Device and method for headspace solid phase microextraction capable of removing water

An extraction device and extraction technology, applied in the direction of solid solvent extraction, etc., can solve the problems of affecting the adsorption of the extraction head on the target compound, reducing the service life of the mass spectrometer detector, affecting the sensitivity and detection limit of the method, and reducing the detection limit of the method. The effect of simple and convenient process and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

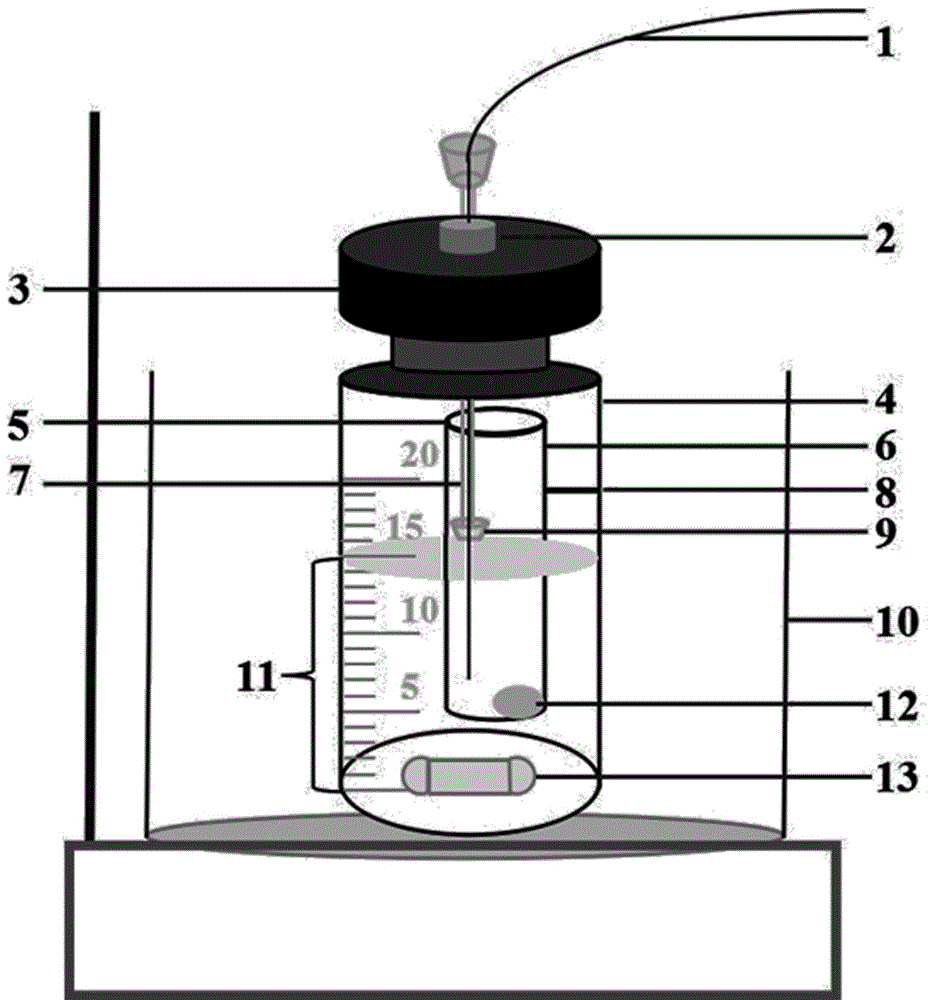

[0027] Such as figure 1 Shown, a kind of headspace solid-phase microextraction device and method that can remove water, described extraction device comprises material container 4, vapor container 6, heating type magnetic stirrer 10, needle 7, extraction fiber 1 and magnetic force stir bar 13; the material container 4 is an airtight container, the material container 4 is arranged on the heating type magnetic stirrer 10, and the material container 4 contains the material to be extracted 11 and the magnetic stirrer 13; the steam container 6 is sealed in the material container 4 Water vapor absorbent 12 is contained in the steam container 6, and one end of the steam container 6 is open, and a pierceable cork 2 is provided at the wall of the material container 4 facing the open end of the steam container 5; the needle 7 passes through the cork 2 to reach In the steam container 6, the extraction fiber 1 is provided with an extraction coating, and the extraction fiber 1 penetrates in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com