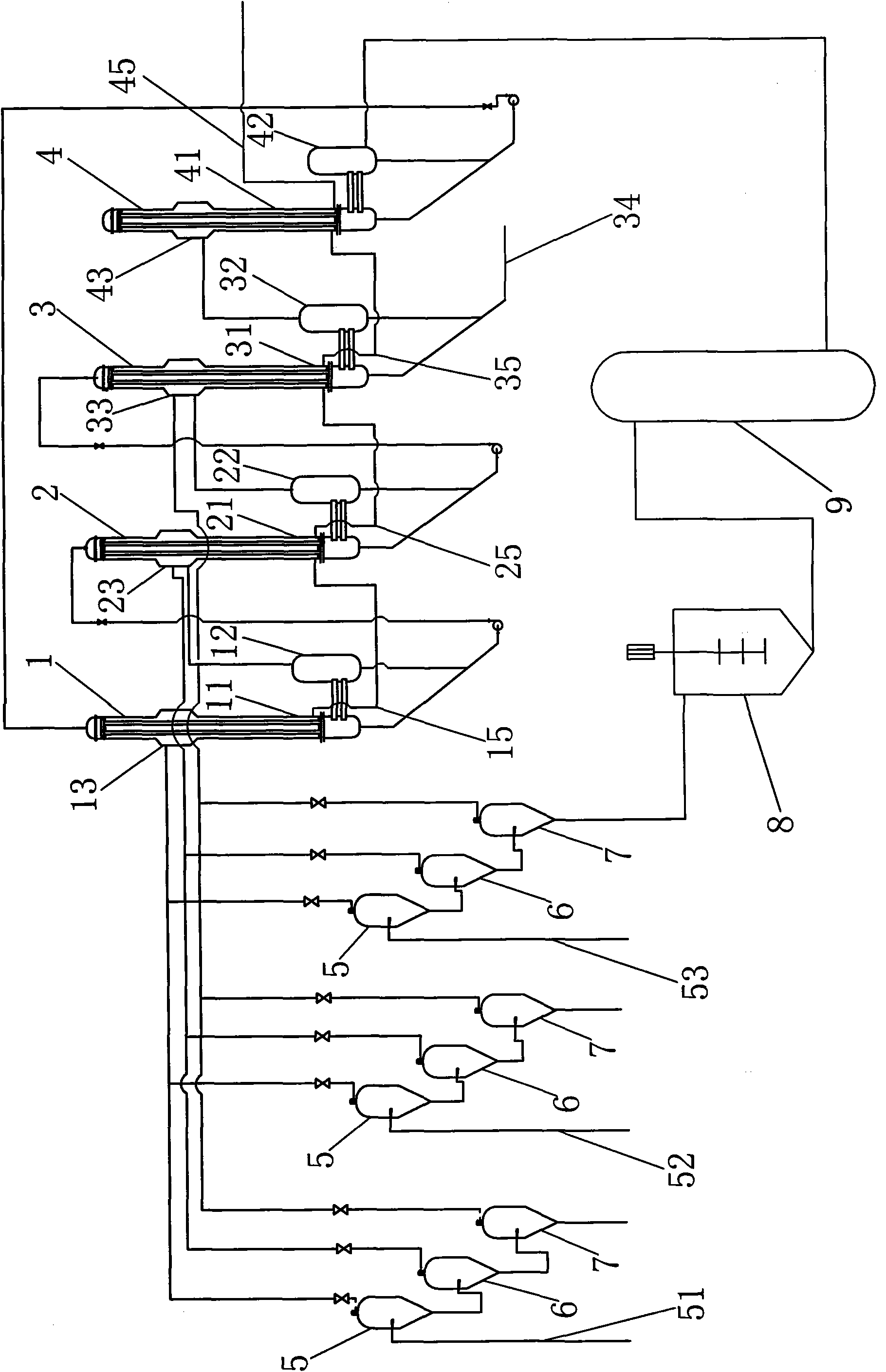

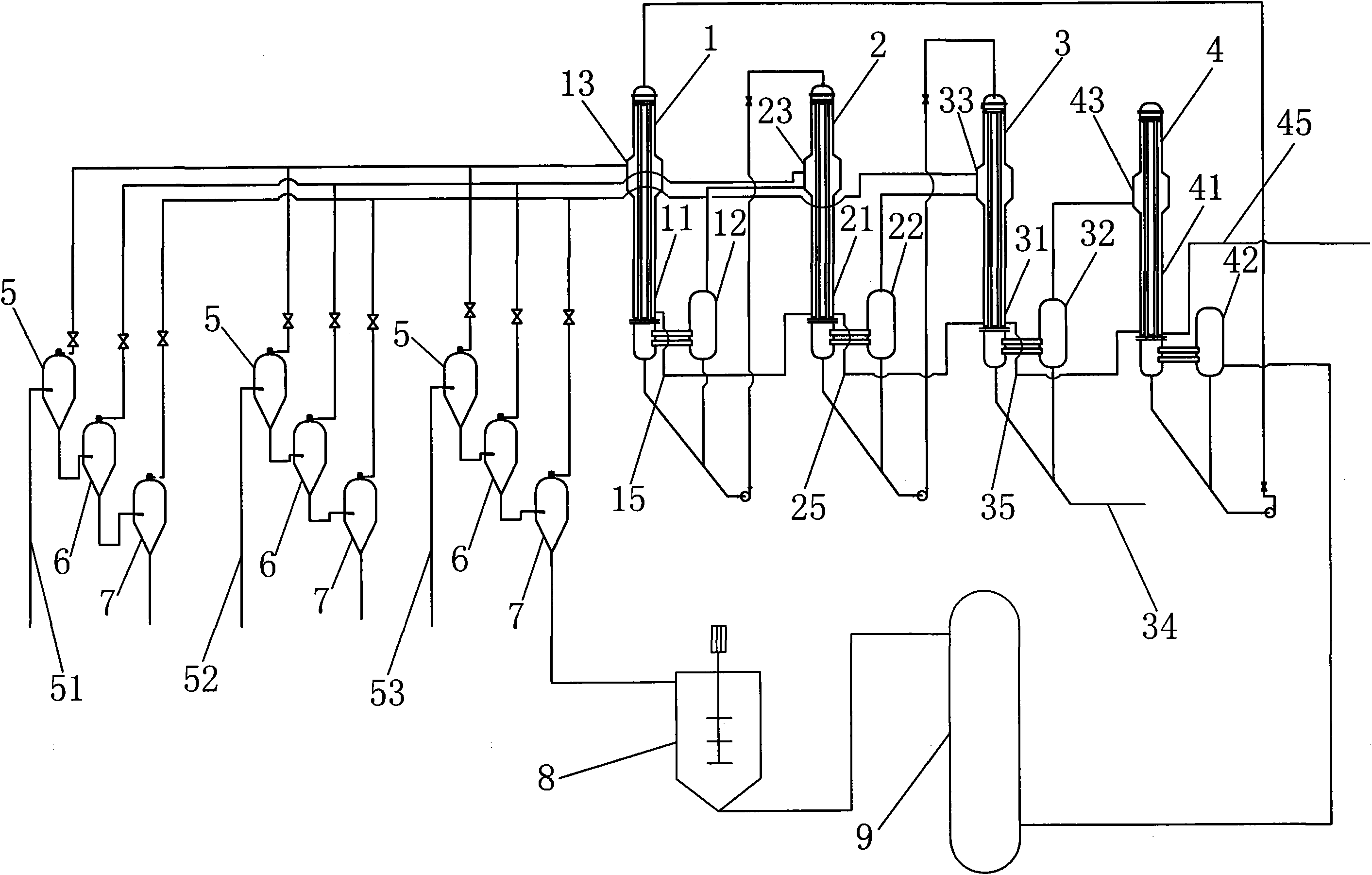

[0027] Such as figure 1 As shown, in the sensible heat recovery and utilization method in the xylose production process, the pretreatment washing water, hydrolyzate, and hydrolyzed slag sugar liquid washing water respectively enter the first-stage flash evaporator 5 and the second-stage flash evaporator 6 connected in series from top to bottom in a stepped manner. Perform three-stage flash evaporation with the three-stage flash evaporator 7, and the temperature of the hydrolyzed solution after flashing drops to 65-75 ° C and directly enters the decolorization process, and the hydrolyzed solution after decolorization enters the four-effect evaporator 4 and one-effect sequentially after ion exchange The evaporator 1, the second-effect evaporator 2, and the three-effect evaporator 3 are evaporated and concentrated, and the final concentrated hydrolyzate is discharged from the hydrolyzate outlet 34 of the three-effect evaporator 3 to enter the next process;

[0028] The pretreatme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com