Patents

Literature

59results about How to "Fast gasification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oxygen enhanced plasma waste treatment system and method

ActiveUS20060075945A1Improve efficiencyReduce amountSolid fuel combustionIncinerator apparatusParticulatesSolid carbon

A method and apparatus that improves the efficiency of waste processing in waste treatment systems utilizing a high temperature plasma as the a energy source by delivering pressurized oxygen to the waste products while the waste products are exposed to the high temperature plasma. Providing oxygen at a speed of at least fifty feet per second obtains more energy content in the syngas, less solid carbon particulate, and faster gasification rates, improving process economics.

Owner:INENTEC

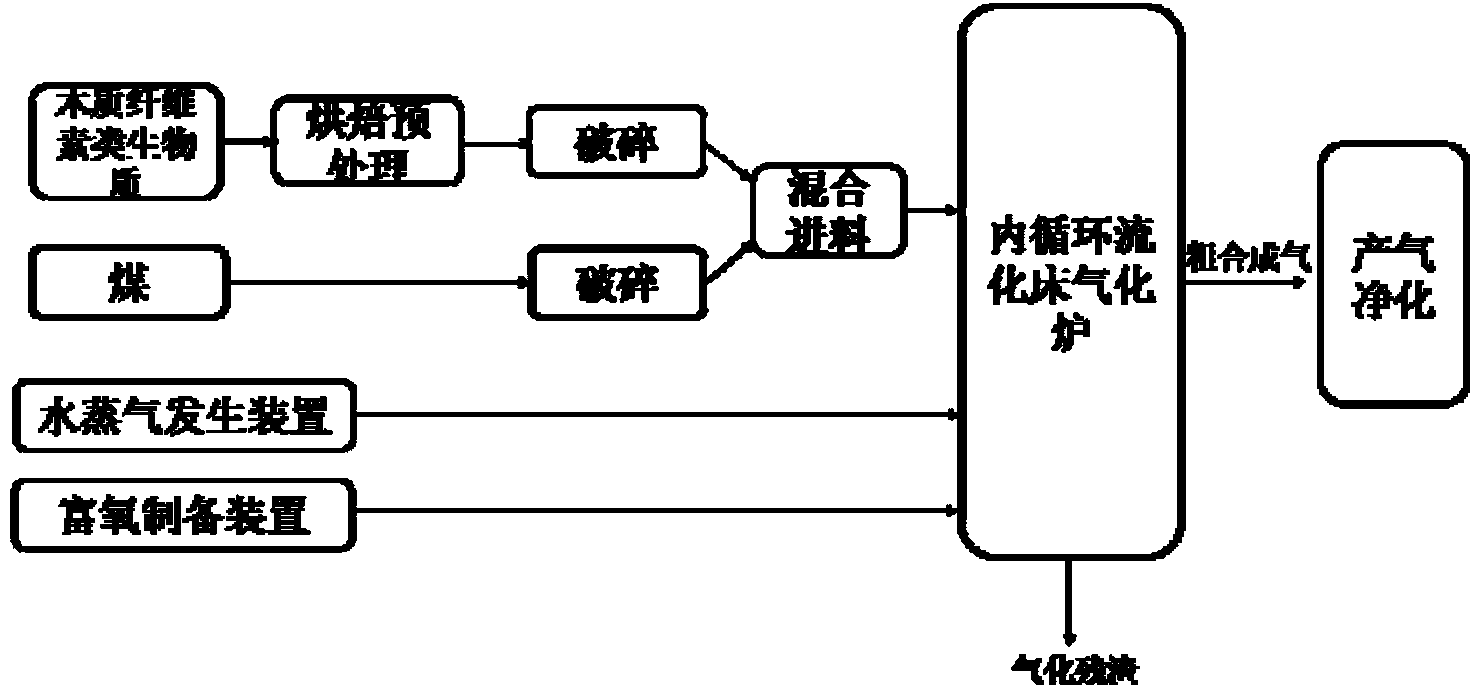

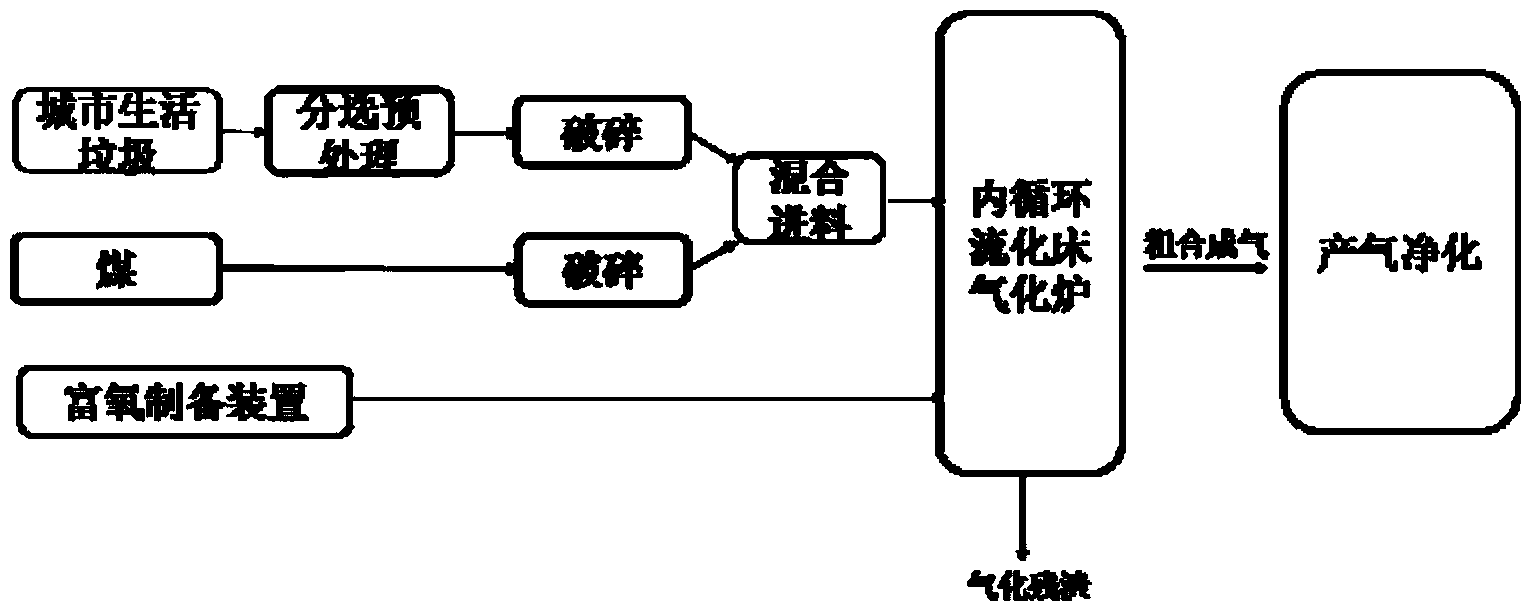

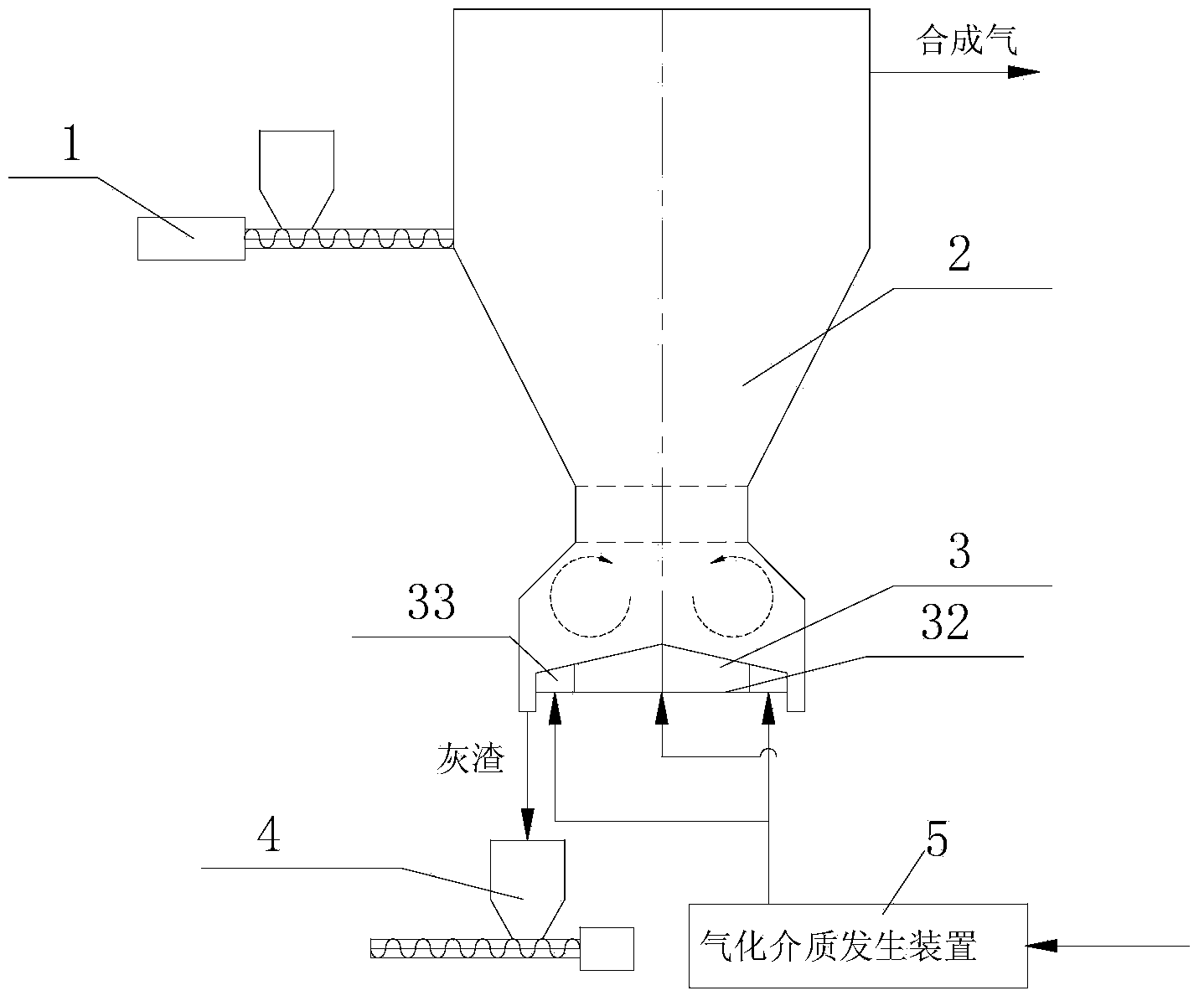

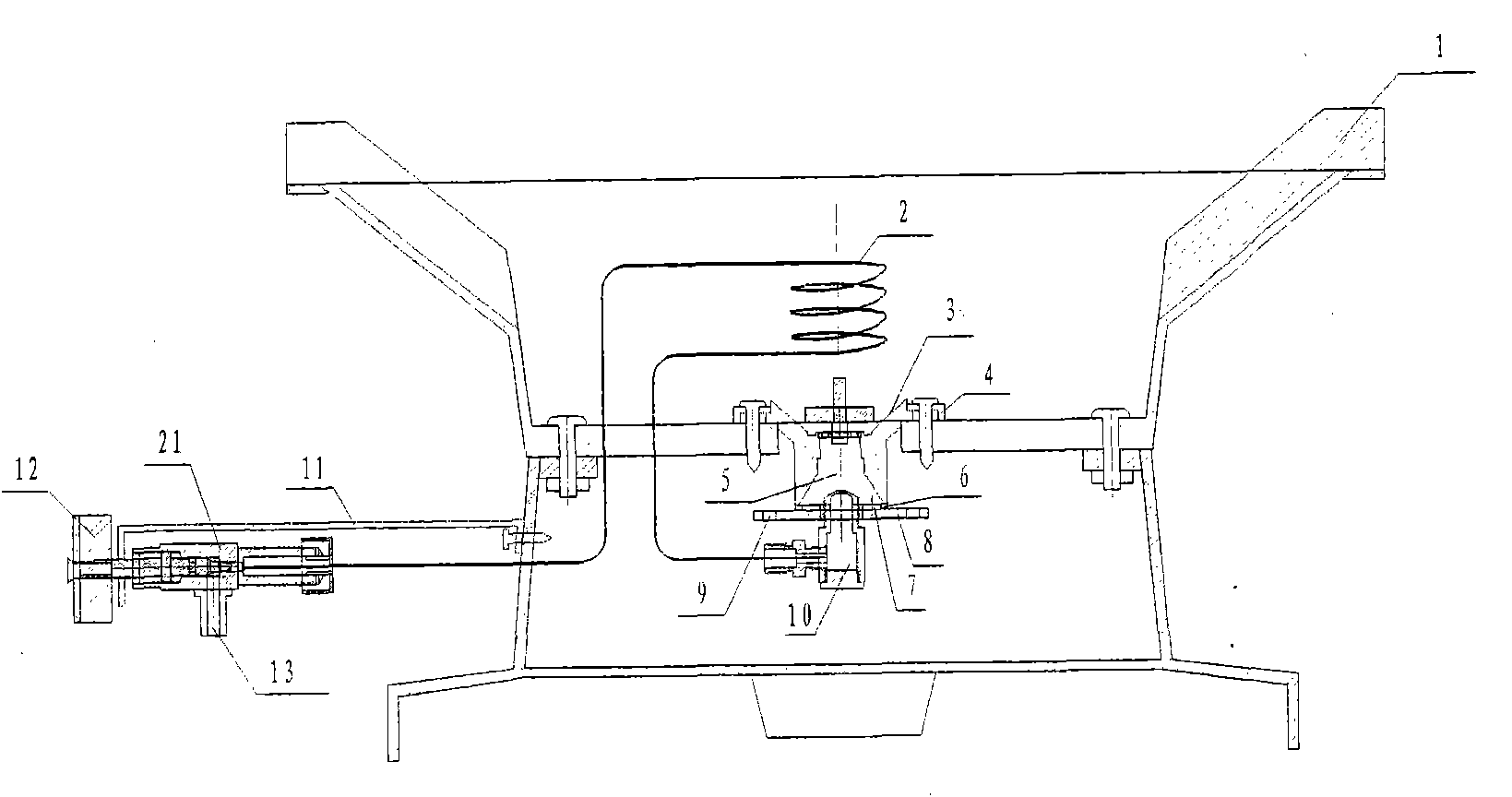

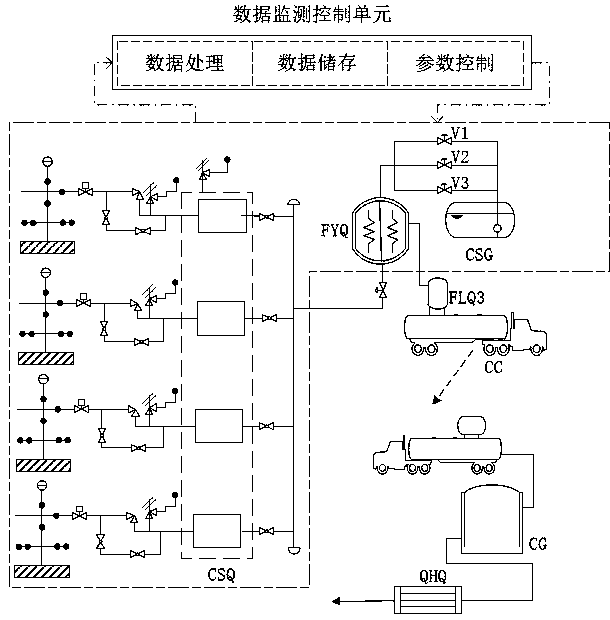

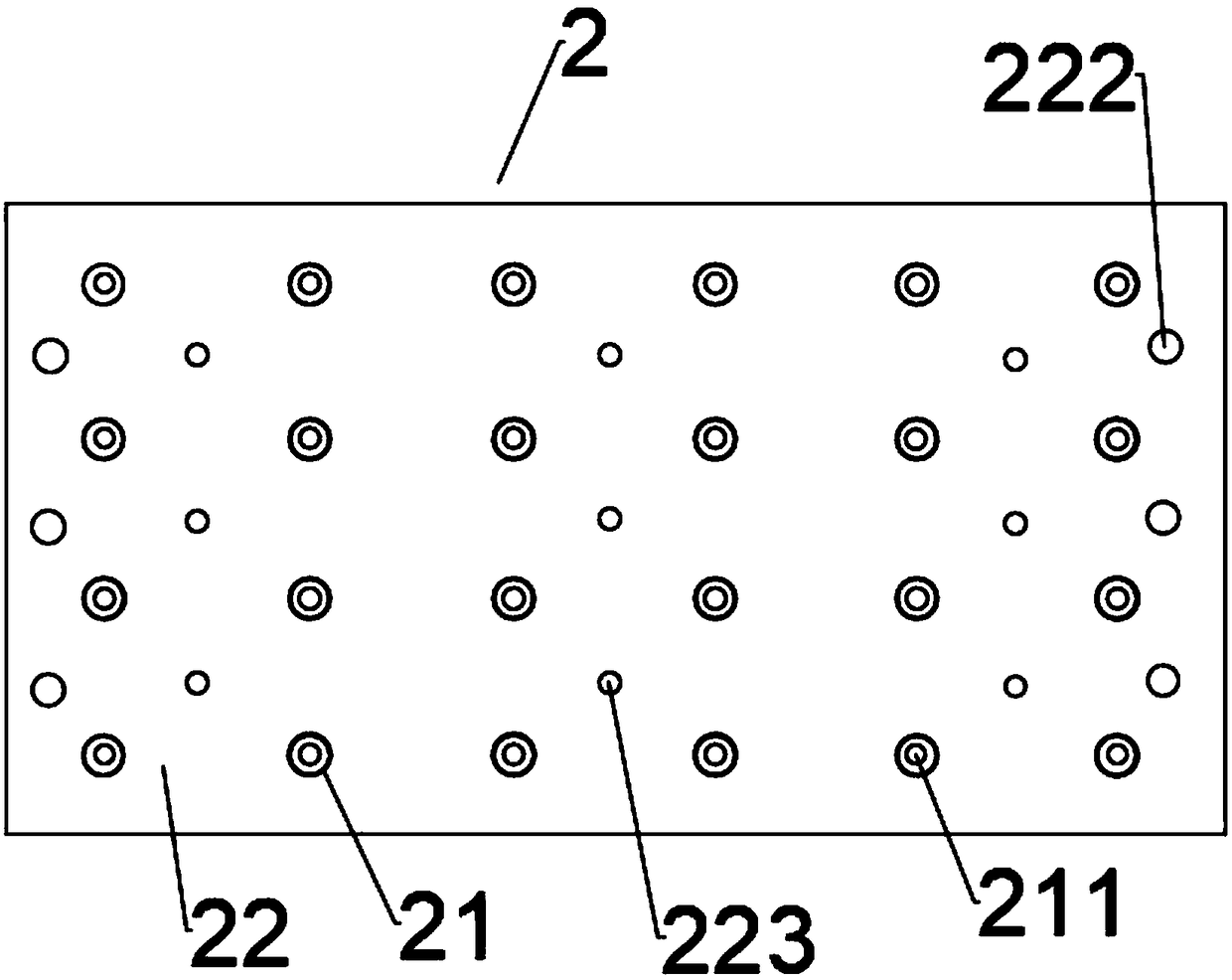

System and process for preparing synthetic gas through co-gasification of coal and biomass

InactiveCN103450948AGasification reaction goes wellWide adaptabilityGranular/pulverulent flues gasificationSlagWater vapor

The invention provides a system and a process for preparing synthetic gas through co-gasification of coal and biomass. The system comprises a feeding device, a gasifier body and a gasifying medium generation device, wherein the gasifier body consists of a lower dense-phase region and an upper dilute-phase region; a multi-air-chamber air distribution device is arranged at the bottom of the dense-phase region and is connected with an outlet of the gasifying medium generation device; the feeding device is connected with the gasifier body at the junction of the dense-phase region and the dilute-phase region; a deslagging device is connected at a slag outlet between the multi-air-chamber air distribution device and the gasifier body; the upper side wall of the dilute-phase region is provided with a synthetic gas outlet; the gasifying medium generation device comprises an oxygen enrichment preparation device and / or a steam generation device; a taper or inverted taper air distribution mode is adopted by the multi-air-chamber air distribution device. According to the system and the process, the co-gasification of the coal, lignocellulose and municipal domestic waste can be effectively realized, and the synergistic effect of the coal and the biomass is effectively utilized; the system and the process have the advantages of wide raw material adaptability, high gasification speed, little deslagging carbon residue, easiness in controlling over pollutants and the like.

Owner:GUANGDONG XIAN JIAOTONG UNIV ACADEMY +1

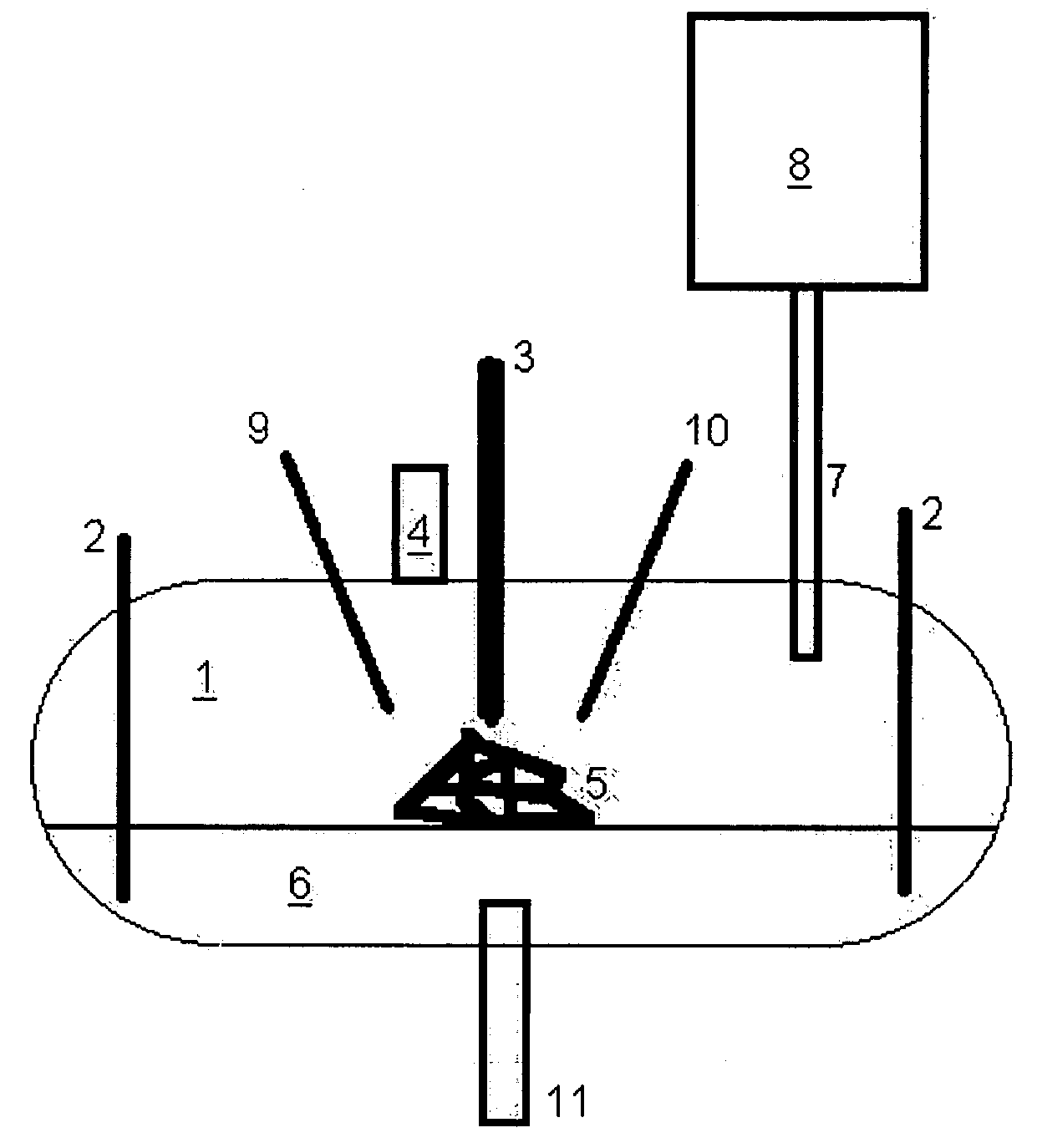

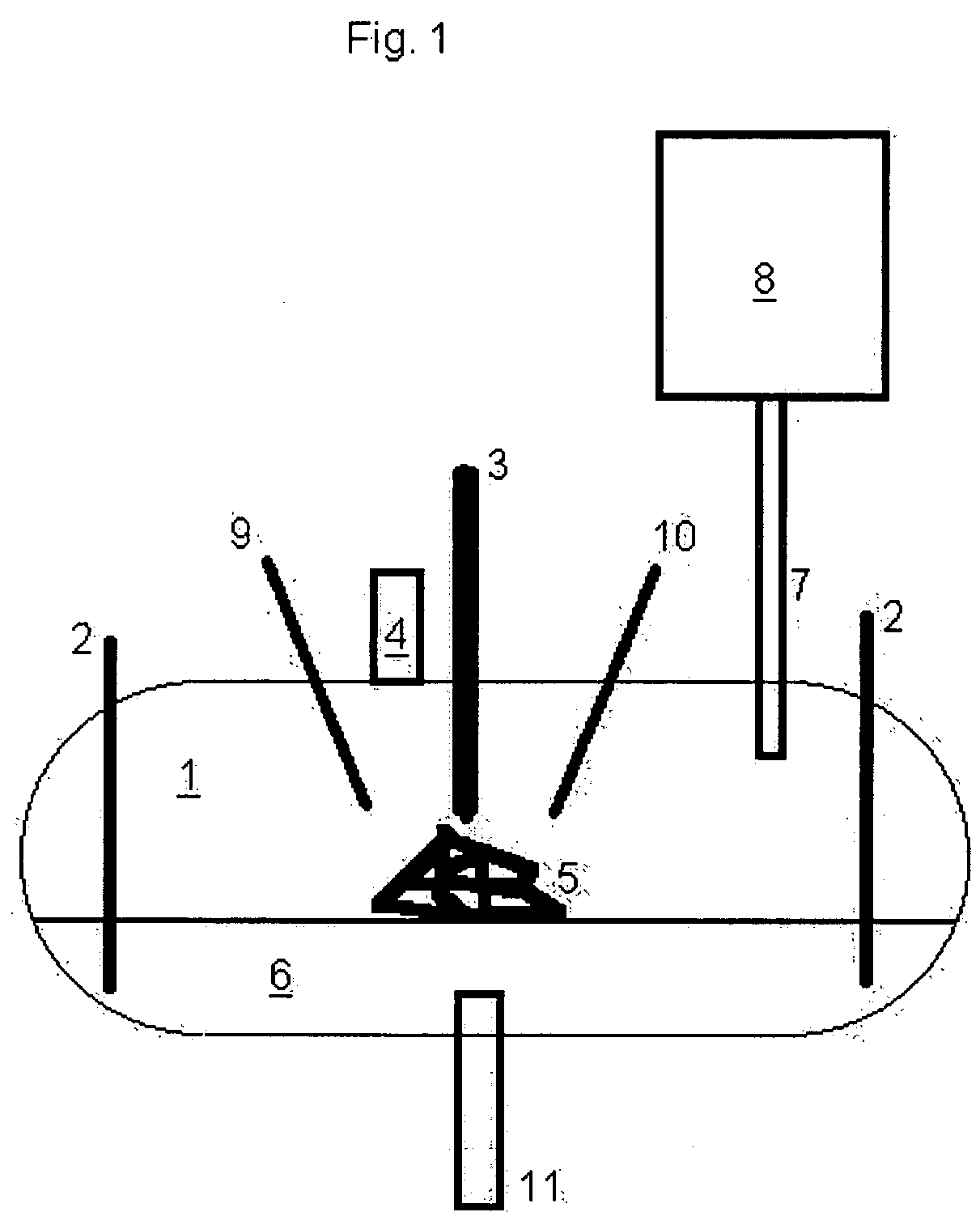

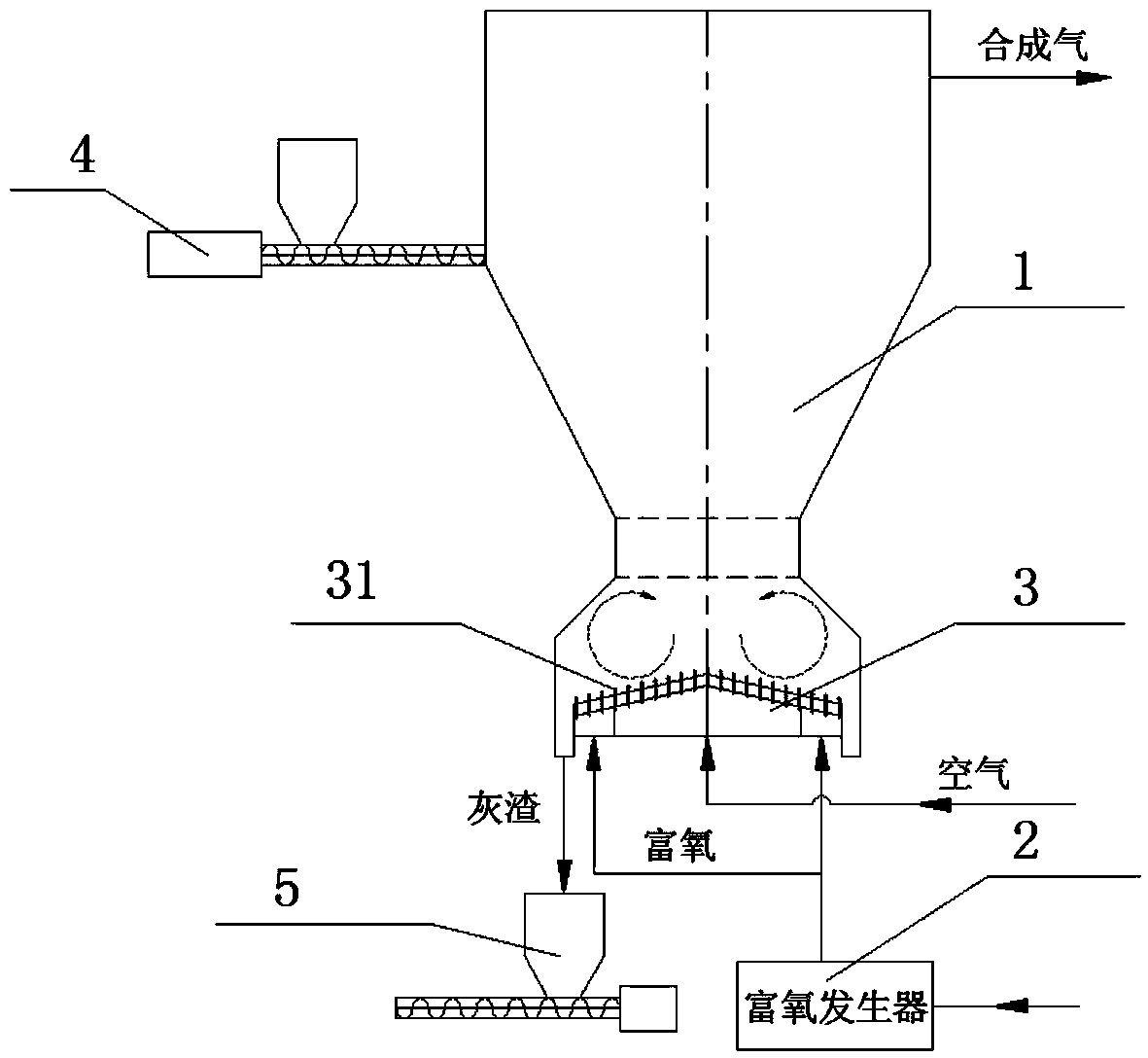

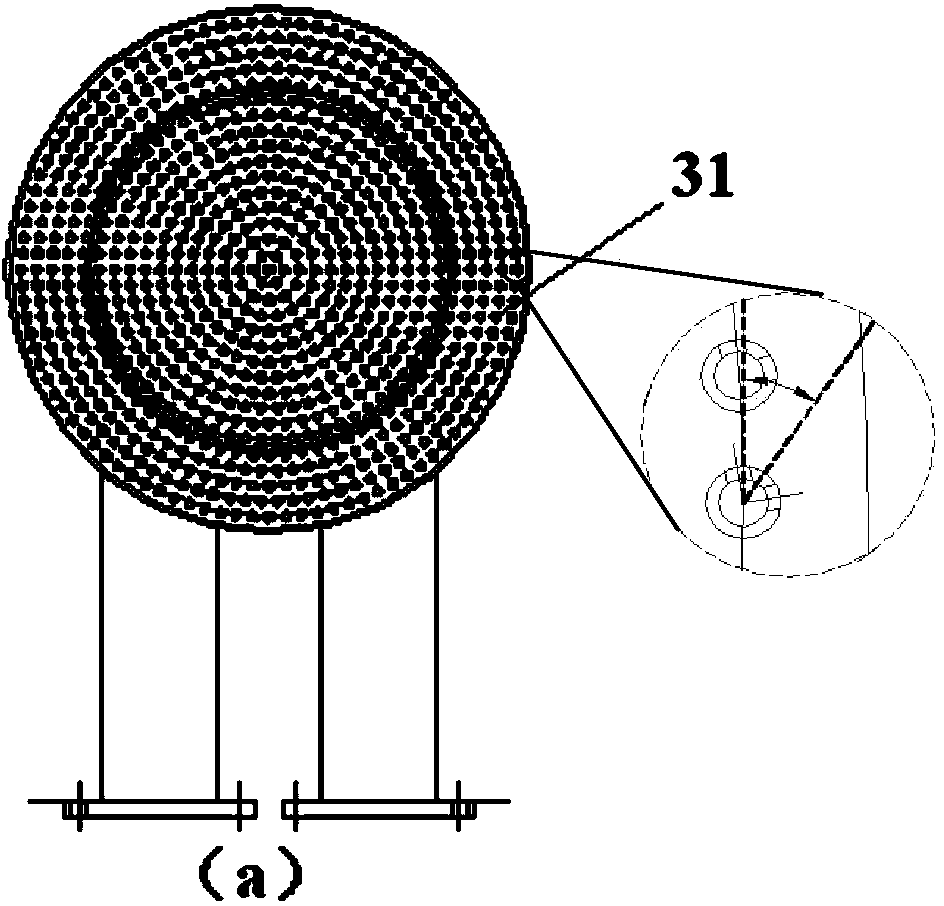

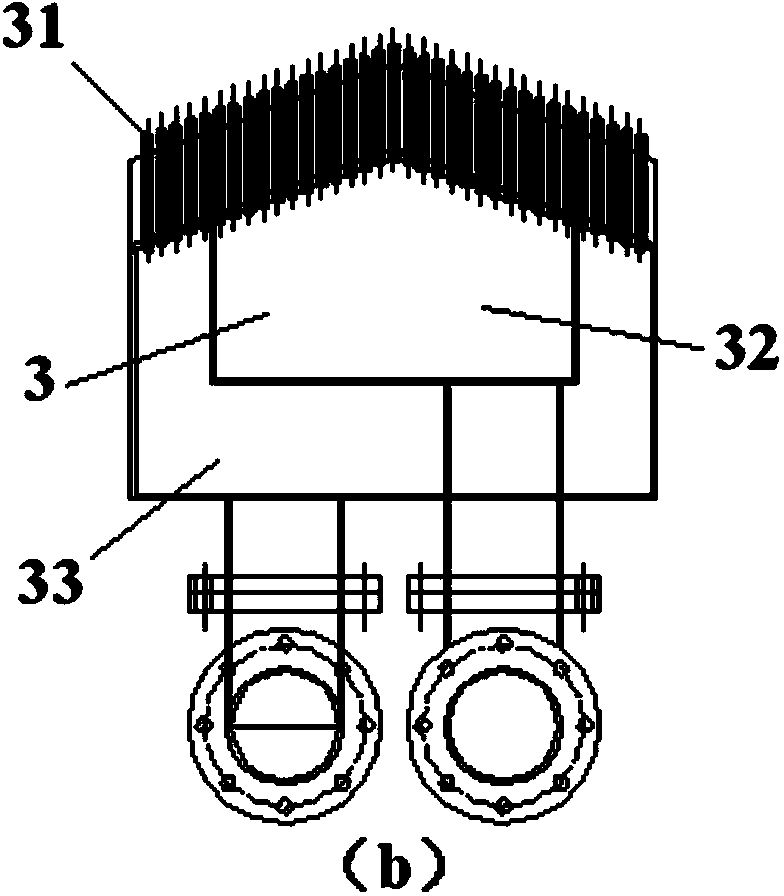

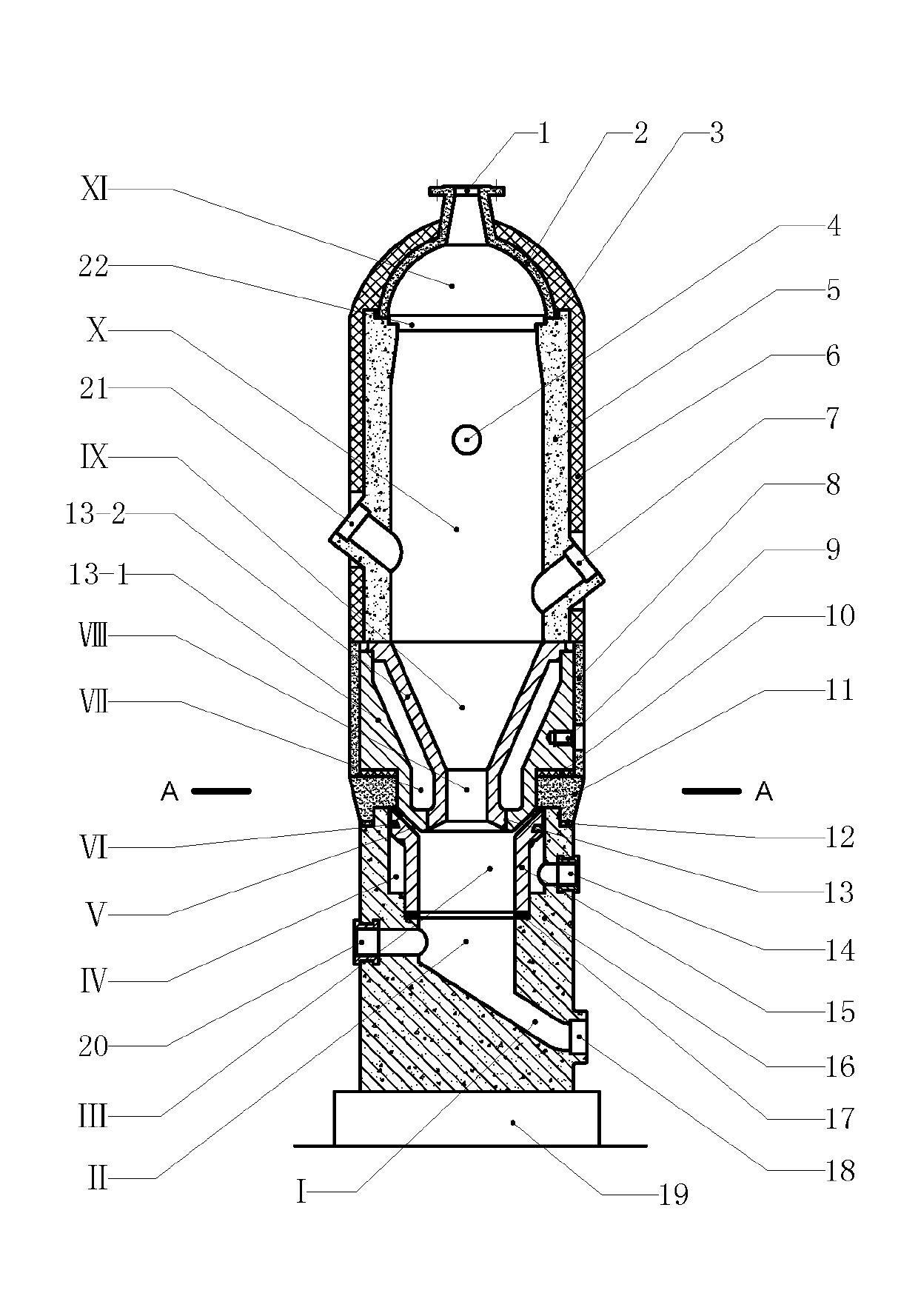

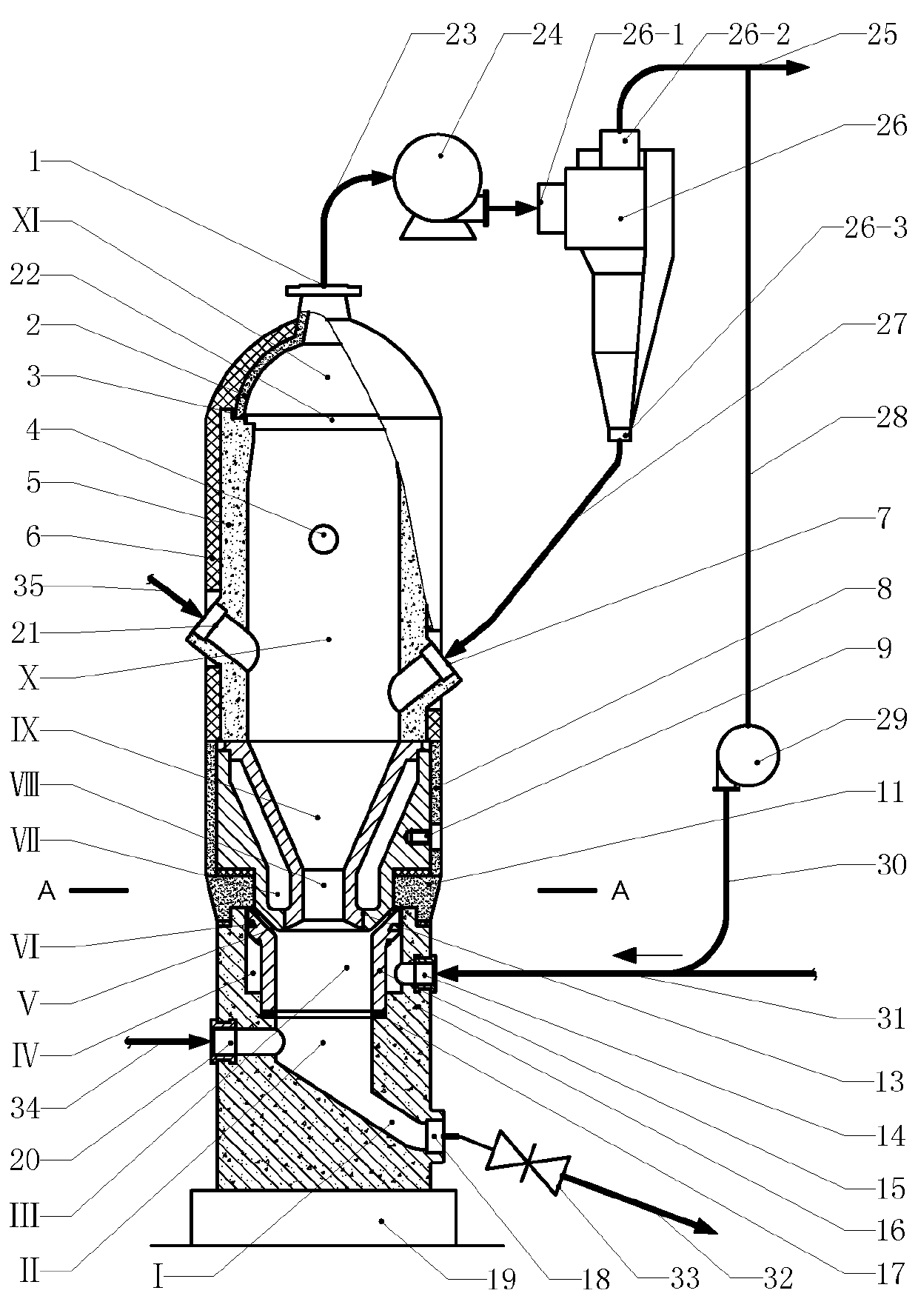

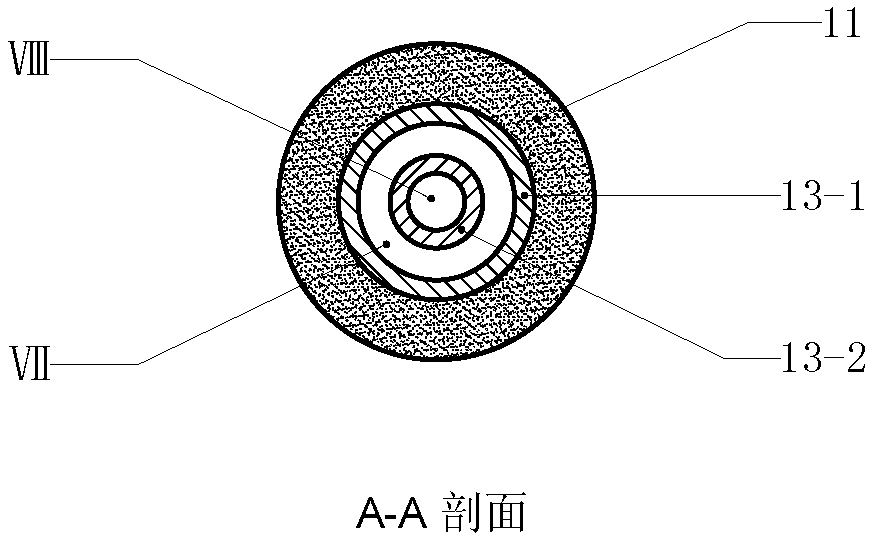

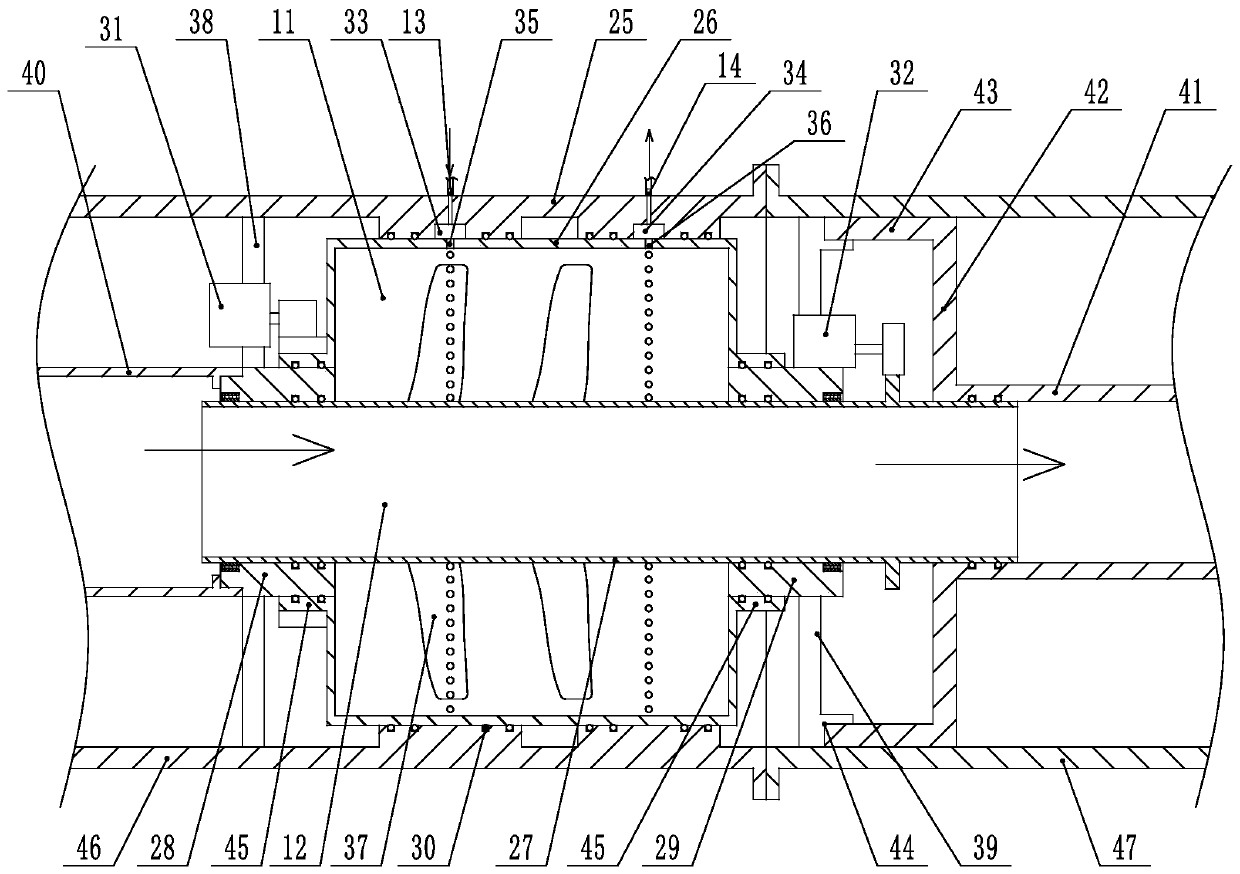

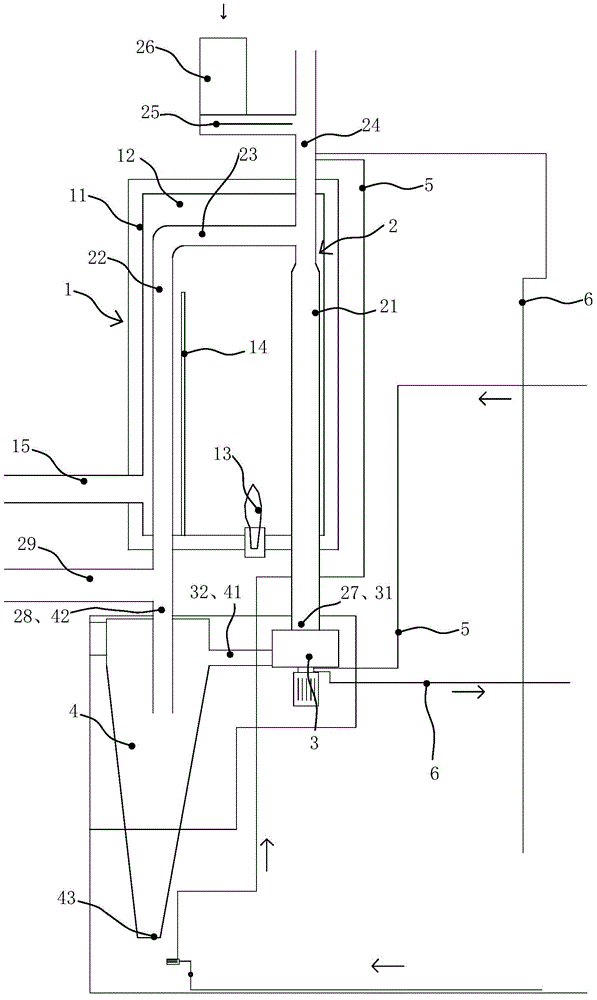

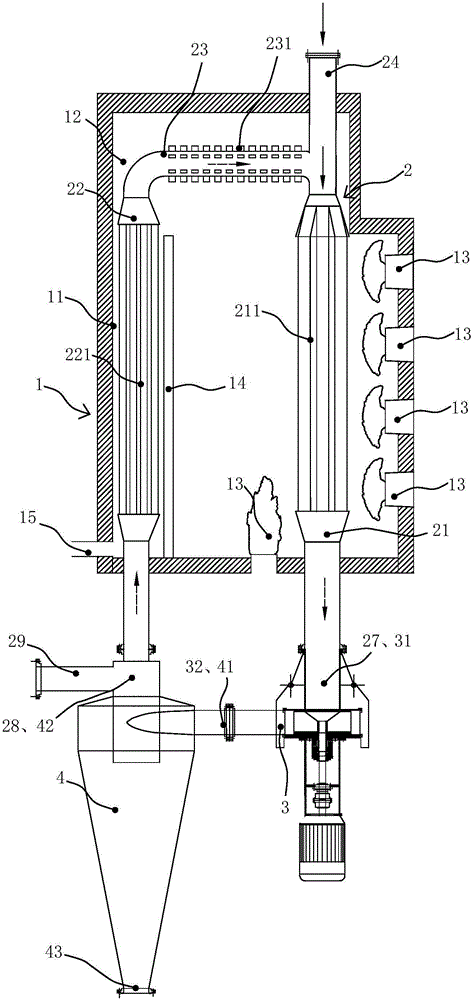

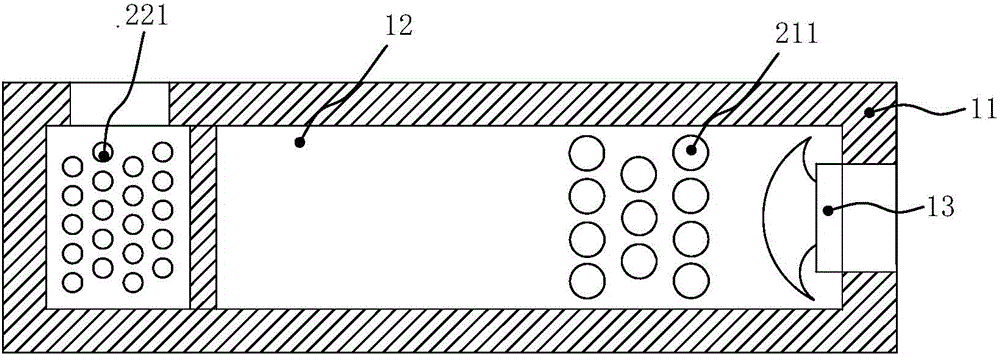

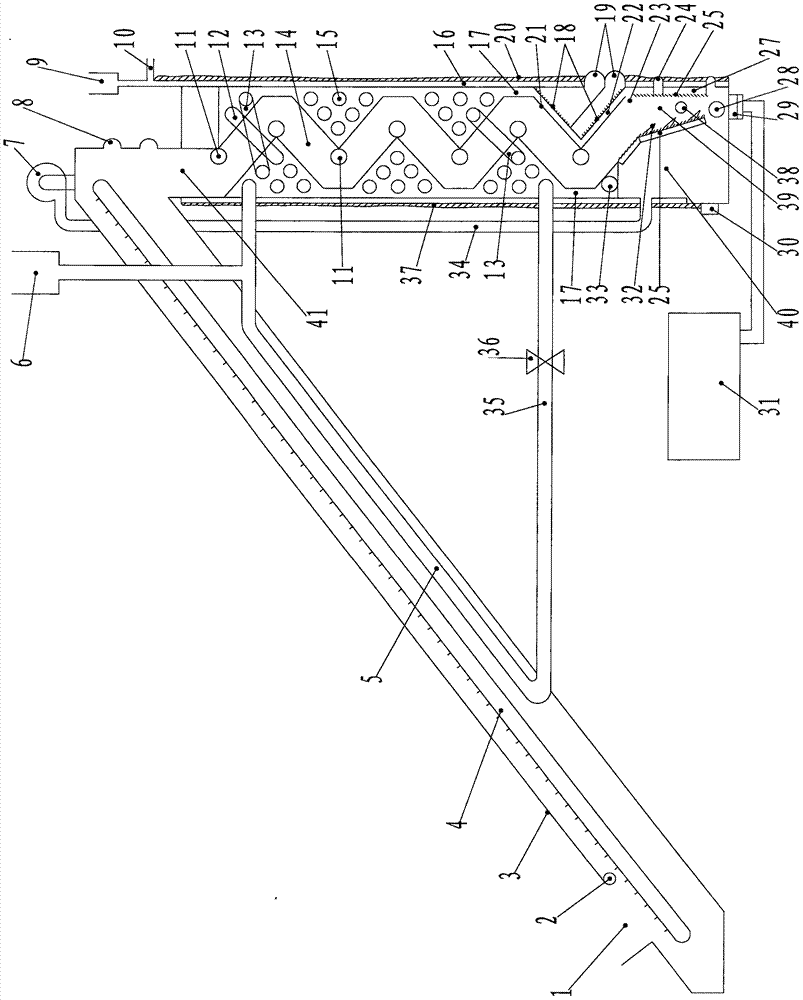

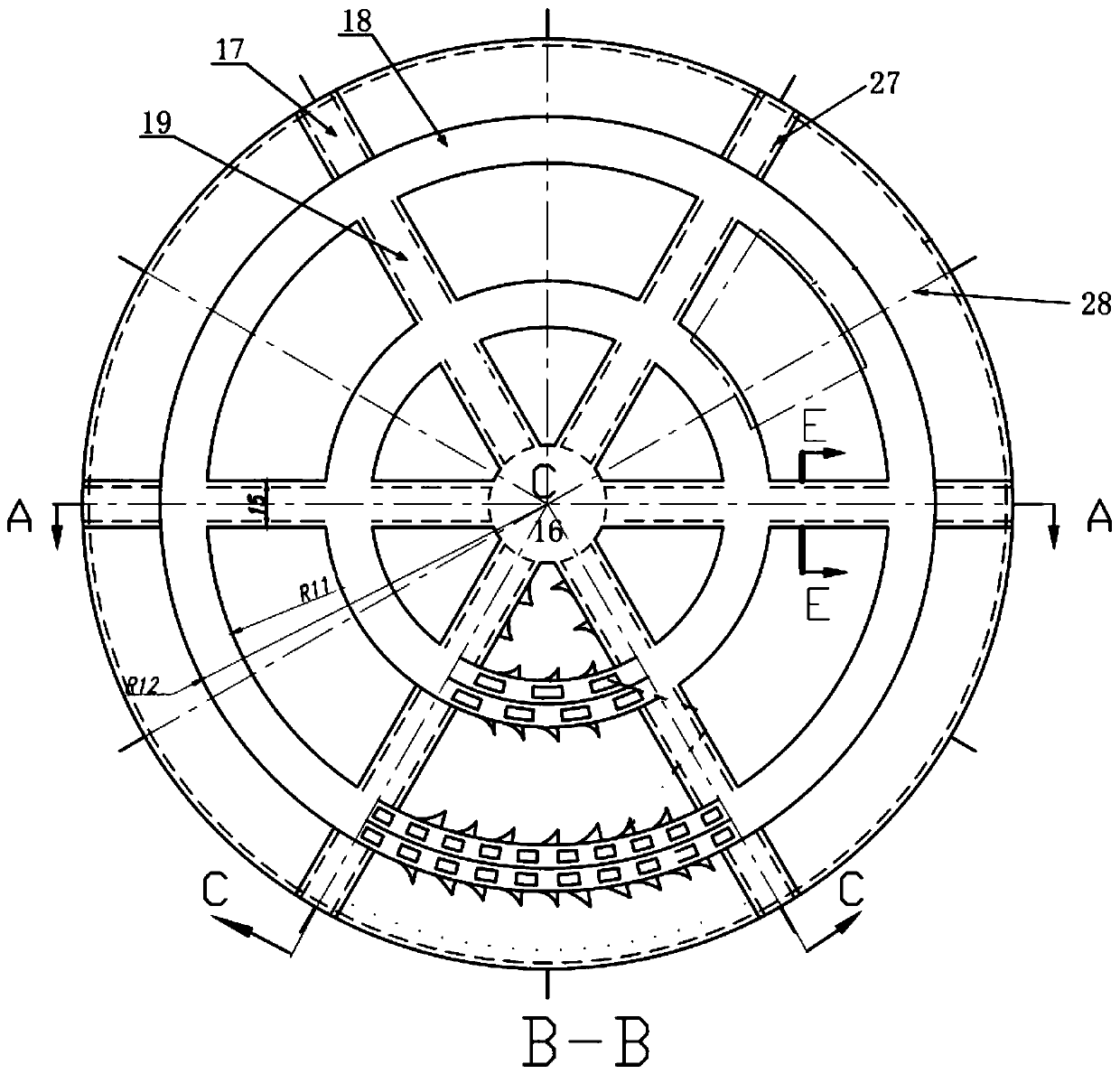

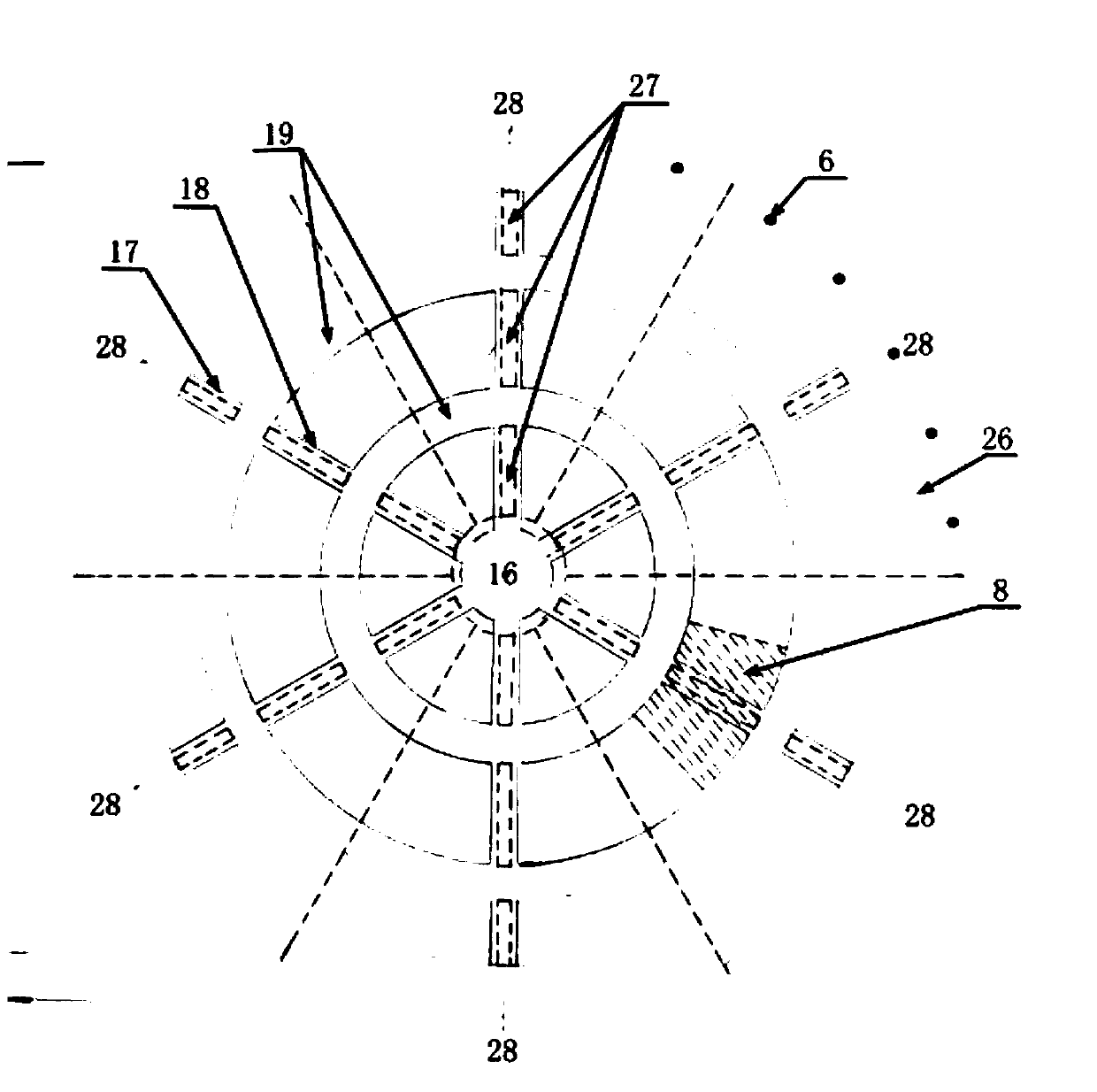

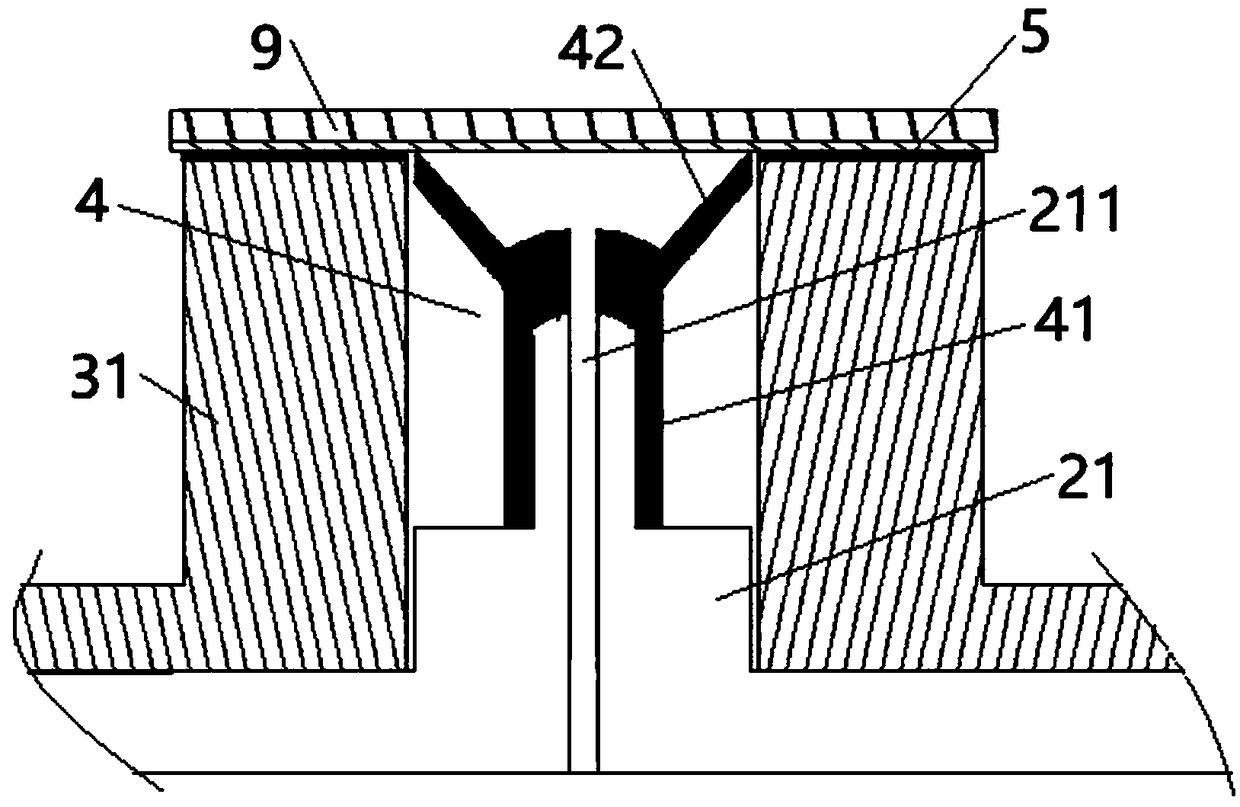

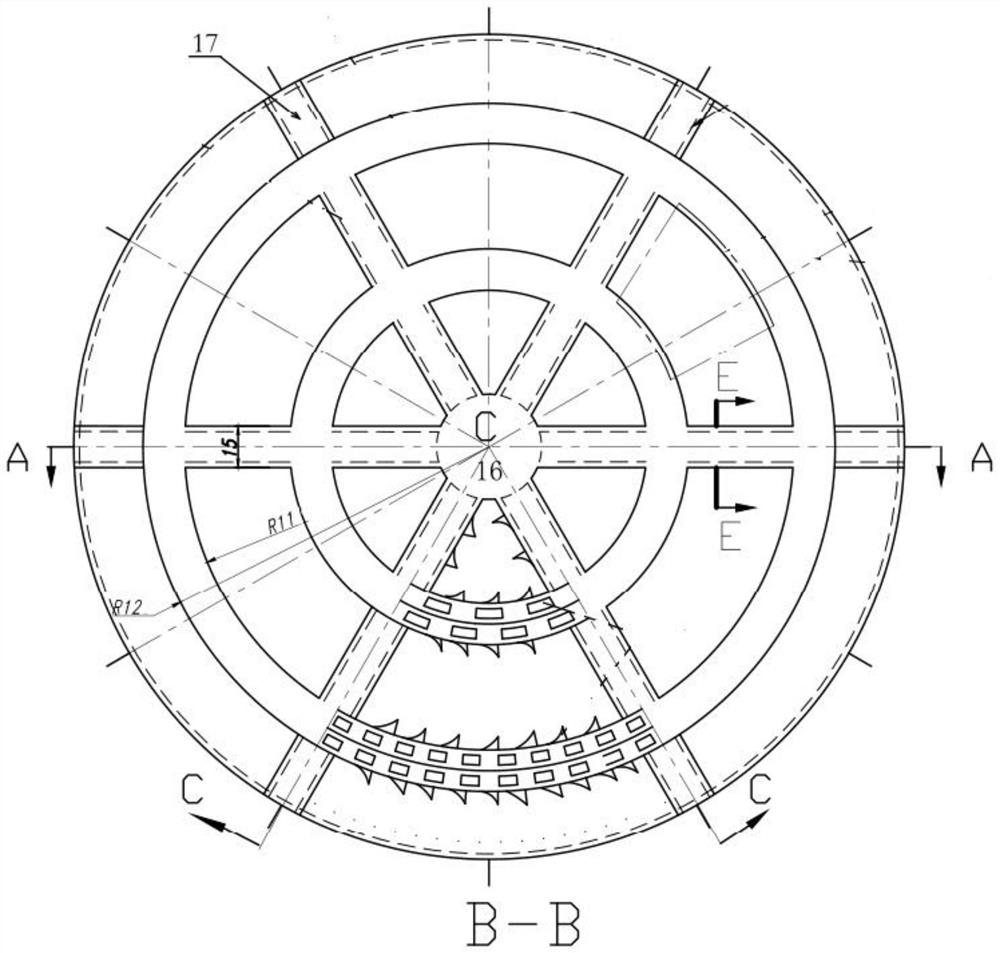

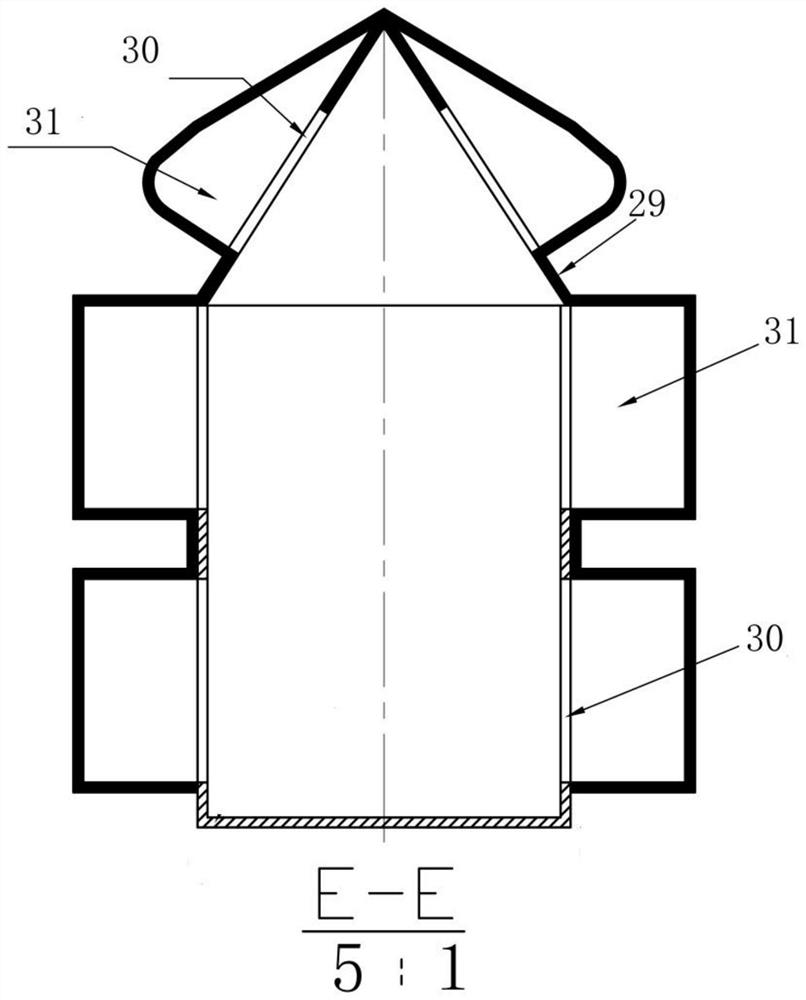

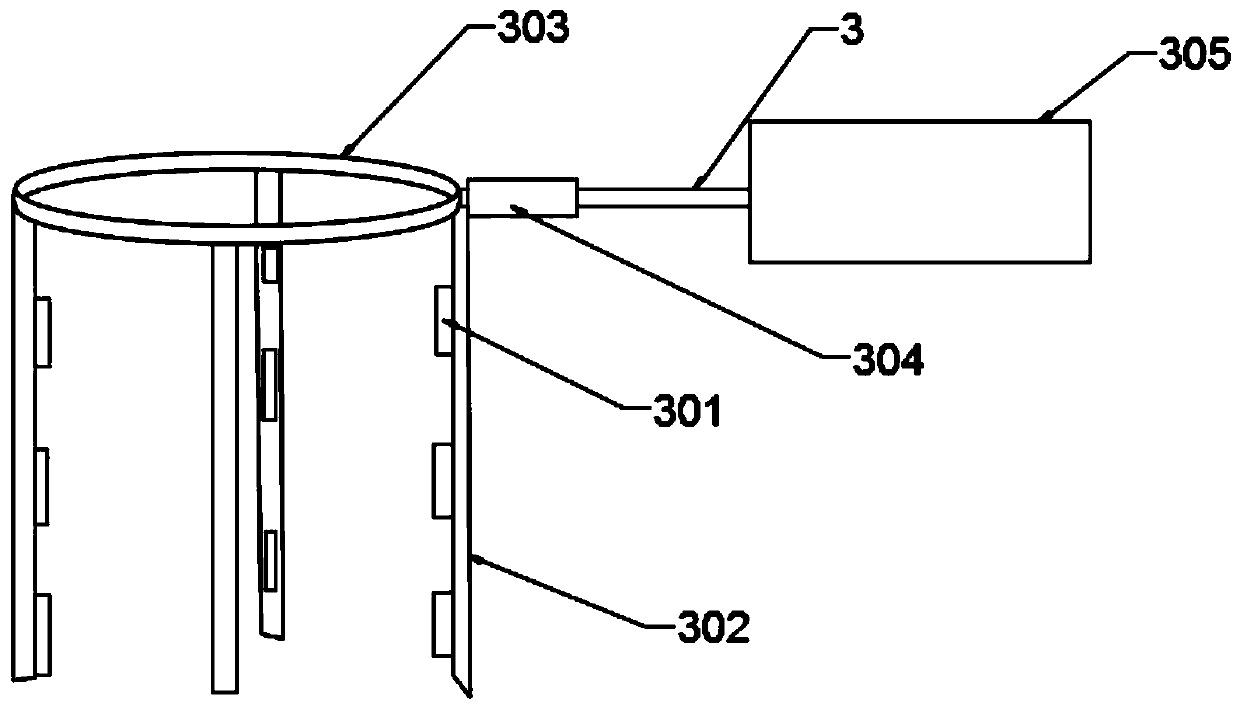

Internal circulating fluidized-bed oxygen-enriched gasification device

ActiveCN103471104AHigh calorific valueGood use effectIndirect carbon-dioxide mitigationIncinerator apparatusFluidized bedSlag

The invention provides an internal circulating fluidized-bed oxygen-enriched gasification device. The device comprises a gasifier body, a rich oxygen generation device, a multi-air-chamber air distribution device, a feeding device and a deslagging device, wherein the gasifier body consists of a lower dense-phase region and an upper dilute-phase region; the dense-phase region is connected with the dilute-phase region through a throat region; the multi-air-chamber air distribution device which is provided with directional wind caps is arranged at the bottom of the dense-phase region and is connected with the rich oxygen generation device; an outlet of the feeding device is arranged at the junction of the dense-phase section and the dilute-phase section; a slag outlet is arranged at a gap of the multi-air-chamber air distribution device and the gasifier body at the bottom of the dense-phase section; the deslagging device is arranged below the slag outlet. The system can efficiently realize pyrolysis and gasification of waste solid organic matters such as garbage and biomass, and has the advantages of high gasification speed, high conversion efficiency, less deslagging carbon residue, easiness in control over pollutants and the like.

Owner:XI AN JIAOTONG UNIV

Air temperature adjusting system for heat exchange type vehicles and vessels

InactiveCN102538287AImprove working conditionImprove cooling effectInternal combustion piston enginesExhaust apparatusLiquid storage tankEngineering

The invention relates to an air temperature adjusting system for heat exchange type vehicles and vessels, which comprises an evaporator using alcohol refrigerant, condenser, an ejecting and sucking device, a pump, a heater and a liquid storage tank. The ejecting and sucking device is capable of sucking refrigerant in the evaporator and outputting the refrigerant to the condenser, and the heater is capable of absorbing heat of engine tail gas by means of heat exchanging to vaporize the refrigerant. The heater is connected between the ejecting and sucking device and the pump through a pipe, and the evaporator comprises both of or one of an air-conditioning evaporator and a cooling evaporator. The evaporator is disposed on an engine air inlet pipe or arranged in an engine air inlet filter and used for cooling air flowing into an engine, dropping of air inlet temperature can improve air sucking efficiency of the engine, the engine can be in or close to the optimum operating state, engine power is improved, fuel consumption is reduced, and waste gas emission is reduced.

Owner:张伟

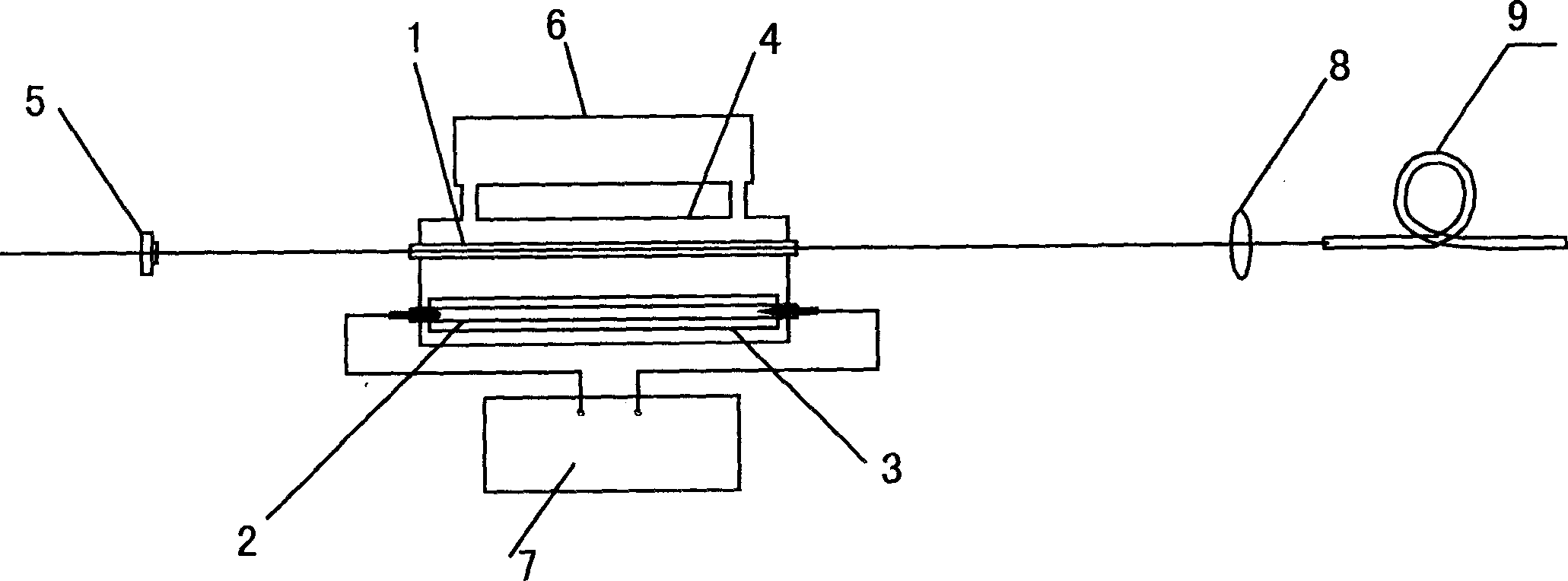

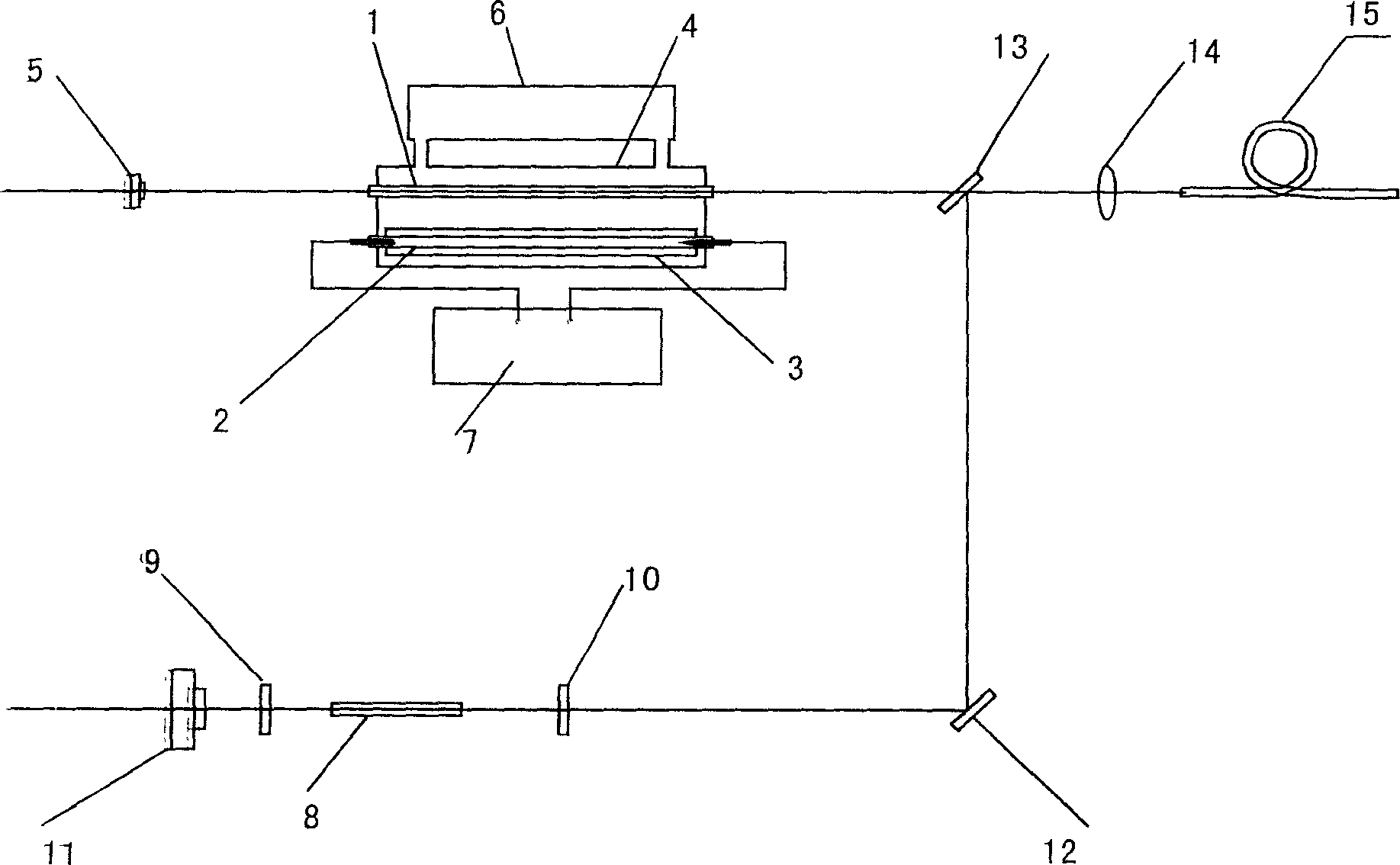

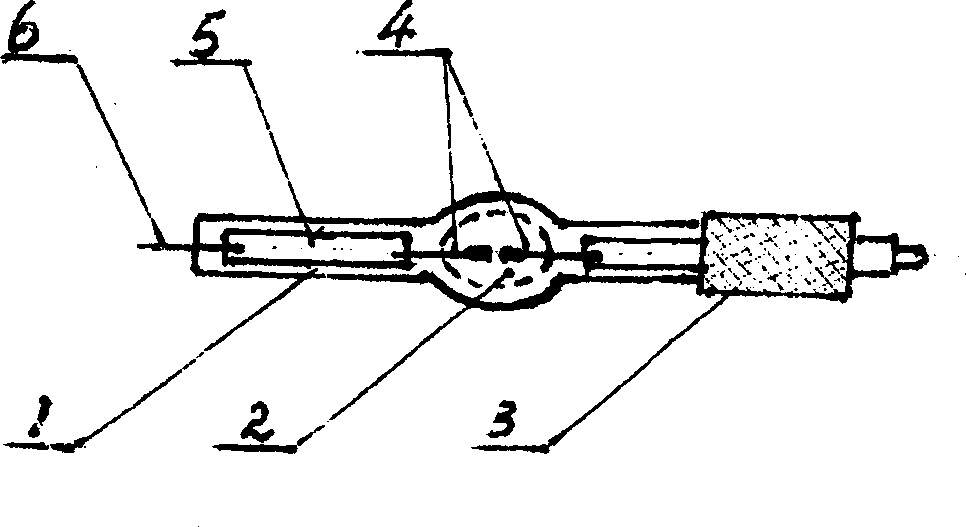

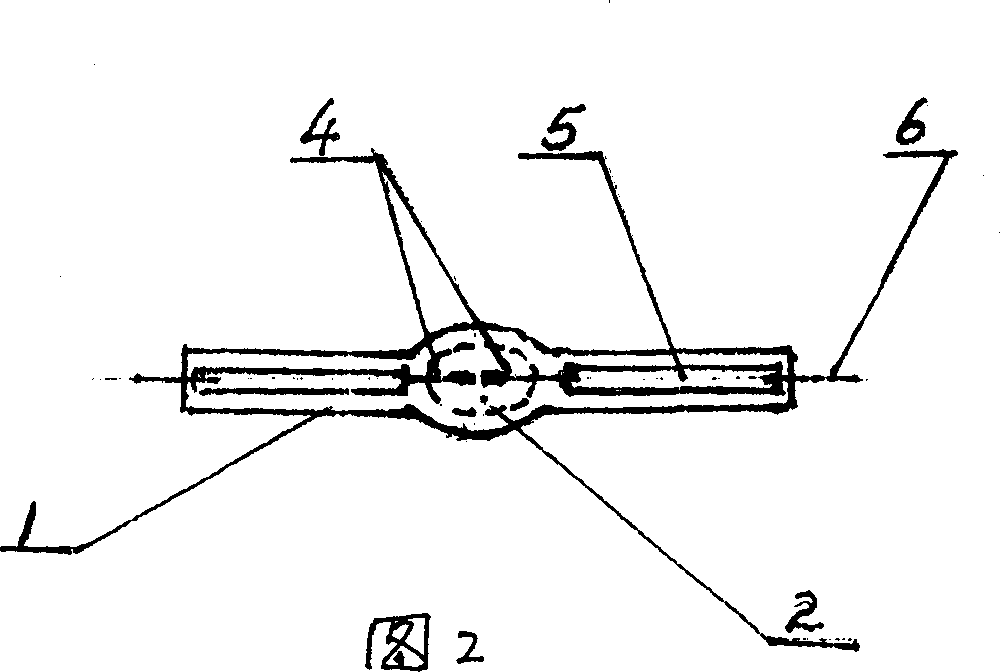

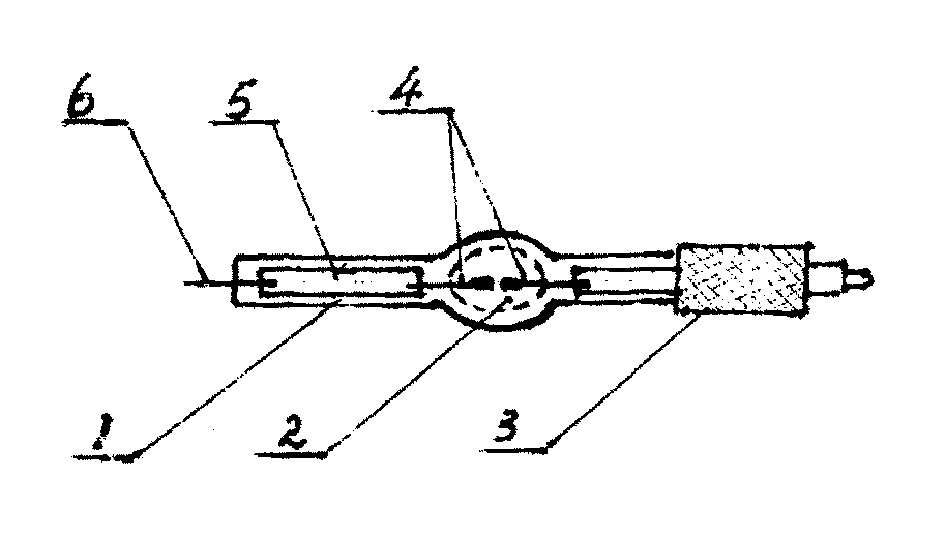

Dual wavelength laser therapeutic machine

InactiveCN1704028AWith laser cuttingFast gasificationSurgical instrument detailsEm couplingLength wave

The invention relates to a dual wavelength laser therapy apparatus in the field of laser medical apparatus which comprises Er:YAG crystal, pumping system, coupled lens, optical fiber and laser with the emission wavelength at 645-990nm. It has the following characters: it uses Er:YAG crystal redaction and the corresponding laser sets with the wavelength at 2940nm and 645-990nm to compound dual wavelength laser therapy apparatus; it couples the laser with the wavelength at 2940nm and 645-990nm into optical fiber so that the two lasers can be transmitted by one optical fiber.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

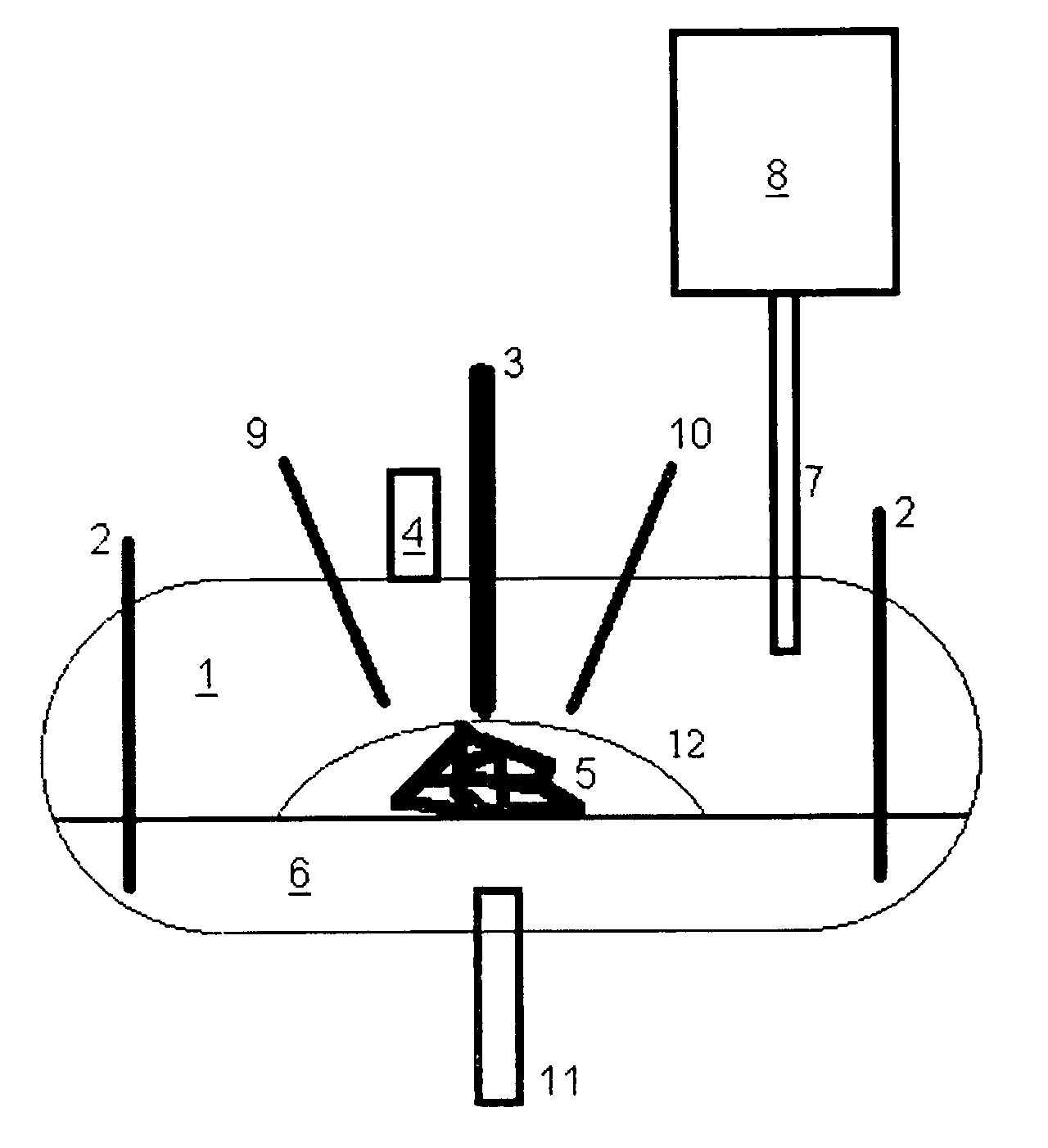

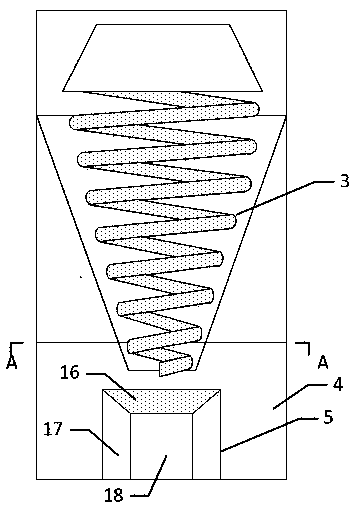

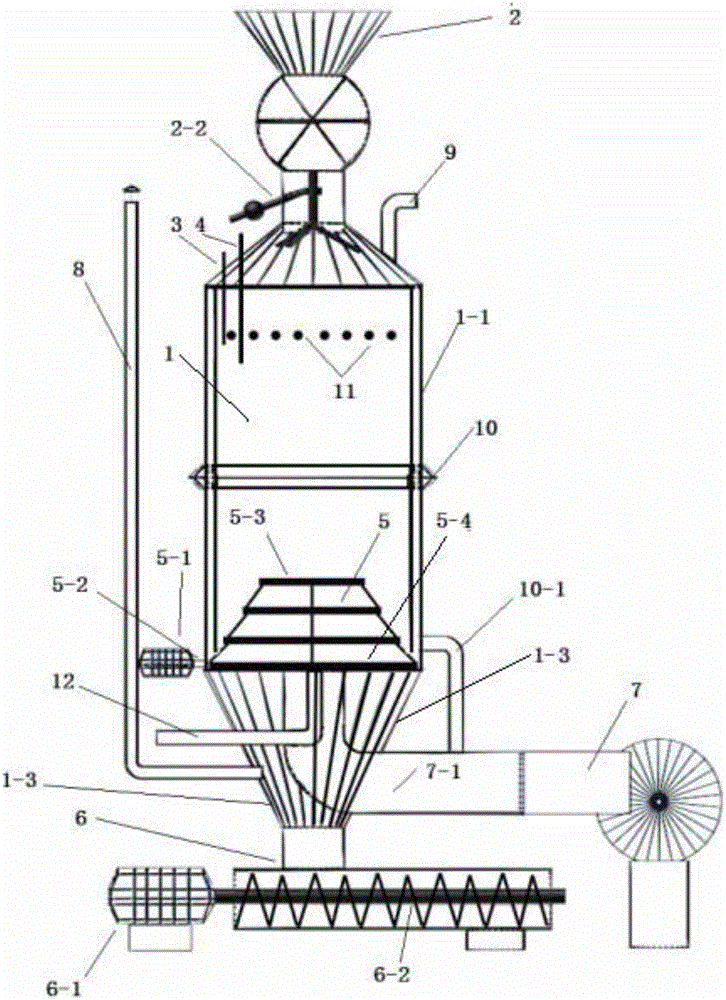

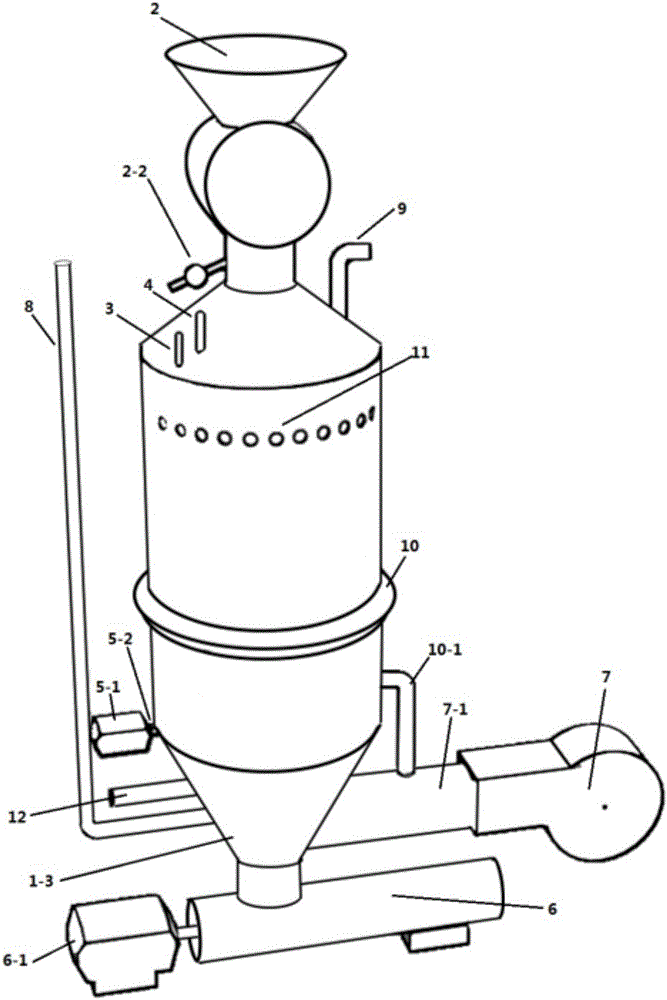

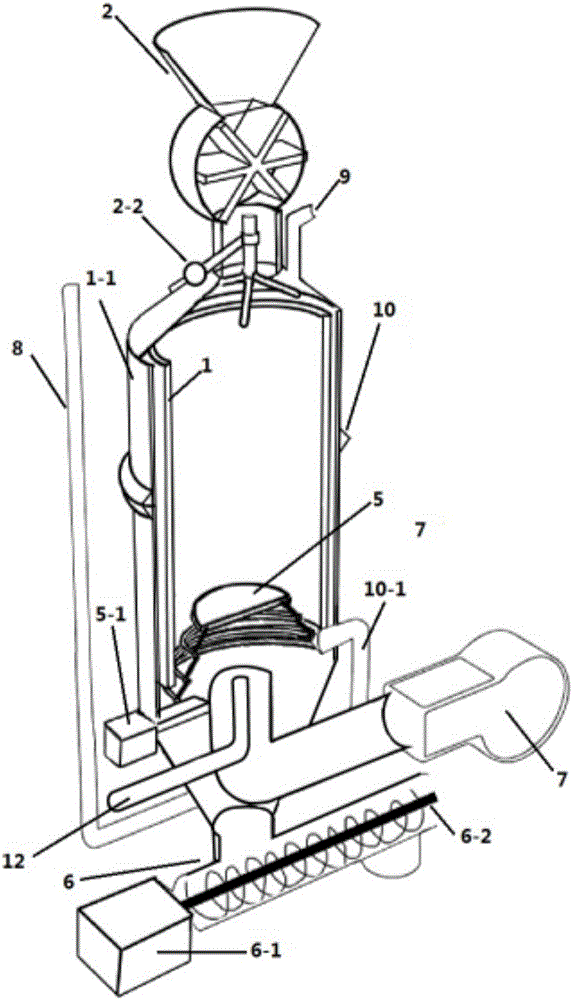

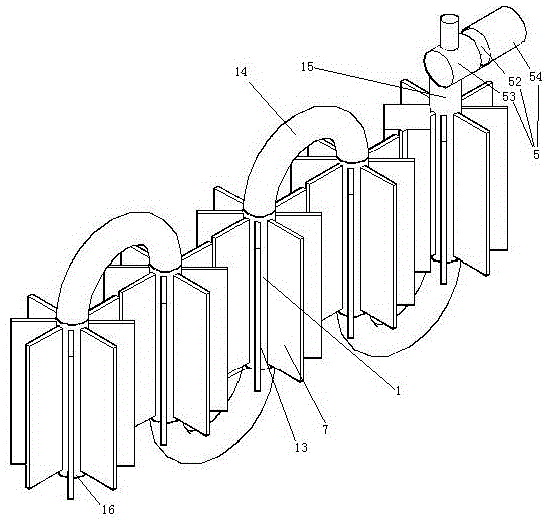

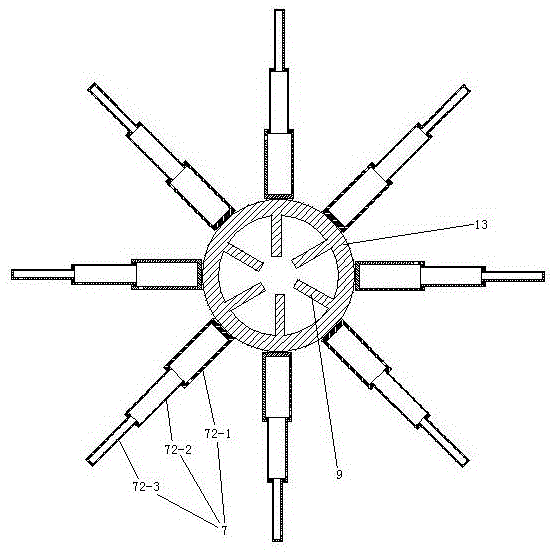

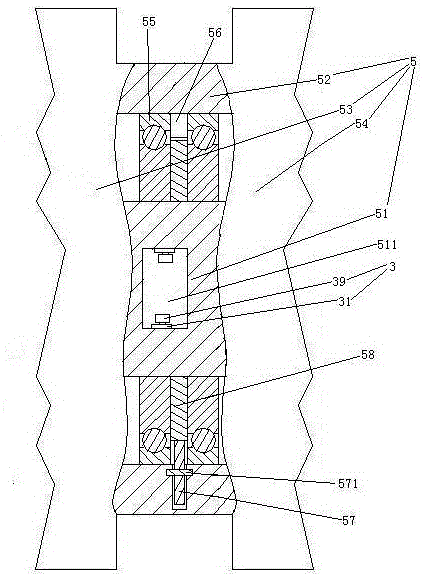

Plasma fluid bed gasifying device

InactiveCN103275762AFast gasificationImprove gasification efficiencyGranular/pulverulent flues gasificationEngineeringWater jacket

The invention relates to a plasma fluid bed gasifying device, relating to plasma gasification furnace equipment. The plasma fluid bed gasifying device mainly comprises a top cover, an upper furnace body, an insulated connecting piece, a lower furnace body, an anode, a cathode and a base, wherein the cathode is arranged in an inner space at the upper part of the lower furnace body; the upper cylindrical end of the cathode is in a horn mouth shape; the outer edge of the horn mouth is provided with a spiral groove; the insulated connecting piece is arranged between the anode and the lower furnace body; through holes in the axle center of the anode form a compressed hole channel; a horn mouth at the outlet of the compressed hole channel forms an anode arc root zone; the anode is internally provided with a cooling water sleeve; the upper furnace body is arranged on the anode; the inner space of the upper furnace body forms a gasification zone; and the top cover is provided with a synthesis gas output port for outputting synthesis gas. The plasma fluid bed gasifying device utilizes the characteristics that gasification raw materials of a fluid bed are wide in adaptability and high-temperature particles move seriously inside the gasification zone so as to strengthen heat transfer, and meanwhile, high-temperature working air at more than 4000 DEG C is taken as fluidized wind, so that coal or garbage biomass is quicker in gasification, higher in gasification efficiency and lower in energy consumption, and hydrogen-enriched synthesis gas with higher quality can be obtained.

Owner:衢州市广源生活垃圾液化技术研究所

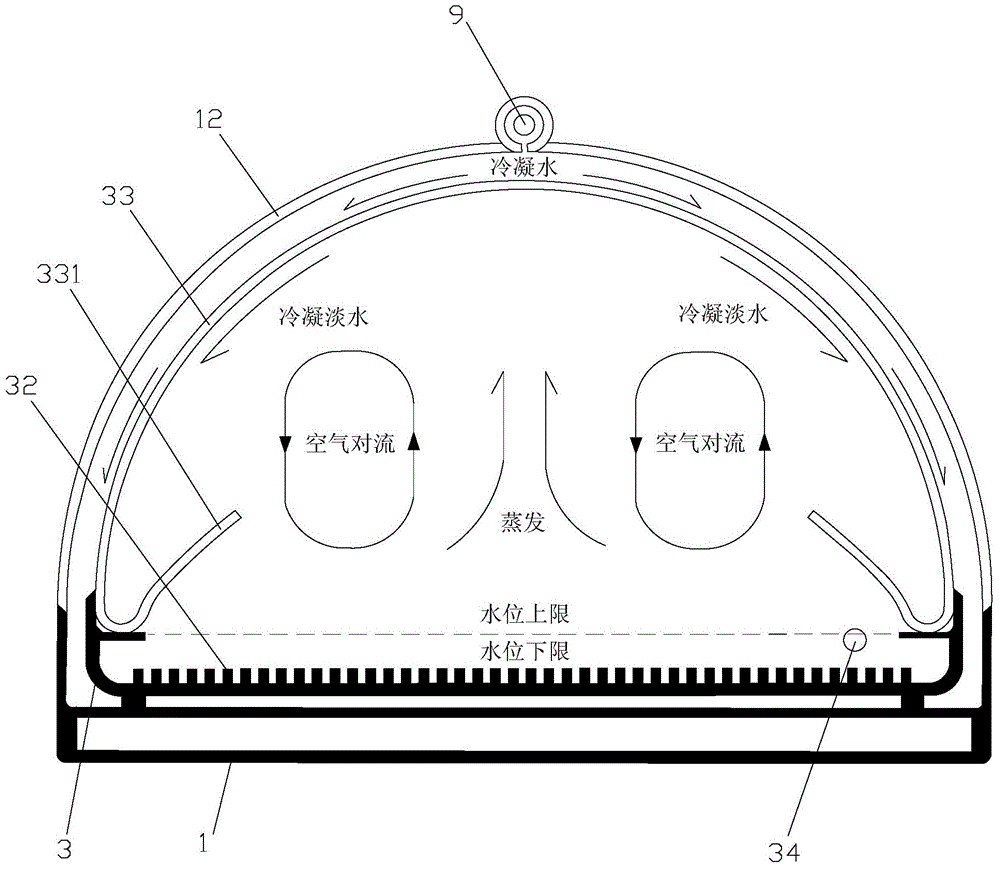

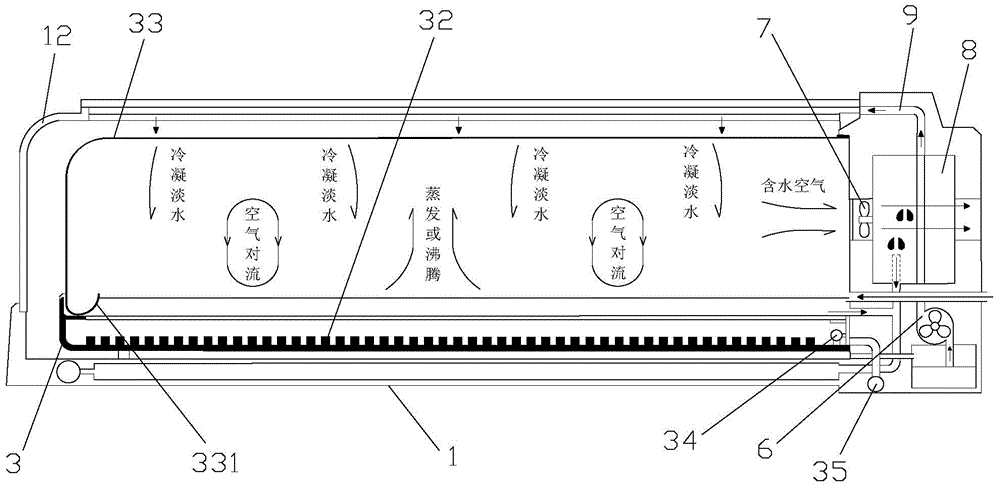

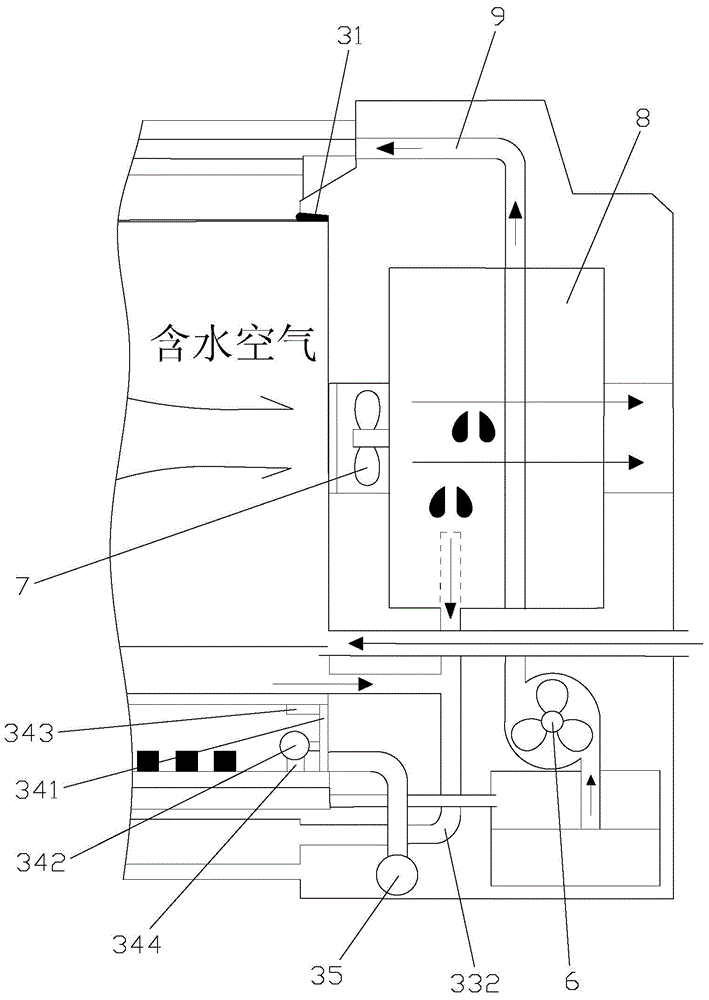

Solar sea water desalination device

ActiveCN104671313ASimple structural designReasonable structural designGeneral water supply conservationSeawater treatmentWater desalinationAir pump

The invention relates to a solar sea water desalination device. The device comprises an outer tank body, a fresh water storage box, a sea water airing tank, a condensing agent recovery tank, a condensing agent storage box, a condensing agent pump, an air pump, a condenser and a condensing agent pipe, wherein a light-transmitting layer is arranged on the outer tank body along tank walls; the fresh water storage box is provided with a fresh water output pipe and a fresh water pipe; the sea water airing tank is mounted at the top of the fresh water storage box in a sealed manner and is a dark metal airing tank; columnar bulges are arranged at the inner tank bottom of the sea water airing tank, a light-transmitting thin-wall condensing layer is arranged along top ends of tank walls, and a floating-ball water level control switch is arranged at the tank bottom on one side; a condensate water collecting tank is formed at the bottom end of the light-transmitting thin-wall condensing layer; the condensing agent recovery tank is formed by a gap between the sea water airing tank and the outer tank body; the condensing agent storage box is communicated with the condensing agent recovery tank; the condensing agent pump is communicated with the condensing agent storage box. The device is simple and reasonable in structural design, convenient to use, good in sea water desalination effect, high in sea water desalination efficiency, low in manufacturing cost, energy-saving and environment-friendly.

Owner:海南瑞亚农业科技有限公司

Double wave-length laser therapeutic apparatus

InactiveCN1618409AFast gasificationOptical resonator shape and constructionSurgical instrument detailsEr:YAG laserLaser cutting

A dual-wavelength laser therapy apparatus has the Er:YAG laser system and the Nd:YAG laser system for outputting the 2940 nm and 1064 nm laser beams, which are transmitted via a single optical fibre made of sapphire or fluoride glass. Its laser cutting function has high gasifying speed, resulting in high staltic effect.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

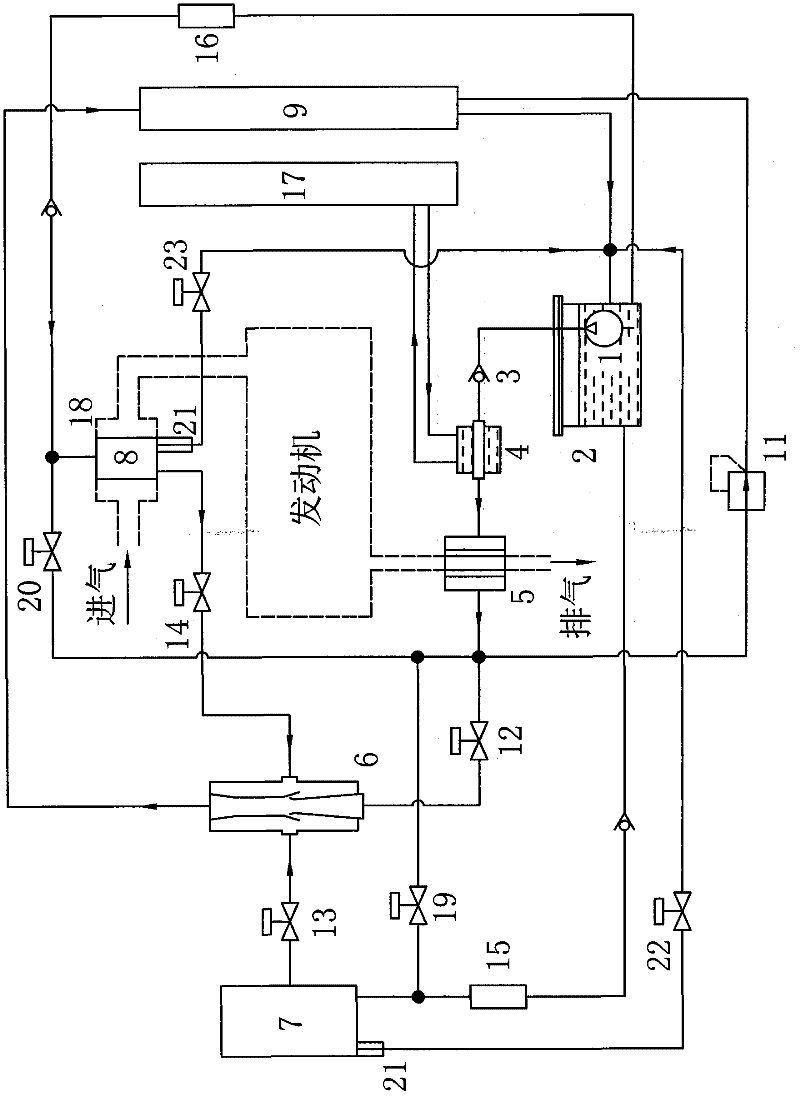

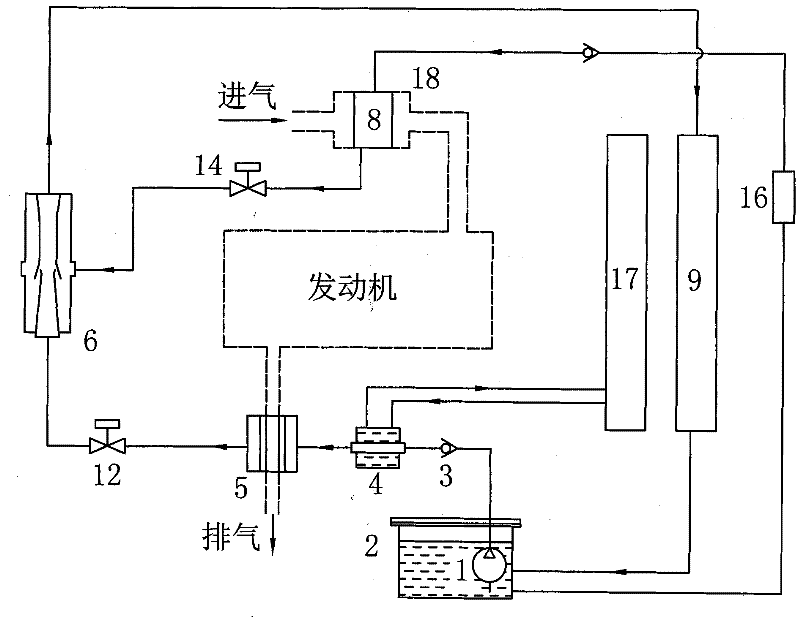

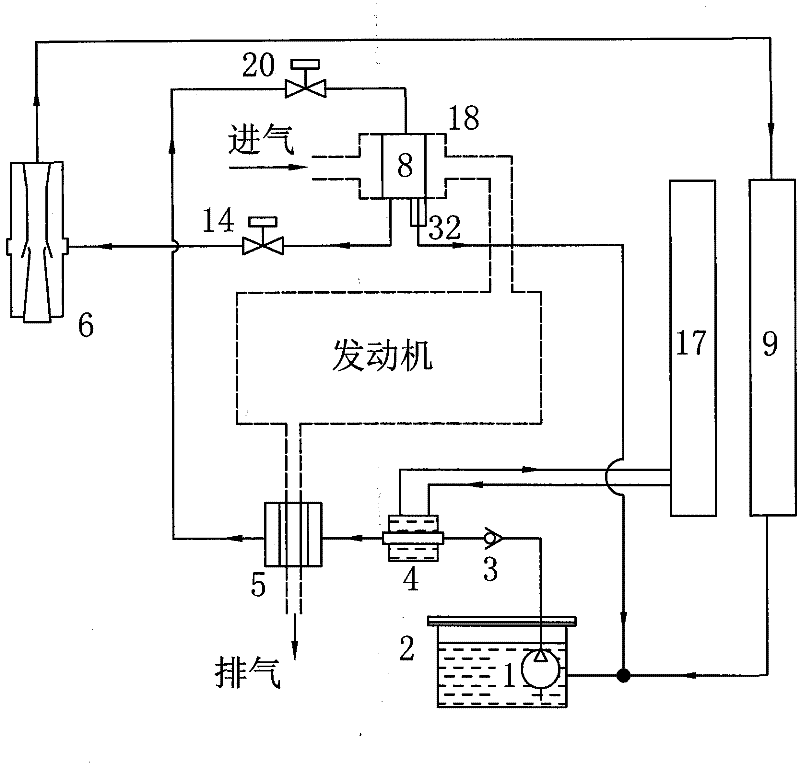

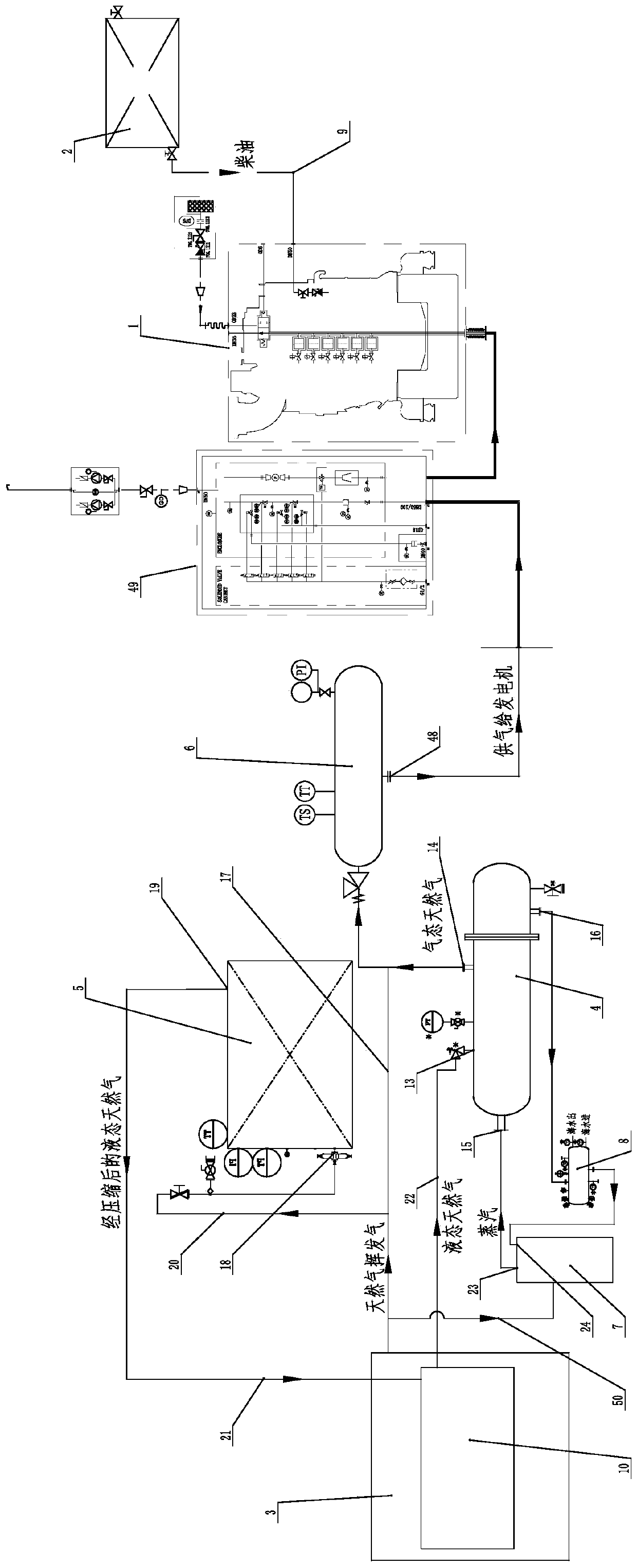

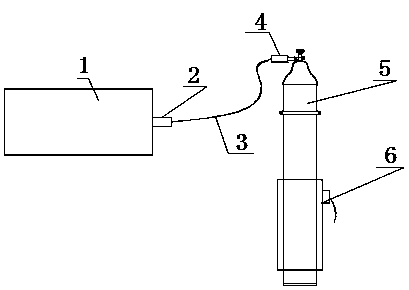

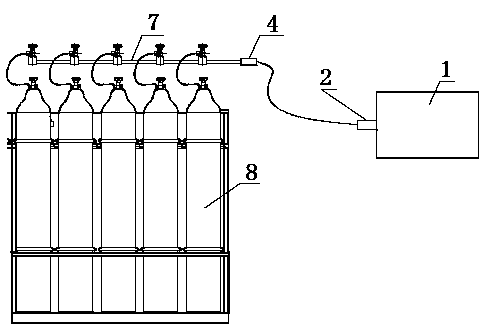

Diesel and natural gas dual-fuel power generation system

ActiveCN109812357ATake advantage ofFast gasificationInternal combustion piston enginesFuel supply apparatusGas compressorBuffer tank

The invention discloses a diesel and natural gas dual-fuel power generation system, and aims to overcome the defect that insufficient gas supply to marine power generators is caused easily by the lowLNG gasification speed. The system comprises a dual-fuel power generator, a diesel cabin, a natural gas storage cabin, a natural gas regasification device, a volatile gas compressor, a buffer tank, aboiler and a condenser; natural gas volatilized by the natural gas storage cabin is stored in the buffer tank to be used as fuel for the dual-fuel power generator; when the volatile gas is insufficient, LNG inside an LNG storage tank is gasified into the gas state by the natural gas regasification device and is sent into the buffer tank for supplementation; when the volatile gas is excessive, onepart is sent into the volatile gas compressor to be compressed into the LNG to be recovered into the LNG storage tank, and the other part is sent into the boiler to be used as the fuel. The volatile natural gas is sufficiently utilized, and the energy saving and environmental protection effects are realized. The LNG gasification speed is high, the gas supply to the marine power generators is sufficient and stable, and the performance of the power generators is guaranteed.

Owner:PAXOCEAN ENG ZHOUSHAN CO LTD

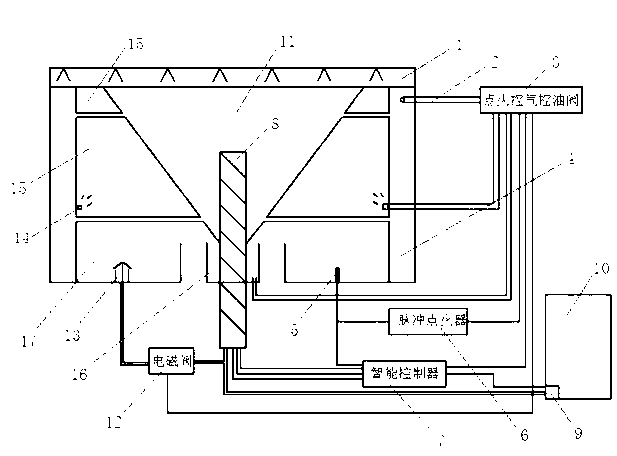

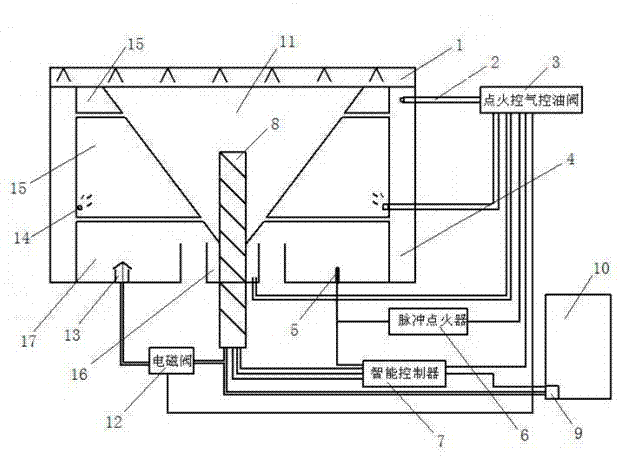

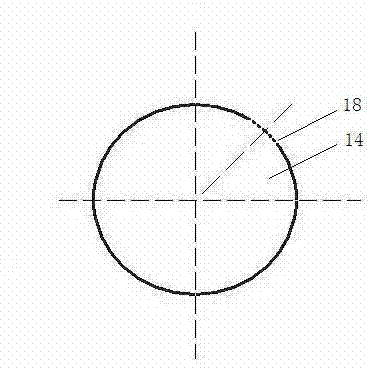

Intelligent gasification furnace and control method thereof

InactiveCN103343987AWith automatic oil controlSave fuelDomestic stoves or rangesLighting and heating apparatusSolenoid valveFuel tank

The invention relates to an intelligent gasification furnace and a control method thereof. The intelligent gasification furnace comprises a combustion net, a fuel pipe, an ignition air control and material control valve, a gasification chamber, an ignition sensor, a fuel pump, a fuel tank, another gasification chamber, a solenoid valve, an oil nozzle, an annular air injection port, a combustion port, a preheating chamber, a pulse igniter, an intelligent controller, a sensor and an air injection groove. The intelligent gasification furnace solves the problems that an existing intelligent gasification furnace valve is low in work efficiency, firepower is not stable, fuel cannot be combusted fully, gas escapes easily, and air content of mixed gas is non-uniform. According to the intelligent gasification furnace, oil is controlled automatically, the fuel is saved, the structure is simple, the firepower is stable and safe, the gasification speed is high, gas is mixed uniformly, and operation is convenient. The operation method is the same as that of an existing cooking range commonly used. The intelligent gasification furnace protects environment and is economical, and liquefied gas can be replaced.

Owner:唐川盛

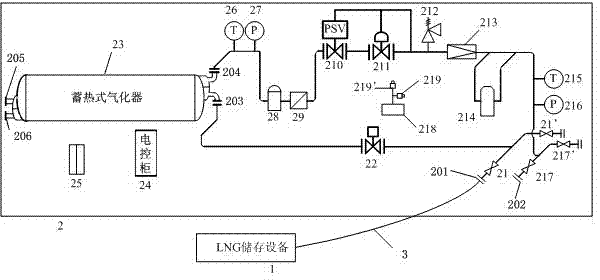

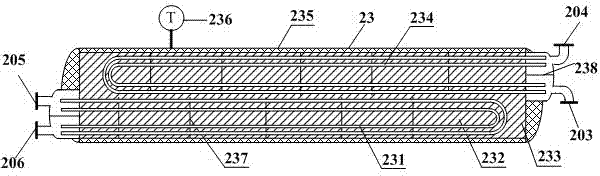

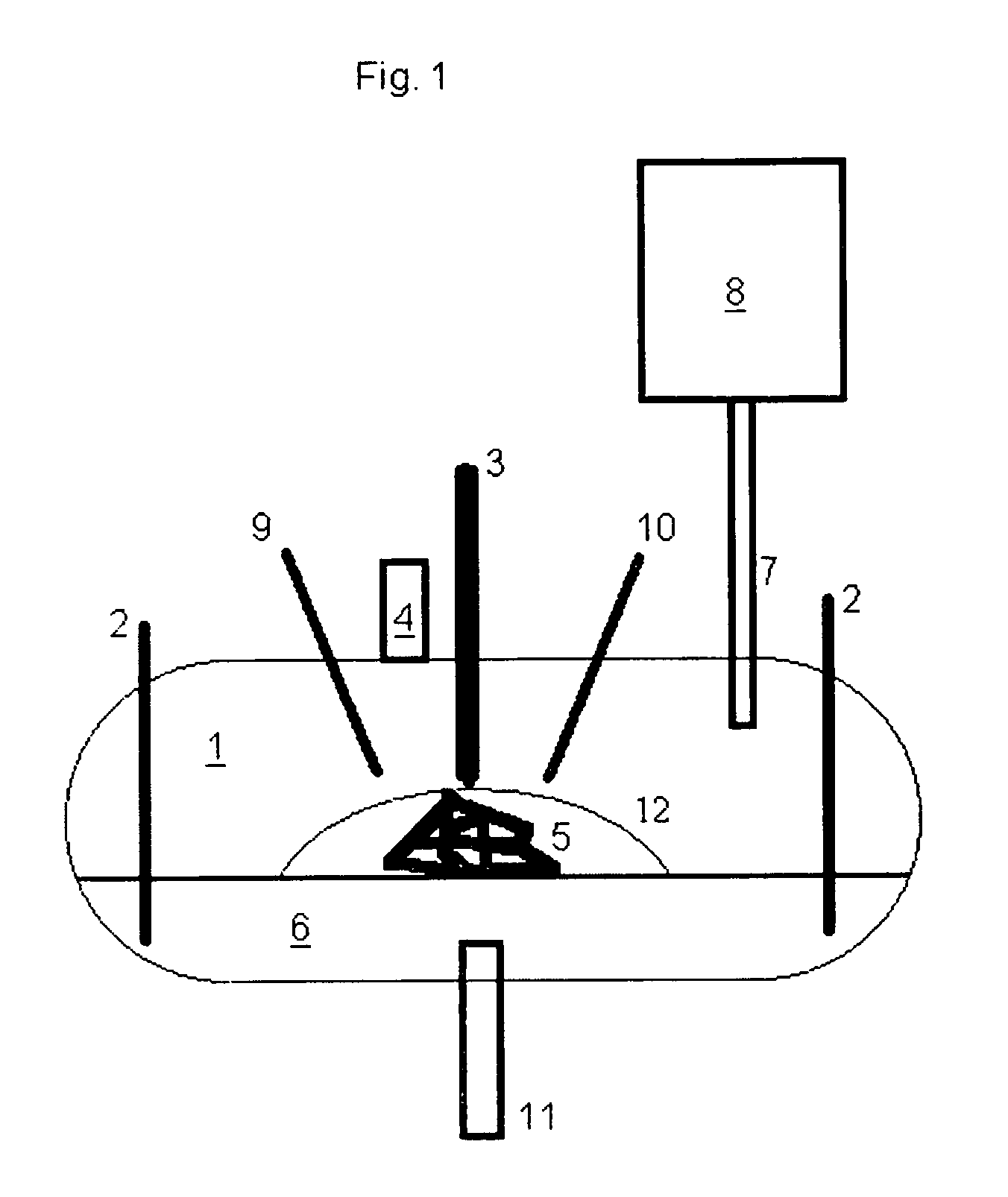

Mobile LNG (Liquefied Natural Gas) supply device utilizing residual heat and waste heat

ActiveCN103899913AAdaptableReduce the impactContainer discharging methodsContainer filling under pressureVaporizationProcess engineering

The invention discloses a mobile LNG (Liquefied Natural Gas) supply device utilizing residual heat and waste heat. The mobile LNG supply device comprises an LNG storage device and a vehicle-mounted vaporization pressure adjusting container, wherein a regenerative vaporizer is arranged in the vehicle-mounted vaporization pressure adjusting container; a first heat exchange pipe and a second heat exchange pipe are arranged inside the regenerative vaporizer; the inlets and outlets of the first heat exchange pipe and the second heat exchange pipe are formed in one pipe plate; end sockets at the two ends of the first heat exchange pipe and the second heat exchange pipe are partitioned into two chambers; the LNG storage device is connected with the regenerative vaporizer through a pipe. According to the mobile LNG supply device, externally connected power source or other power sources are not needed when gas is supplied; the LNG is vaporized through the residual heat and waste heat recycled by the regenerative vaporizer, the environment impact on a vaporization amount is extremely small, the gas supply amount of the device is large and the vaporization speed is fast; meanwhile, an electric control cabinet and a safety device are arranged so as to ensure the safety and reliability of gas supply; the mobile LNG supply device has the characteristic of being compact in structure, convenient to move, energy-saving and environment-friendly, fast in starting speed, strong in gas supply capability and environmental adaptability and high in safety performance and reliability.

Owner:SOUTH CHINA UNIV OF TECH

Alcohol-based fuel oven

InactiveCN101900361AFast gasificationEmission reductionDomestic stoves or rangesLiquid heating fuelTemperature controlAlcohol

The invention provides an alcohol-based fuel oven, which consists of a shell, a burning device, a gasification device and a valve assembly, wherein the gasification device is arranged on the burning device; the burning device is fixed on the shell; and one end of the gasification device is connected with the valve assembly, while the other end is connected with a burner of the burning device. The alcohol-based fuel oven solves the world-class problems that: 1, the alcohol-based fuel is changes from liquid to gas for burning to solve the problem of high energy consumption, and tests prove that energy conservation reaches over 60 percent; 2, the temperature of the alcohol-based fuel in a gasification pipe can be effectively controlled to be at 250 DEG C to solve the problem of carbonization; 3, the flame temperature is improved to be over 1,100 DEG C along with strong fire power and fast heating speed; 4, the gasification has high speed, and the liquid alcohol-based fuel can be completely changed into the gas for burning; and 5, the fuel is sufficiently burnt, and emission of waste gas after burning is over ten times lower than that of related standards in the country, so the fuel stove is every environmental protection. The alcohol-based fuel oven breaks through the technical barrier of alcohol-based fuel burning, and popularization of the alcohol-based fuel is changed from idea into reality. Popularization of the alcohol-based oven contributes to the country.

Owner:李永安

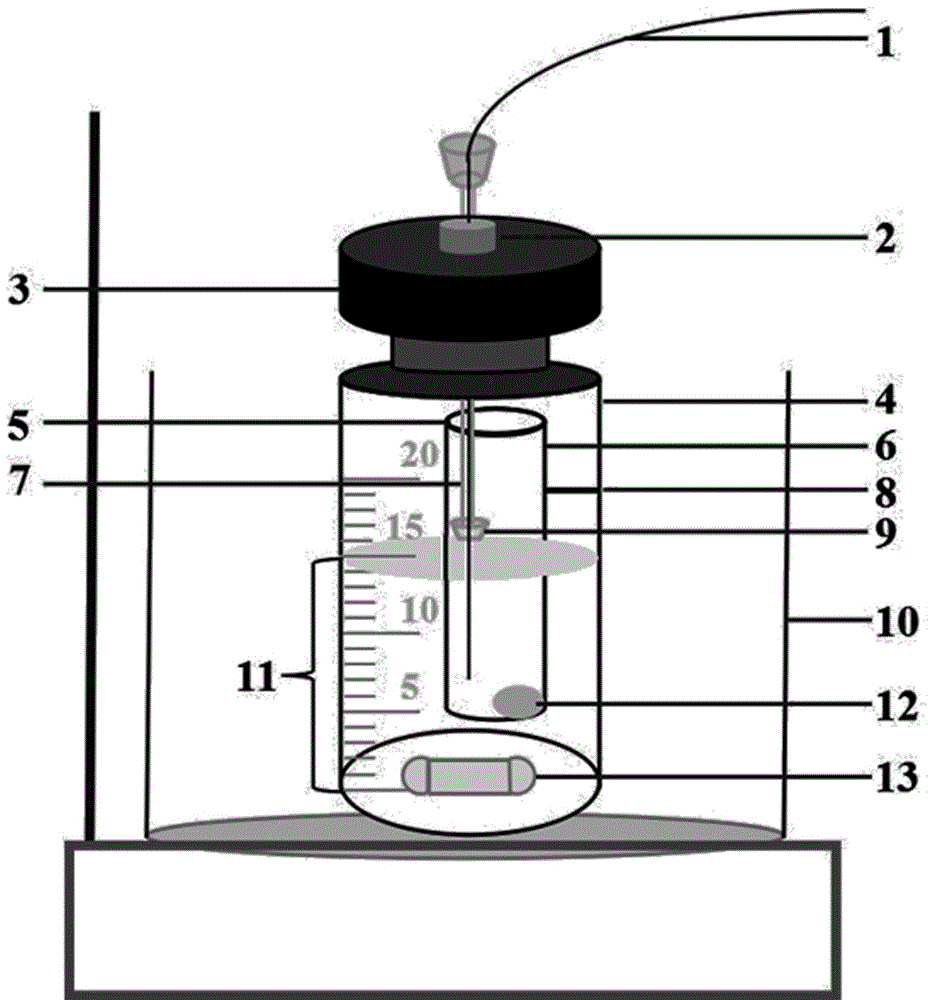

Device and method for headspace solid phase microextraction capable of removing water

ActiveCN106474764AIncrease contentHigh sensitivitySolid solvent extractionFiberSolid-phase microextraction

The invention provides a device and a method for headspace solid phase microextraction capable of removing water. The device comprises a material container, a steam container, a heating type magnetic stirrer, a needle head, extraction fiber and a magnetic stirring bar, wherein the material container is a sealed container and is arranged on the heating type magnetic stirrer; the interior of the material container is filled with a to-be-extracted material and the magnetic stirring bar; the steam container is in sealed arrangement inside the material container; the interior of the steam container is filled with a water vapor absorption material; one end of the steam container is opened; the position of the wall of the material container facing the opened end of the steam container is provided with a puncturable soft plug; the needle head penetrates through the soft plug and reaches the interior of the steam container; and an extraction coating layer is arranged on the extraction fiber which extends into the steam container through the inner channel of the needle head. According to the invention, the water vapor located at the headspace part of an extraction container during headspace extraction operation can be removed through the arrangement of a simple device.

Owner:FUZHOU UNIV

Dry distillation gasification device and rapid pulverized coal dry distillation method

InactiveCN104099134AIncrease gasification rateLow residual combustible gas contentGranular/pulverulent flues gasificationActivated carbonEngineering

The invention provides a dry distillation gasification device which comprises a gasification furnace, a gasification pipeline, a fan and a gas-solid separator, wherein a material is sent to the gasification pipeline through a feed inlet and mixed with gas in a pipeline system to form a gas-solid mixture; the material is subjected to dry distillation and gasification in the gasification pipeline; the gas-solid mixture is driven by the fan to circulate in the pipeline system; solids in the gas-solid mixture are separated by the gas-solid separator and discharged from a solid outlet, and gas after gas-solid separation returns the gasification pipeline through a gas return port; and finished gas can be discharged from a finished gas discharge pipe. The pulverized coal containing volatile matters is subjected to rapid dry distillation, most of the volatile matters of the coal are gasified and converted into gas fuel, and meanwhile, residual coal particles are used for producing activated carbon.

Owner:LICHENG LANTIAN GAS DEV

Oxygen enhanced plasma waste treatment system and method

A method and apparatus that improves the efficiency of waste processing in waste treatment systems utilizing a high temperature plasma as the a energy source by delivering pressurized oxygen to the waste products while the waste products are exposed to the high temperature plasma. Providing oxygen at a speed of at least fifty feet per second obtains more energy content in the syngas, less solid carbon particulate, and faster gasification rates, improving process economics.

Owner:INENTEC

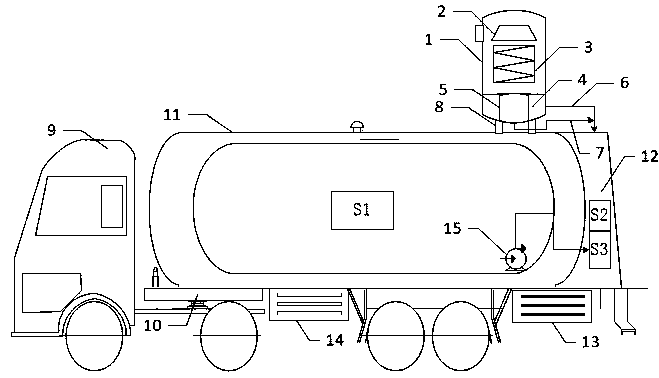

Device and method for rapid conveying and unloading of shale gas hydrate slurry

PendingCN110345384AIncrease concentrationIncrease the effective gas storage capacityTank vehiclesPipeline systemsSafety instrumented systemSlurry

The invention relates to a device and method for rapid conveying and unloading of shale gas hydrate slurry, and belongs to the technical field of natural gas hydrate storage and transportation. A hydrate slurry separator is designed, a rotating wheel is installed at an upper separation section, a spiral flow channel is formed in the middle separation section, a first liquid storage chamber and a slurry separation chamber are arranged on the lower separation section, and the hydrate slurry is subjected to dehydration thickening is carried out; a slurry tank truck is provided with a slurry vehicle-mounted storage tank, a matched emergency gasification system and a safety instrument system are arranged, so that the safe storage and rapid conveying of the hydrate slurry can be realized; a tanktruck chassis is provided with an air temperature type vaporizer and an electric heating vaporizer, an immersed pump is arranged in the storage tank, a matched pipeline system is combined to form four hydrate slurry rapid unloading processes. The invention provides the method for rapid conveying and unloading of the shale gas hydrate slurry. the slurry enters a slurry dewatering separator along the tangential direction, after the slurry is subjected to centrifugation, sedimentation and filtering separation, the slurry is stored in the slurry vehicle-mounted storage tank and rapidly conveyed to a user terminal, the slurry is unloaded by a corresponding unloading process and then enters an urban gas pipe network.

Owner:SOUTHWEST PETROLEUM UNIV +1

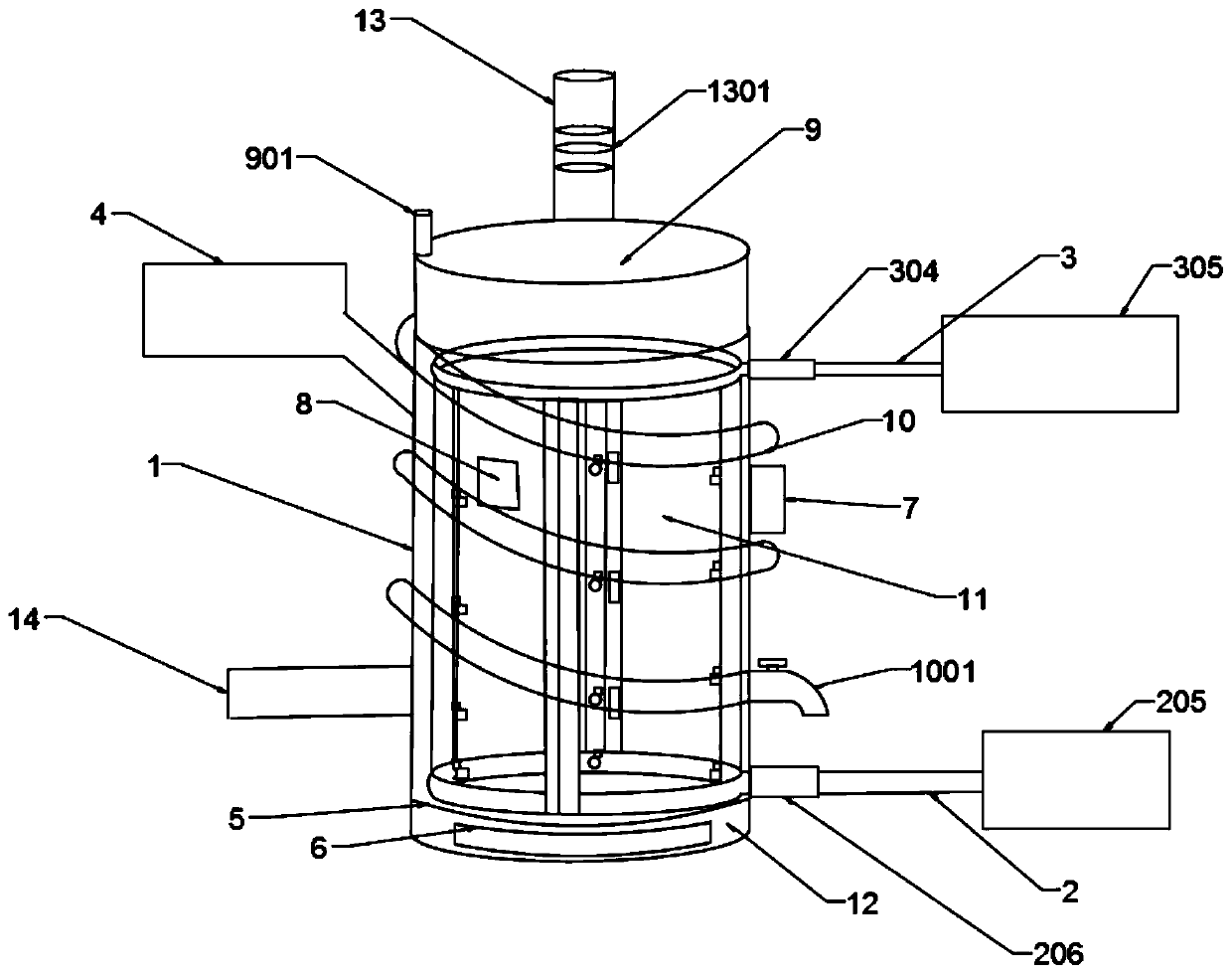

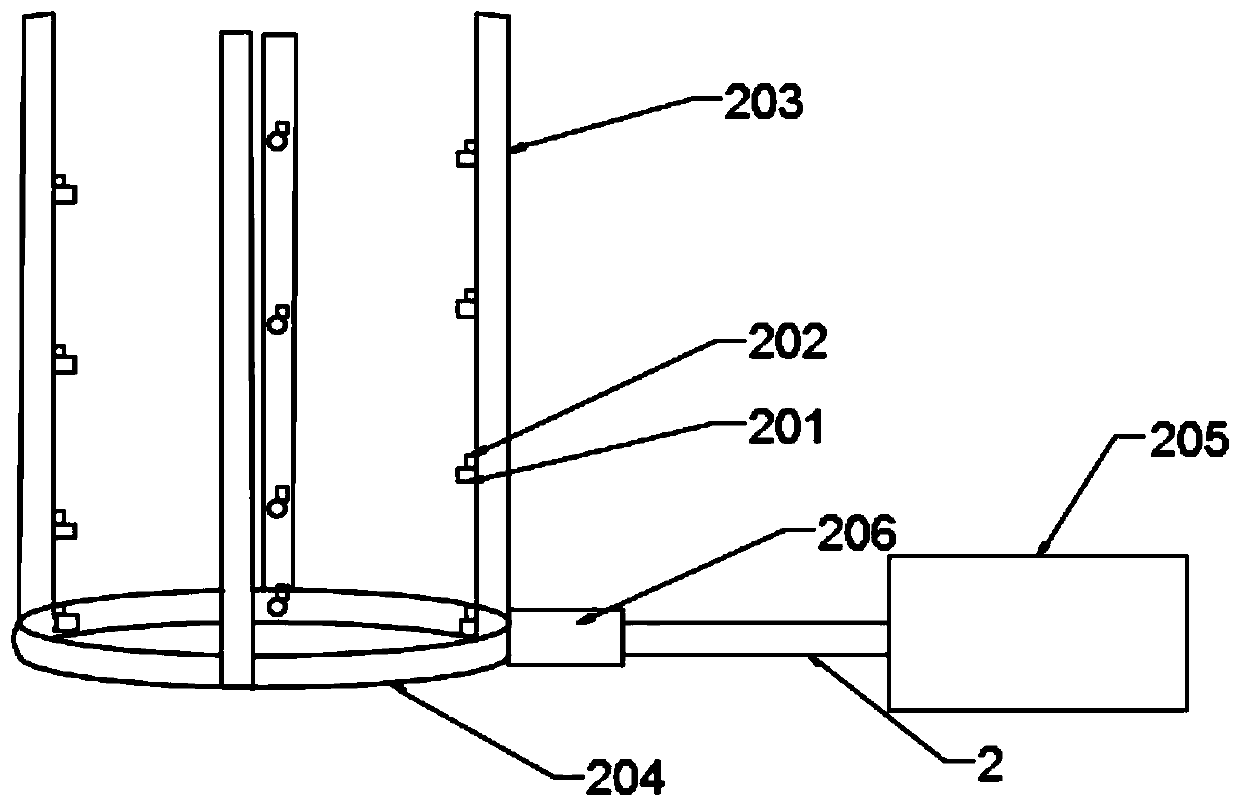

Small-grain-diameter lignite gasification device based on vacuum thermal decomposition and gasification method thereof

ActiveCN105112103AHigh methane contentIncrease the calorific value of combustionGranular/pulverulent flues gasificationChemical reactionProcess engineering

The invention provides a small-grain-diameter lignite gasification device based on vacuum thermal decomposition and a gasification method thereof and relates to a lignite gasification device and method. The small-grain-diameter lignite gasification device based on the vacuum thermal decomposition and the gasification method aim at solving the problem that an existing lignite gasification device and method are low in lignite gasification efficiency, high in cost and complicated in production process, cause environmental pollution and enable the heat value of produced gas to be low. A boiler cylinder of the small-grain-diameter lignite gasification device is installed in a reactor, a fully-sealed cover is installed at the upper end of a top cover of the reactor in a sealed mode, the upper end of the fully-sealed cover is connected with a charging-metering device, a first sensor and a second sensor are installed on the fully-sealed cover, a rotary ash removal pan is installed inside the reactor, a screw feeder is installed at the lower end of the reactor, and a combustor is inserted into the rotary ash removal pan. The gasification method comprises the steps of 1 enabling the inside of the reactor to be in a negative-pressure vacuum state, 2 igniting bottom-layer lignite, 3 adjusting the temperature and pressure of the inside of the reactor, 4 adding steam into the reactor to produce chemical reaction and 5 injecting oxyhydrogen gas into the reactor. The small-grain-diameter lignite gasification device based on the vacuum thermal decomposition and the gasification method are used for lignite gasification.

Owner:王晓峰 +1

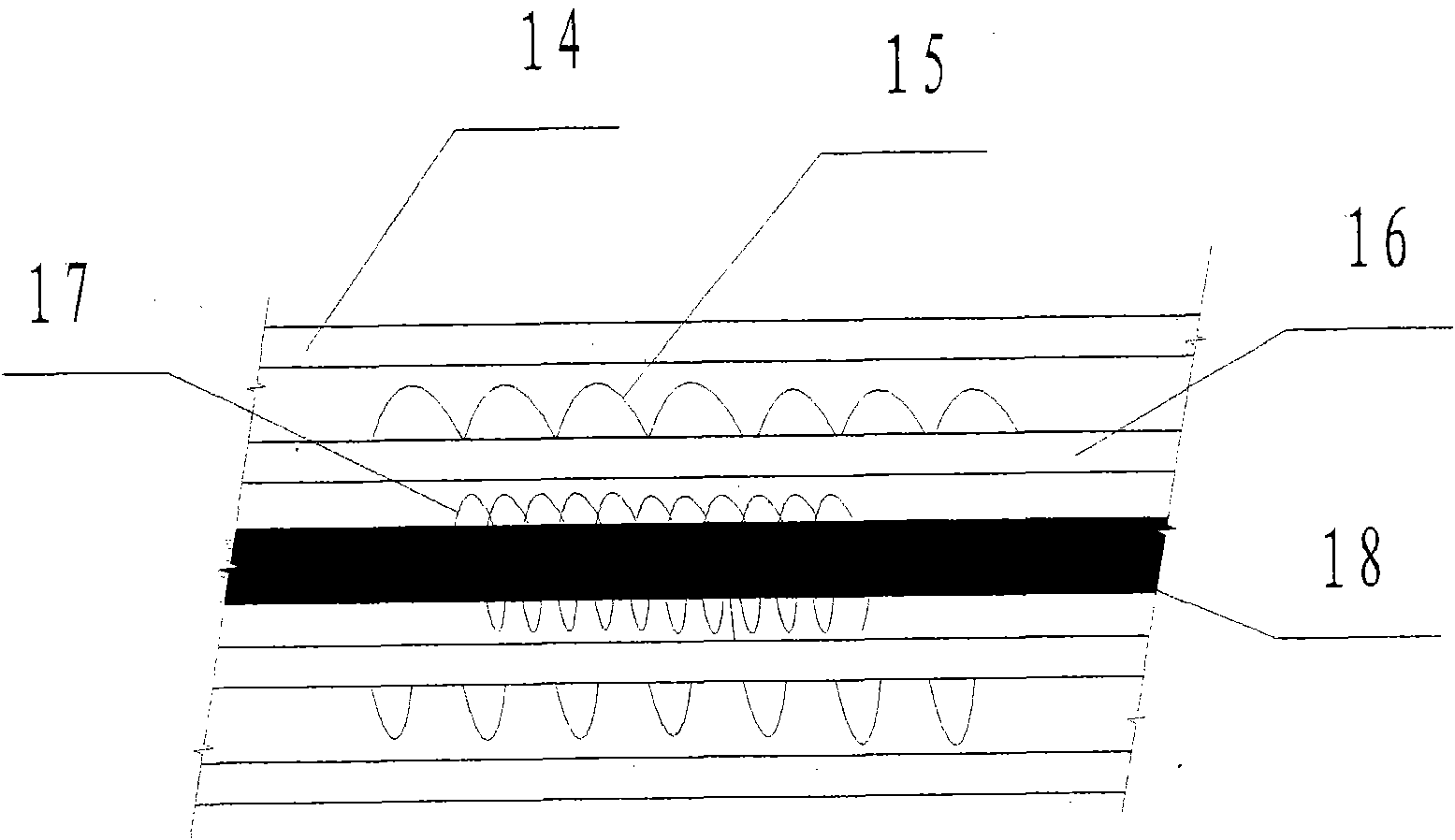

Rubbish pyrolysis smokeless furnace

InactiveCN106949481ASolve unsolvable problemsSatisfied with the effectIncinerator apparatusInsulation layerHydrogen

The invention discloses a rubbish pyrolysis smokeless furnace. The rubbish pyrolysis smokeless furnace comprises a furnace body and a rubbish conveyor. The rubbish conveyor is arranged beside the furnace body, a dampness discharging pipe is arranged beside the furnace body, the furnace body wall is provided with a water cavity, and a heat insulation layer is arranged on the outer surface of the furnace body. An S-shaped rubbish channel from top to bottom is arranged in the furnace body. A smoke channel is formed by a cavity between the two sides of the rubbish channel and the inner wall of the furnace body. Heat conduction oil heat collection pipes are arranged in the smoke channels. A pyrolysis chamber is arranged at the lower end of the rubbish channel, and a draught fan port is arranged on the part, beside of the smoke channel, of the furnace body wall. According to the rubbish pyrolysis smokeless furnace, strong wind pyrolysis is carried out, auxiliary fuels are not needed, energy conservation is remarkable, pyrolysis is sufficient, carbon monoxide, hydrogen, water gas, coal tar and other harmful gases and hazardous substances generated during combustion are completely burned and utilized and turned into benefits, no smoke is generated, the environmental-friendly effect is obvious, resources are saved, and the environment is protected.

Owner:梁长安

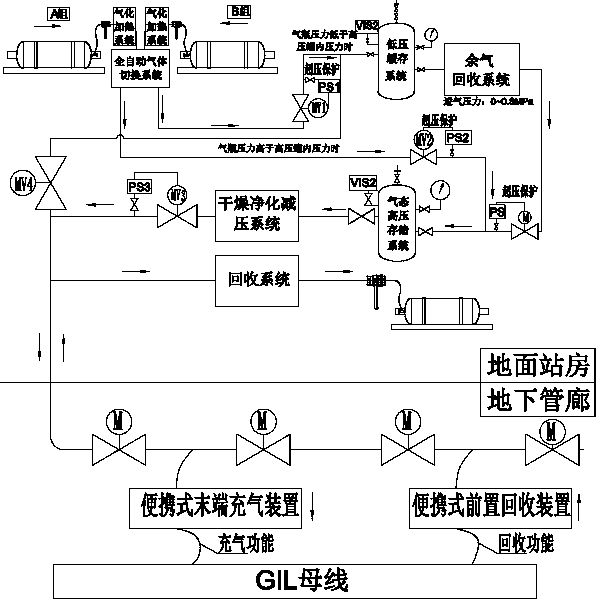

Ultrahigh-purity SF6 pipe gas transmission system

PendingCN111089228AAvoid cross assignmentShorten filling timeVessel mounting detailsGas handling/storage effectsSulfur hexafluorideGas cylinder

The invention discloses a ultrahigh-purity SF6 pipe gas transmission system. The system is characterized by comprising an automatic safety monitoring system, a gas supply station building, an intermediate station storage system and a gas charging system; the gas supply station building, the intermediate station storage system and the gas charging system are serially connected in sequence for communication; and the automatic safety monitoring system is electrically connected with the gas supply station building, the intermediate station storage system and the gas charging system. The device takes out liquid-state sulfur hexafluoride from a steel cylinder, and realizes gasification of sulfur hexafluoride in equipment to achieve high gasification speed and high heat exchange efficiency. The gas cylinder has no need to be transported in a pipe rack to prevent mutual crossing operations with GIL bus transportation and installation machines; through actual operation demonstration, the systemachieves the gas charging efficiency being 12 times of a traditional single-cylinder gas charging mode, greatly shortens the gas charging time, and effectively solves the construction period bottleneck problem caused by the traditional gas charging mode; and the sulfur hexafluoride gas cylinder is management on the grounded in a centralized mode to effectively control the safety risk.

Owner:JIANGSU POWER TRANSMISSION & DISTRIBUTION CO LTD +2

Steam oven equipment used for cake and pastry food processing and method used for steam oven equipment

ActiveCN109028170AAvoid condensationTurn down the heating powerLiquid fuel feeder/distributionDomestic stoves or rangesCombustionAlcohol

The invention discloses steam oven equipment used for cake and pastry food processing. The steam oven equipment comprises an alcohol steam generator and an oven, wherein an alcohol steam exhaust end of the alcohol steam generator is connected with an alcohol steam lead-in end of the oven through a steam guide tube; and a flow control valve is further arranged in the steam guide tube. The steam oven equipment is simple in structure; and a plurality of rows of alcohol steam emerging holes and a plurality of rows of combustion-supporting air emerging holes are alternatively distributed on the upper surface of a fire spraying stove, so that alcohol steam emerged from each row of alcohol steam emerging holes is quickly mixed with combustion-supporting air emerged from each row of combustion-supporting air emerging holes, and therefore, lasting combustion flame is generated above the fire spraying stove under ignition of an ignition device.

Owner:肇庆市华发食品有限公司

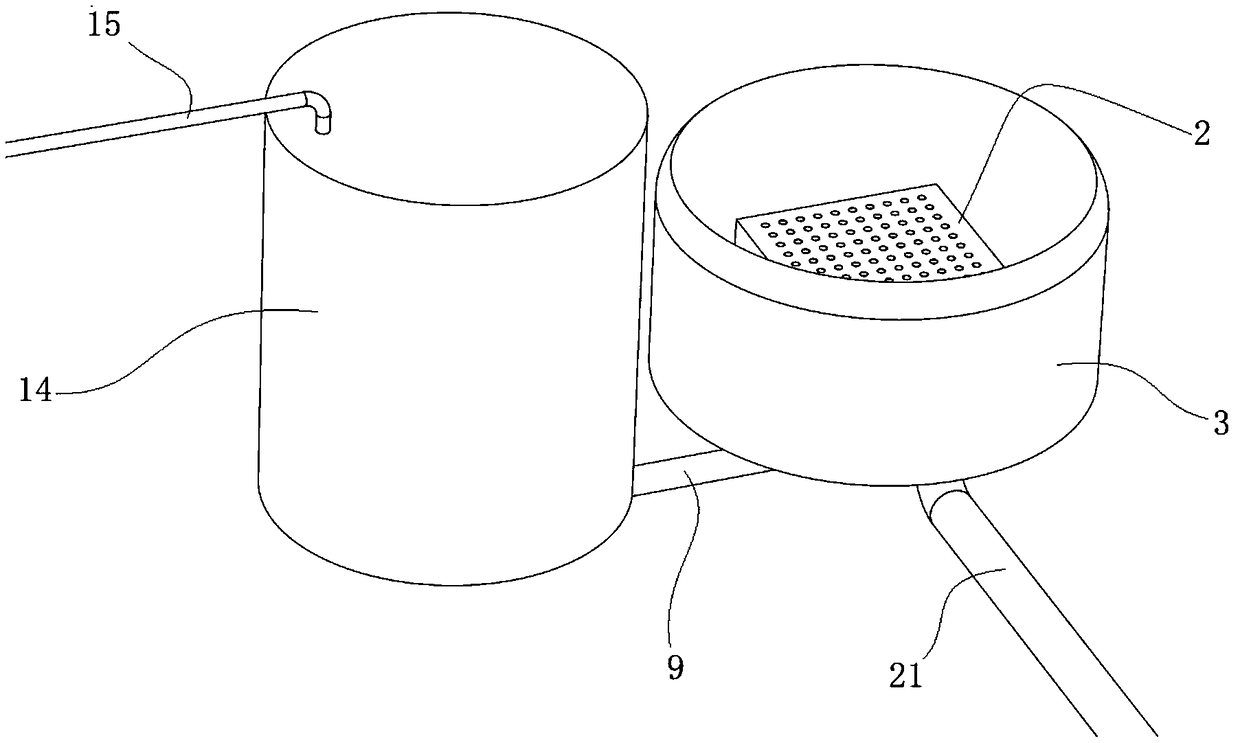

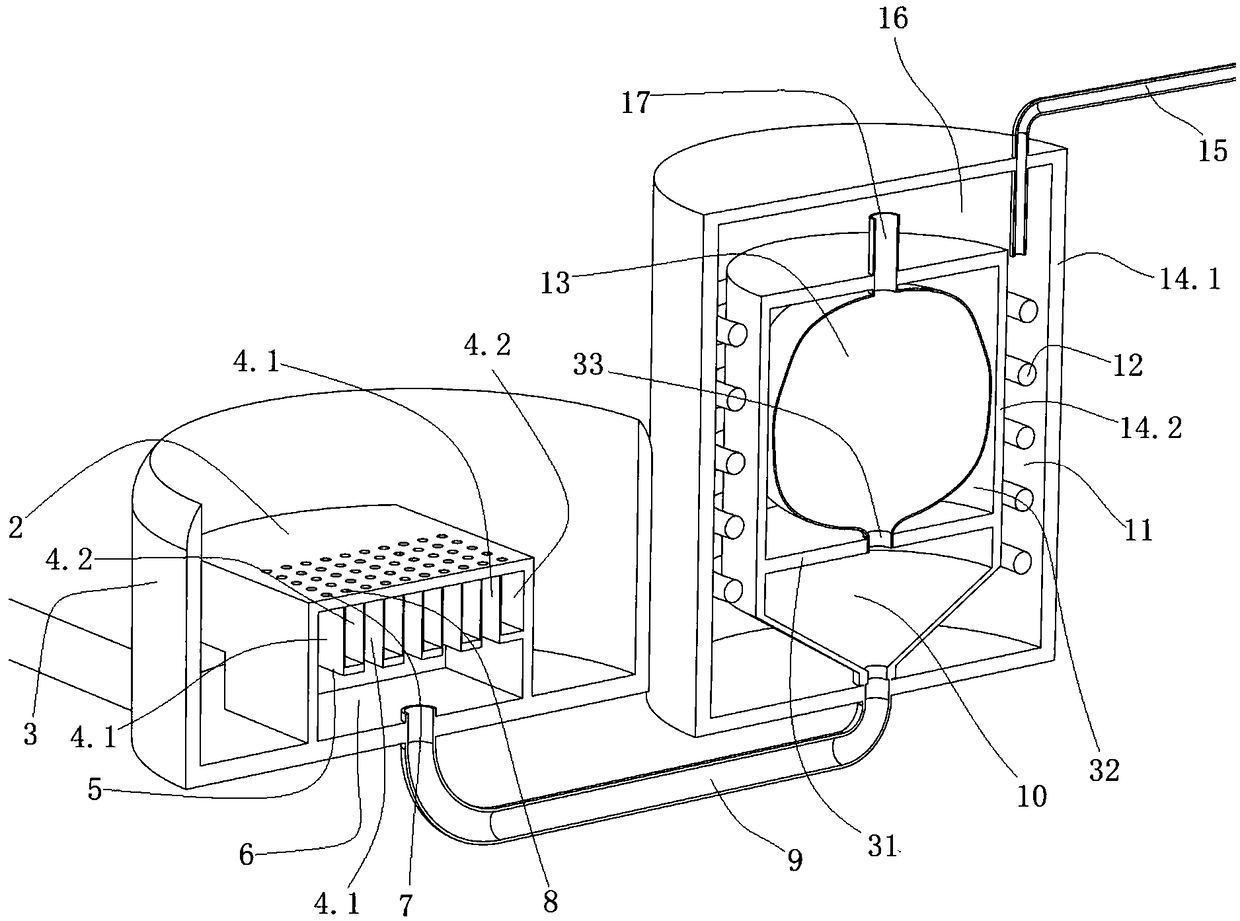

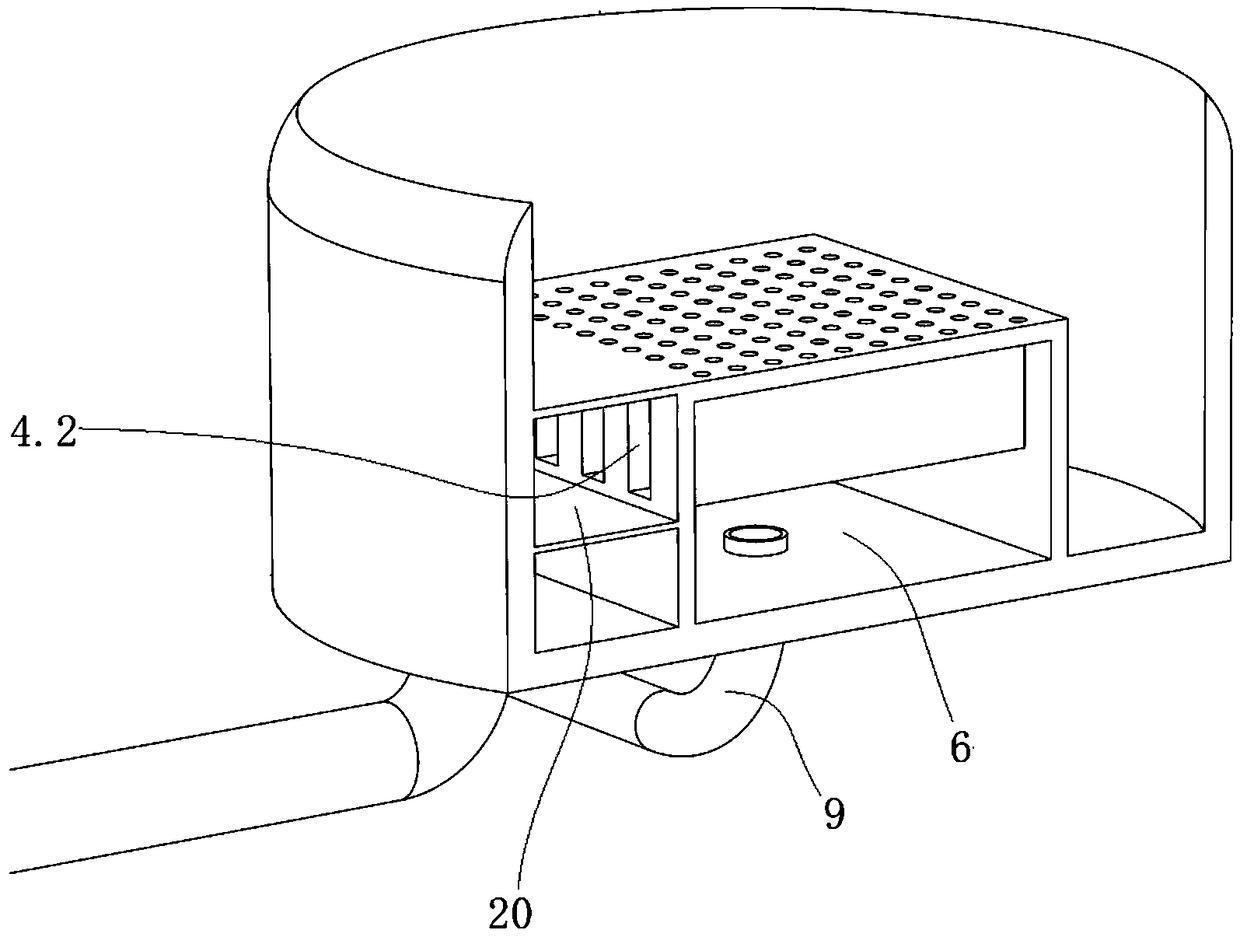

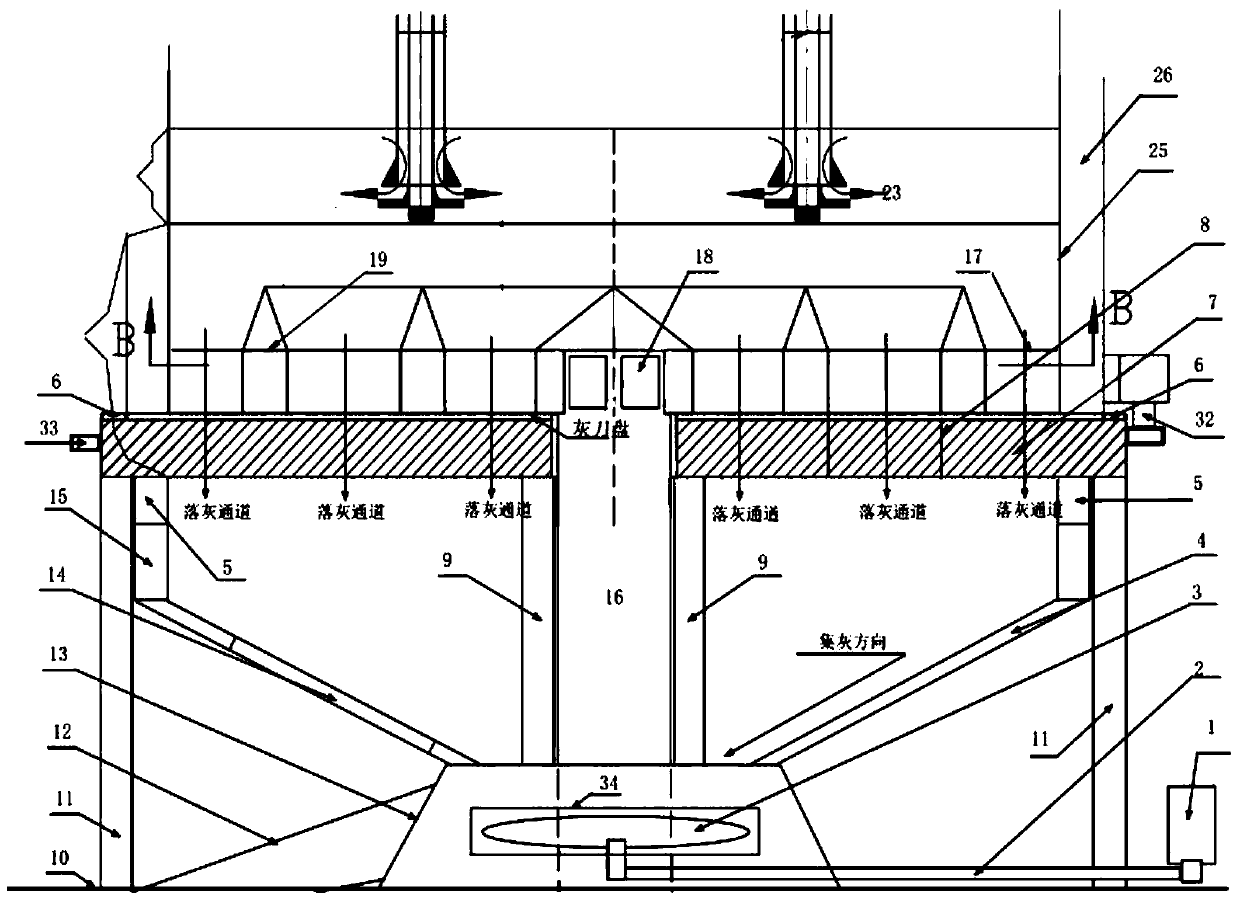

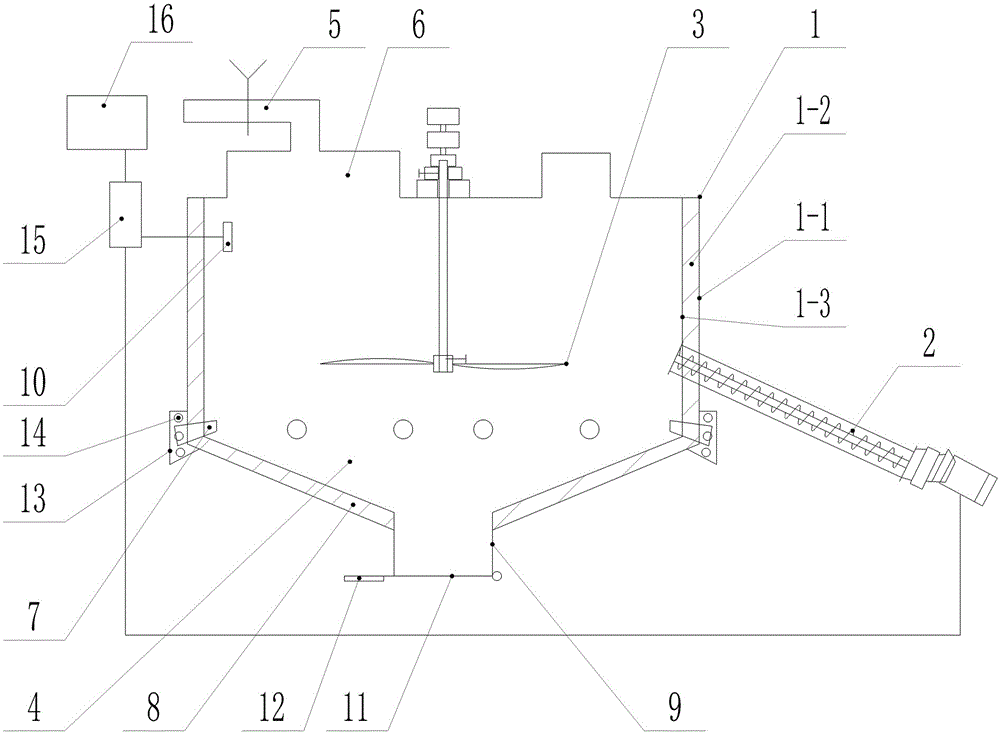

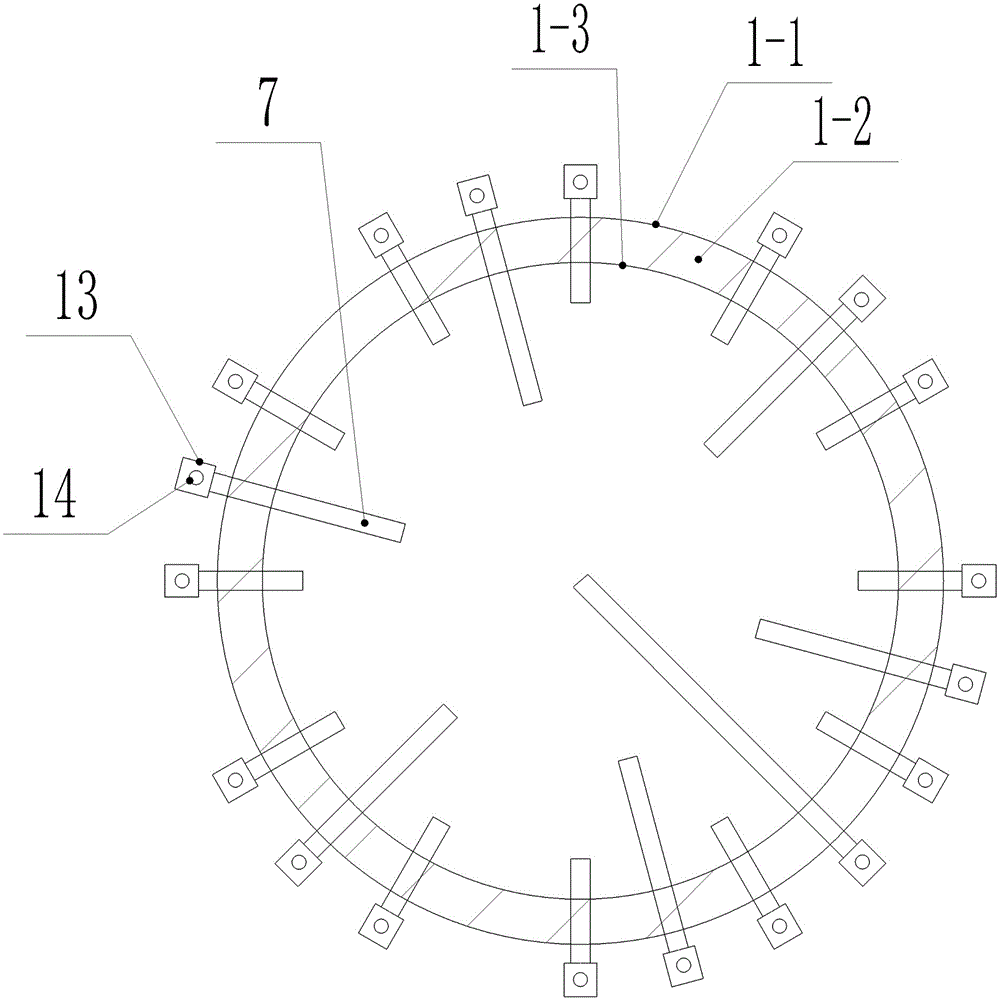

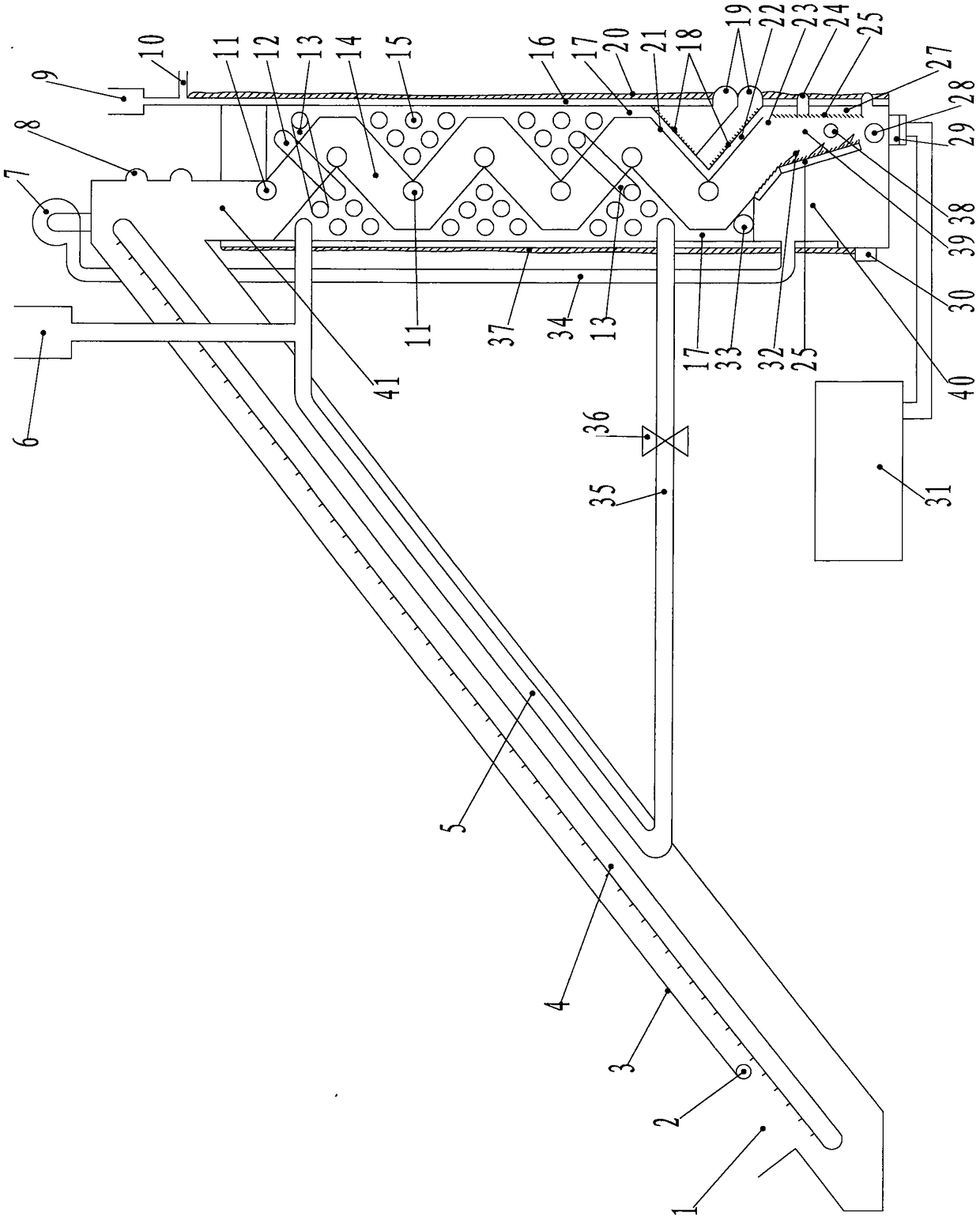

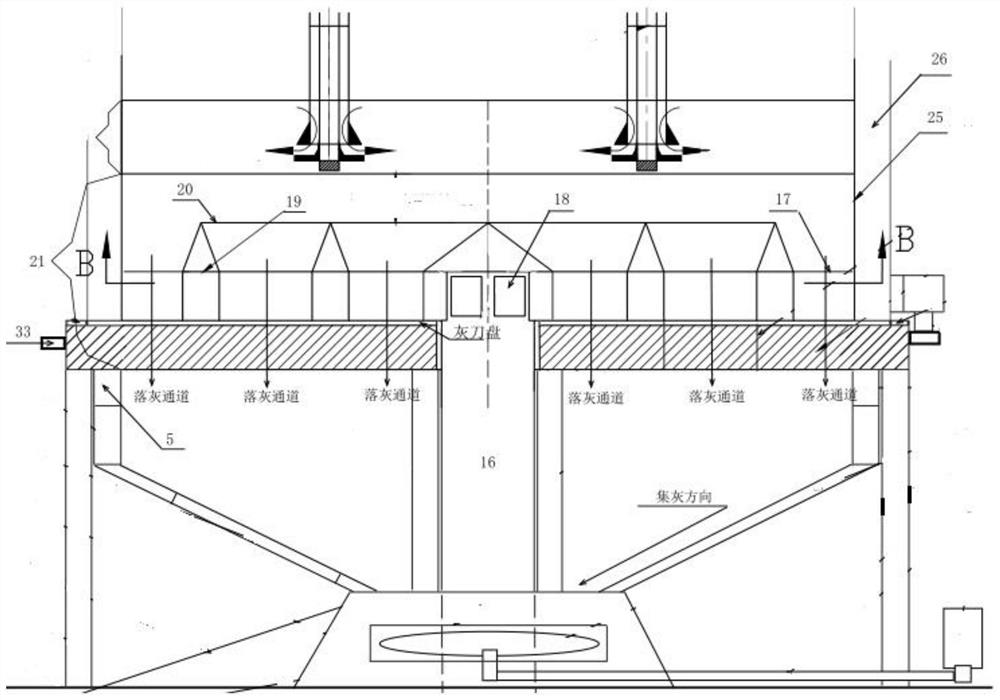

Ash discharge system of biomass gasification furnace

ActiveCN111253982AIncrease effective volumeReduce volumeGasification processes detailsCombustible gas productionCombustionSlag

The invention discloses an ash discharge system of a biomass gasification furnace, which sequentially comprises an ash channel system, an ash falling system, an ash collecting system and an ash outputsystem from top to bottom. The ash channel system is arranged in a furnace body, and the ash falling system, the ash collecting system and the ash output system are arranged at the bottom of the furnace body. The ash channel system is a dish-shaped grate. The ash falling system is arranged on the lower side of the ash channel system and can rotate to open and block the ash falling channel to enable ash to fall. The ash collecting system is arranged below the ash falling system, and the ash output system is connected with the ash collecting system. The dish-shaped grate is uniform in air outlet, the number of ash falling channels is increased, the ash falling section is increased, ash falling is more uniform, collapse of a fixed carbon combustion layer is more uniform, the probability thatthe grate bar body is burnt out by non-uniformly collapsed scorching carbon is reduced, the ignition loss rate is reduced, and the physical and chemical properties of ash slag are more stable. The combustion speed and the gasification speed of the RDF can be effectively increased, so that the unit consumption of the biomass waste is increased.

Owner:刘跃伟

Superhigh pressure mecury lamp

InactiveCN1332469AImprove balanceHigh Luminous EfficiencyGas discharge lamp detailsLight sourceEngineering

The present invention belongs to the field of discharge lamp, and especially relates to superhigh pressure mercury lamp as projecting light source and in LCD display, which has two oppositely positioned electrodes separated by 0.8-1.8 mm, and inside the lamp, is filled mixture of mercury and halide in the amount of 0.08-0.25 mg / cu cm and in the weight ratio of 10-30. The power load in the inner wall of the lamp is 120-250 W / sq cm.

Owner:丹东新亚照明电器有限公司

Negative-pressure low-position automatic-charging gasification furnace

InactiveCN105018147AAdapt to a wide rangeSimple structureCombustible gas productionCombustion chamberEngineering

Owner:秦家运

Novel dry ice cleaning base and cleaning method thereof

The invention discloses a novel dry ice cleaning base and a cleaning method thereof. The novel dry ice cleaning base comprises a vacuum cavity base, a vacuum base and a supporting base set, wherein the vacuum cavity base is provided with a vacuum cavity communicating with a vacuum section system; the vacuum base is in seal connection with the vacuum cavity; a plurality of bosses arranged at intervals are arranged on the side, away from the vacuum cavity, of the vacuum base in a protruding mode; the bosses are provided with through grooves communicating with the vacuum cavity in the extending directions of the bosses; the supporting base set comprises a plurality of supporting bases which can be replaceably mounted to the vacuum base; the supporting bases are provided with hollow pylons arranged on the outer sides of the bosses in a sleeving mode; the size of the hollow pylons in the axial direction of the pylons is greater than that of the bosses; and the surfaces of the sides, away from the vacuum base, of the hollow pylons are provided with supporting faces for supporting products. Rapid dismounting and mounting of an original supporting base are achieved, and the machine replacement time is shortened, and the whole steps are simple and easy to operate, labor input in the replacement process is reduced, and the machine utilization rate and production efficiency are improved.

Owner:HUANWEI ELECTRONICS SHANGHAI CO LTD

A kind of garbage pyrolysis smokeless furnace

InactiveCN106949481BSolve unsolvable problemsSatisfied with the effectIncinerator apparatusHydrogenInsulation layer

The invention discloses a rubbish pyrolysis smokeless furnace. The rubbish pyrolysis smokeless furnace comprises a furnace body and a rubbish conveyor. The rubbish conveyor is arranged beside the furnace body, a dampness discharging pipe is arranged beside the furnace body, the furnace body wall is provided with a water cavity, and a heat insulation layer is arranged on the outer surface of the furnace body. An S-shaped rubbish channel from top to bottom is arranged in the furnace body. A smoke channel is formed by a cavity between the two sides of the rubbish channel and the inner wall of the furnace body. Heat conduction oil heat collection pipes are arranged in the smoke channels. A pyrolysis chamber is arranged at the lower end of the rubbish channel, and a draught fan port is arranged on the part, beside of the smoke channel, of the furnace body wall. According to the rubbish pyrolysis smokeless furnace, strong wind pyrolysis is carried out, auxiliary fuels are not needed, energy conservation is remarkable, pyrolysis is sufficient, carbon monoxide, hydrogen, water gas, coal tar and other harmful gases and hazardous substances generated during combustion are completely burned and utilized and turned into benefits, no smoke is generated, the environmental-friendly effect is obvious, resources are saved, and the environment is protected.

Owner:梁长安

A biomass gasifier grate system

ActiveCN111253981BIncrease effective volumeReduce volumeGasification processes detailsCombustible gas productionThermodynamicsCombustion

Owner:刘跃伟

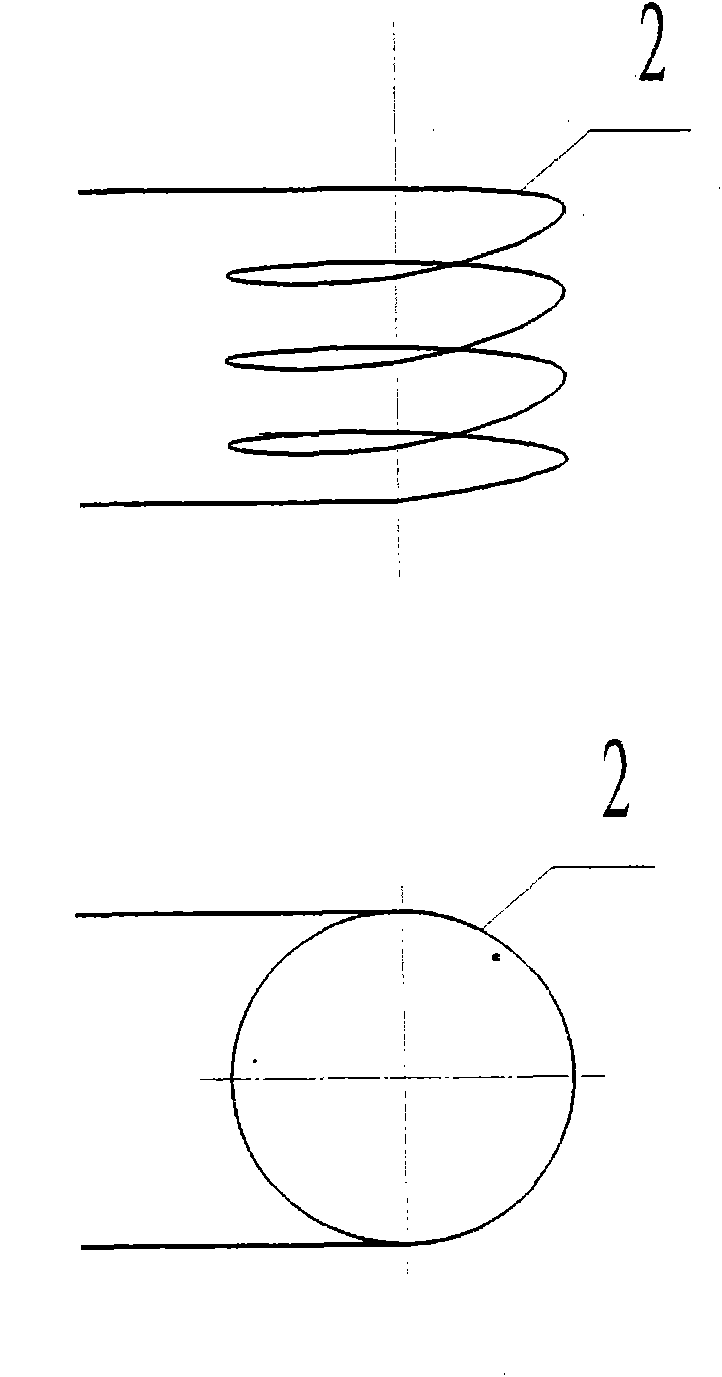

Liquefied natural gas gasifier fixedly connected with inner heat exchange fins and retractable outer heat exchange fins

InactiveCN105257979AFully vaporizedMeet the needs of different gas consumptionPressure vesselsContainer discharging from pressure vesselsEngineeringLiquefied natural gas

The invention relates to a gasifier, in particular to a liquefied natural gas gasifier fixedly connected with inner heat exchange fins and retractable outer heat exchange fins. The liquefied natural gas gasifier comprises a gasification pipe and a speed-adjustable delivery pump; the gasification pipe comprises multiple gasification sections and bent sections; the gasification sections and the bent sections are arranged at intervals to form a returning structure; the multiple outer heat exchange fins are arranged on the outer surfaces of the gasification sections; the multiple inner heat exchange fins are arranged inside the gasification sections; the inner heat exchange fins and the gasification sections are connected into a whole; the outer heat exchange fins comprise at least two heat dissipation plates; the adjacent heat dissipation plates are retractably connected together in the radial direction of the gasification sections in a sleeving mode; only one of the heat dissipation plates is welded to the gasification sections together. The liquefied natural gas gasifier has the advantages that cold can be rapidly dissipated when the liquefied natural gas flow passes through the gasification sections, and gas delivery speed can be adjusted as required. The problems of slow cold dissipation and constant gas delivery speed of existing liquefied natural gas gasifiers are solved.

Owner:ZHEJIANG OCEAN UNIV

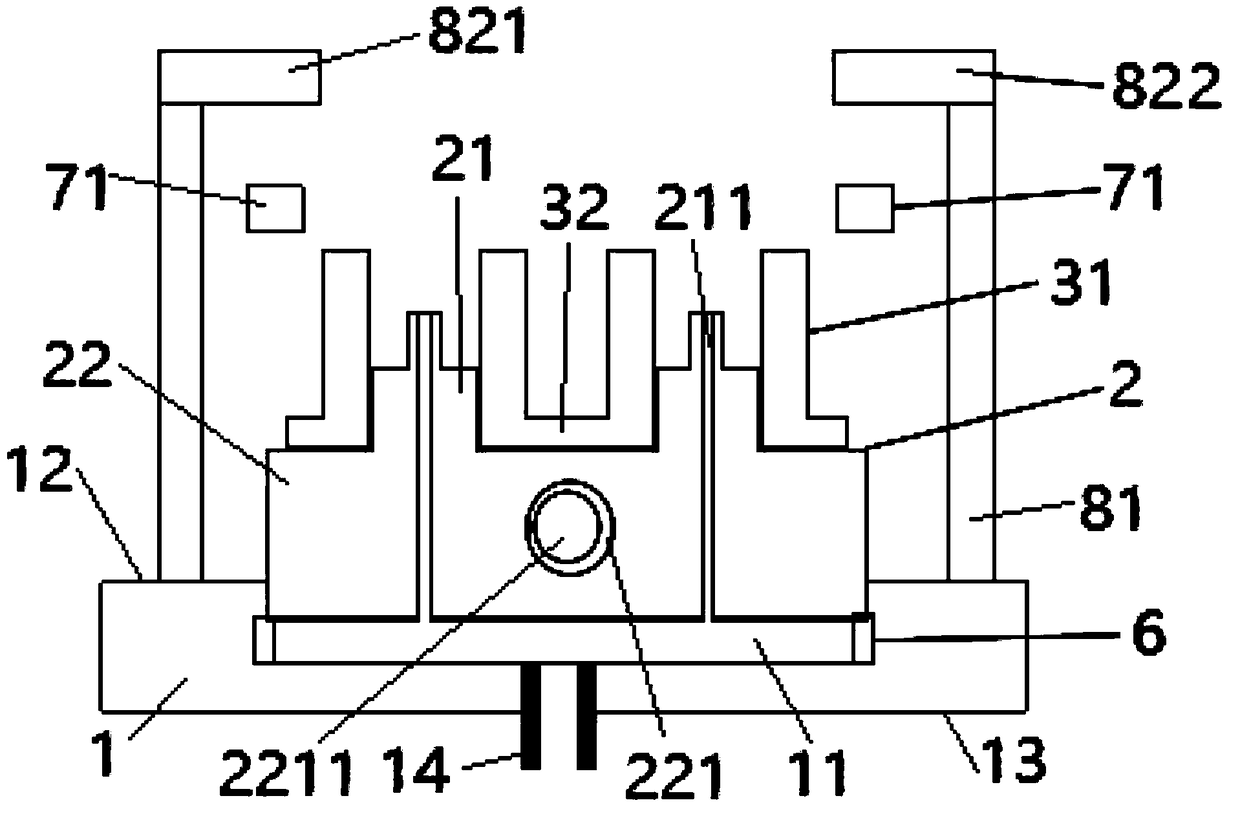

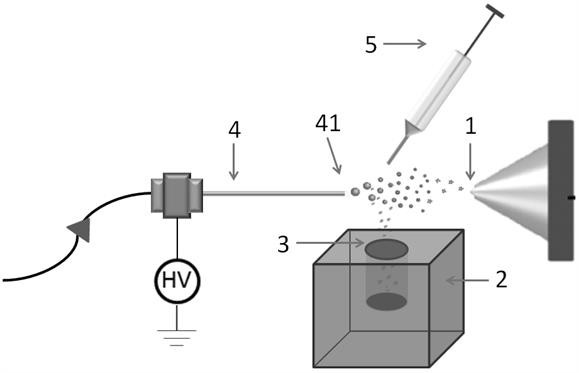

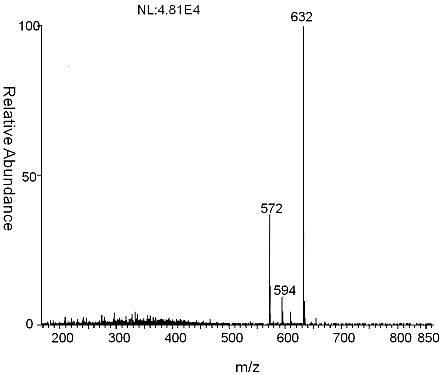

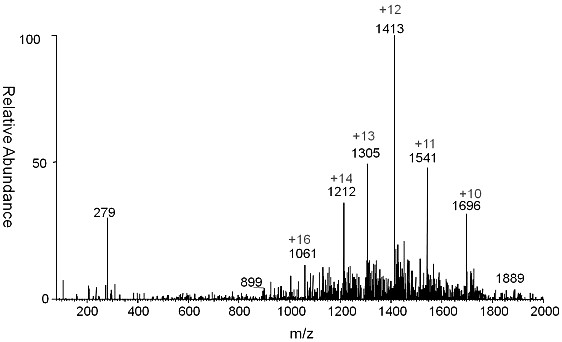

A rapid evaporation electrospray ion source and analysis method

ActiveCN109632454BFast gasificationVaporization fastPreparing sample for investigationMaterial analysis by electric/magnetic meansESI mass spectrometryElectro spray

A rapid evaporation electrospray ion source and an analysis method, the invention relates to a rapid evaporation electrospray ion source and an analysis method, and belongs to the technical field of atmospheric pressure mass spectrometry ionization. The ionization source is composed of four parts: electrospray generating unit, heating unit, vaporization chamber and sampling unit. Put the gasification chamber into the heating unit and heat it to T B ‑T L The sample solution is dripped into the gasification chamber using the sampling unit; when the sample vapor rises to the entrance of the mass spectrometer, the sample vapor is converted into sample ions using the electrospray ionization unit, and these ions are then introduced into the mass spectrometer for detection. The operation is simple, no sample pretreatment is required, and high-throughput online detection can be realized.

Owner:HEILONGJIANG UNIV

Intelligent gasification furnace and control method thereof

InactiveCN103343987BWith automatic oil controlSave fuelDomestic stoves or rangesLighting and heating apparatusCombustionSolenoid valve

Owner:唐川盛

Oxygen supply flaming apparatus of biomass gasification furnace

PendingCN110724566AEvenly distributedBurn fullyChemical industryGasification processes detailsCombustion chamberEnvironmental engineering

The invention discloses an oxygen supply flaming apparatus of a biomass gasification furnace. The apparatus comprises a furnace body, a water tank is arranged at the top of the furnace body, a combustion chamber is arranged in the middle of the furnace body, an ash storage chamber is arranged at the bottom of the furnace body, a layer of filter plate is arranged between the combustion chamber andthe ash storage chamber, a flaming device is mounted in the combustion chamber and placed on a filter plate, and an oxygen supply device is arranged in the combustion chamber and matched with the flaming device; a feeding device and an exhaust port are arranged at the left side of the furnace body, a fan, an oil tank and an ignition device are arranged at the right side of the furnace body, a chimney is arranged at the rear side of the furnace body, and a heat-conducting water pipe is wound on the furnace body. The oxygen supply device and the flaming device are arranged to make a fuel fully combusted in the furnace body, so the heat production efficiency is improved, and the gasification speed is increased; and the water tank, the heat conduction water pipe and the chimney are arranged tomaximize energy utilization, save resources and protect the environment.

Owner:合肥鸿叶紫新能源有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com