Analysis method for whole process of cable hoisting

A technology of cable hoisting and analysis methods, which is applied in the direction of erecting/assembling bridges, bridge forms, instruments, etc., and can solve problems such as not considering horizontal displacement, not considering the relevant effects of towers and main arches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] This cable hoisting whole process analysis method of the present embodiment mainly comprises the following four steps of carrying out respectively, is respectively::

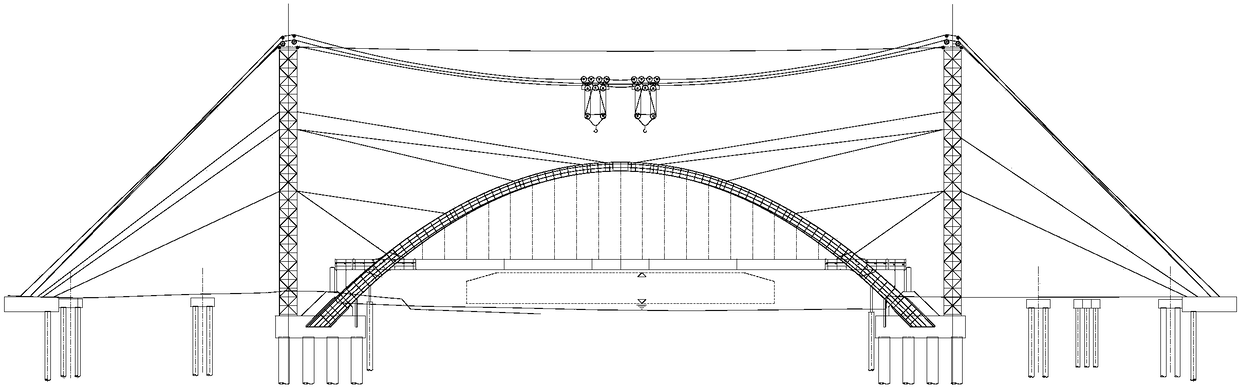

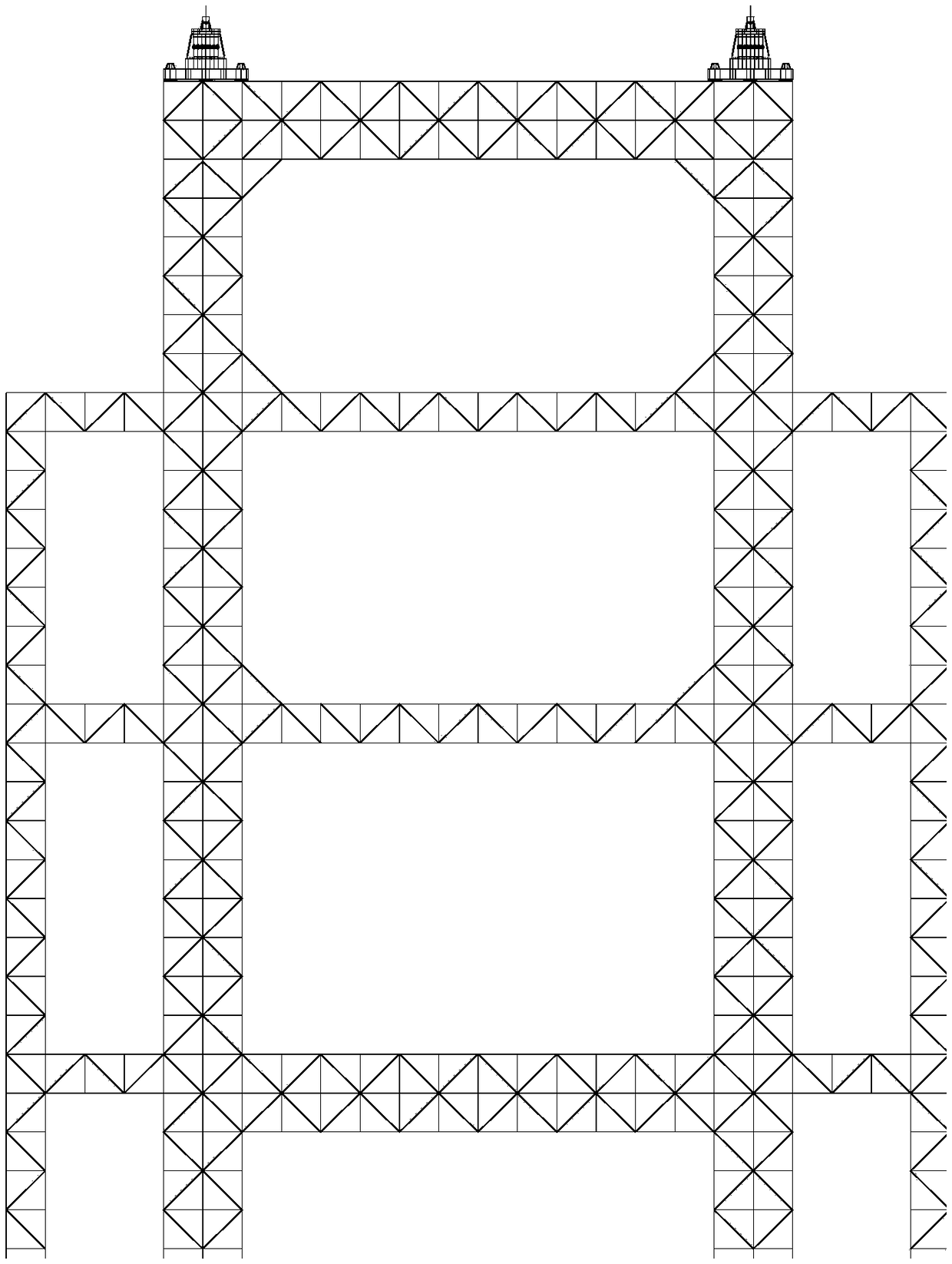

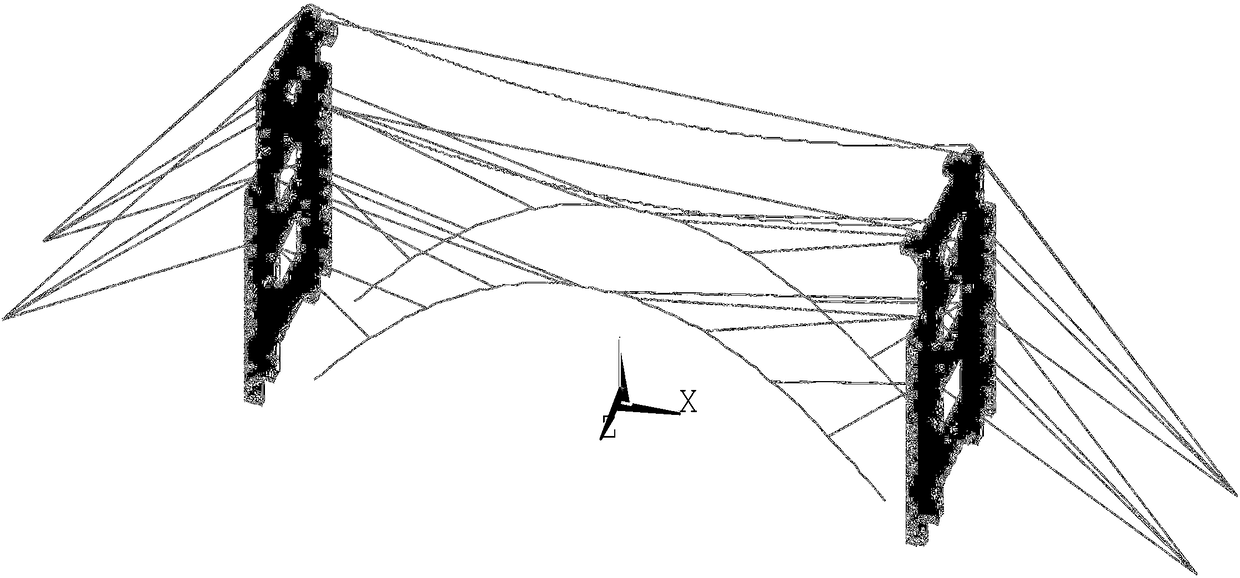

[0042] S1, first according to figure 1 and figure 2 The shown construction drawings establish a traditional cable hoisting analysis model without main cables and saddles. The established cable hoisting analysis model is as follows: image 3 As shown, it includes models of towers, main arches, buckles, anchor cables and ventilation cables.

[0043] S2. Considering the actual interaction between the cable saddle and the main cable through the pulley, the cable saddle is simulated with a rigid shell element. The bottom of the cable saddle is connected to the tower, and the outer surface of the cable saddle is in contact with the main cable. Firstly, the flexible iteration method is used to obtain The initial catenary equation of the main cable under the action of gravity, and then select the part of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com