Method for mounting large-sized rolling mills

An installation method and rolling mill technology, which are applied in the processing of building materials, infrastructure engineering, construction, etc., can solve the problems of long distance of the roll changing transmission device, difficulty in ensuring the installation quality, and inability to quantify the control of the forbidden torque, so as to solve the problem of hoisting , saving work efficiency and ensuring the quality of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

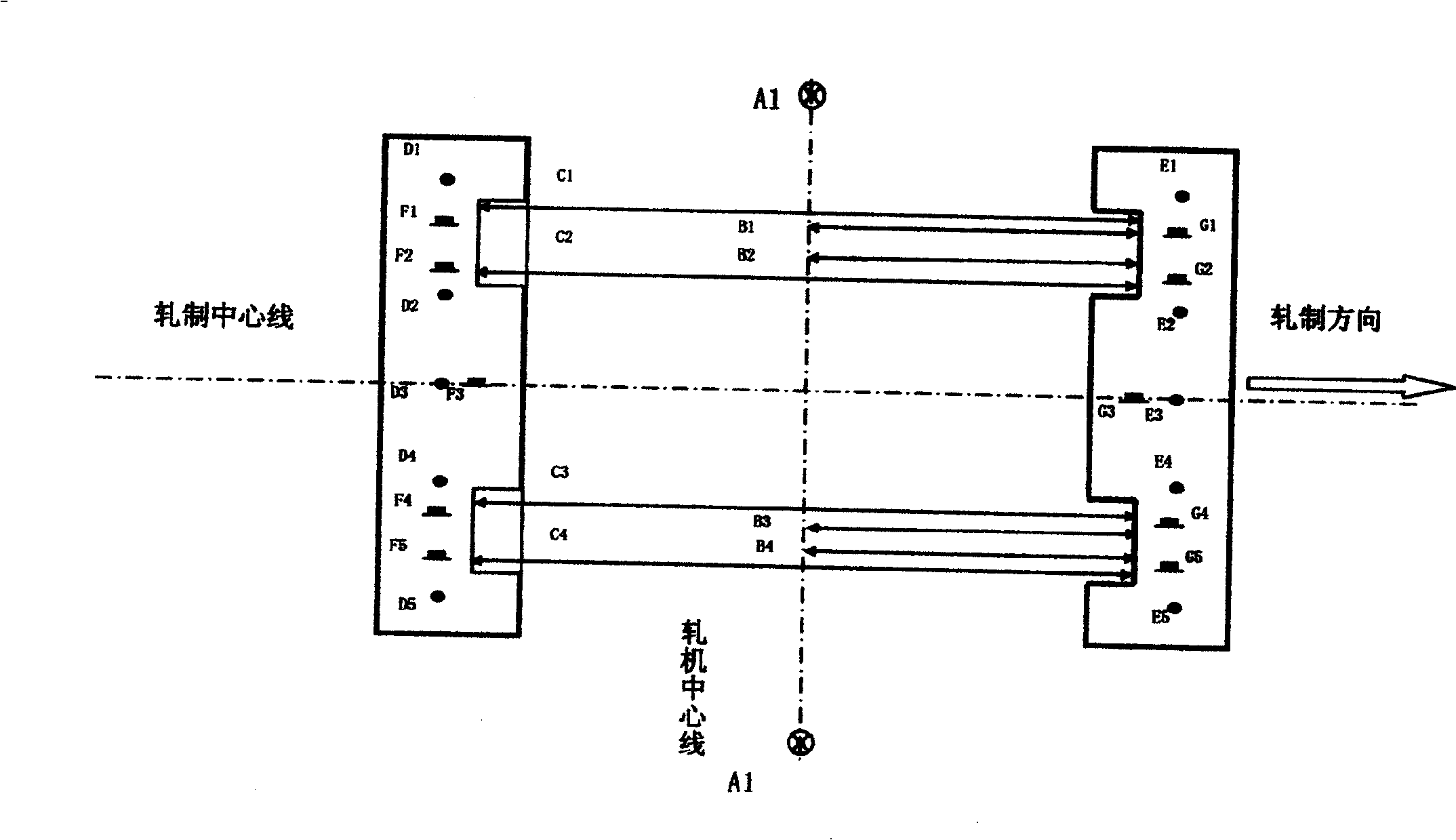

[0085] The 4300 rolling mill is the most advanced reversing rolling mill at home and abroad. Due to its high installation precision and large tonnage of the archway, it is very typical in the current rolling mill installation. The present invention takes the installation of 4300 rolling mills as a test, which will be described in detail below in conjunction with the accompanying drawings.

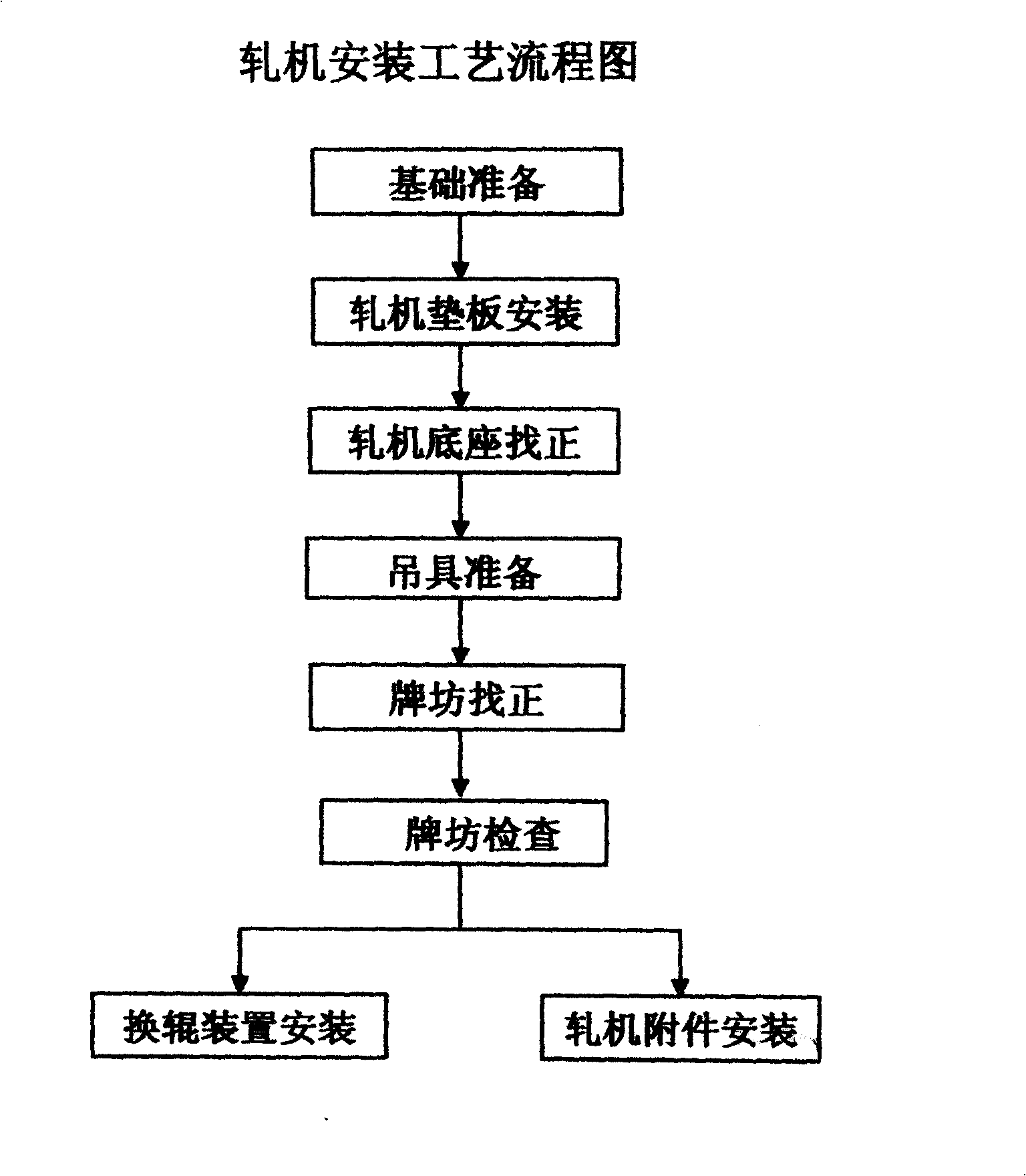

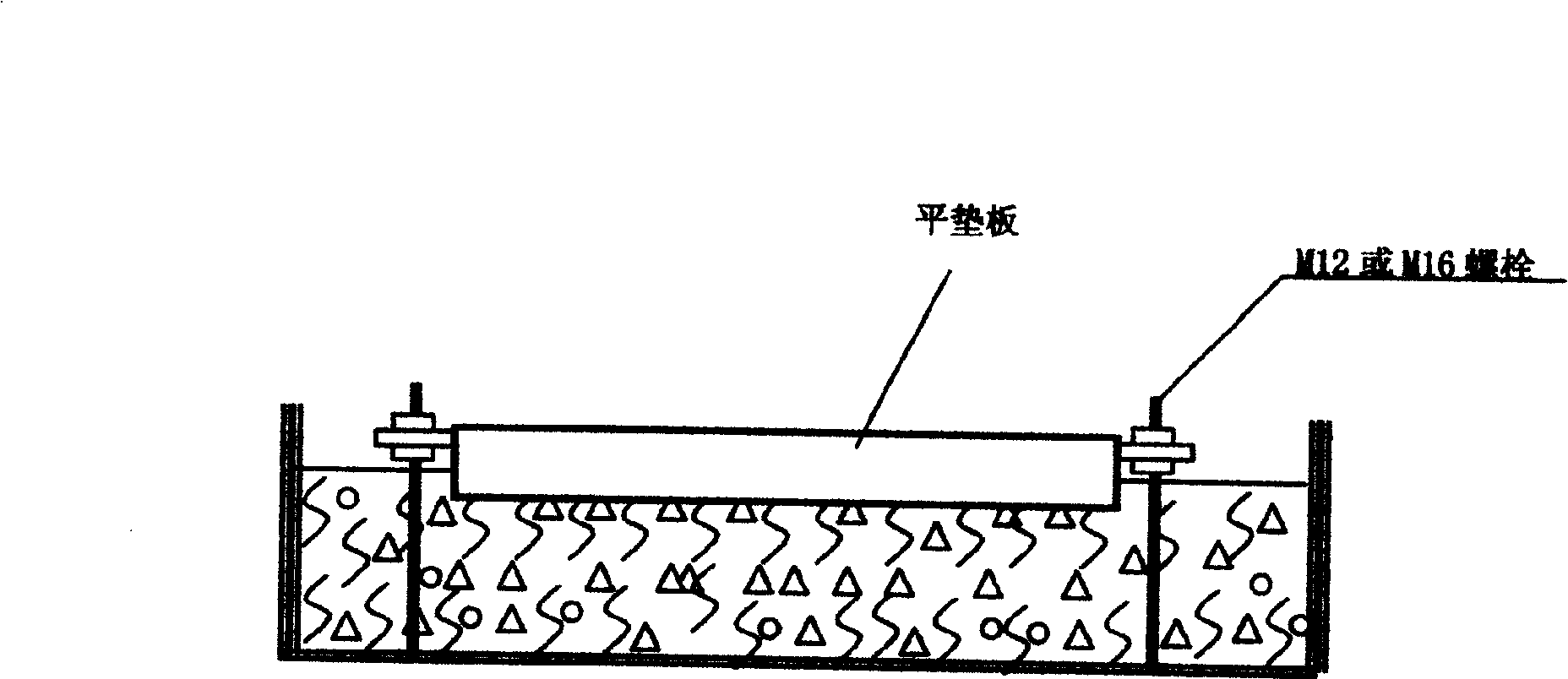

[0086] See figure 1 According to the process flow chart of large rolling mill installation, the process steps of foundation preparation, mill backing plate installation, mill bottom plate alignment, spreader preparation, arch alignment, arch inspection, roll changing device installation and mill accessories installation are adopted.

[0087] Basic preparation: According to the construction characteristics of the project, set the rolling center line, the rolling mill transverse center line, the rolling mill reducer center line, and the roll changing device center line. Set a permanent cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com