Mechanical equipment lifting frame and lifting method

A technology of mechanical equipment and hoisting frame, applied in hoisting devices, portable lifting devices, etc., can solve problems such as time-consuming, laborious, dangerous, and difficult to move and hoist large equipment, and achieve convenient use, small space occupation, and convenient movement and hoisting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

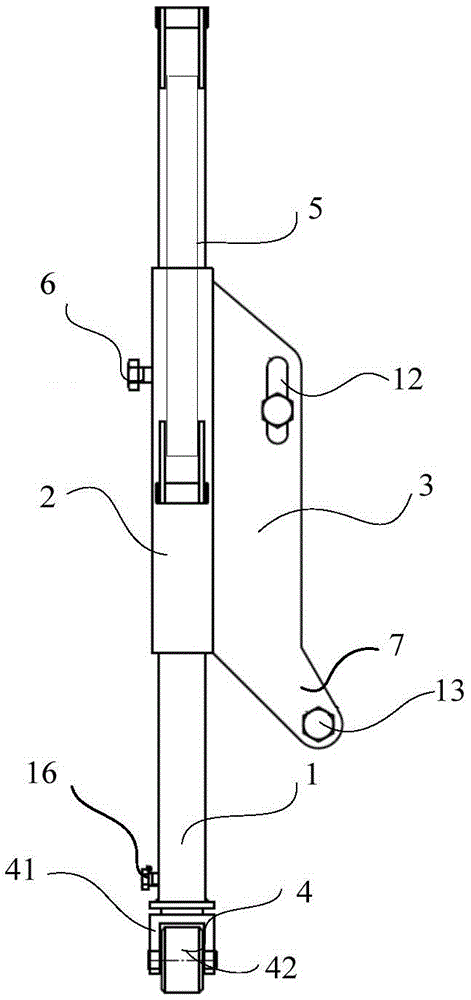

[0036] figure 1 It is the front view of the mechanical equipment lifting frame of the first embodiment of the present invention; please refer to figure 1 , the present embodiment provides a mechanical equipment hoisting frame, including a column 1, a sliding sleeve 2 is set on the column 1, and a connecting piece 3 for connecting with the mechanical equipment to be hoisted is fixedly arranged on the sliding sleeve 2; the bottom end of the column 1 A roller device 4 is provided; a driving device 5 for driving the sliding sleeve 2 to move axially relative to the column 1 is provided between the sliding sleeve 2 and the column 1 ; a locking device 6 for locking the sliding sleeve 2 is also provided on the sliding sleeve 2 .

[0037] Specifically, the shape of the connecting piece 3 can be plate-shaped or other shapes, and the plate-shaped connecting piece 3 can save costs and ensure the convenience of connecting the connecting piece 3 and the mechanical equipment to be hoisted; i...

Embodiment 2

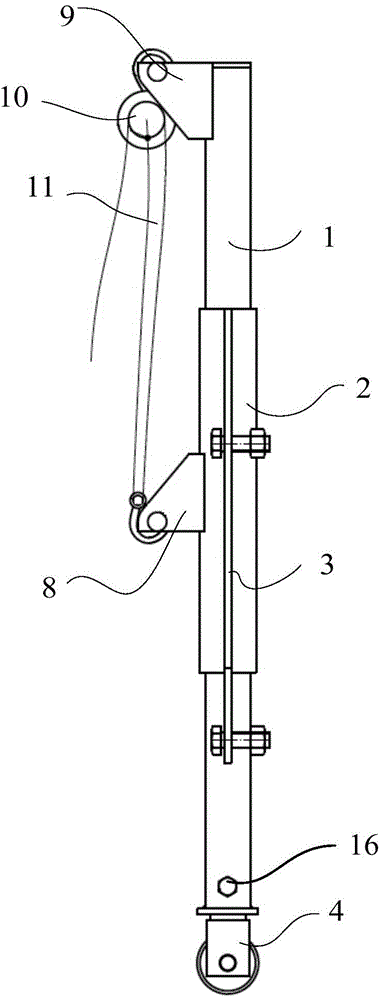

[0045] figure 2 It is the left view of the mechanical equipment lifting frame of the second embodiment of the present invention; this embodiment is based on the first embodiment, and the driving device adopts the chain-reversing device as an example to describe in detail. Such as figure 2 As shown, in this embodiment, the driving device is a chain-rewinding device; the sliding sleeve 2 is fixed with a first lifting lug 8, the top of the column 1 is provided with a second lifting lug 9, and the chain-rewinding device is installed on the second lifting lug 9 and the first lug 8. Specifically, in order to better control the chain-winding device, the first lifting lug 8 and the connecting piece 3 can be arranged on different busbars of the sliding sleeve 2. Of course, the first lifting lug 8 and the connecting piece 3 can also be set on the same busbar. In addition, even the first lifting lug 8 can be directly arranged on the connecting piece 3. At the same time, in order to e...

Embodiment 3

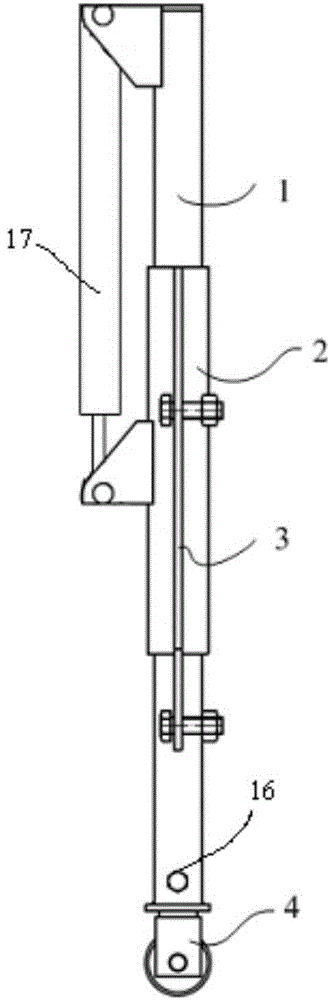

[0050] Such as image 3 It is the left view of the mechanical equipment in the second embodiment of the present invention. This embodiment is based on the first embodiment, and the driving device adopts a hydraulic cylinder as an example to describe in detail. Such as image 3 As shown, in this embodiment, the driving device can be a hydraulic cylinder 17, the cylinder body of the hydraulic cylinder 17 is hinged to the top of the column 1, and the piston rod of the hydraulic cylinder 17 is fixedly connected to the sliding sleeve 2. The hydraulic cylinder 17 is driven by hydraulic pressure to change the hydraulic energy into mechanical energy, and the extension and contraction of the piston rod pushes and pulls the sliding sleeve 2 to slide up and down in the axial direction; of course, in addition to the form of the hydraulic cylinder, you can also choose a similar device such as an air cylinder. I won't go into details here. The use of hydraulic cylinders can realize automa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com