Fully-assembled well of existing building loading elevator and mounting method thereof

A technology of existing construction and installation methods, applied in elevators, buildings, building maintenance and other directions in buildings, can solve problems such as higher requirements for connecting parts, and achieve the effect of shortening construction period, eliminating noise and saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0052] Example 1. The structure and installation of the assembled elevator shaft using PC standard parts

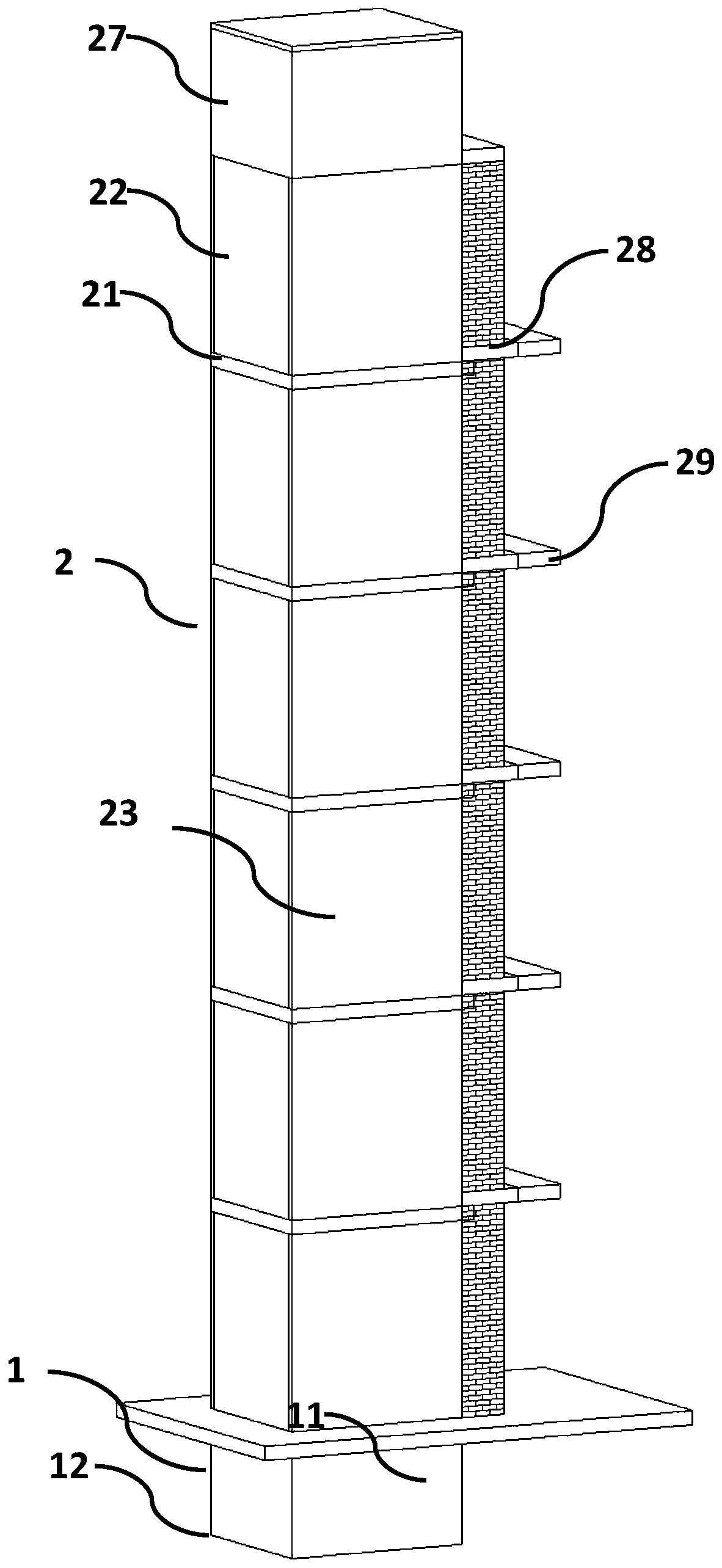

[0053] From figure 1 It can be seen that the prefabricated concrete standard component assembled elevator shaft structure is composed of an underground structure 1 and an above-ground structure 2 . The underground structure 1 is composed of a box without a cover 11 , a bottom plate 12 and a pile foundation 13 . The underground structure 1 is buried by slotting or caisson method. The pile foundation 13 is to use the pre-embedded connecting nuts installed on the top surface of the box body 11 without a cover, install a static pressure reaction force frame 14 and a reaction force frame beam 15, and provide the reaction force through the friction force between the box body 11 and the surrounding soil. , use the static pressure jack 18 to press the prefabricated pile or the steel pipe pile 13 into the foundation soil, such as Figure 4 shown.

[0054] The prefabricated rei...

example 2

[0060] Example 2. The structure and installation method of the assembled elevator shaft using steel standard parts

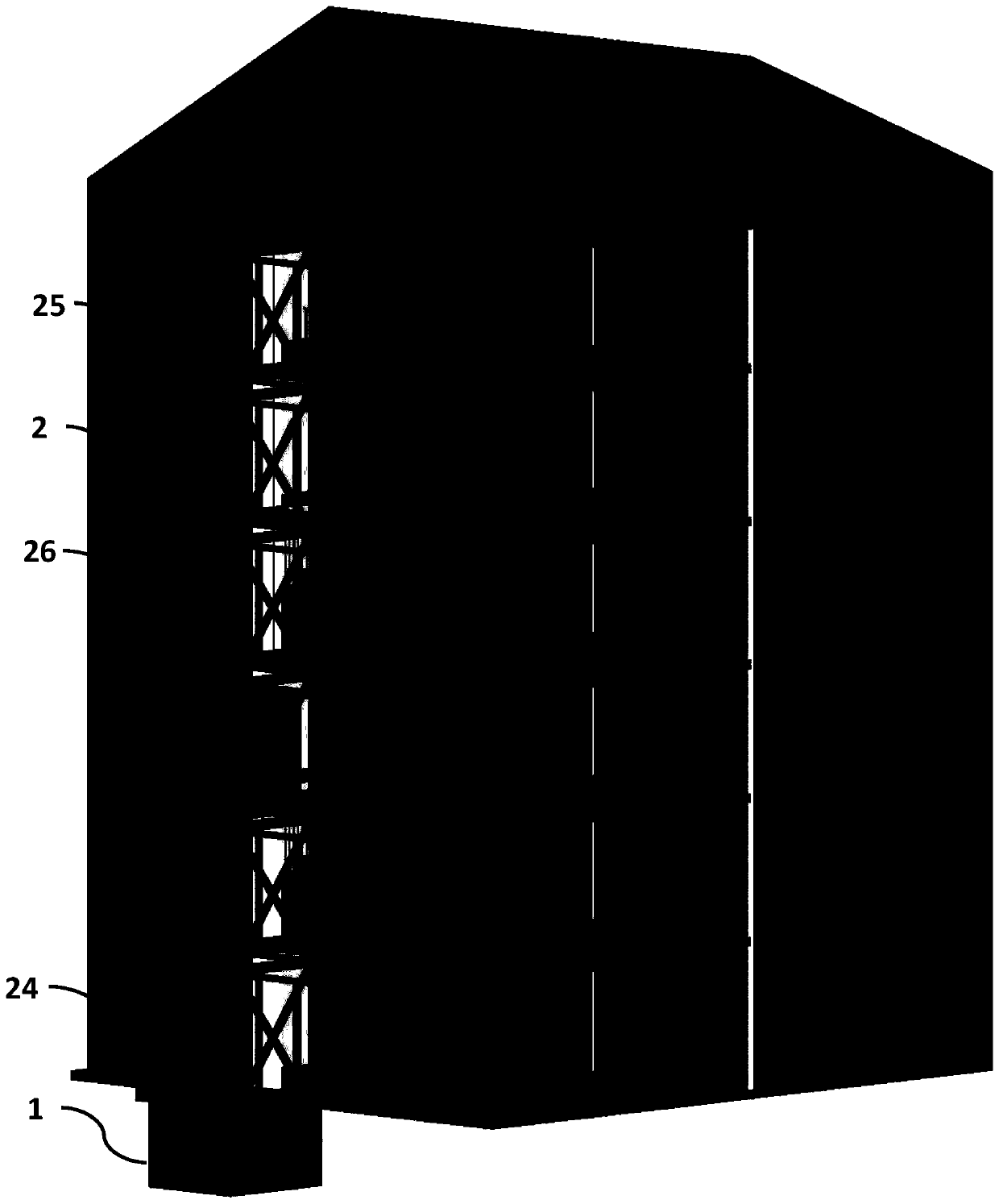

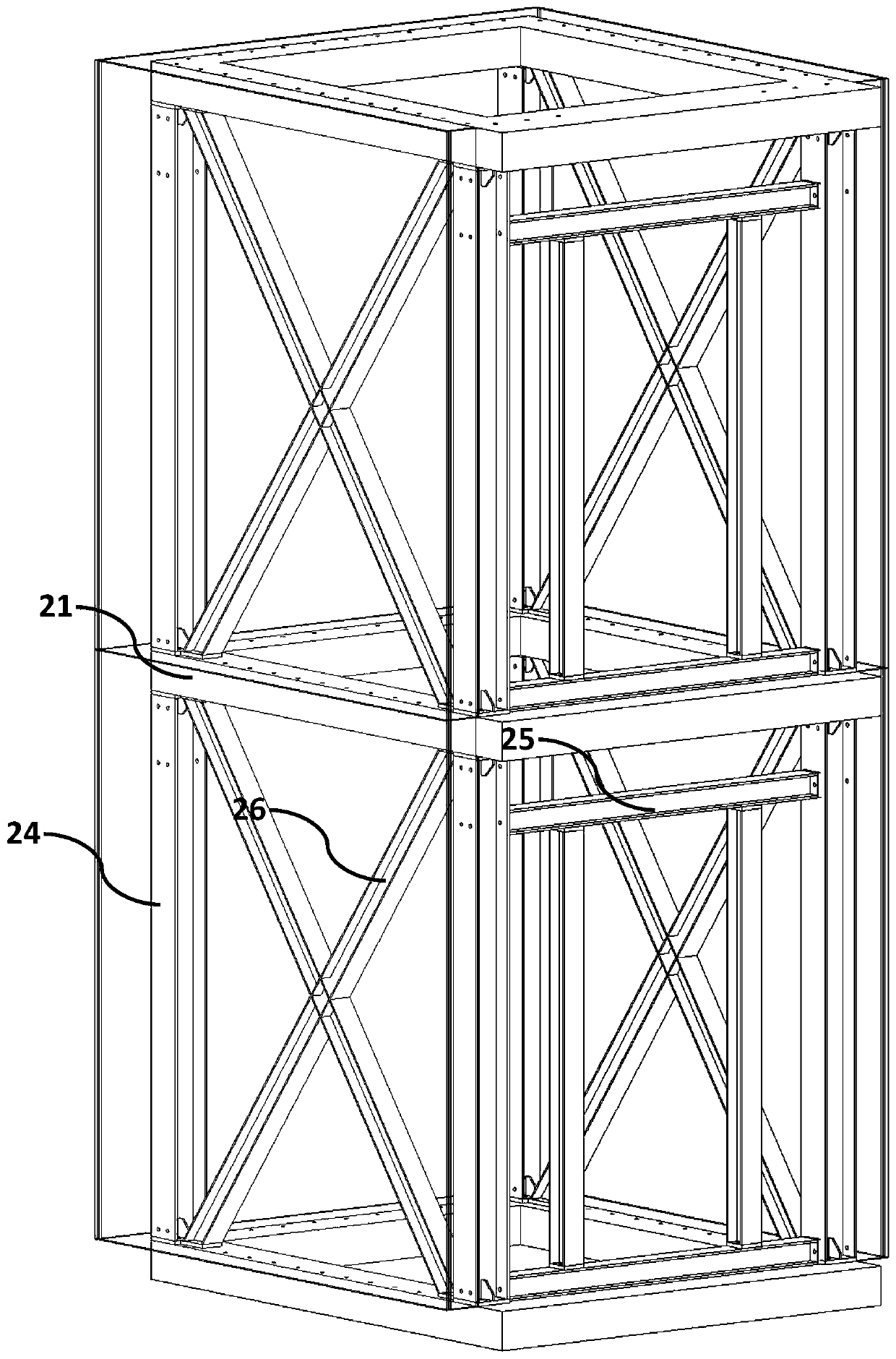

[0061] figure 2 Shown is the elevator shaft structure assembled with steel standard parts. It can be seen from the figure that the shaft structure is composed of an underground structure 1 and an above-ground structure 2. The underground structure 1 is composed of a box without a cover 11 , a bottom plate 12 and a pile foundation 13 . The underground structure 1 is buried by slotting or caisson method. The pile foundation 13 utilizes the pre-embedded connecting nuts installed on the top surface of the box body 11 without a cover to install a static pressure reaction force frame 14 and a reaction force frame beam 15, and provides a reaction force through the friction force between the box body 11 and the surrounding soil. Force, using static pressure 18 to press the prefabricated pile 13 into the foundation soil, such as Figure 4 shown.

[0062] The prefabr...

example 3

[0067] Example 3: Elevator shaft structure and installation method assembled with PC standard parts and section steel standard parts

[0068] image 3 Shown is the elevator shaft structure assembled with steel standard parts and PC standard parts. It can be seen from the figure that the shaft structure is composed of an underground structure 1 and an above-ground structure 2. The underground structure 1 is composed of a box without a cover 11 , a bottom plate 12 and a pile foundation 13 . The underground structure 1 is buried by slotting or caisson method. The pile foundation 13 utilizes the pre-embedded connecting nuts installed on the top surface of the box body 11 without a cover to install a static pressure reaction force frame 14 and a reaction force frame beam 15, and provides a reaction force through the friction force between the box body 11 and the surrounding soil. Force, using static pressure 18 to press the prefabricated pile 13 into the foundation soil, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com