Method and device for preventing machine lifting of water-turbine generator set

A technology for generator sets and water turbines, which is applied in the directions of hydroelectric power generation, safety devices, engine components, etc., can solve the problems of damage to the thrust bearing and structural components of the hydro-generator, and achieve the effect of solving the problem of lifting the machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

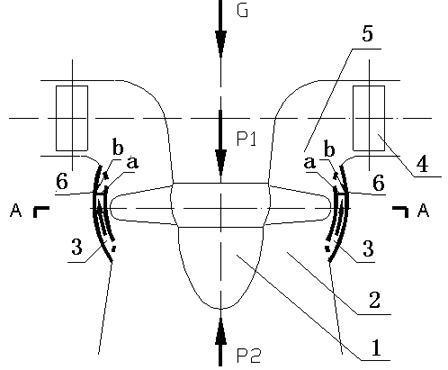

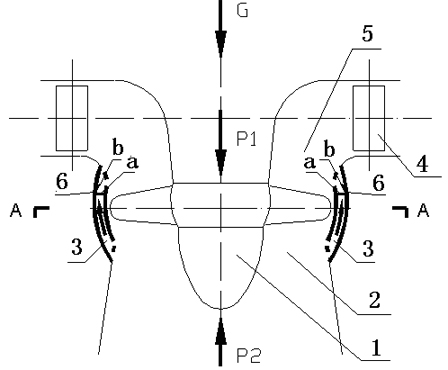

[0018] As shown in Fig. 1, from the mechanical point of view, the conditions for lifting the turbine generator set are: the downward axial water thrust P1 generated by the water flow at the inlet of the turbine runner, plus the weight G of the rotating part of the turbine generator set is less than the turbine rotation speed. The upward axial water thrust P2 generated by the water flow at the wheel outlet is:

[0019] P1+G

[0020] The hydro-generator set will be lifted, otherwise:

[0021] P1+G≥P2 (2)

[0022] Lifting does not occur, which is the mechanical condition of the hydraulic generator set lifting.

[0023] From the force analysis, it can be seen that the weight of the unit remains unchanged, and the lift mainly depends on the downward axial water thrust P1 generated by the water flow at the inlet of the runner and the upward axial water thrust generated by the water flow at the outlet of the turbine runner during the operation of the turbine Changes in P2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com