All-wet-joint precast prestressed underground continuous wall and construction method thereof

A technology for underground diaphragm walls and wet joints, which is applied in excavation, sheet pile walls, foundation structure engineering, etc. It can solve problems such as easy seepage, increase construction costs, and leaking reinforcement in walls, so as to delay cracking time and increase bending resistance Effect of stiffness, enhanced shear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing.

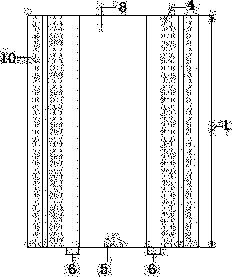

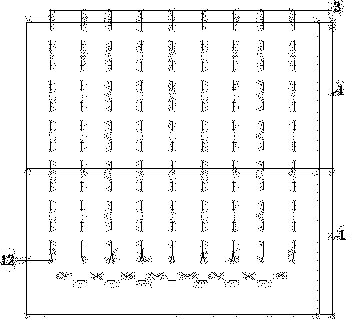

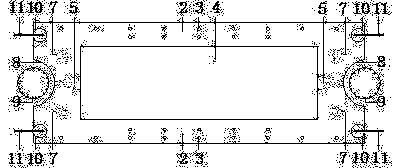

[0035] like figure 1 , figure 2 , image 3 and Figure 4 As shown, the prefabricated prestressed underground diaphragm wall with full wet joints of the present invention includes several wall sections 1 sequentially connected from top to bottom, and the wall sections 1 include a prefabricated box-shaped concrete structure 2, and a Prestressed tendon holes 3, the wall sections 1 are connected by a plug-in structure, the middle part of the section of the wall section 1 is a cavity 4, and the center of the wall section 1 along the length direction is provided with a concave groove section 8, so The upper and lower connection parts of the box-shaped concrete structure 2 are provided with a semi-conical hole 5, the semi-conical hole 5 communicates with the cavity 4 and the groove section 8, and concrete is poured in the semi-conical hole 5 to form a waterproof Wet joints, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com