Lifting lug and using method thereof

A technology of lifting lugs and lifting lug plates, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of increasing equipment manufacturing costs, complex and cumbersome processes, and reducing manufacturing costs, so as to improve construction efficiency, simple operation steps, The effect of less material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

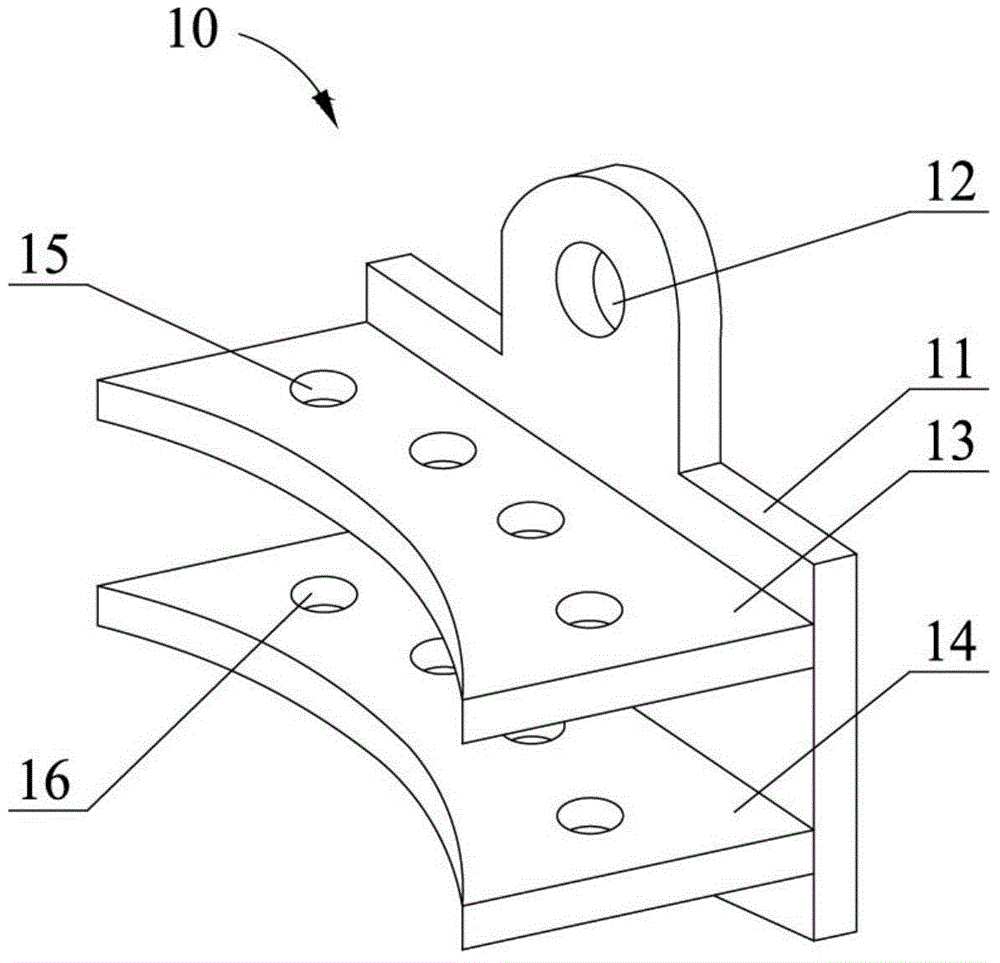

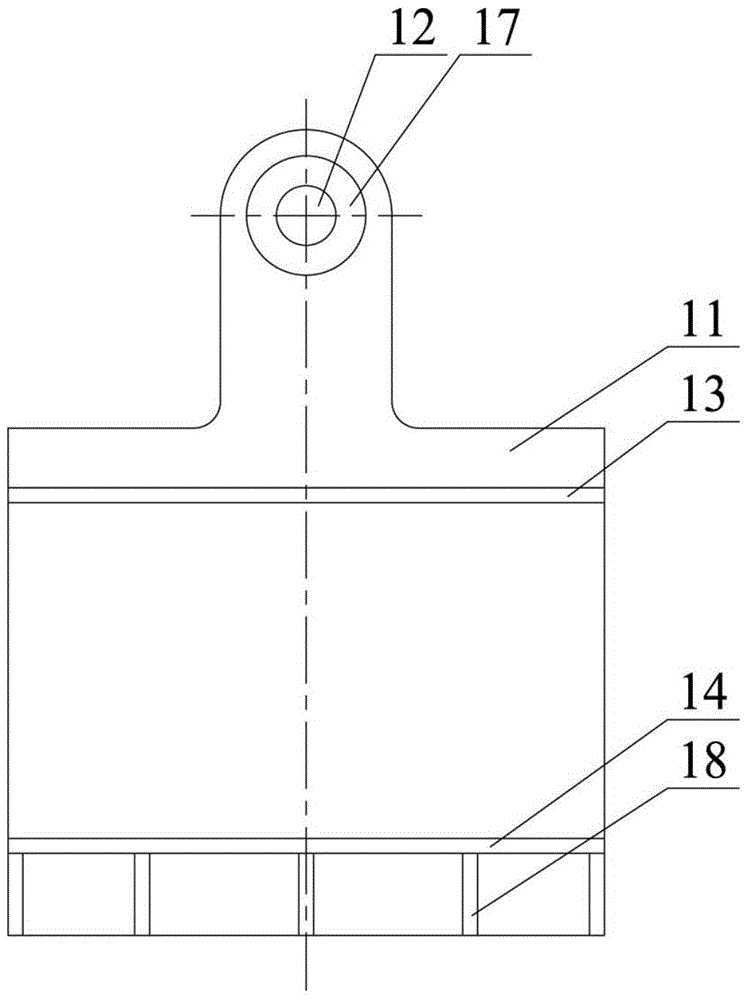

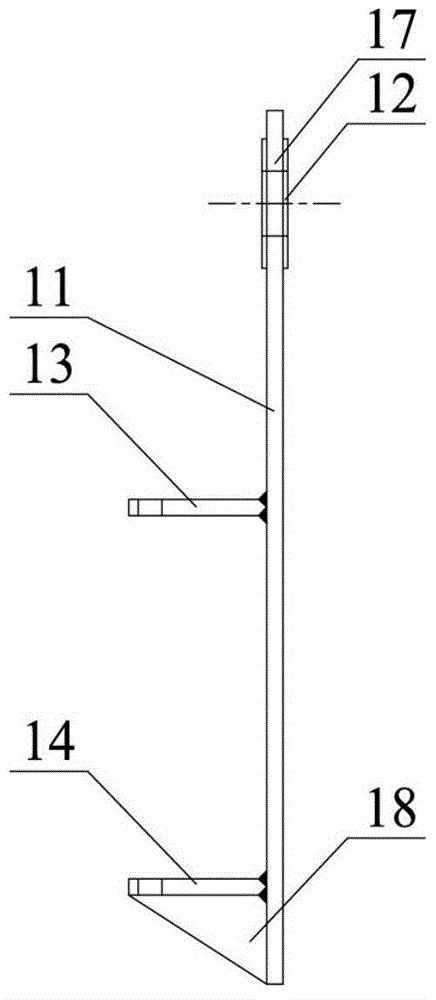

[0025] Embodiment one: this embodiment is based on Figure 4 The hoisting of the chemical equipment 20 shown in the vertical setting and the upper part is provided with a head flange 21 is taken as an example, and the structure and composition of the lifting lug 10 of the present invention are specifically described, as Figure 1 to Figure 3 As shown, it includes a lifting lug plate 11 with a hoisting hole 12 at one end arranged vertically; two splints arranged side by side and vertically fixed to the lug plate 11 respectively are an upper splint 13 and a lower splint 14, and the chemical equipment The head flange 21 of 20 can be embedded between the upper splint 13 and the lower splint 14, and the two splints 13, 14 are provided with bolts corresponding to the bolt holes (not shown in the figure) of the head flange 21. holes 15, 16, and the bolt holes 15, 16 of the two splints 13, 14 coincide with the axes of the bolt holes of the head flange 21, that is to say, the bolt hole...

Embodiment 2

[0033] Embodiment 2: Combination Figure 1 to Figure 5To illustrate the method of using the lifting lugs of the present invention, firstly, according to the loading position of the chemical equipment 10, install a pair of lifting lugs 10 on the horizontally symmetrical position of the head flange 21 of the chemical equipment 20. Specifically, remove the original connecting bolts at the head flange 21 of the chemical equipment 20, buckle a pair of lifting lugs 10 on the head flange 21 respectively, adjust and align the splints 13, 14 with the head method. The positions of the bolt holes of the flange 21 are then penetrated into the longer lifting bolts 19 for fastening, so that a pair of lifting lugs 10 are stably installed at the flange 21 of the head of the chemical equipment 20 . Before hoisting the chemical equipment 20, install shackles, hoisting balance beams, sling jacks and other lifting tools according to the hoisting process and construction plan requirements, and car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com