High-strength escape pipeline convenient to lift

An escape pipeline and high-strength technology, which is applied in the field of escape pipelines and high-strength escape pipelines, can solve problems such as poor compression resistance, heavy weight of tunnel escape pipelines, and unstable connection and installation, so as to reduce quality, ensure stable connections, and improve The effect of compressive properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

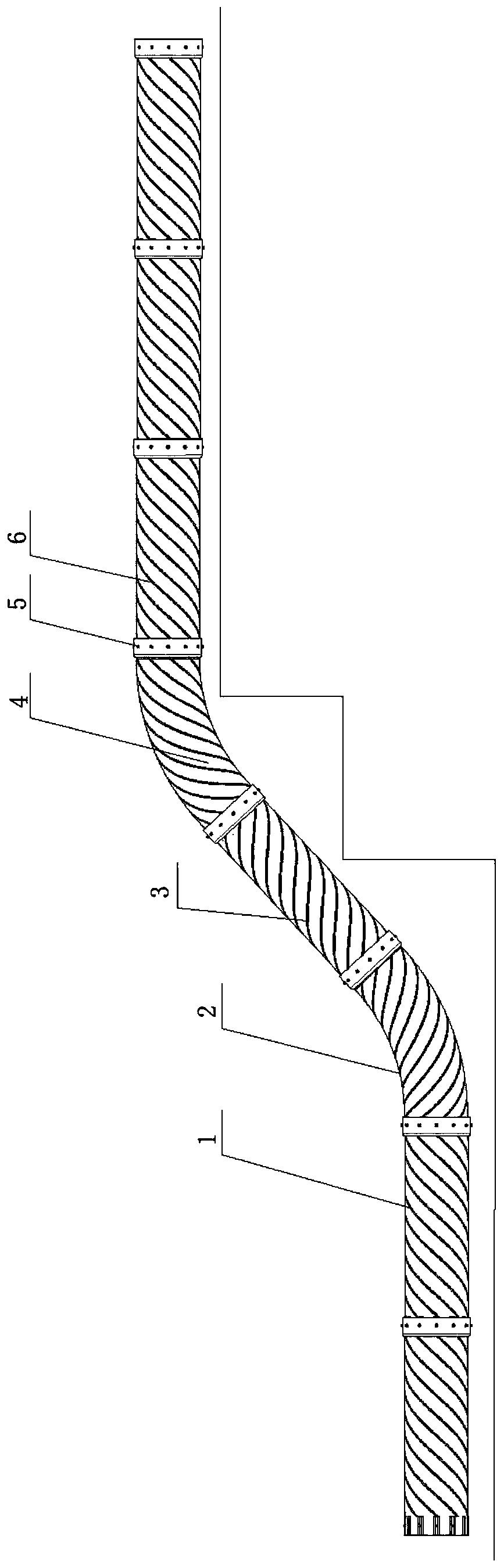

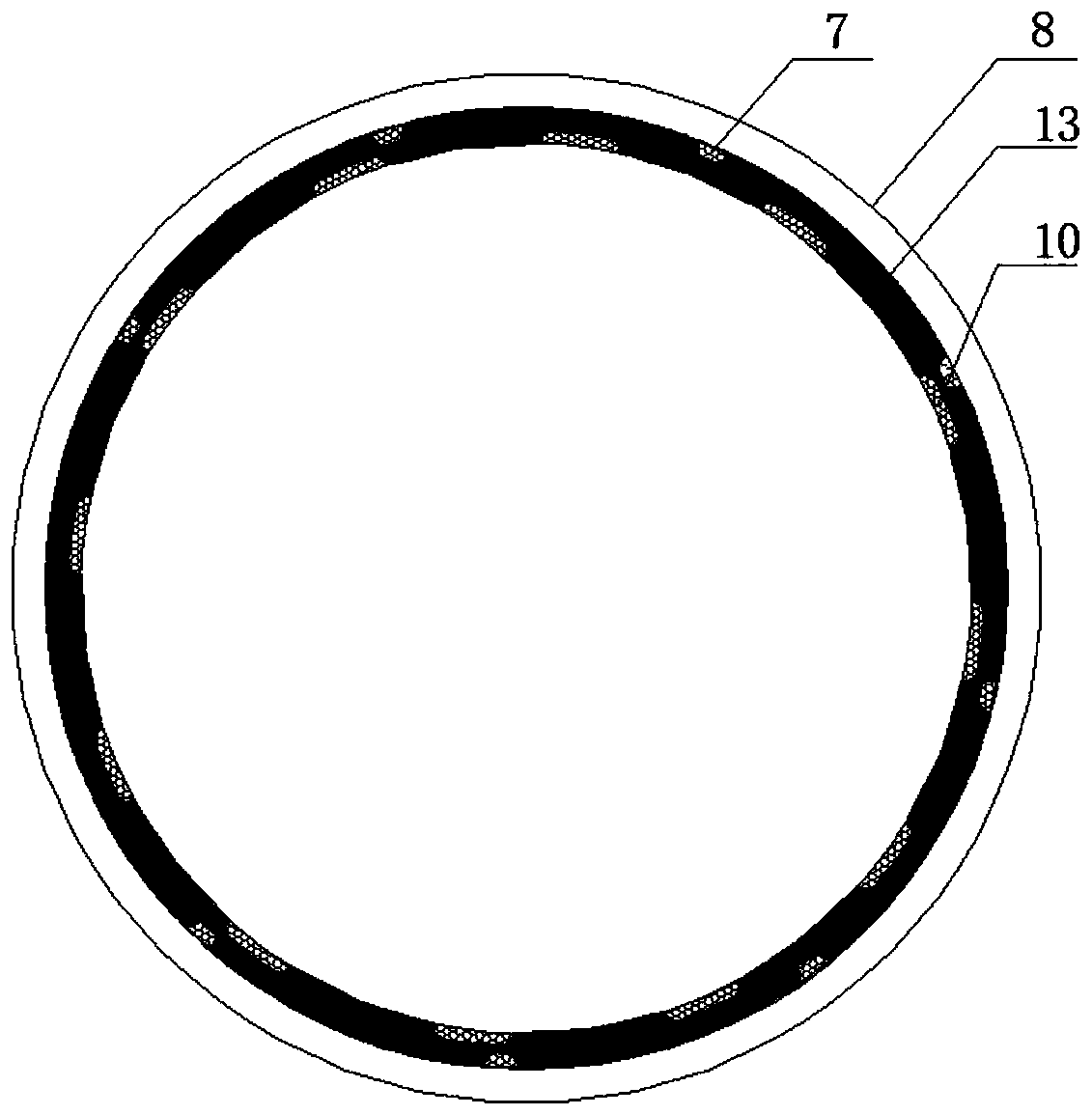

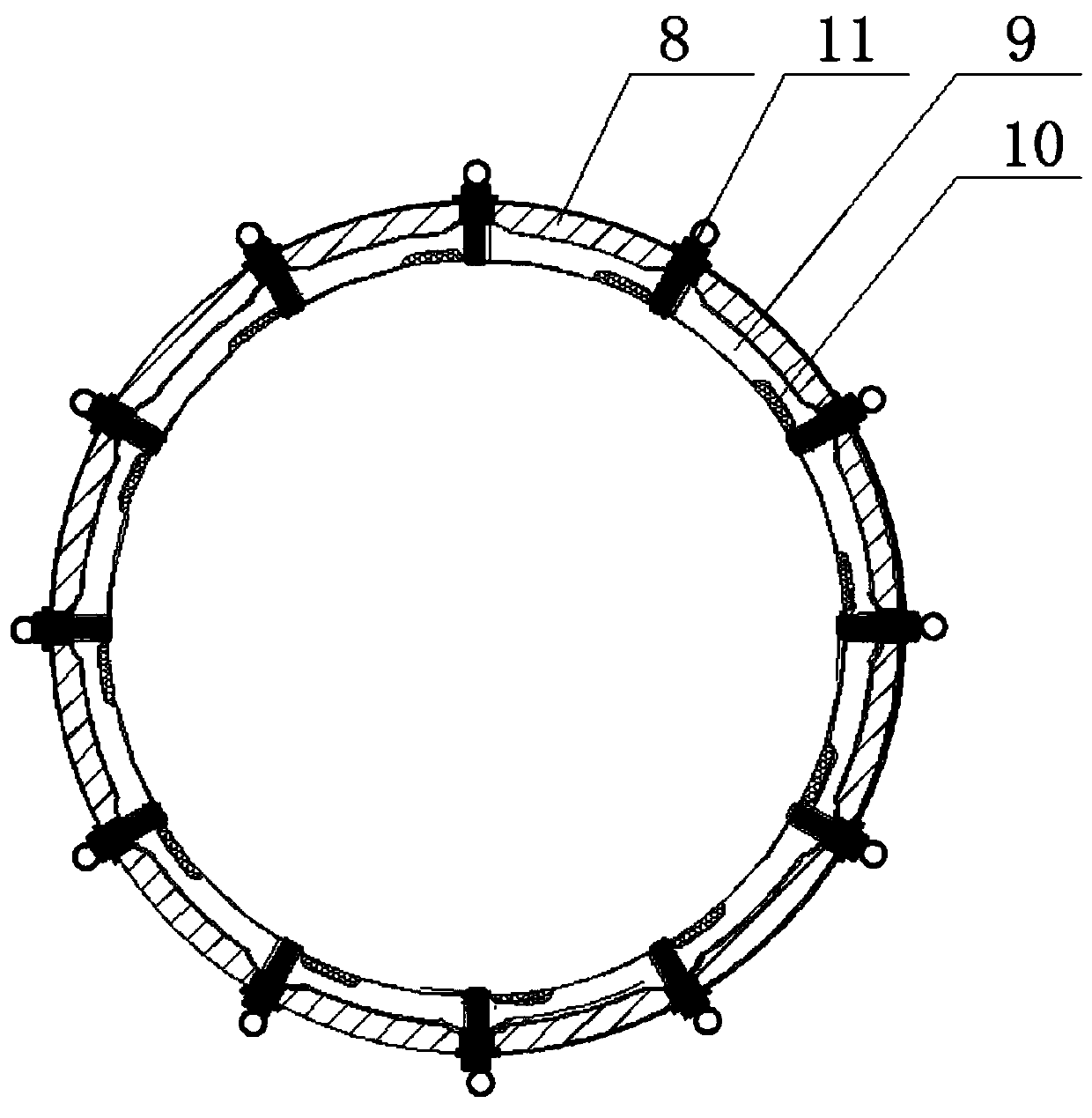

[0033] A high-strength escape pipeline that is easy to hoist, including several pipe bodies 13 connected end to end, each of which is made of high molecular polyethylene material, one end of each pipe body extends to form a socket section 8, and the other end of each pipe body Extend to form a plug section 9; the inner diameter of the socket head section is greater than the outer diameter of the plug section; the outer surface of the pipe body is uniformly spaced and integrated with nine thread grooves, and the inner surface of the pipe body is uniformly spaced and axially formed. There are twelve vertical grooves, the cross-sections of the threaded grooves and the vertical grooves are both arc-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com