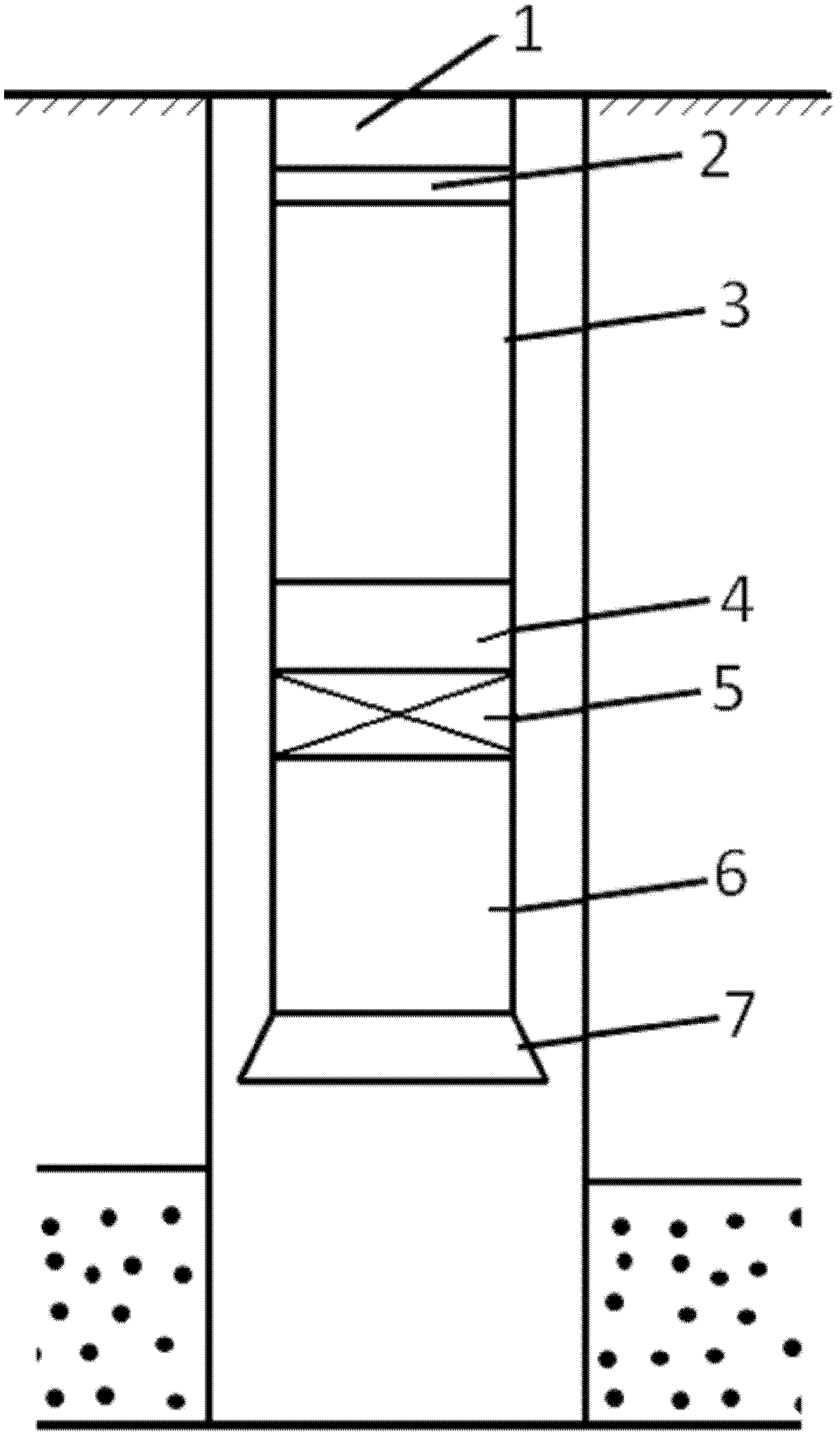

Method for lifting heavy oil through shaft in heavy oil cold production

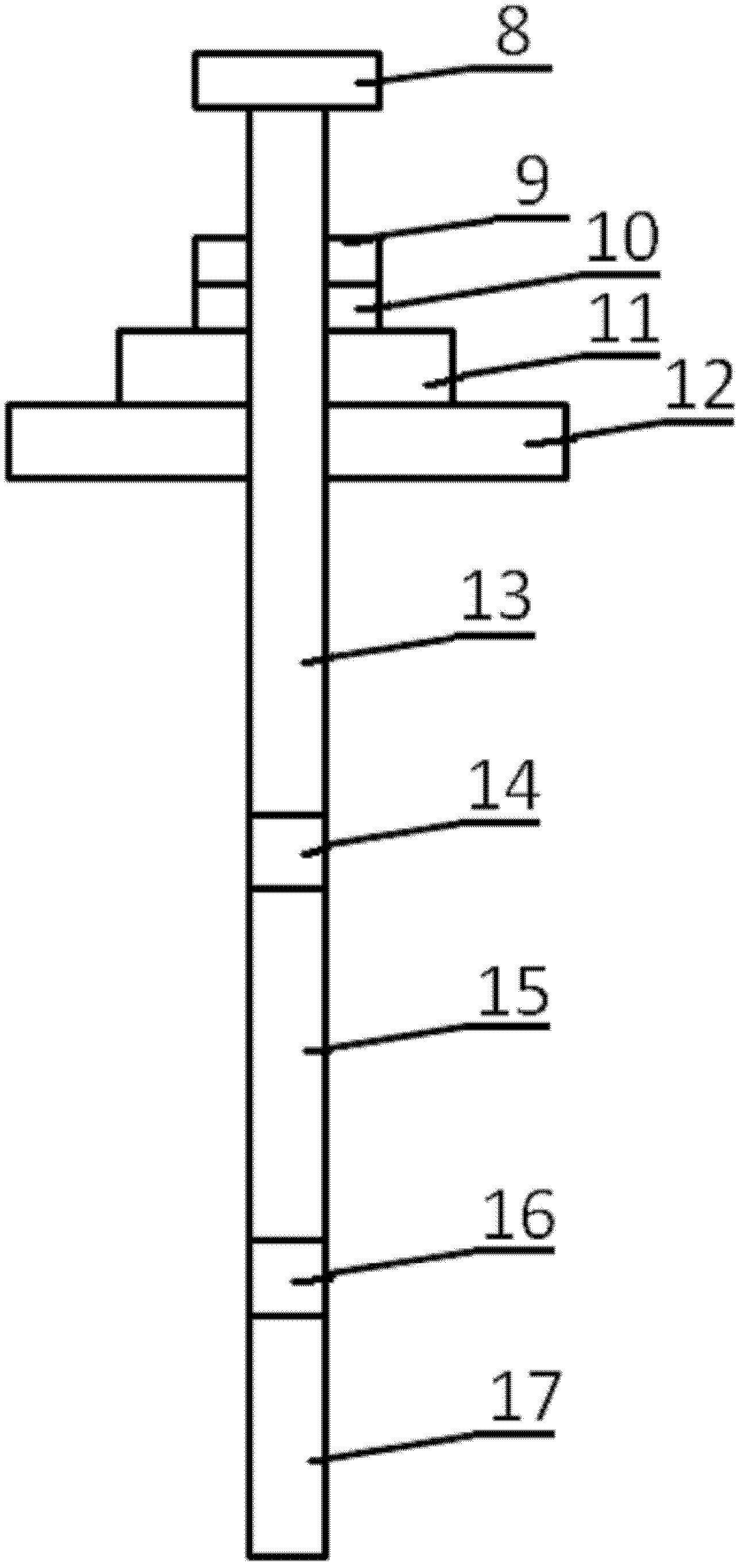

A heavy oil and cold recovery technology, applied in chemical instruments and methods, production fluids, earthwork drilling, etc., can solve the difficulty of starting, the large torque of lifting sucker rods, the asynchronous lifting and descending of coaxial double hollow rods, etc. problems, to prolong the pump inspection time, solve the wellbore lifting, and reduce the load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: Taking Well X-9 as an example, the method for lifting heavy oil in a heavy oil cold recovery wellbore of the present invention is further described in detail. The viscosity of crude oil at 50°C in Well X-9 is 16037mPa.s, and the liquid level is 300m. Due to the thick oil, normal cold recovery has not been possible. The coaxial double hollow rods are used to support the ground-driven screw pump to make the X-9 well produce normally. The depth of the lower pump is 1200m, and the length of the coaxial double hollow rods is 1000m. Daily liquid 8.5m 3 , with a daily oil output of 7.3t, and has been in normal production for 352 days.

[0032] The implementation process of X-9 well:

[0033] 1. Preparation of viscosity reducer A: The weight percentage of each component of viscosity reducer A: 38% of 0# diesel oil, 1.5% of propylene glycol polyoxypropylene polyoxyethylene block polyether series, 23.5% of 200# solvent oil , 0.8% polyoxyethylene alkylphenol ether...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com