Dry distillation gasification device and rapid pulverized coal dry distillation method

A gasification device and dry distillation technology, which is used in the gasification of granular/powdered fuel, the manufacture of combustible gas, and the petroleum industry. It can solve the problems of low production efficiency of pulverized coal gasification device, and achieve easy automatic control and stable operation , the effect of fast gasification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the invention is capable of various changes in different embodiments without departing from the scope of the invention, and that the description and illustrations therein are illustrative in nature and not limiting. this invention.

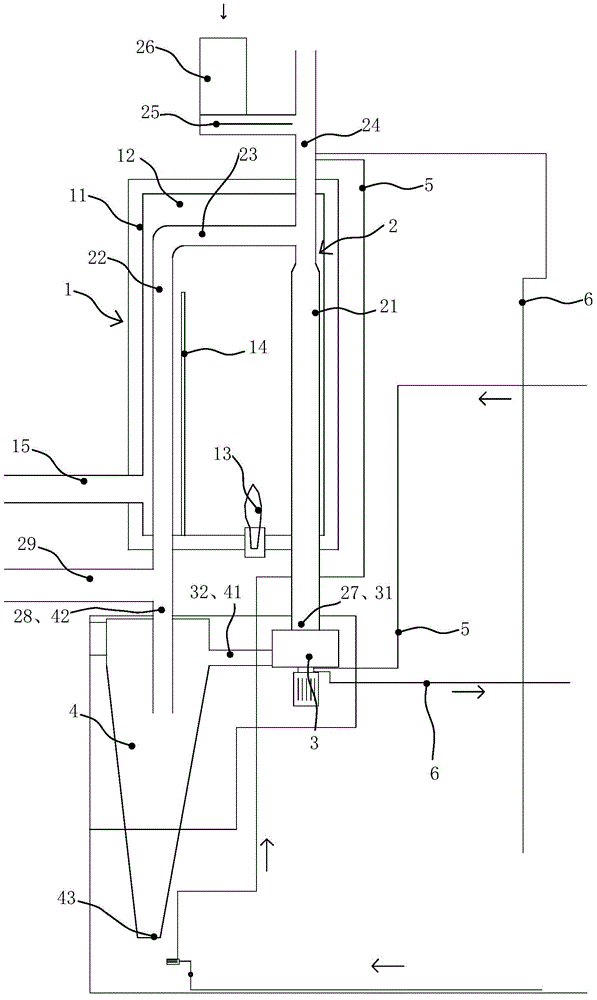

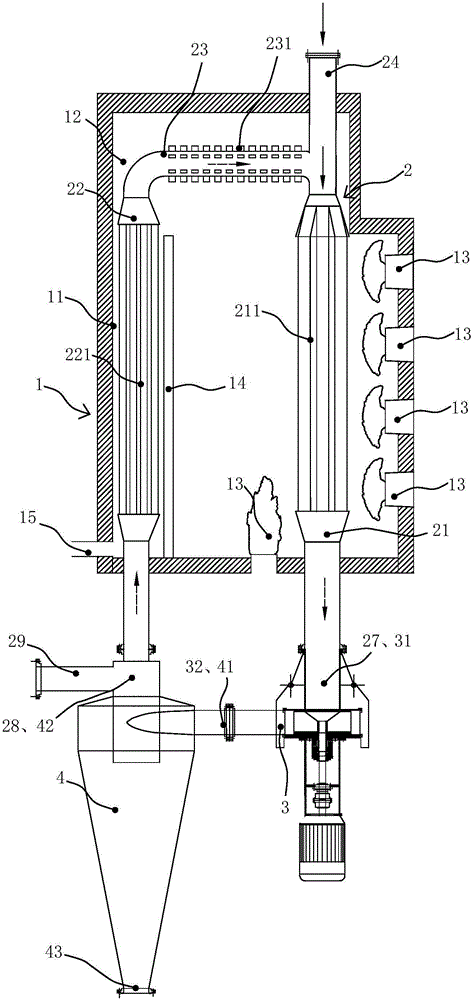

[0046] An embodiment of the present invention provides a dry distillation gasification device, referring to figure 1 , figure 2 As shown, it includes a gasifier 1 , a gasification pipeline 2 , a fan 3 and a gas-solid separator 4 .

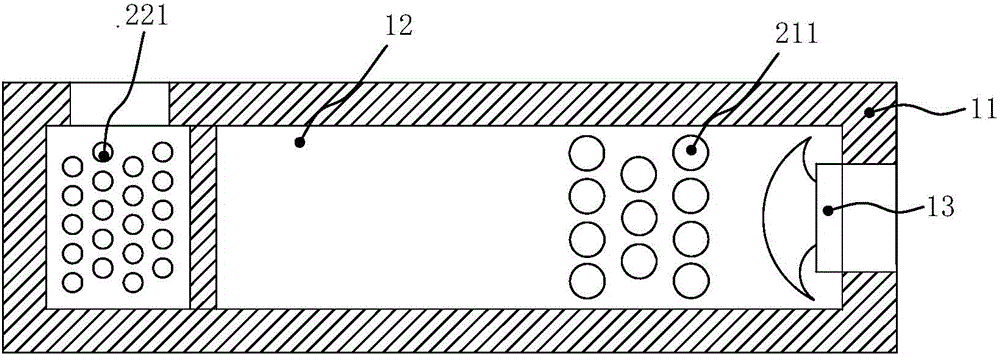

[0047] The gasification furnace 1 comprises a body of furnace 11 and a heating chamber 12 in the body of furnace 11. The body of furnace 11 can be made of a furnace wall and an insulating material. The heating chamber 12 has a heating device 13, which is used to heat the heating chamber 12 with the heating device 13 to provide The temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com