Ultrahigh-purity SF6 pipe gas transmission system

A technology of gas transmission system and inflation system, which is applied in fixed-capacity gas storage tanks, gas treatment/storage purposes, gas treatment/storage effects, etc., and can solve problems such as difficulty in inflation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

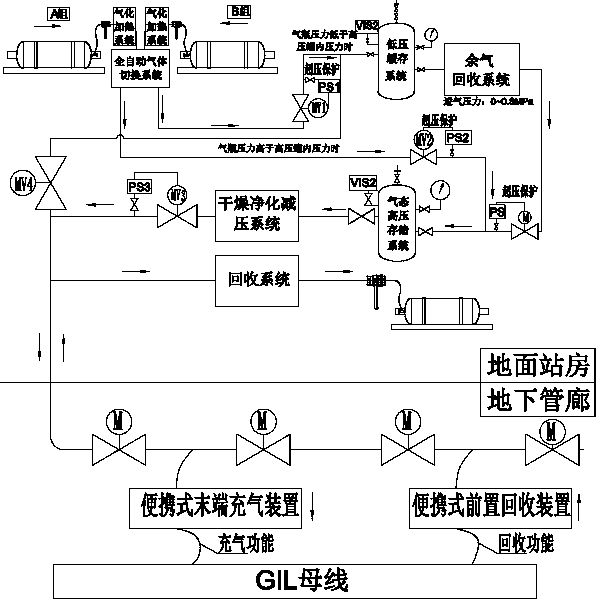

[0059] An ultra-high-purity SF6 pipeline gas transmission system, including an automatic safety monitoring system, a gas supply station, an intermediate station storage system, and an inflation system. The gas supply station, the intermediate station storage system, and the inflation system are sequentially connected in series, and the automatic safety monitoring system Electrically connect the gas supply station, intermediate station storage system and inflation system.

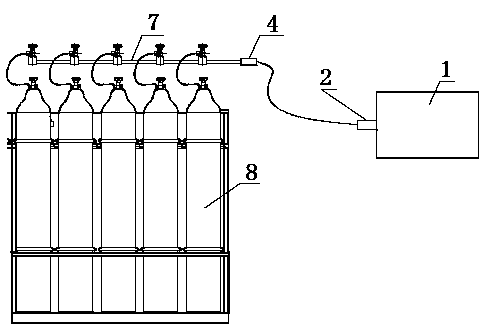

[0060] Further, the gas supply station includes several gas supply bottles, a gasification heating system and a fully automatic gas switching system, and several gas supply bottles, a gasification heating system and a fully automatic gas switching system are sequentially connected in series;

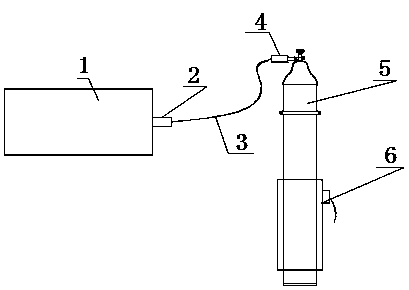

[0061] Several gas supply cylinders include gas cylinders of group A and gas cylinders of group B. Both gas cylinders of group A and gas cylinders of group B include steel cylinders, liquid phase conduits (10) and liqui...

Embodiment 2

[0132] The difference from Example 1 is that, if Figure 9As shown, the steel cylinders of Group A and Group B can also adopt the standard 40L steel cylinder multi-cylinder group connected in series and place the structure obliquely to achieve the method of inflating SF6 liquid. However, this scheme is labor-intensive and inconvenient for equipment hoisting and transportation, but it can realize liquid extraction. Function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com