Jacking device

A technology of jacking device and clamping device, which is applied in the direction of lifting device, lifting frame, etc., to achieve the effect of good adaptability and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

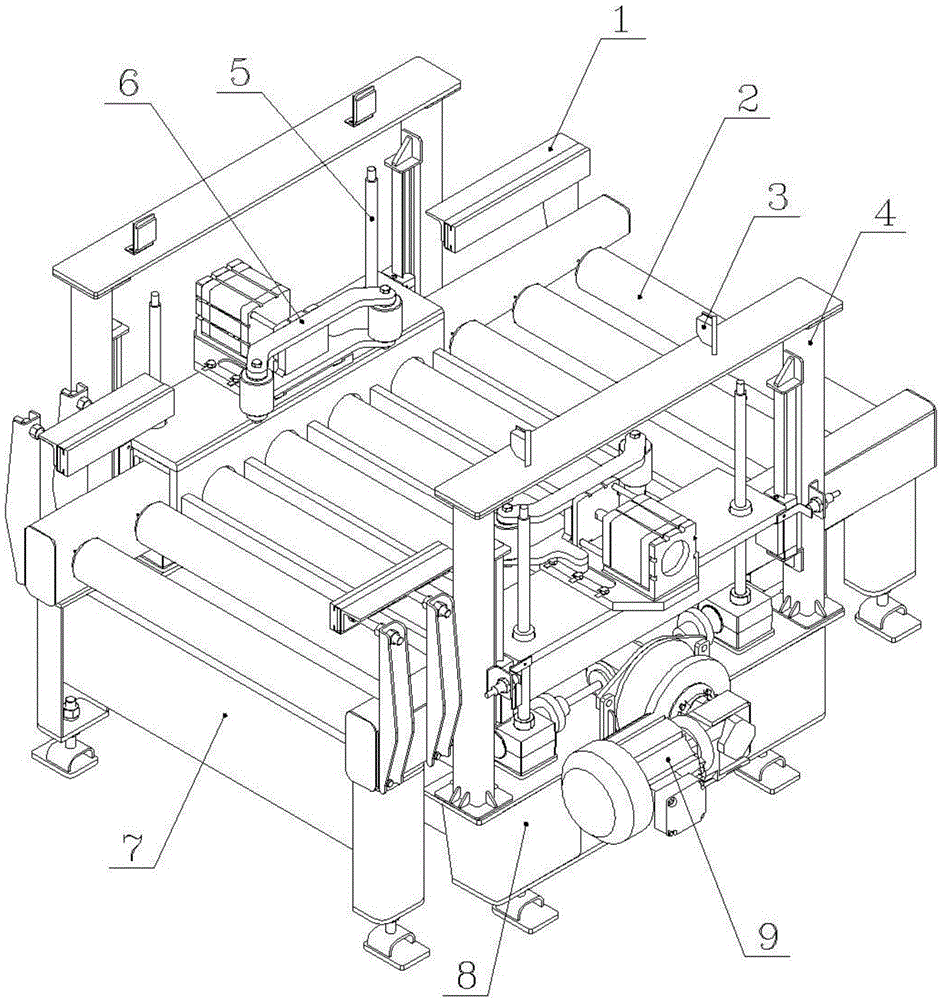

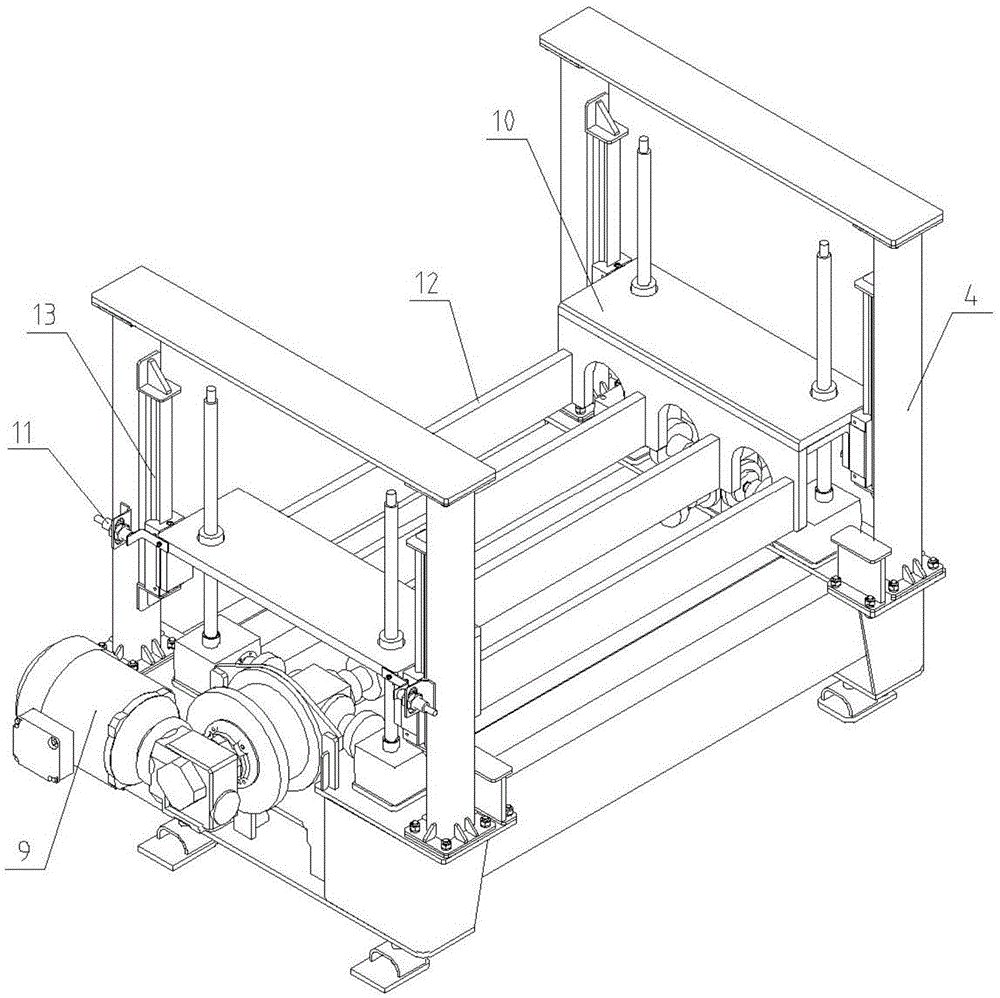

[0015] as attached Figure 1-2 As shown, the jacking device of the present invention includes a base 8 and a bracket 10; two sides of the base 8 are respectively provided with two columns, each column is provided with a vertical guide rail 13, and the base 8 is also provided with a motor 9 A plurality of lead screws 5 are provided between the two columns on each side of the two sides of the base 8, and each lead screw can be linked under the drive of the motor 9; the bracket 10 is arranged on the top of the base 8, and The bottom of the frame 10 is composed of a group of parallel joists 12. Driven by each lead screw 5, the bracket 10 can move up and down in the vertical direction along the guide rails 13 provided on the column; A waste bin clamping device 6 is provided; photoelectric detection devices 3 for detecting the position of the waste bin are also provided on both sides of the bracket 10 .

[0016] The waste bin clamping device 6 can be driven by an air cylinder; prox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com