Rotating multi-crane integrated operation platform with integral automatic lifting function

A technology of operating platforms and multiple cranes, applied in the direction of cranes, etc., can solve the problem of multiple sets of large-scale boom tower cranes, and achieve the effects of improving the carrying capacity, optimizing the configuration of cranes, and reducing the number of cranes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

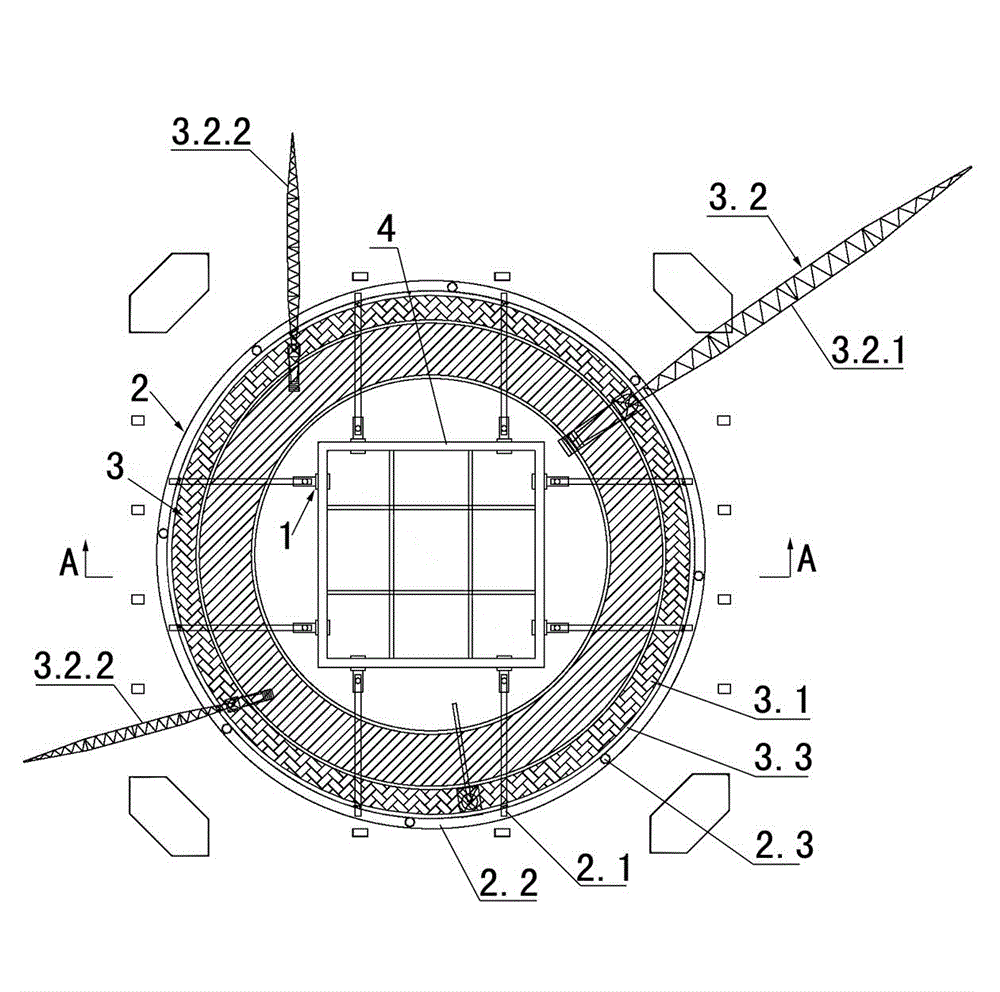

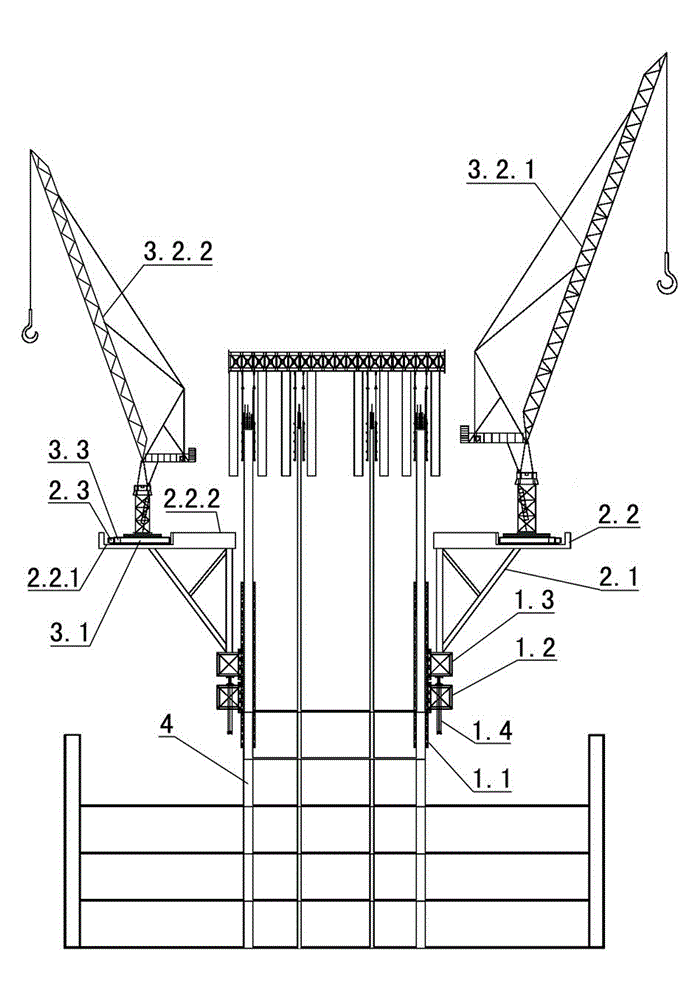

[0017] Examples see figure 1 , figure 2 , this overall automatic jacking and swiveling multi-crane integrated operating platform includes a wall-climbing automatic jacking system 1 arranged on the core tube shear wall 4, which surrounds the core tube shear wall 4 and is connected to the climbing wall. The ring bracket 2 on the wall-type automatic jacking system 1, and the ring-shaped turnaround platform 3 that is surrounded by the core tube shear wall 4 and supported on the ring bracket 2 and integrates multiple cranes.

[0018] The annular bracket 2 includes a supporting truss group 2.1, an annular supporting platform 2.2 and an active system 2.3. The supporting truss group 2.1 is in an inverted triangle shape and is fixedly connected to the climbing wall type automatic jacking system 1. The annular supporting platform 2.2 Fixedly placed on the support truss set 2.1, the support truss set 2.1 and the annular support platform 2.2 form a bowl-like structure, and the upper sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com