Superhigh pressure mecury lamp

A technology of ultra-high pressure and mercury lamps, which is applied in the direction of discharge lamps, gas discharge lamps, and parts of gas discharge lamps. Good color rendering and anti-splash effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

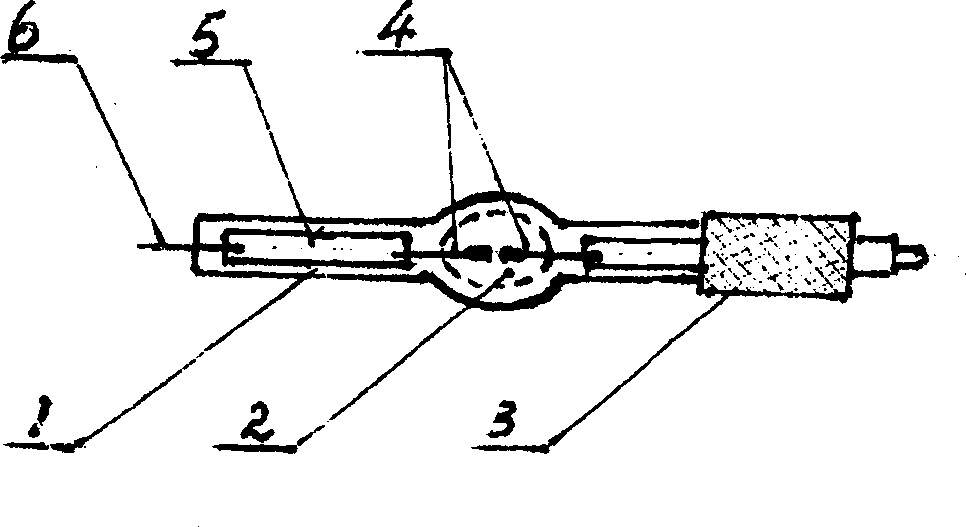

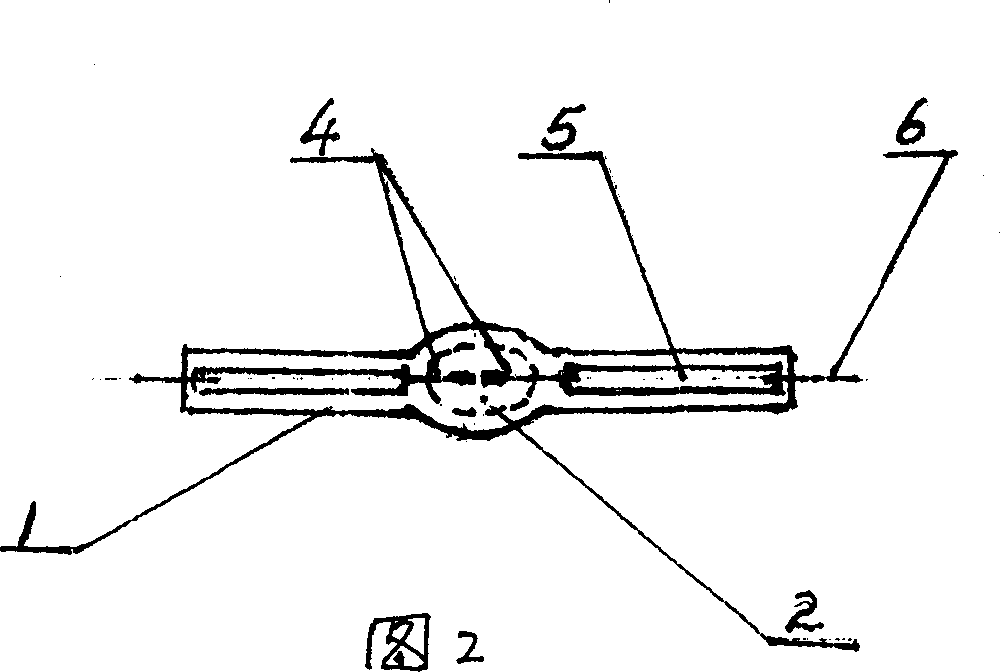

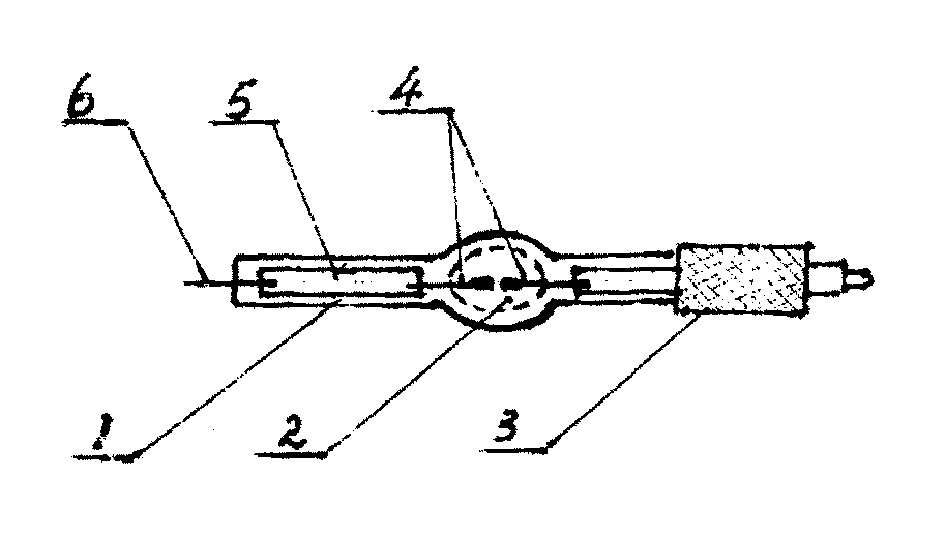

[0020] In the accompanying drawings, 1 is the lamp body, 2 is the lamp cavity, 3 is the lamp cap, 4 is the electrode, 5 is the molybdenum foil, and 6 is the outer lead.

[0021] The shell of the lamp body 1 is made of high-quality quartz glass, the hydroxyl group of the quartz glass is less than 1ppm, including 1ppm, and the volume of the lamp cavity is 113cm 3 , the electrode is made of high-quality pure tungsten, with a diameter of 0.45mm, and the electrode ring at the end is wound with a tungsten wire of φ0.15mm. The introduction amount of the mixture of mercury and halide in chamber 2 is 24 mg; the ratio (by mass ratio) of mercury to halide is 20:1, and the introduction amount of xenon gas is 5×10 5 Pa, the load power in the lamp cavity 2 is 1.33w / cm 2 .

[0022] In addition, the present invention also adopts that the distance between the two electrodes 4 is 1.0 mm and 1.7 mm, and the amount of the mixture of mercury and halide introduced into the lamp cavity 2 is 0.1 mg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com