Slurry suction machine with self-cleaning function

A self-cleaning, functional technology, applied in the field of pulping machines with self-cleaning function, can solve the problems of sticking excess pulp, etc., and achieve the effect of avoiding air leakage, preventing low production efficiency, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below by means of specific embodiments:

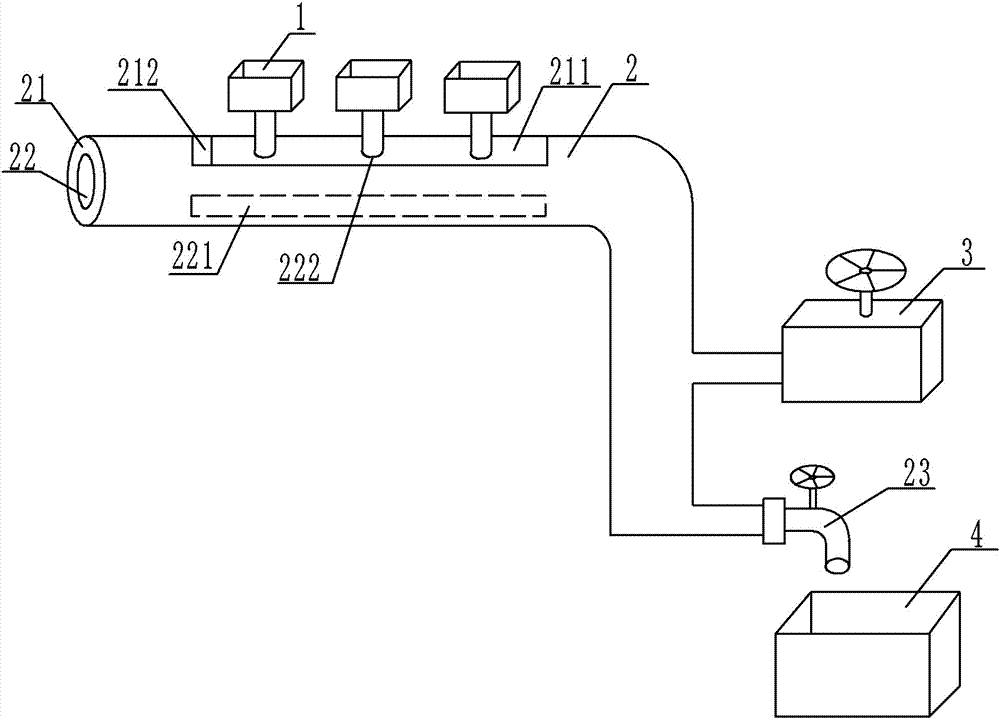

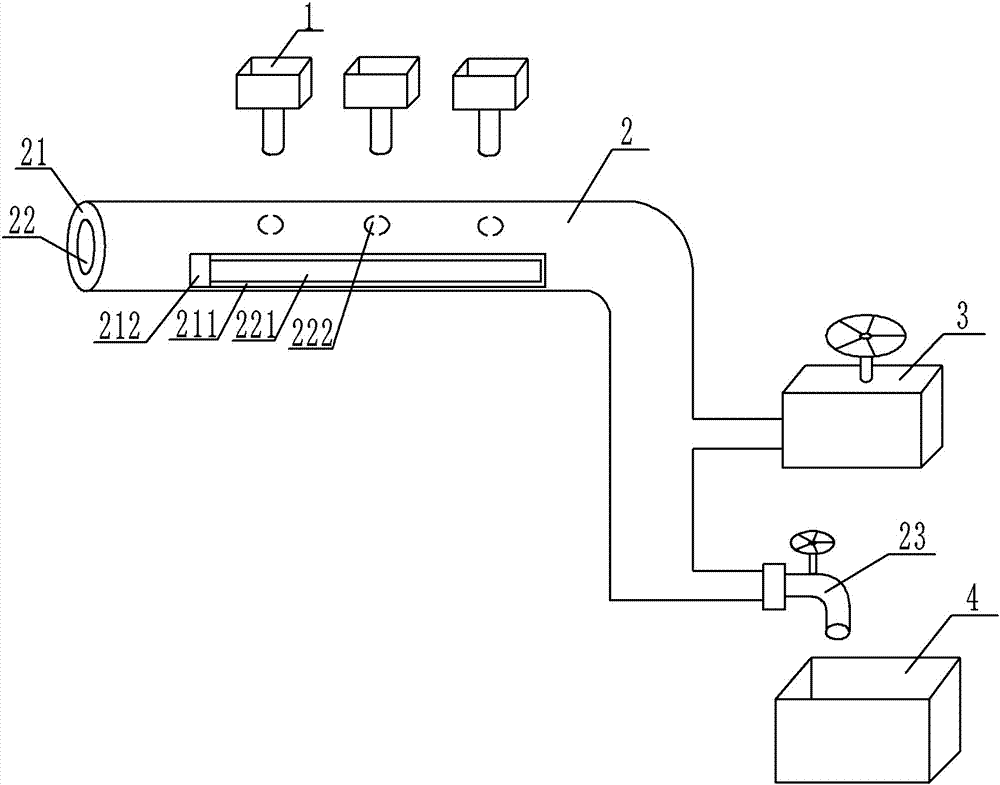

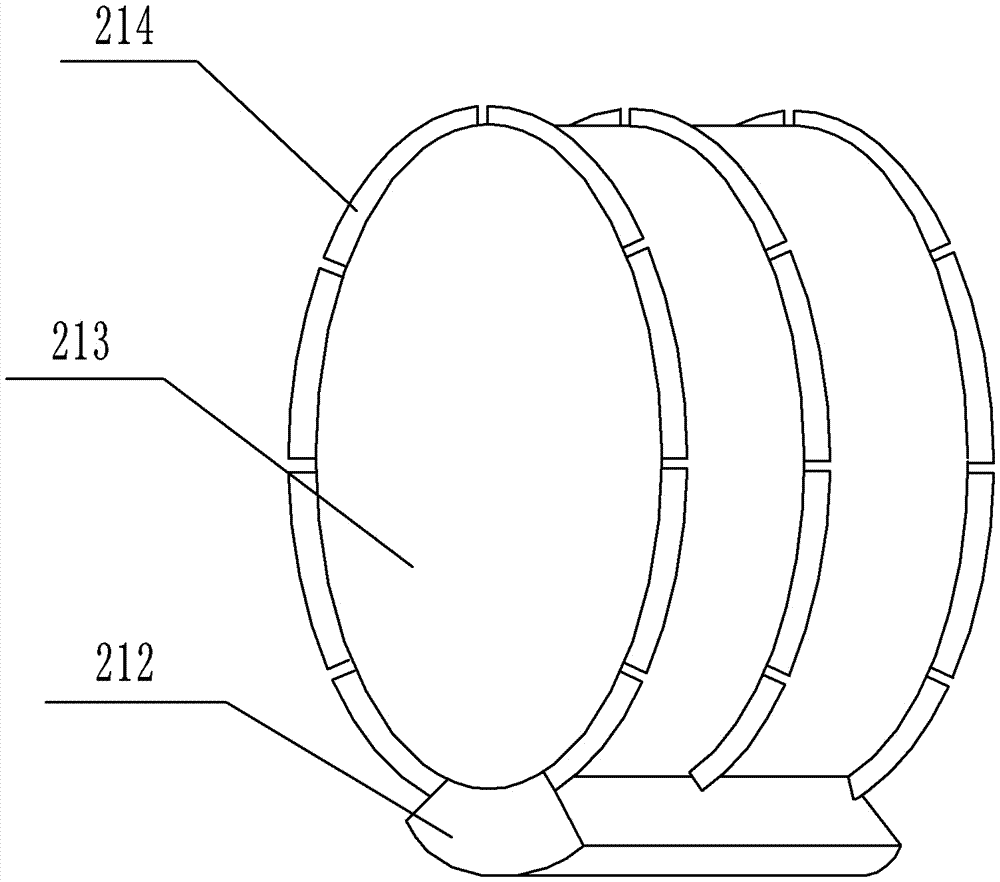

[0022] The reference signs in the accompanying drawings of the description include: pumping bucket 1, pumping pipe 2, outer pipe 21, outer pipe through groove 211, slider 212, air bag 213, scraper 214, inner hole 215, inner pipe 22, inner pipe Through groove 221 , through hole 222 , sealing ring 223 , pulp valve 23 , pulp pumping machine 3 , and waste recycling barrel 4 .

[0023] Such as figure 1 , figure 2 and image 3 As shown, the pulping machine with self-cleaning function includes three pulping barrels 1, pulping pipe 2, outer pipe 21, outer pipe through groove 211, slider 212, air bag 213, 24 scrapers 214, inner pipe 22, Inner pipe through groove 221, three through holes 222, sealing ring 223, pulp valve 23, pulp pump 3 and waste recovery barrel 4.

[0024] The pumping barrel 1 is set above the pumping pipe 2. The pumping pipe 2 is an inner and outer pipe stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com