Patents

Literature

67results about How to "Conducive to follow-up reactions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

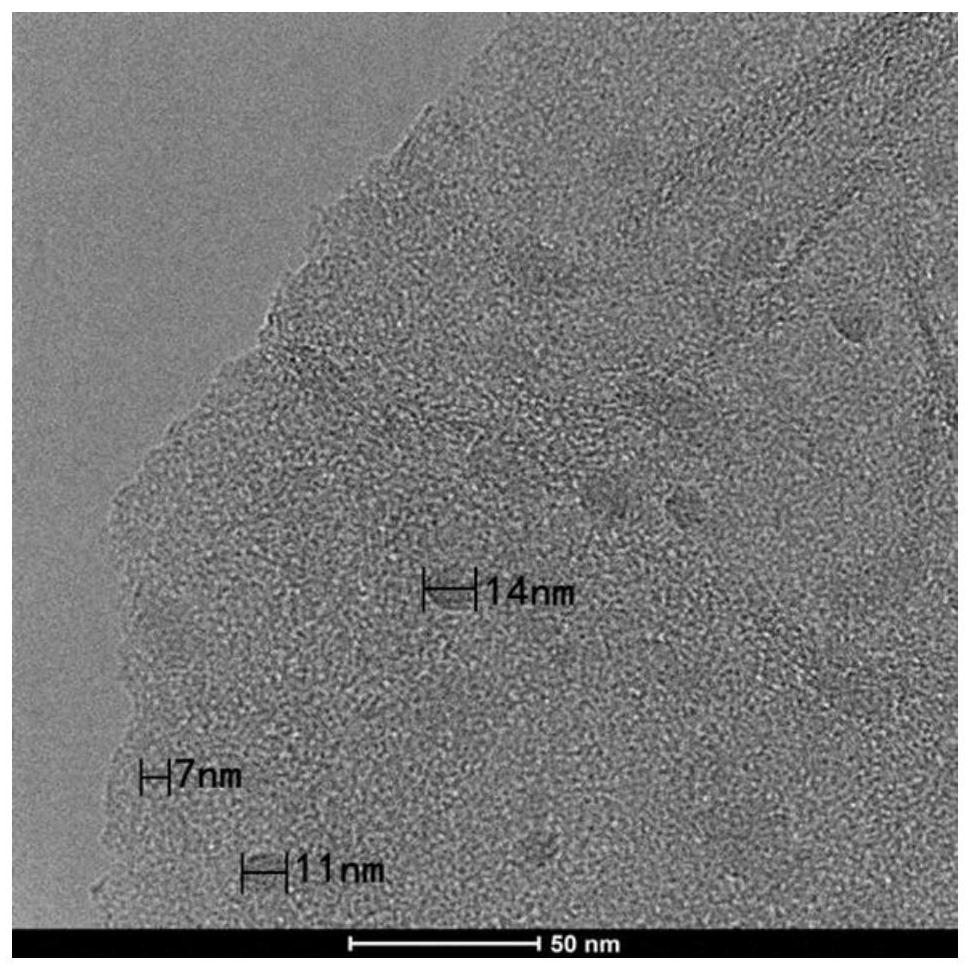

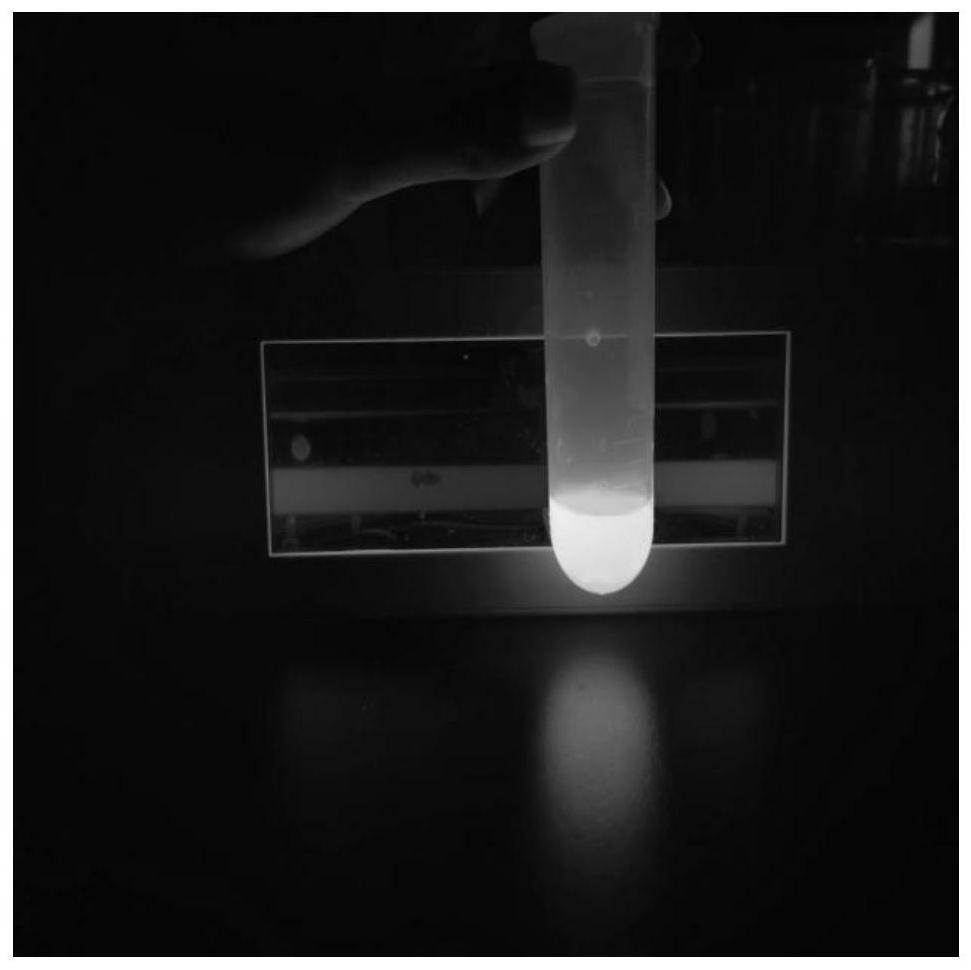

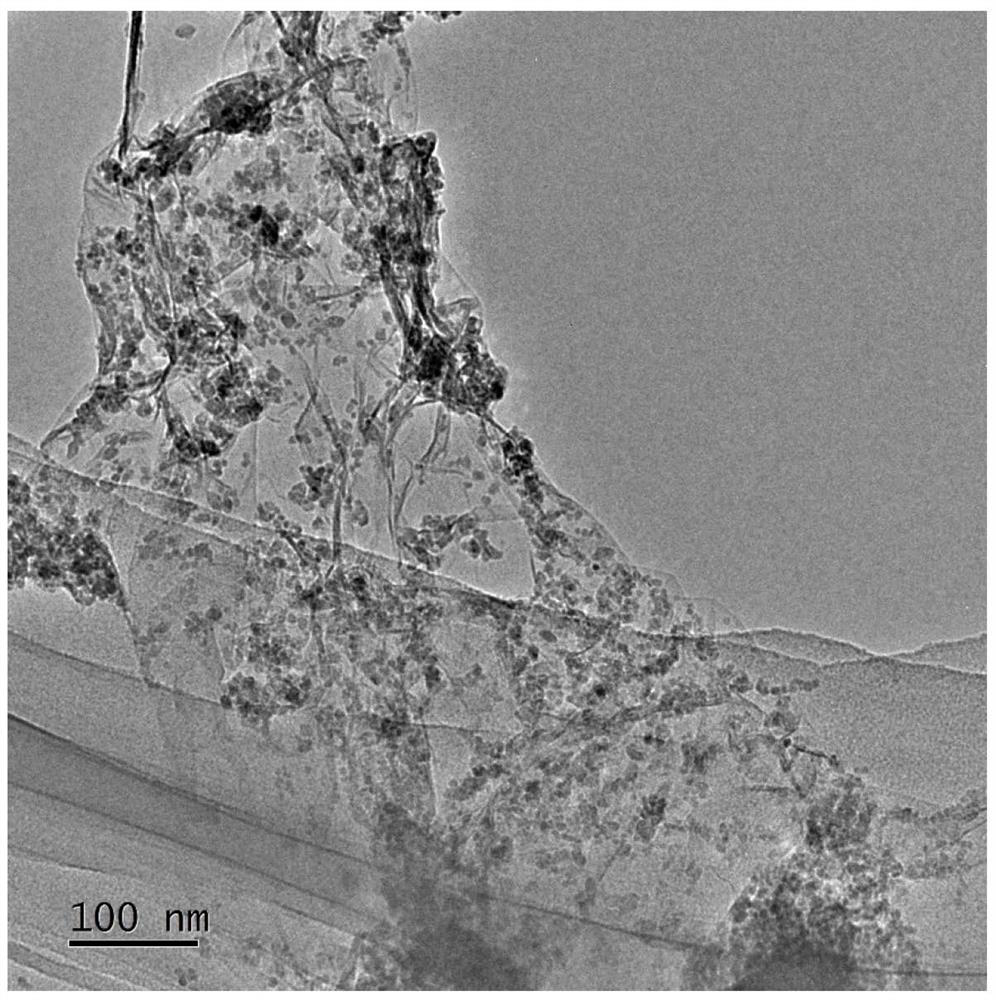

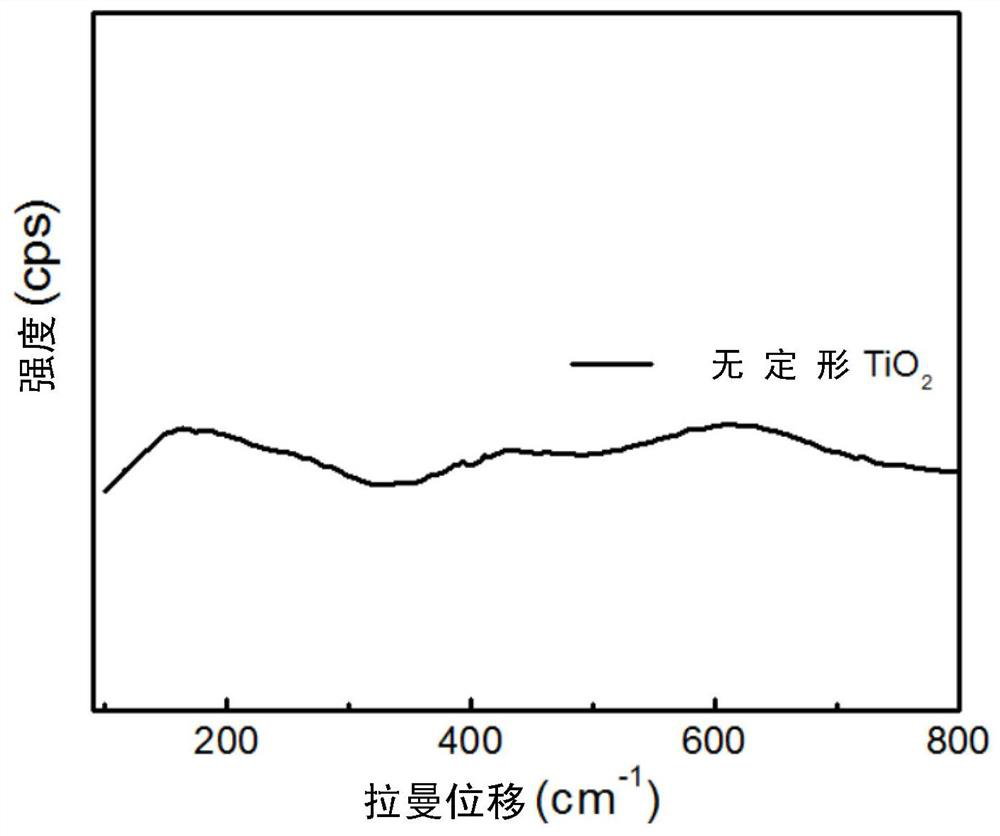

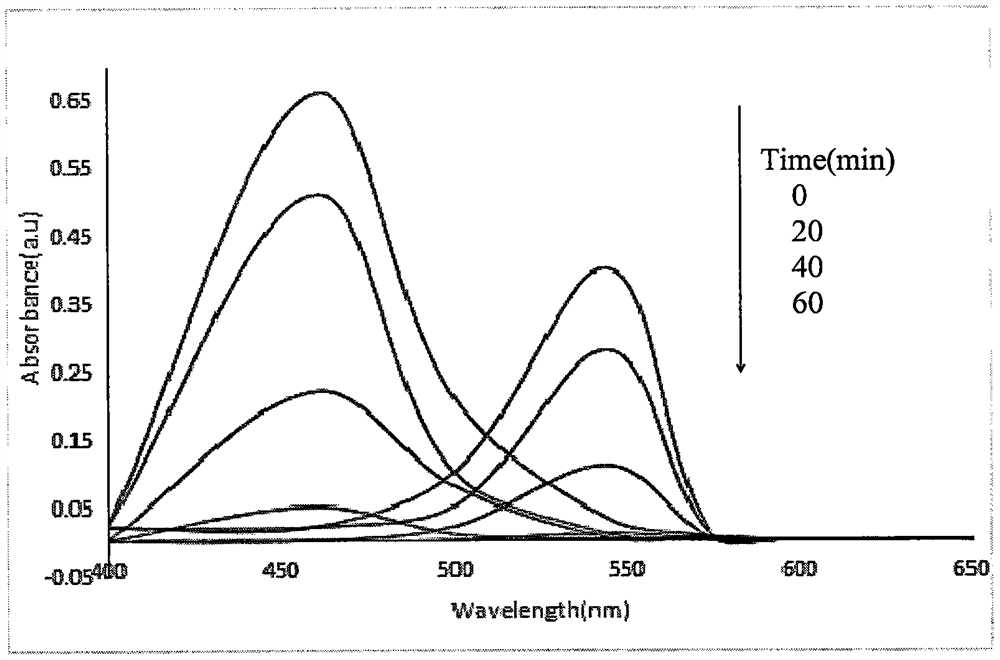

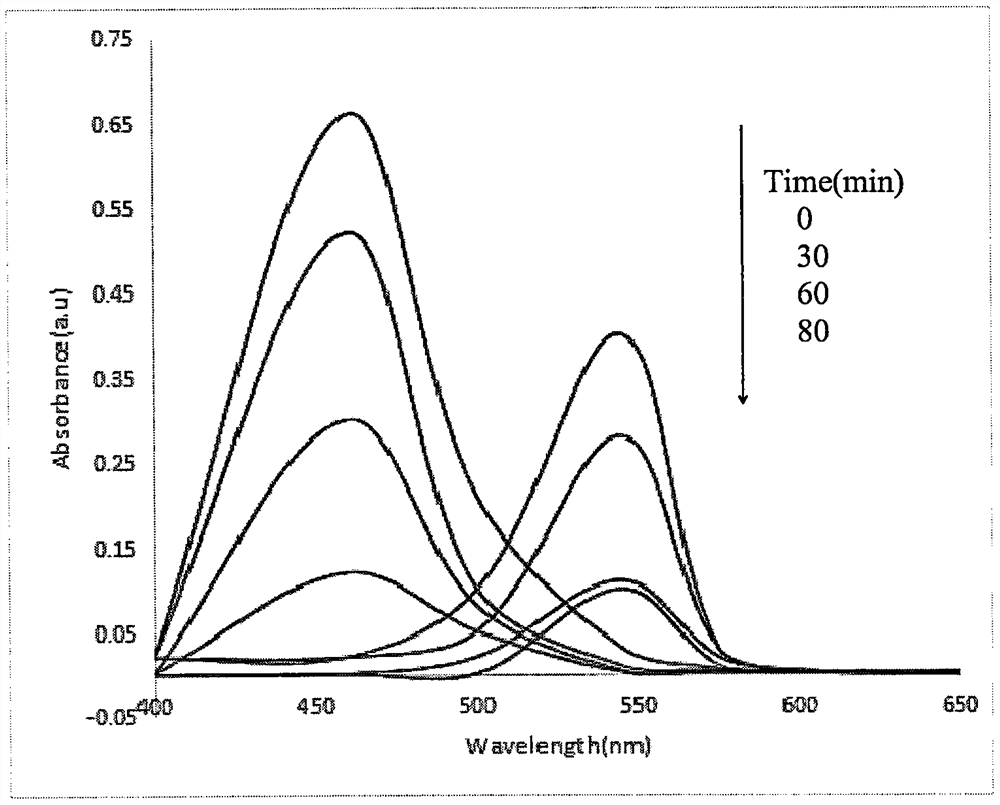

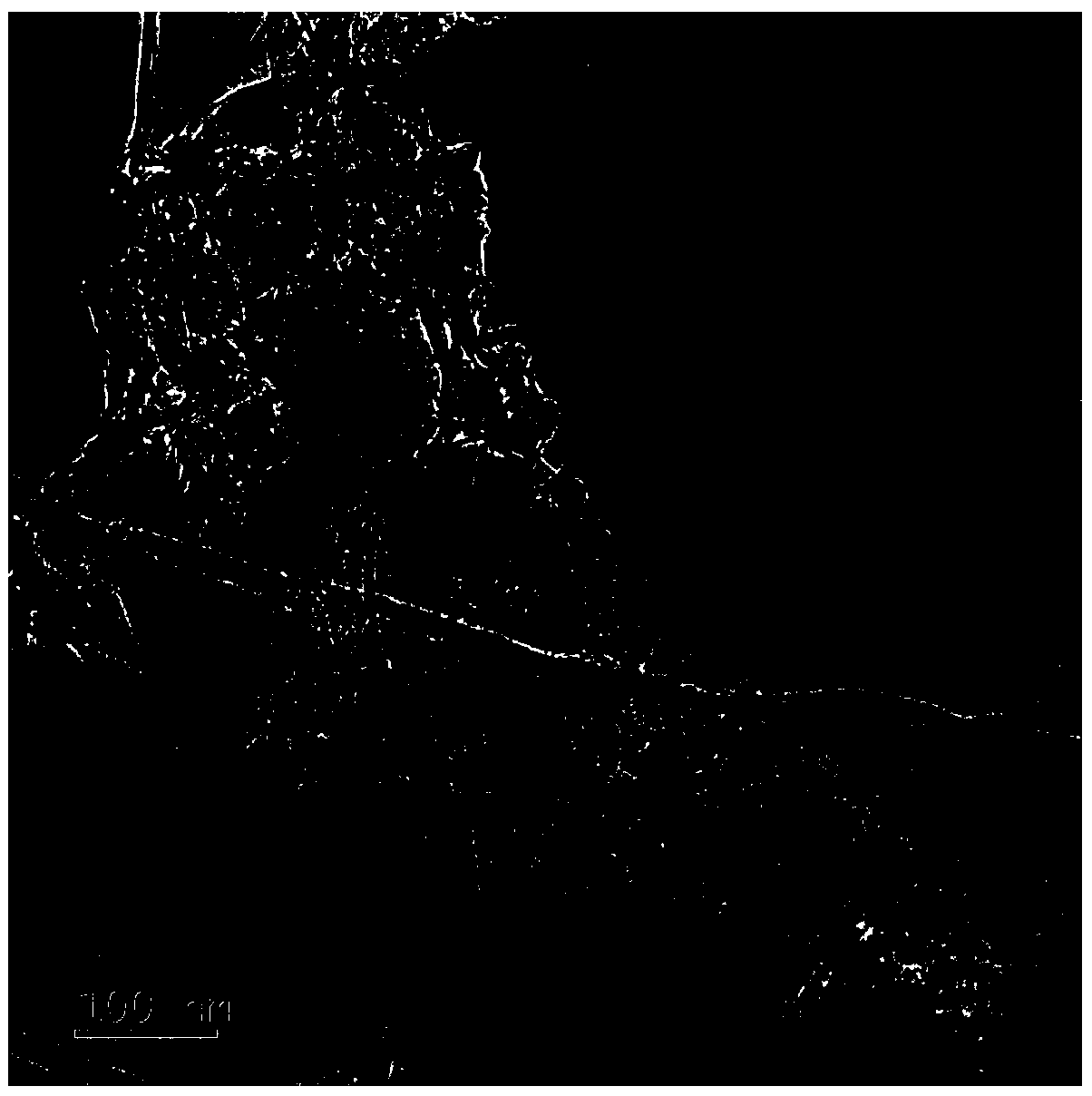

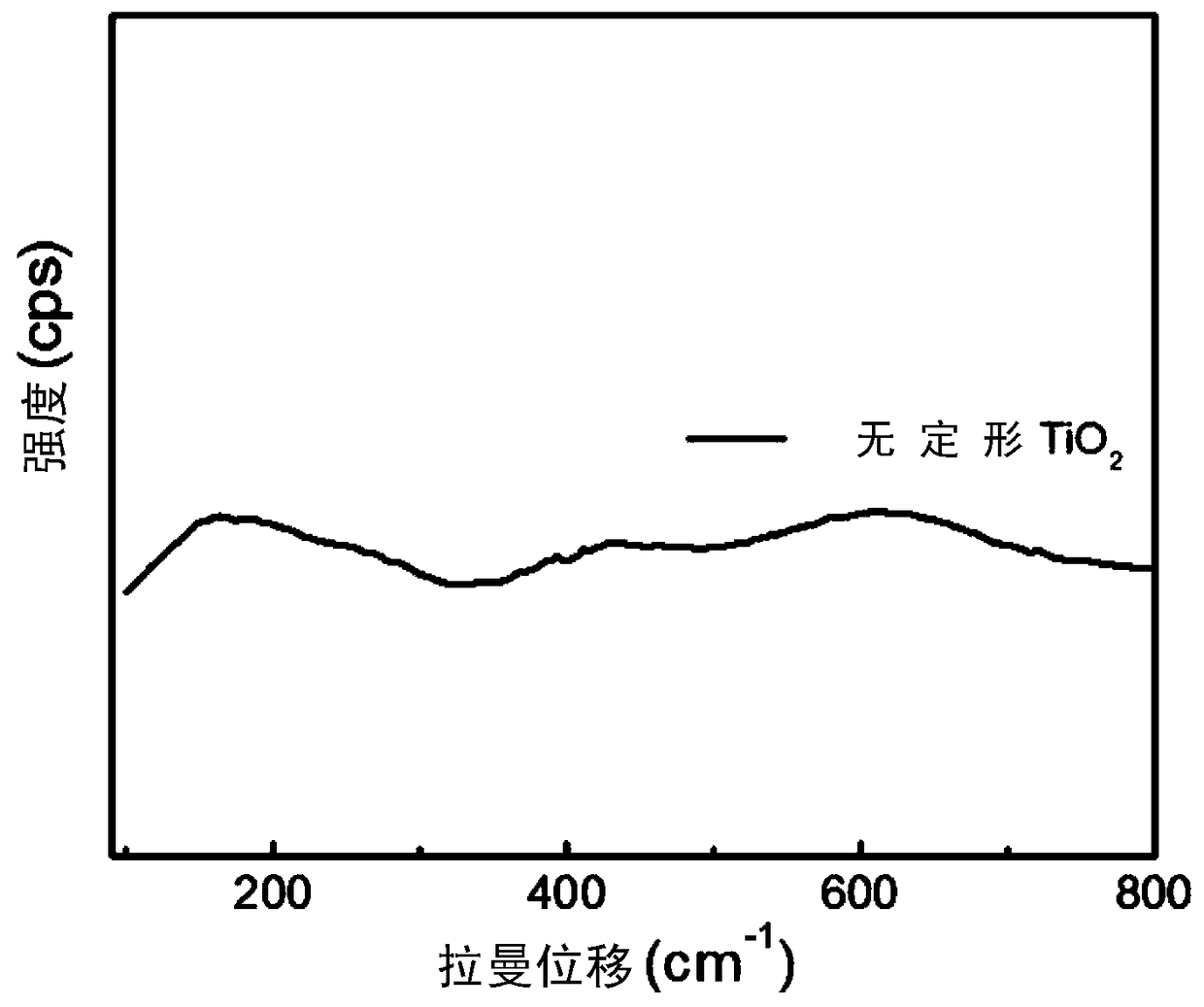

Graphene/titanium dioxide composite material, preparation method and application thereof

ActiveCN108160064ASimplify the linkConducive to follow-up reactionsGas treatmentPhysical/chemical process catalystsCvd grapheneTitanium oxide

The invention relates to a graphene / titanium dioxide composite material, a preparation method and application thereof. The graphene / titanium dioxide composite material comprises: graphene and titaniumdioxide particles closely attached to the graphene sheet. According to the invention, graphene and titanium dioxide are selected for compounding to obtain an efficient photocatalyst with the excellent properties of graphene and titanium oxide simultaneously.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

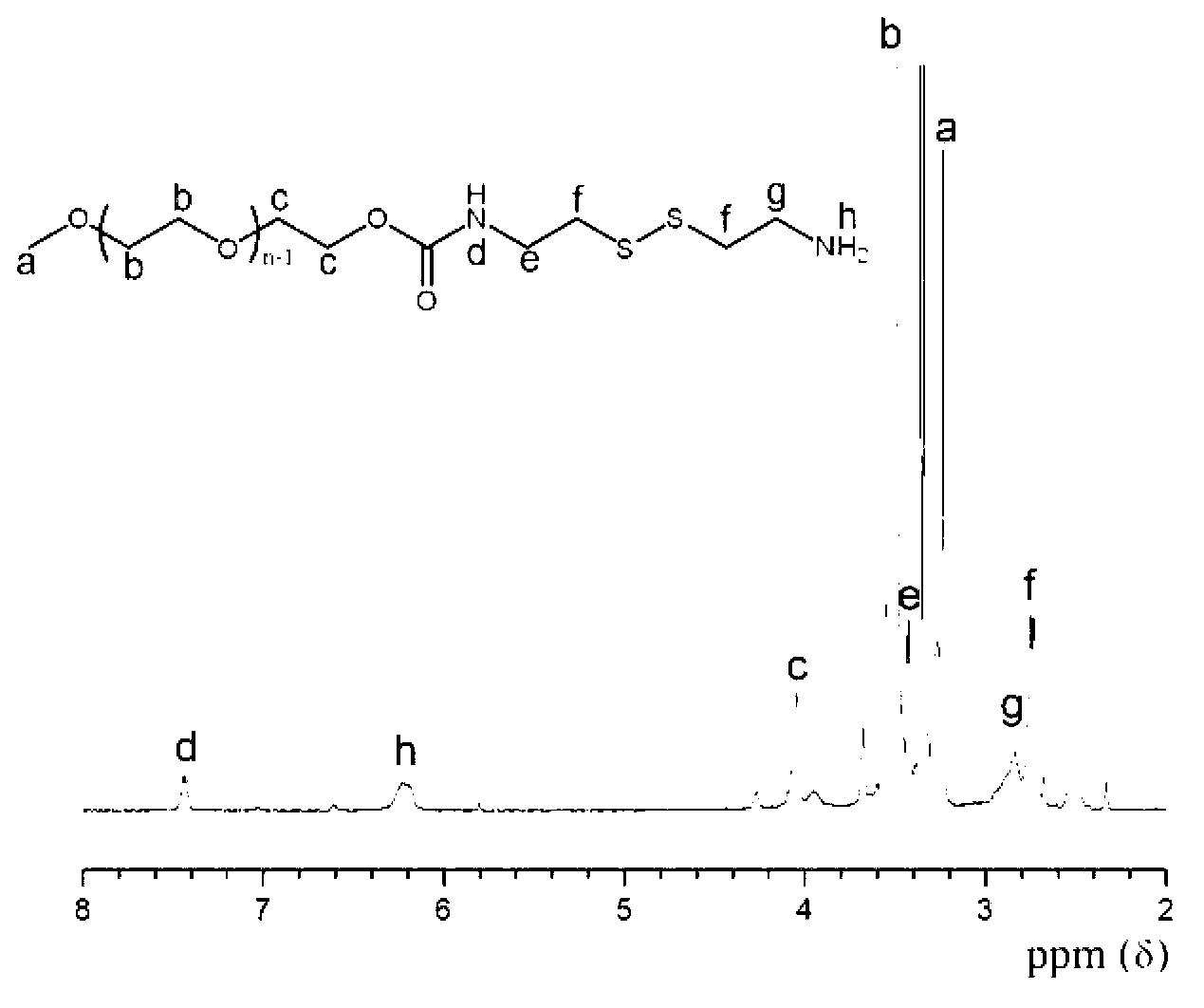

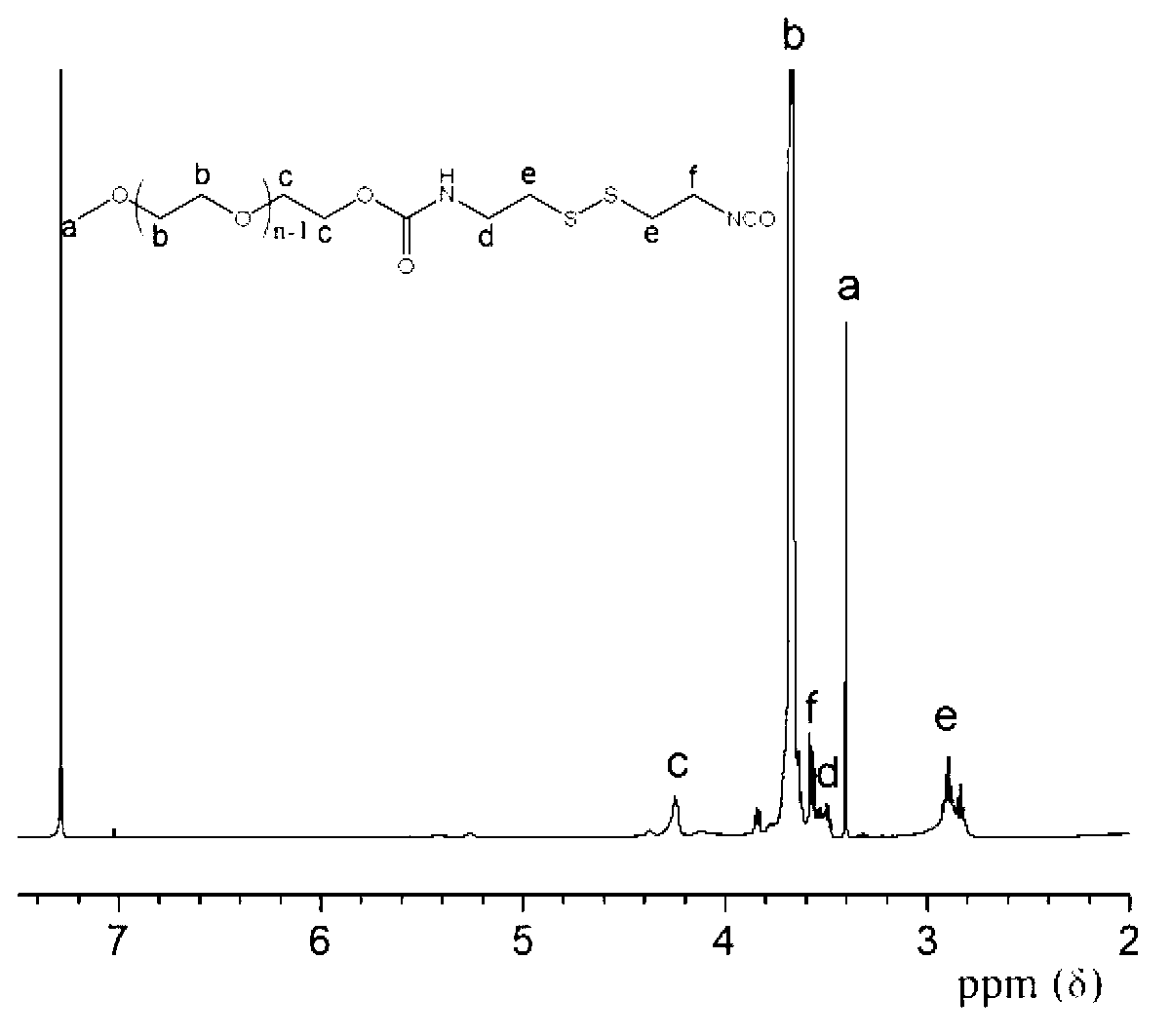

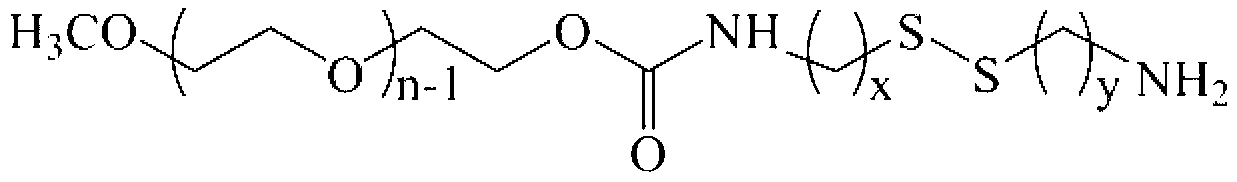

Bi-functional polyethylene glycol derivative and preparation method thereof

InactiveCN103319388AHigh reactivityRaw materials are easy to getPharmaceutical non-active ingredientsHydropoly/poly sulfide preparationPolyethylene glycolDrug release

The invention relates to a bi-functional polyethylene glycol derivative and a preparation method thereof. The preparation method of the difunctional polyethylene glycol derivative comprises following steps: conducting esterification, hydrazinolysis and Curtius rearrangement in dibasic acid with disulfide bond at first to generate diisocyanate containing disulfide bond, then conducting a reaction of the diisocyanate and the polyethylene glycol to generate isocyanat-terminated polyethylene glycol and obtaining the bi-functional polyethylene glycol derivative through hydrolysis reaction of the resultant. In the invention, the preparation method has the advantages that raw materials can be gotten easily, reaction conditions are gentle, yield and product purity are high and the method is beneficial to mass production. Meanwhile, the bi-functional polyethylene glycol derivative is beneficial to both consequent reactions and controlled release of drugs and transfer of the drugs from endosome to cytoplasm. Application prospects of the bi-functional polyethylene glycol derivative are wide in surface finish of a nano-drug carrier, preparation of pro-drug and control of drug release speed etc.

Owner:XI AN JIAOTONG UNIV

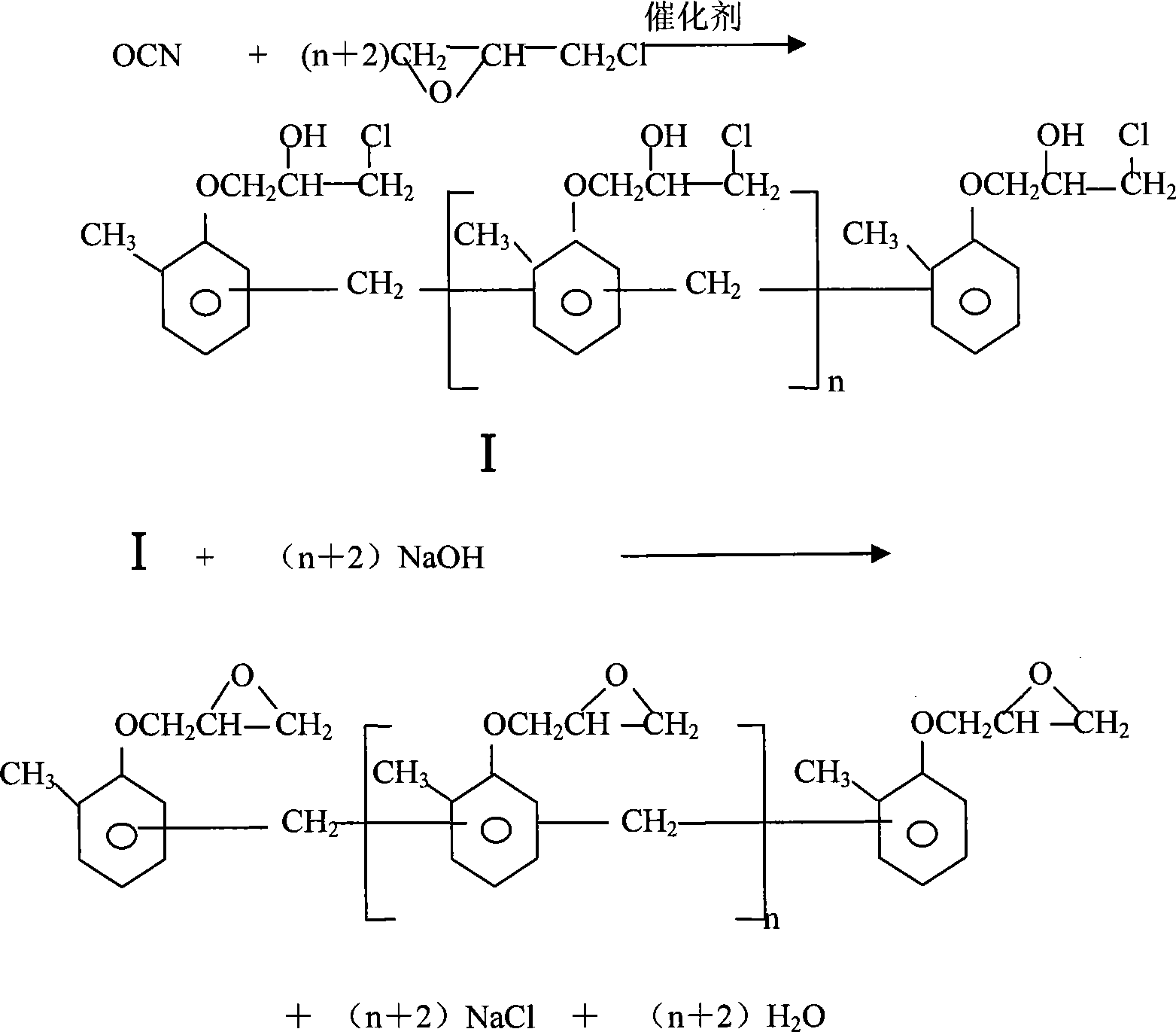

Synthesis of o-cresol formaldehyde epoxy resin

The invention provides a synthesis method of o-cresol formaldehyde epoxy resin, which comprises steps that: at 0.01-0.1Mpa vacuum degree, the o-cresol formaldehyde epoxy resin is dissolved by epichlorohydrin and a catalyzer is added for circumfluence and etherification reaction; at the 0.02-0.1Mpa vacuum degree, alkali is added for catalyzing cyclization reaction; the epichlorohydrin is recycled and processed after refining reaction. The o-cresol formaldehyde epoxy resin obtained by the synthesis method of the invention can reach a scheduled softening point and has high epoxy value and low content of easily saponifiable chlorine.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Method for improving quality of bio-oil

ActiveCN104560102ARaise the pHImprove qualityBiofuelsEfficient propulsion technologiesAlkaneNitrogen atmosphere

The invention relates to a method for improving the quality of bio-oil. The method comprises the following steps: adding bio-oil produced by the pyrolysis into an autoclave, adding calcium oxide and reacting for 1-4 hours at 30-80 DEG C under nitrogen atmosphere, heating to 160-180 DEG C, reacting for 0.5-2 hours, and finally cooling to 80-120 DEG C, and further carrying out heat preservation and reacting for 0.5-2 hours to obtain precursors of C7-C15 alkane fuels. By the method, the content of acid in the bio-oil can be well decreased, the pH and stability of the bio-oil are increased and meanwhile, produced ketone substances and aldehyde substances in the bio-oil can be reacted to obtain the precursors of the C7-C15 alkane fuels and thus the quality of the bio-oil is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

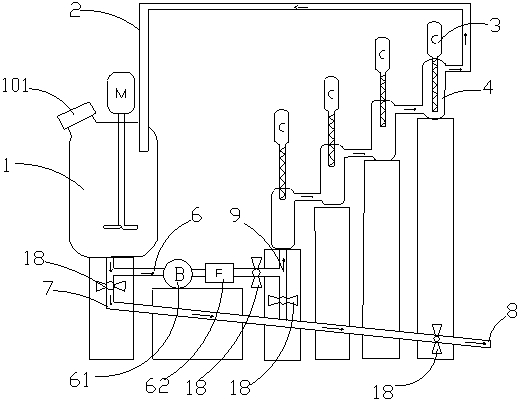

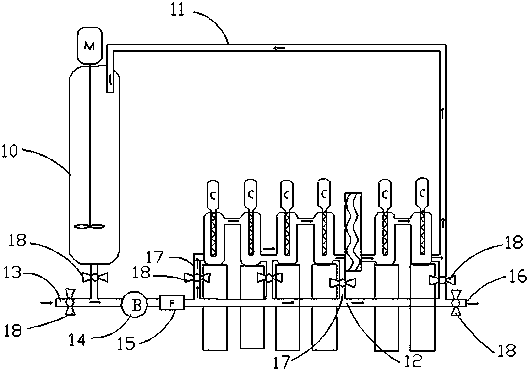

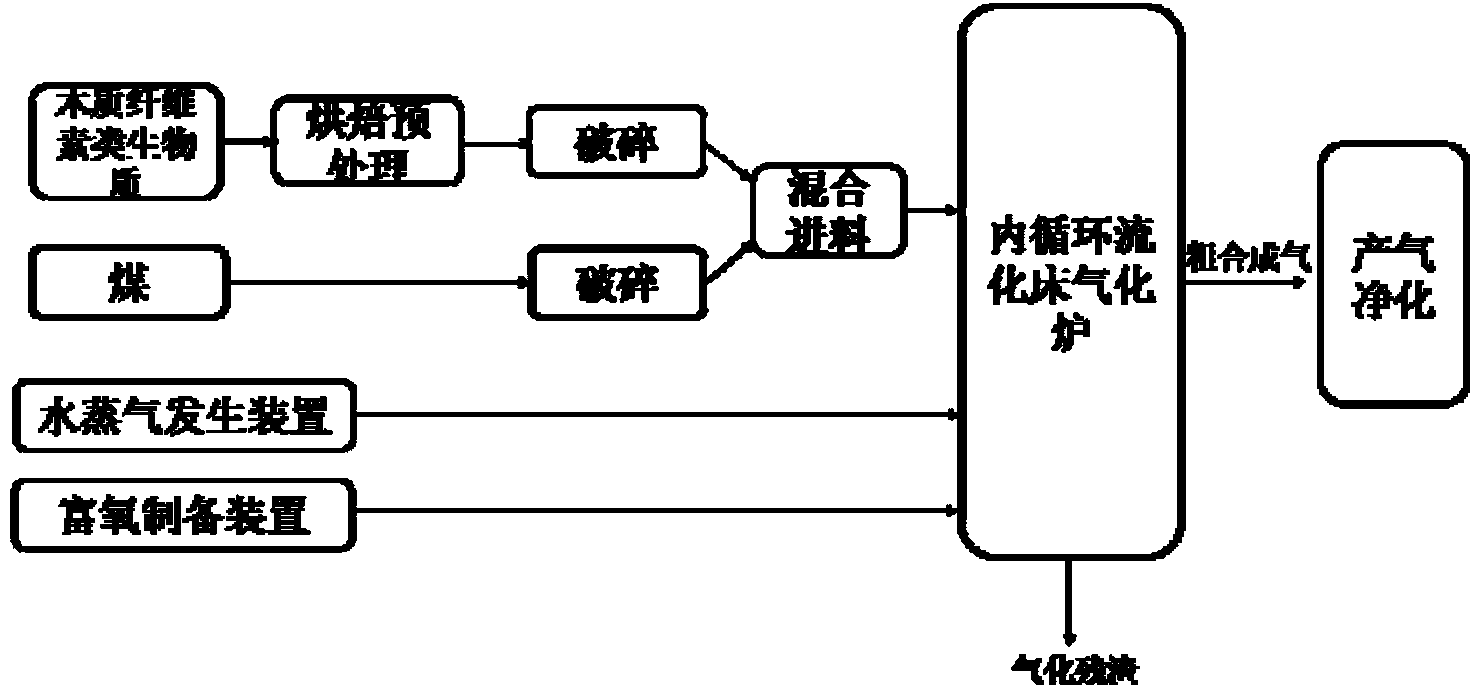

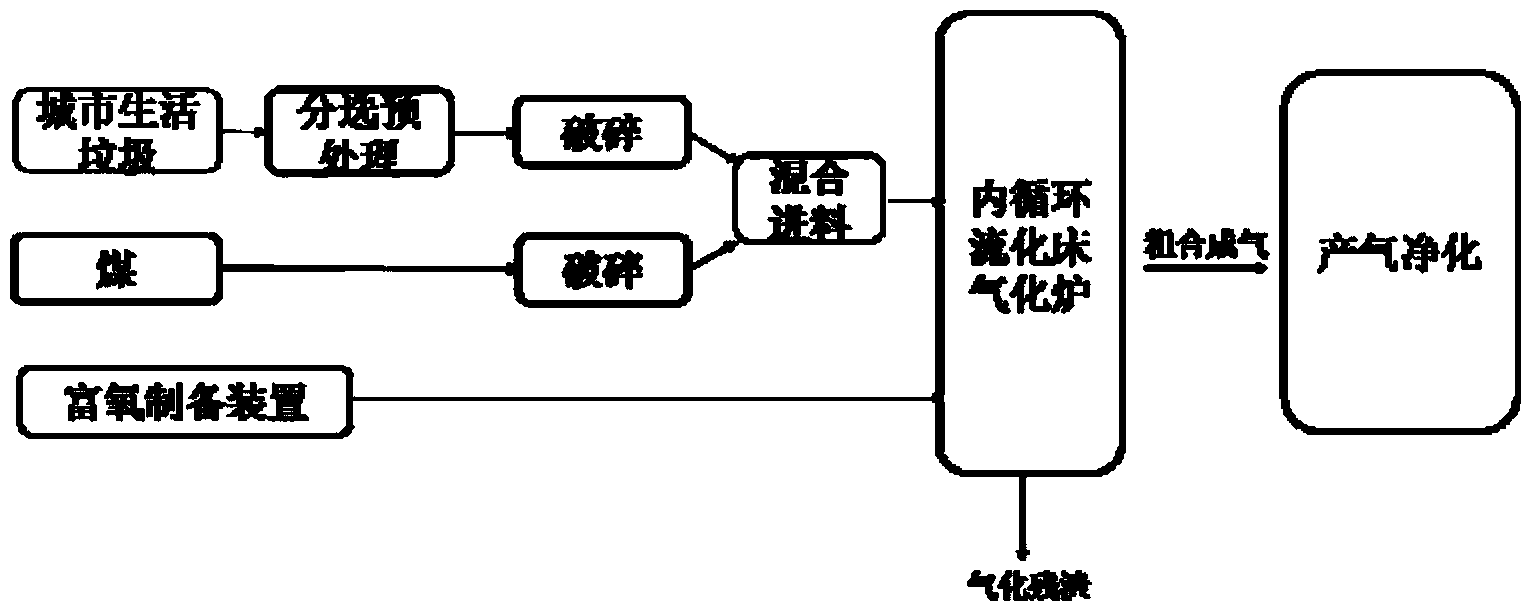

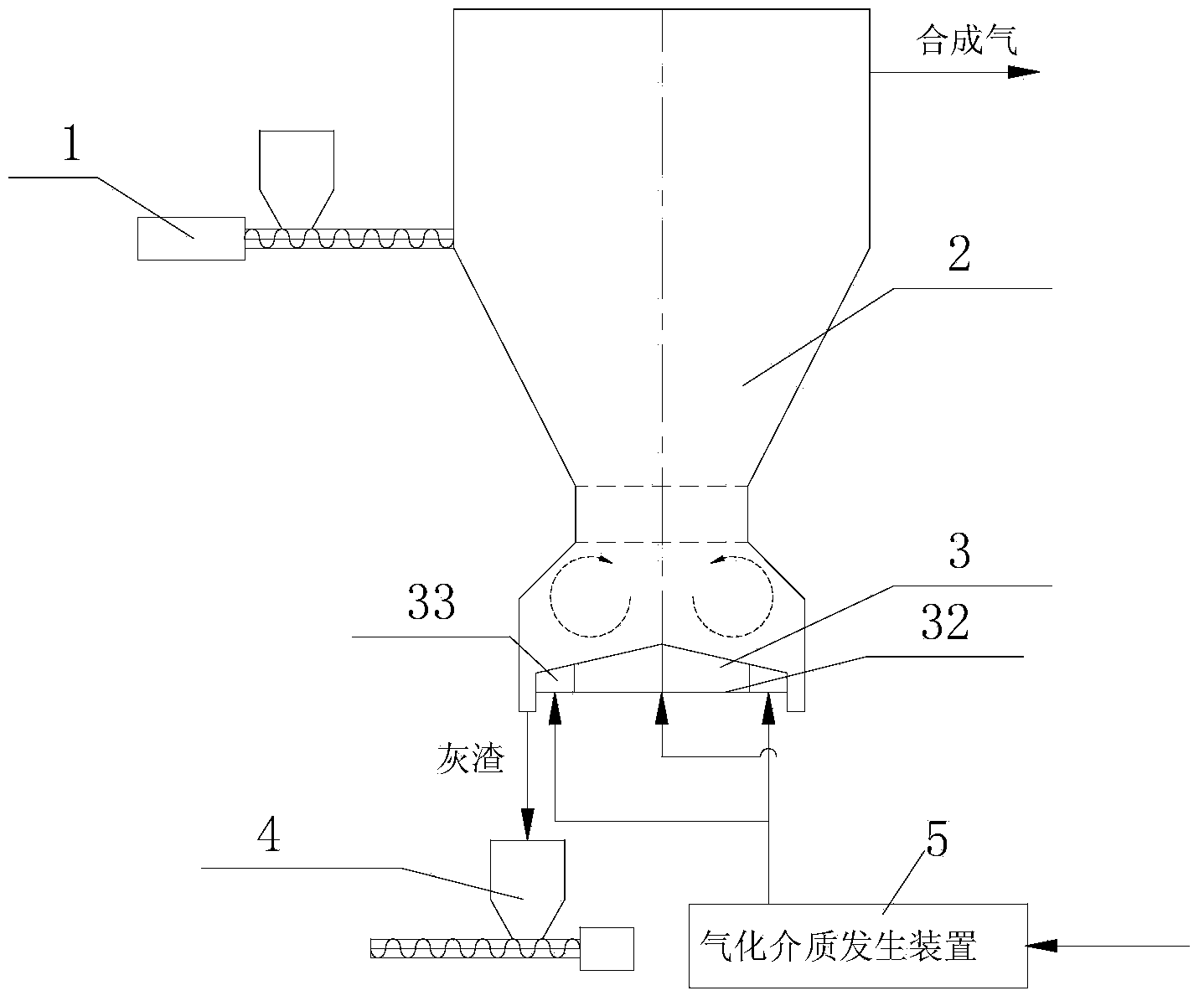

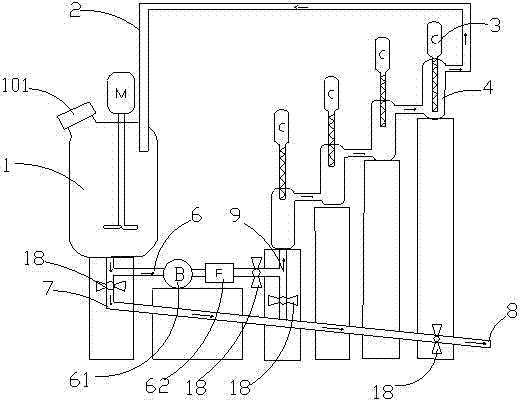

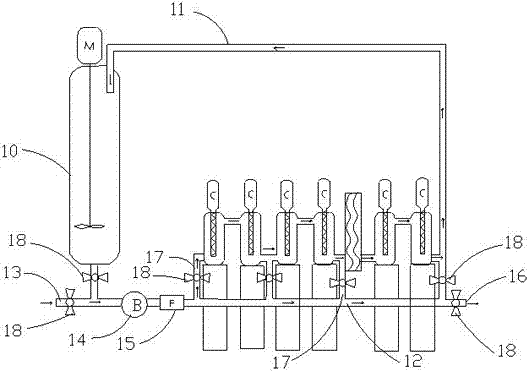

System and process for preparing synthetic gas through co-gasification of coal and biomass

InactiveCN103450948AGasification reaction goes wellWide adaptabilityGranular/pulverulent flues gasificationSlagWater vapor

The invention provides a system and a process for preparing synthetic gas through co-gasification of coal and biomass. The system comprises a feeding device, a gasifier body and a gasifying medium generation device, wherein the gasifier body consists of a lower dense-phase region and an upper dilute-phase region; a multi-air-chamber air distribution device is arranged at the bottom of the dense-phase region and is connected with an outlet of the gasifying medium generation device; the feeding device is connected with the gasifier body at the junction of the dense-phase region and the dilute-phase region; a deslagging device is connected at a slag outlet between the multi-air-chamber air distribution device and the gasifier body; the upper side wall of the dilute-phase region is provided with a synthetic gas outlet; the gasifying medium generation device comprises an oxygen enrichment preparation device and / or a steam generation device; a taper or inverted taper air distribution mode is adopted by the multi-air-chamber air distribution device. According to the system and the process, the co-gasification of the coal, lignocellulose and municipal domestic waste can be effectively realized, and the synergistic effect of the coal and the biomass is effectively utilized; the system and the process have the advantages of wide raw material adaptability, high gasification speed, little deslagging carbon residue, easiness in controlling over pollutants and the like.

Owner:GUANGDONG XIAN JIAOTONG UNIV ACADEMY +1

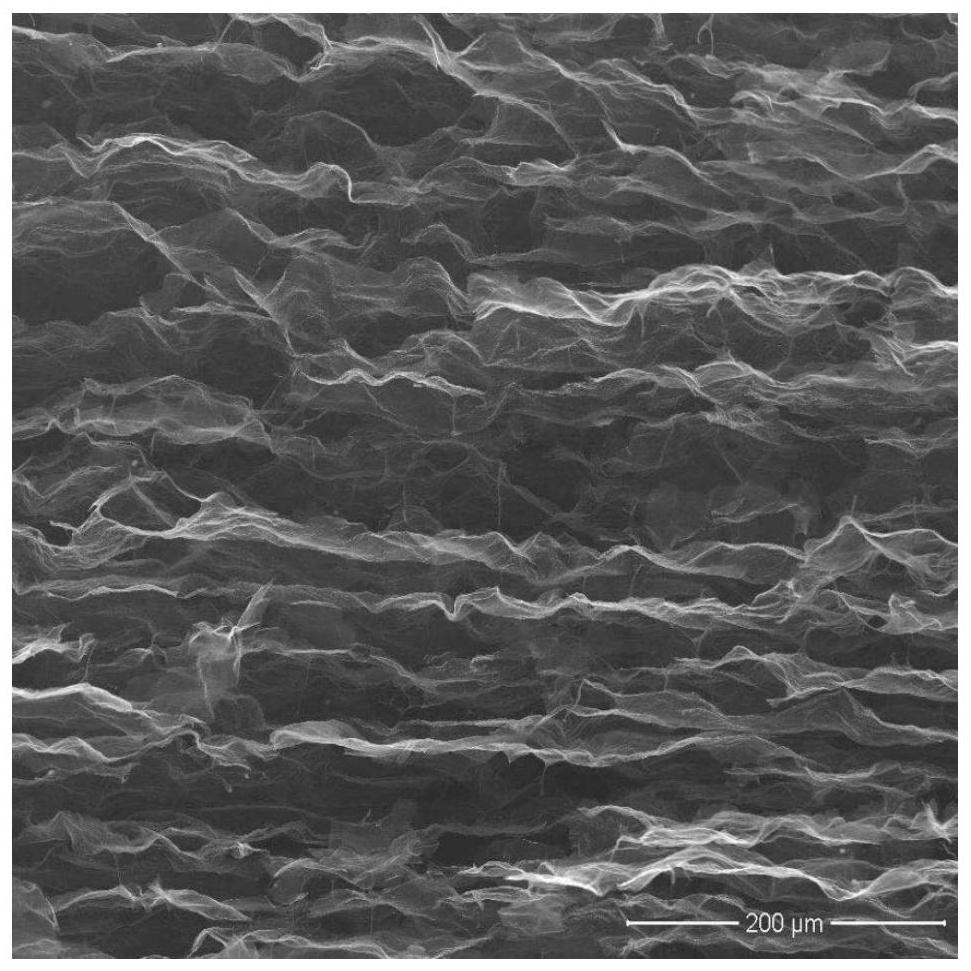

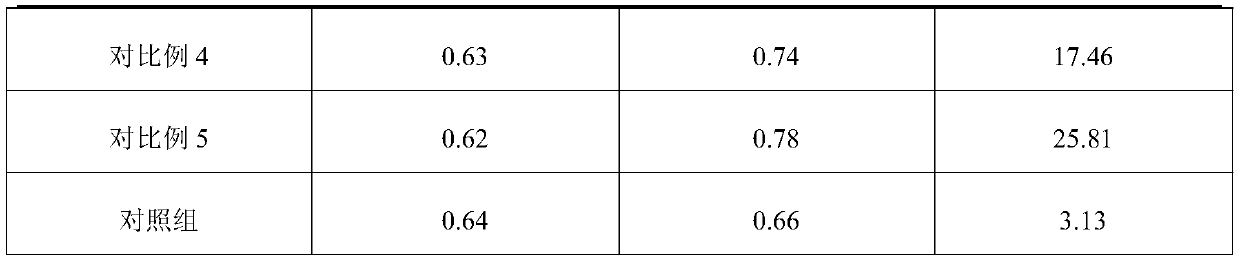

Nano silver loaded graphene antibacterial composite material and preparation method thereof

InactiveCN107568246AReturn to normal structureAvoid discontinuitiesBiocideDisinfectantsEscherichia coliAntibacterial activity

The invention relates to the field of graphene composite materials and discloses a nano silver loaded graphene antibacterial composite material and a preparation method thereof. A single-layer graphene oxide solution is obtained through a secondary ultrasonic dispersion technology and a discontinuous sheet layer is prevented; a carbon cake formed by mutually mixing a plurality of layers of graphene oxide sheets is innovatively subjected to secondary hydrothermal method reaction; green reduction agents including glucose and ascorbic acid and a green stabilizer soluble starch are adopted respectively and the hydrothermal method reaction is matched, so that the reduction rate is extremely improved and a sealing system with relatively high temperature and inner pressure is adopted; the recycling of dehydrated p conjugation is also promoted and the minimization of defects is facilitated; after heat treatment is carried out, the structure of graphene is easy to recover; the antibacterial activity of free Ag nanoparticles is remained in the composite material. The loading amount of silver particles in the nano silver loaded graphene antibacterial composite material reaches 58.0 percent and the antibacterial rate on escherichia coli reaches 99.9 percent.

Owner:郴州博太超细石墨股份有限公司

Preparation method for cadmium telluride

InactiveCN103818886AOvercome the defect of being easily oxidizedWell mixedBinary selenium/tellurium compoundsHydrogenMercury cadmium telluride

The invention discloses a preparation method for cadmium telluride. The preparation method sequentially comprises the following steps: qualified tellurium powder and cadmium powder are taken according to the molar ratio of 1:1 and then subjected to homogeneous mixing, the mixed raw materials subjected to homogenizing are loaded into a graphite boat, and the graphite boat is placed into a synthesis furnace for first synthesis; the material obtained after first synthesis is taken out of the graphite boat and crushed; the crushed material is loaded into the graphite boat, and the graphite boat is placed into the synthesis furnace for second synthesis; screening and ball milling are performed, wherein in the processes of the first synthesis and the second synthesis, multistage temperature rising and temperature dropping are performed under the protection of nitrogen and hydrogen. According to the invention, homogeneous treatment is performed on the tellurium powder and cadmium powder firstly so as to enable the two raw materials to be mixed fully and uniformly, meanwhile, the defect that the cadmium powder is easy to oxidize is overcome, the two raw materials can be synthesized preliminarily under relatively low temperature, purity of a synthesized product is improved, and the utilization ratios of raw materials are increased; synthesis is performed for two times, so that the raw materials react fully, thereby improving the purity and yield of the product finally.

Owner:张家港绿能新材料科技有限公司

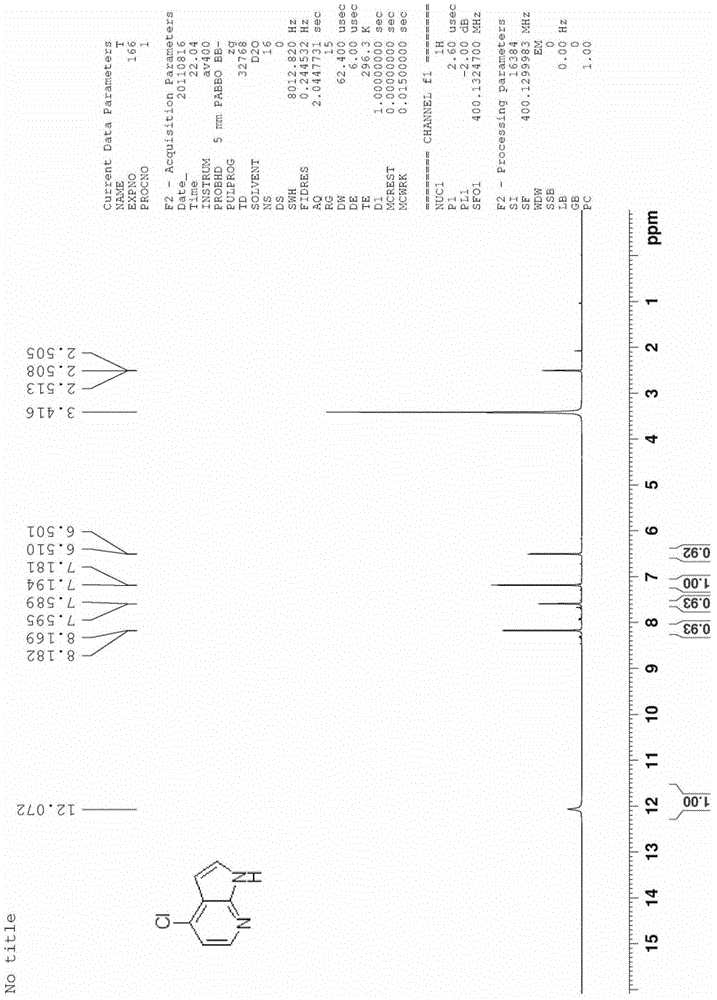

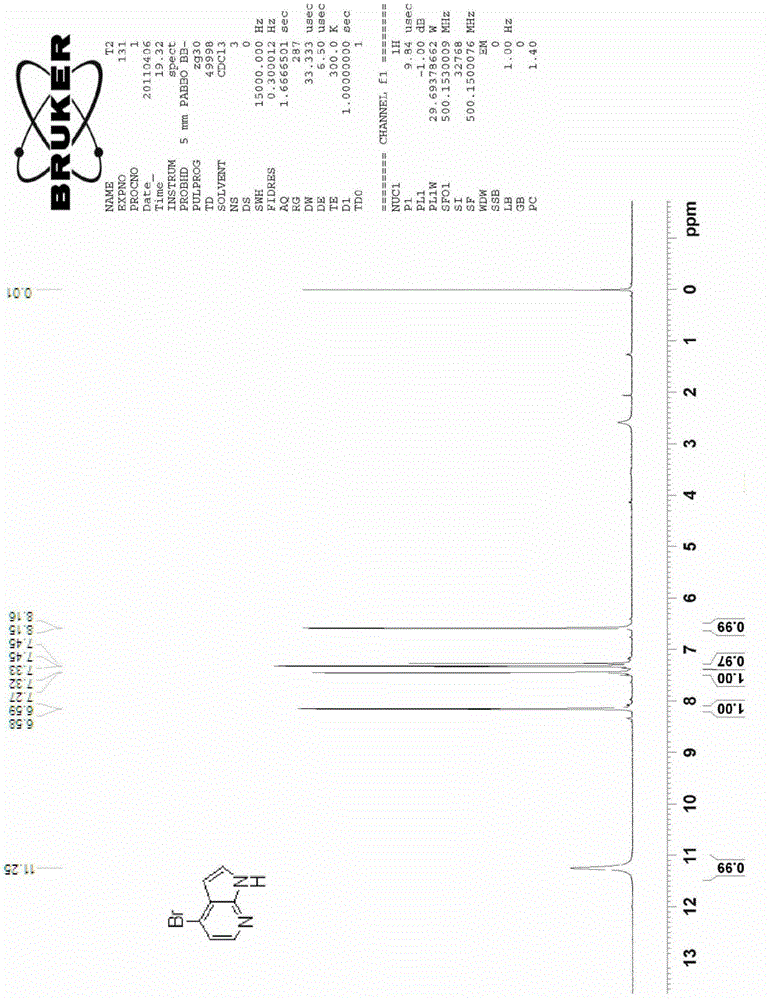

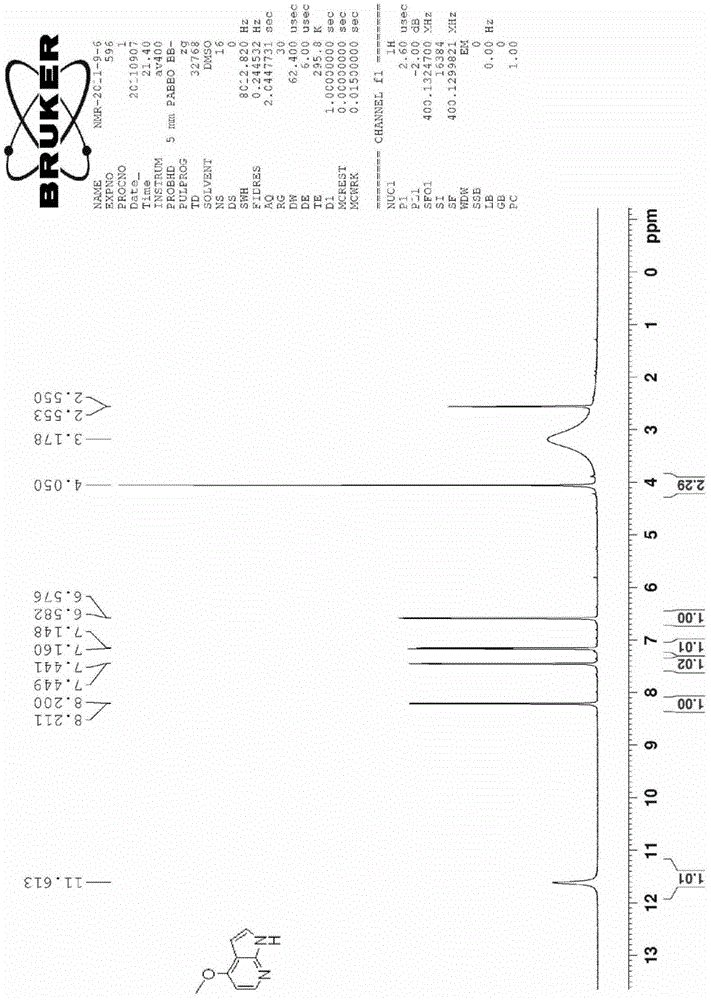

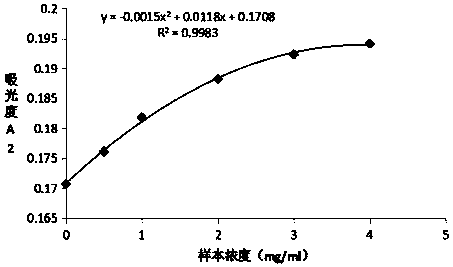

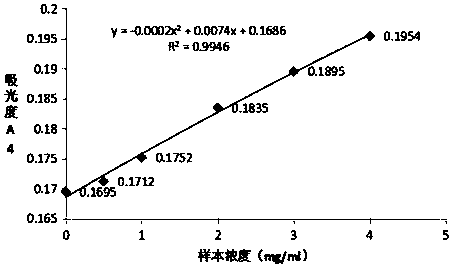

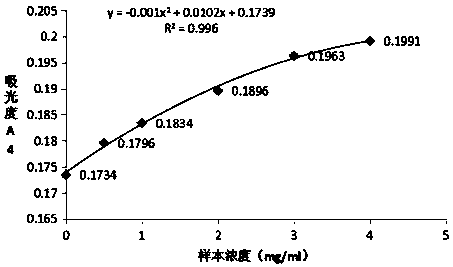

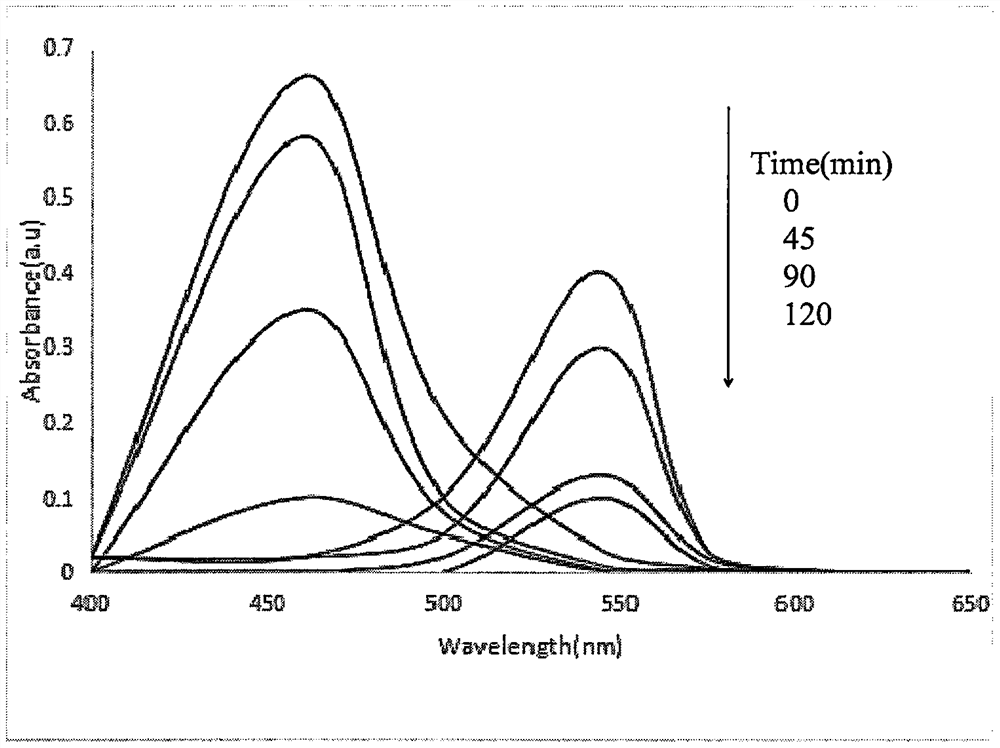

Crystal form of 6, 7-dihydro-6-mercapto-5H-pyrazolo[1,2-alpha][1,2,4] triazoliumchloride and preparation method thereof

ActiveCN101735220AEasy to operateImprove efficiencyOrganic chemistryColumn chromatographyDiffraction spectrum

The invention relates to a crystal form of 6, 7-dihydro-6-mercapto-5H-pyrazolo [1,2-alpha][1,2,4] triazoliumchloride and a preparation method thereof. The 6, 7-dihydro-6-mercapto-5H-pyrazolo [1,2-alpha][1,2,4] triazoliumchloride is a key intermediate for synthesizing the carbapenem antibiotic biapenem. The crystal form of 6,7-dihydro-6-mercapto-5H-pyrazolo[1,2-alpha][1,2,4] triazoliumchloride is characterized in that the X-ray diffraction spectrum of powder of the crystal form is represented by an angle of 2theta, and has peaks at 27.487+ / -0.2 and 26.707+ / -0.2, the intensity of the peak is 100% when 2theta is 27.487+ / -0.2, and the ratio of intensity of the peak I / I0 is no less than 60% when 2theta is 26.707+ / -0.2. The 6, 7-dihydro-6-mercapto-5H-pyrazolo[1,2-alpha][1,2,4] triazoliumchloride is prepared by the recrystallization method which abandons the column chromatography and has high efficiency and low cost and is more suitable for industrialized production.

Owner:石药集团中诺药业(石家庄)有限公司 +1

Environmentally friendly preparation method of fluorine-containing acrylate

ActiveCN108911983ANo potential risk of PFOAIn line with industrial policyOrganic compound preparationCarboxylic acid esters preparationIodideHydrolysis

The invention relates to the technical field of preparation of new fluorine-containing materials, particularly to an environmentally friendly preparation method of fluorine-containing acrylate. The environmentally friendly preparation method comprises: carrying out a reaction on short-chain perfluoroiodoalkane and ethylene, separating, and purifying to obtain perfluoroalkylethyl iodide; carrying out hydrolysis on the perfluoroalkylethyl iodide, separating, and purifying to obtain perfluoroalkylethanol; and carrying out a reaction on the perfluoroalkylethanol and acrylic acid, separating, and purifying to obtain the product. According to the present invention, the perfluorooctyl-free product is synthesized, the potential risk of PFOA production cannot exist, and the obtained product is theenvironmentally friendly product, and meets the national industrial policy; the preparation method is simple, and is suitable for industrial production; and the reaction conversion rate is high, and the purity of the intermediate product is high, such that the subsequent reaction is easily performed, the yield is easily increased, and the cost is reduced.

Owner:济南齐氟新材料技术有限公司 +1

High-density graphene/silver composite and preparation method thereof

InactiveCN107761081AEvenly dispersedResolve continuityMaterial nanotechnologyGrapheneHigh densitySingle layer graphene

The invention relates to the field of graphene composite materials, and discloses a high-density graphene / silver composite material and a preparation method thereof. The high-density graphene / silver composite material and its preparation method obtain a single-layer graphene oxide solution through a secondary ultrasonic dispersion process, which prevents discontinuity of the lamellae, and is a "carbon" composed of multi-layer graphene oxide sheets mixed with each other. and using the substrate as the graphene oxide solution substrate, by growing silver or nano-silver on the surface of the graphene oxide substrate; at the same time, in order to obtain silver or nano-silver with higher density and lower particle size, the present invention impregnates the substrate. Multiple reactions are carried out, and finally a highly dense graphene / composite is obtained.

Owner:郴州博太超细石墨股份有限公司

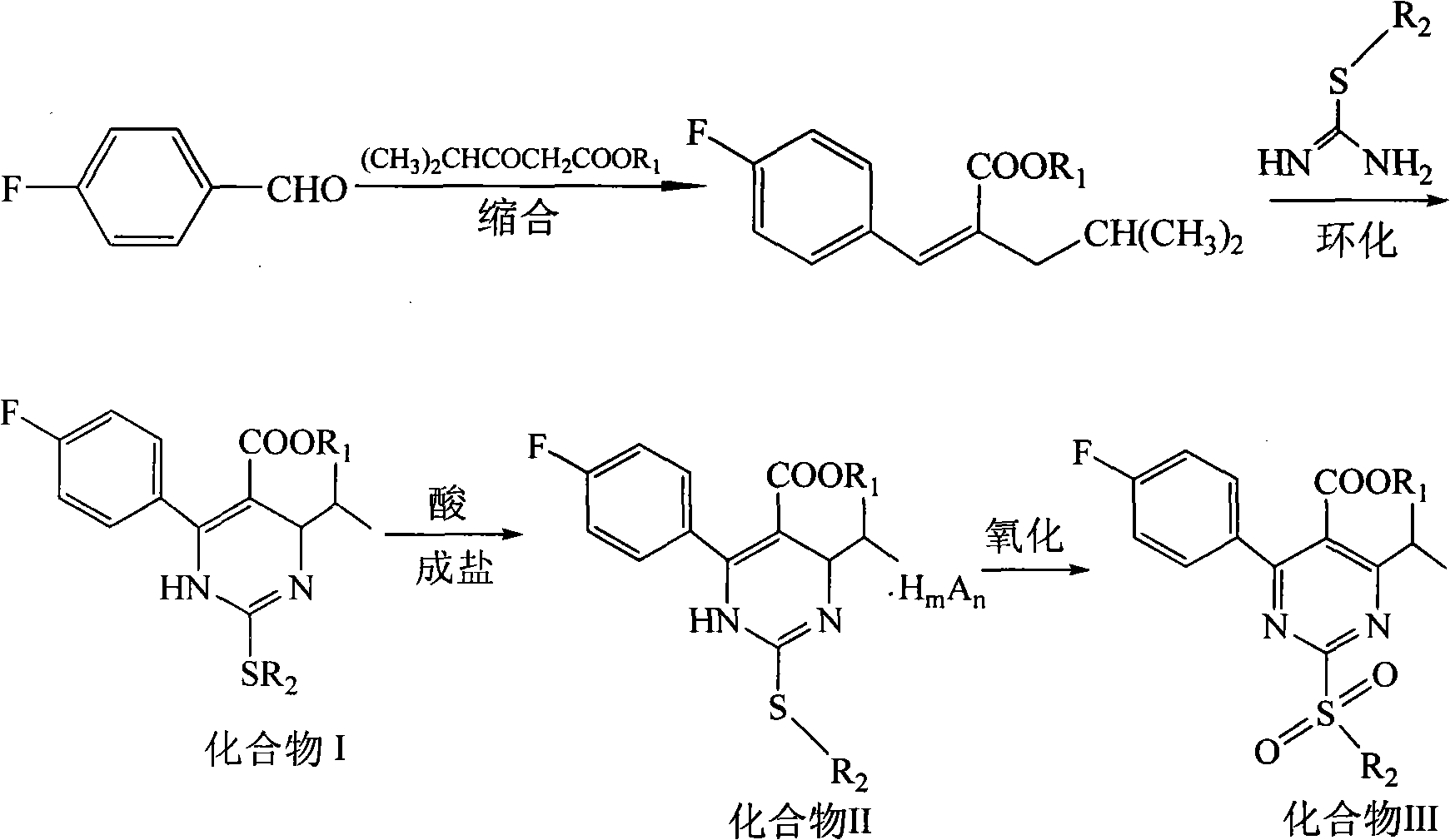

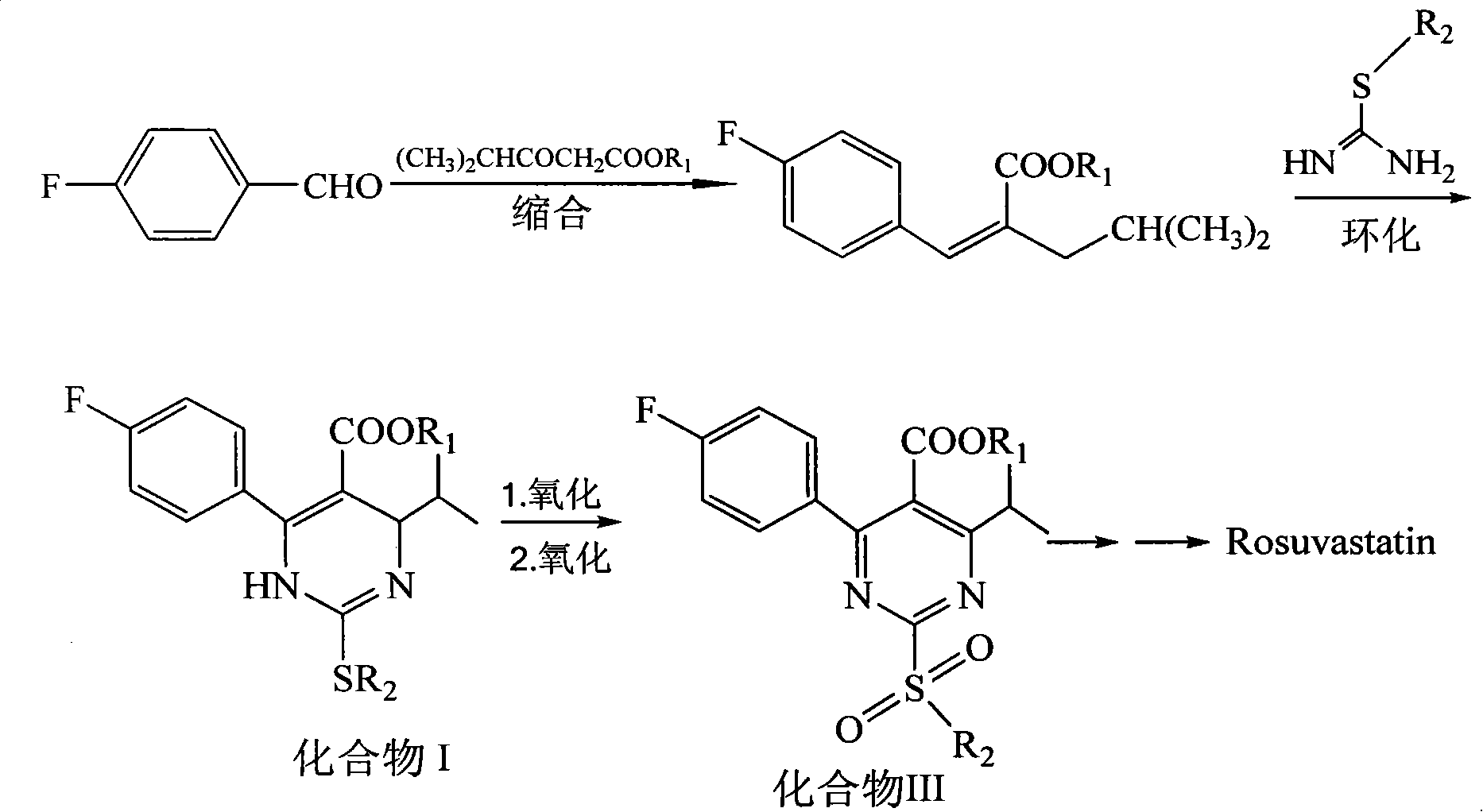

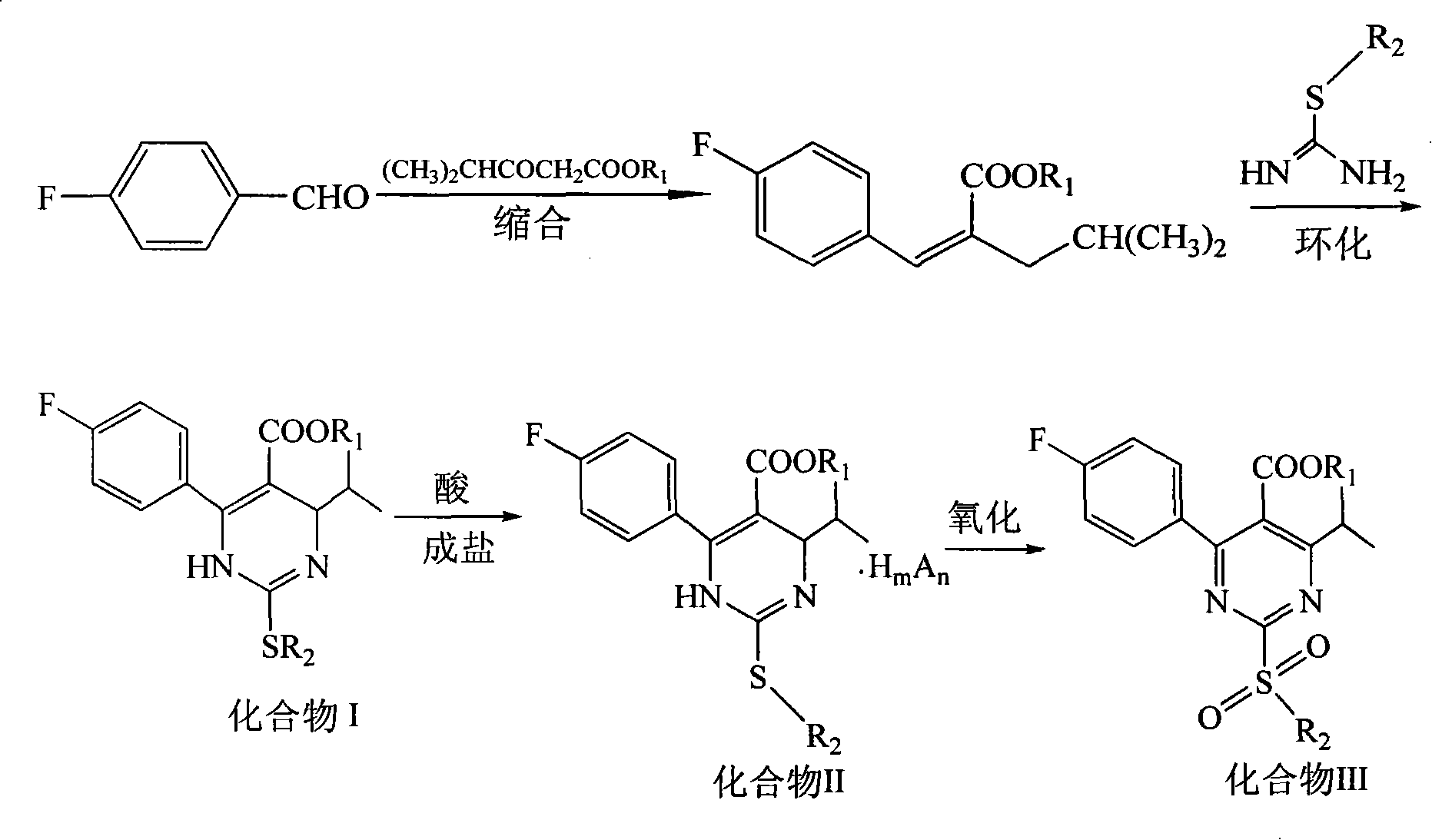

Method for synthesizing key intermediate of rosuvastain calcium

InactiveCN101624377AImprove product qualityHigh yieldOrganic chemistryChromatographic separationColumn chromatography

The invention discloses a method for synthesizing a key intermediate [4-(4-fluorophenyl)-6-isopropyl-2-alkylsulfanyl-5-yl] formate III of rosuvastain calcium, which takes fluorobenzaldehydes and ethyl isobutyrylacetate as raw materials, comprises the steps of condensation, cyclization, salification and oxidation, and adopts a reaction route as shown on the right, wherein R1 is selected from C1 to C6 alkyls and C6 to C12 aryls; and R2 is selected from C1 to C6 alkyls and C6 to C12 aryls. The method has the advantages that: as a compound I reacts with an acid to form a solid compound II which is a salt, the product quality is improved, the yield is increased, the package, storage, transportation and use of products are convenient, the consequent reactions are smooth, and low-efficiency, high consumption and trivial operation of rectification, column chromatography and the like is avoided; and a compound III can be obtained in one oxidation process.

Owner:ENANTIOTECH CORP

A kind of preparation method of cadmium telluride

InactiveCN103818886BOvercome the defect of being easily oxidizedWell mixedBinary selenium/tellurium compoundsHydrogenNitrogen

The invention discloses a preparation method for cadmium telluride. The preparation method sequentially comprises the following steps: qualified tellurium powder and cadmium powder are taken according to the molar ratio of 1:1 and then subjected to homogeneous mixing, the mixed raw materials subjected to homogenizing are loaded into a graphite boat, and the graphite boat is placed into a synthesis furnace for first synthesis; the material obtained after first synthesis is taken out of the graphite boat and crushed; the crushed material is loaded into the graphite boat, and the graphite boat is placed into the synthesis furnace for second synthesis; screening and ball milling are performed, wherein in the processes of the first synthesis and the second synthesis, multistage temperature rising and temperature dropping are performed under the protection of nitrogen and hydrogen. According to the invention, homogeneous treatment is performed on the tellurium powder and cadmium powder firstly so as to enable the two raw materials to be mixed fully and uniformly, meanwhile, the defect that the cadmium powder is easy to oxidize is overcome, the two raw materials can be synthesized preliminarily under relatively low temperature, purity of a synthesized product is improved, and the utilization ratios of raw materials are increased; synthesis is performed for two times, so that the raw materials react fully, thereby improving the purity and yield of the product finally.

Owner:张家港绿能新材料科技有限公司

Preparation method of ring-opening epoxidized soybean oil modified sulfonated waterborne polyurethane

ActiveCN105713175AAbundant productionLow priceOrganic compound preparationCarboxylic acid esters preparationEthylenediaminePetroleum

A preparation method of ring-opening epoxidized soybean oil modified sulfonated waterborne polyurethane is characterized by comprising a first part, namely, preparation of ring-opening epoxidized soybean oil and a second part, namely, synthesis of sulfonated waterborne polyurethane, wherein the first part comprises steps as follows: epoxidized soybean oil and isooctyl alcohol are added to a first reaction kettle, a catalyst is added, and the ring-opening epoxidized soybean oil is obtained; the second part comprises steps as follows: polyatomic alcohol, the ring-opening epoxidized soybean oil and polyisocyanate are added to a second reaction kettle; stannous octoate is added for catalysis; a chain extender is added for a chain extension reaction; the temperature is reduced, and aliphatic diamine sulphonate is added; ethylenediamine is added for a chain extension reaction, and a ring-opening epoxidized soybean oil modified sulfonated waterborne polyurethane emulsion is obtained. The bio-based raw material epoxidized soybean oil is used for modifying the sulfonated waterborne polyurethane, and the water resistance and the heat resistance of sulfonated waterborne polyurethane are improved; besides, renewable resources are used to replace a petroleum raw material, and a cheap raw material source is provided for the polyurethane industry.

Owner:KUSN ZHANGPU COLOR PRINTING FACTORY

Halogen-free catalytic polyphenylene sulfide and preparation method thereof

The invention discloses halogen-free catalytic polyphenylene sulfide and a preparation method thereof. Concentration of a sodium hydroxide solution in a reaction kettle is 400 g / mL, at the moment, sodium hydroxide has maximum absorbing rate on hydrogen sulfide, and yield of sodium sulfide is highest. Vacuum degree in a polymerization kettle is 0.098 MPa. Dewatered sodium sulfide obtained at the vacuum degree is loose, free of melting and boiling and wall sticking and conducive to subsequent reaction. Sectional heating is adopted, so that conversion of sodium sulfide in the heating process can be prevented, and vacuum dewatering time can be shortened. Polycondensation is performed in two steps to enable further reaction of active end group of oligomer and enable further growth of molecular chains.4, 4'-dihydroxybiphenyl is added into polycondensation, so that the polyphenylene sulfide is enabled to be oxidation-resistant. Therefore, by adopting the preparation method, the halogen-free catalytic polyphenylene sulfide is high in quality, little in pollution, great in market potential and promising in prospect.

Owner:四川中科兴业高新材料有限公司

Preparation method for 4-substituted-7-azaindole

The invention relates to the field of organic synthesis and medicine, and discloses a preparation method for 4-substituted-7-azaindole. Firstly, N-oxide-7-azaindole is prepared by employing 7-azaindole as a raw material and hydrogen peroxide as an oxidizing agent; then 4-halogenated-7-azaindole is synthesized by adding acetonitrile and phosphorus oxyhalides (POX3) and by using diisopropyl ethyl amine as a catalyst; and 4-methoxy-7-azaindole is synthesized by reacting the synthesized 4-halogenated-7-azaindole and alkoxide. The 4-substituted-7-azaindole synthesized by the method has high yield and low cost, and the method is easy for industrialization.

Owner:SHANGHAI DAMAS REAGENT

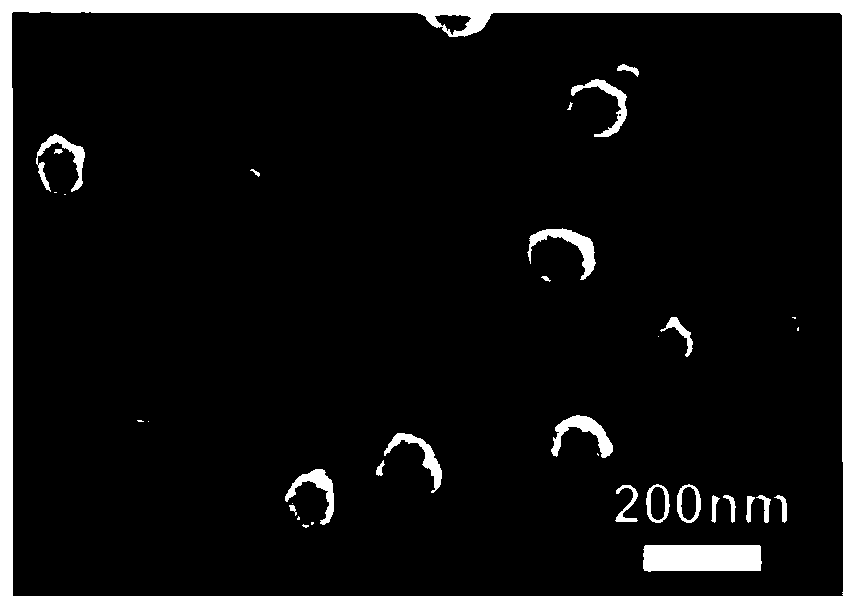

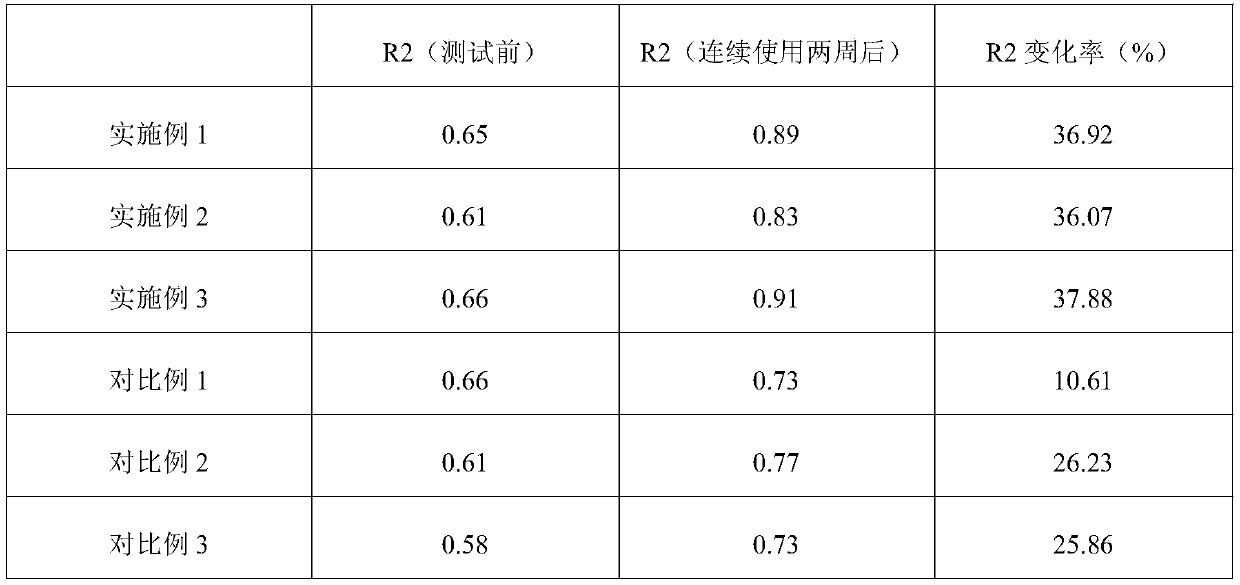

Kit for detecting mycoplasma pneumonia

InactiveCN109342724AIncrease turbidityStable acid-base environmentDisease diagnosisMicrosphereMycoplasma pneumonia

The invention relates to a kit for detecting mycoplasma pneumonia. The kit comprises an R1 reagent and an R2 reagent. The R1 reagent comprises a first buffer, a first stabilizer, a first protectant, afirst preservative, an opacifier and water. The R2 reagent comprises mycoplasma pneumonia antigens, polystyrene latex microspheres, a second buffer, a second stabilizer, a second protectant, a secondpreservative and water. The kit of the invention has the advantages of high sensitivity, high detection speed, stable result, wide linear range, good repetition, easy to standardize and specimen collection, and small in specimen usage amount and the like. Also, the kit of the invention has the advantages that it provides a novel method for early, rapid, high sensitivity and specificity for the diagnosis of clinical mycoplasma pneumonia infection.

Owner:廖朝晖

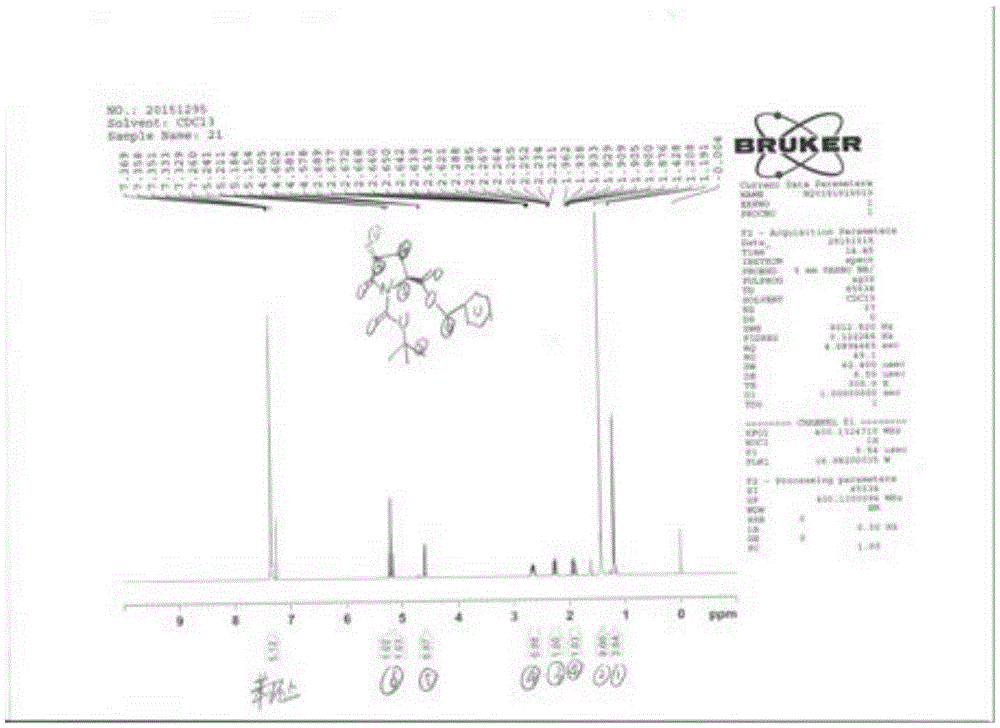

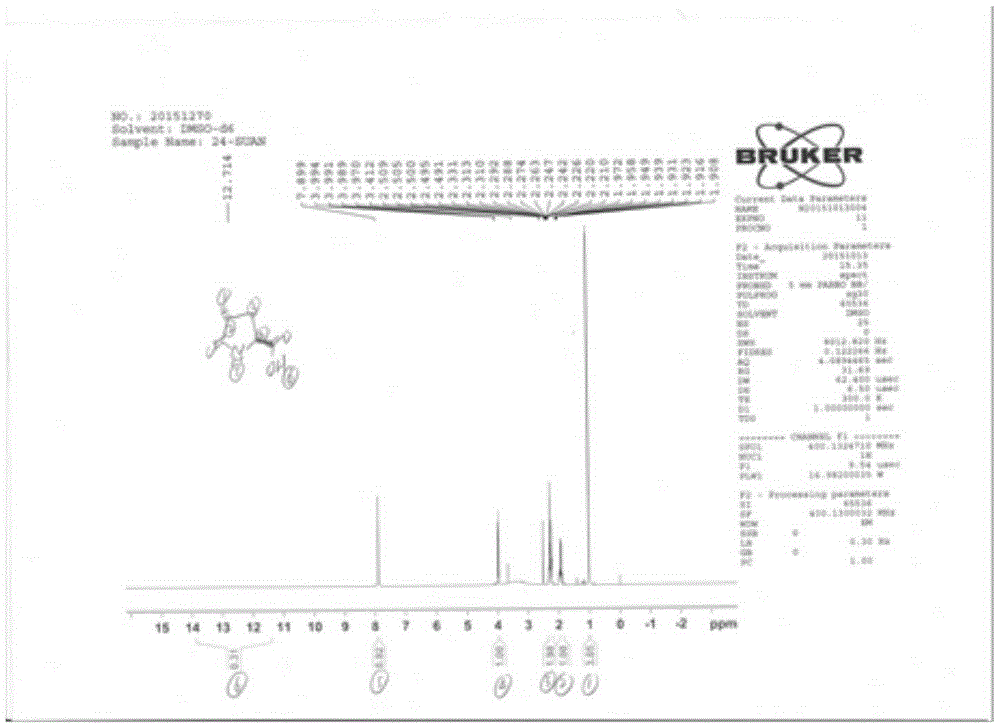

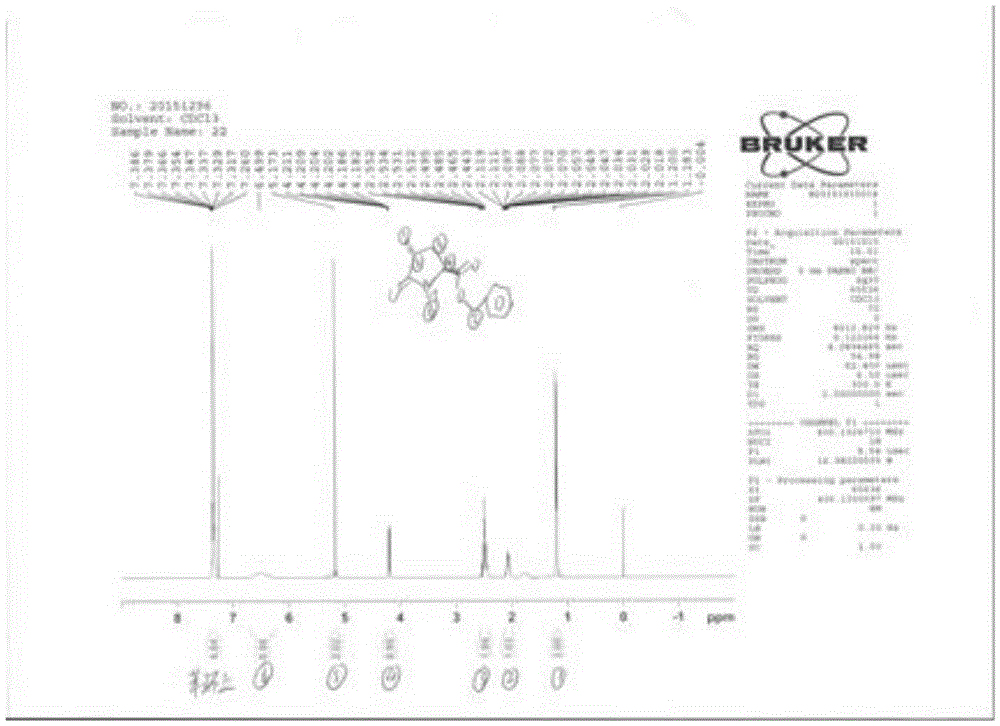

Method for preparing chiral diphenyl pyrrolidone and intermediate compounds

The invention relates to the technical field of chiral diphenyl pyrrolidone preparation methods. Compared with the prior art disclosed in the patent WO2008083967, a method for preparing chiral diphenyl pyrrolidone disclosed by the invention avoids the two steps of adding a protection group of the pivaloyl group and removing the protection group of the pivaloyl group and is short in route, and does not need pivaloyl chloride which may cause serious pollution. Meanwhile, the purity of the important intermediate compound chiral diphenyl pyrrolidone obtained by the method is high, and the follow-up reaction is facilitated. The invention further provides a plurality of novel intermediate compounds.

Owner:SHANGHAI SHYNDEC PHARMA CO LTD +1

Nitrogen-doped carbon quantum dots and preparation method thereof, and reduced graphene oxide and preparation method and application thereof

ActiveCN113089015AHigh yieldIncrease the proportion of C contentElectrodesPtru catalystElectrolysed water

The invention discloses nitrogen-doped carbon quantum dots and a preparation method thereof, and reduced graphene oxide and a preparation method and application thereof. When nitrogen-doped carbon quantum dots prepared from vinegar residues are directly used as a catalyst in water electrolysis hydrogen evolution, the effect of obviously accelerating the catalytic process in the water electrolysis process is not achieved, therefore, vertical graphene oxide with a stable structure is selected as a substrate material, nitrogen-doped carbon quantum dots are loaded on graphene oxide to form a nitrogen-doped carbon quantum dot loaded reduced graphene oxide material, and the material is used as a catalyst in a water electrolysis process. The material has good catalytic performance and conductive performance, the overpotential in the water electrolysis hydrogen production process can be reduced, the water electrolysis process can be catalyzed and accelerated, and the utilization rate of waste can be increased. Therefore, the material is applied to water electrolysis hydrogen evolution to replace a noble metal catalyst, the preparation cost of the catalyst is reduced, and large-scale production of hydrogen prepared by water electrolysis is realized.

Owner:NORTHWEST UNIV(CN)

Preparation method of high-energy graphene battery negative electrode material

InactiveCN110544765AWiden the interlayer structureAdequate responseGrapheneSecondary cellsHigh energySodium azide

The invention discloses a preparation method of a high-energy graphene battery negative electrode material, and belongs to the technical field of energy storage materials. The preparation method comprises the following steps: enabling graphene oxide to react with a dimethylformamide solution of isocyanate and sodium azide, lithium aluminum hydride and concentrated hydrochloric acid in sequence andpreparing hydrolyzed and reduced graphene oxide; equally dividing the hydrolyzed and reduced graphene oxide into two parts, enabling the two parts to respectively react with silicate ester and ferricsalt to respectively prepare concentrated acidic dispersion liquid and concentrated alkaline dispersion liquid, and mixing the two solutions to prepare a dry filter cake; performing reaction under ahigh-temperature condition, and performing cleaning with hydrofluoric acid to obtain the high-energy graphene battery negative electrode material. The obtained high-energy graphene battery negative electrode material is uses as a battery negative electrode material and has excellent cycling stability; after multiple times of charging and discharging cycling tests, the electrochemical performance and the volume expansion rate are kept at the optimal level.

Owner:长沙凯泽工程设计有限公司

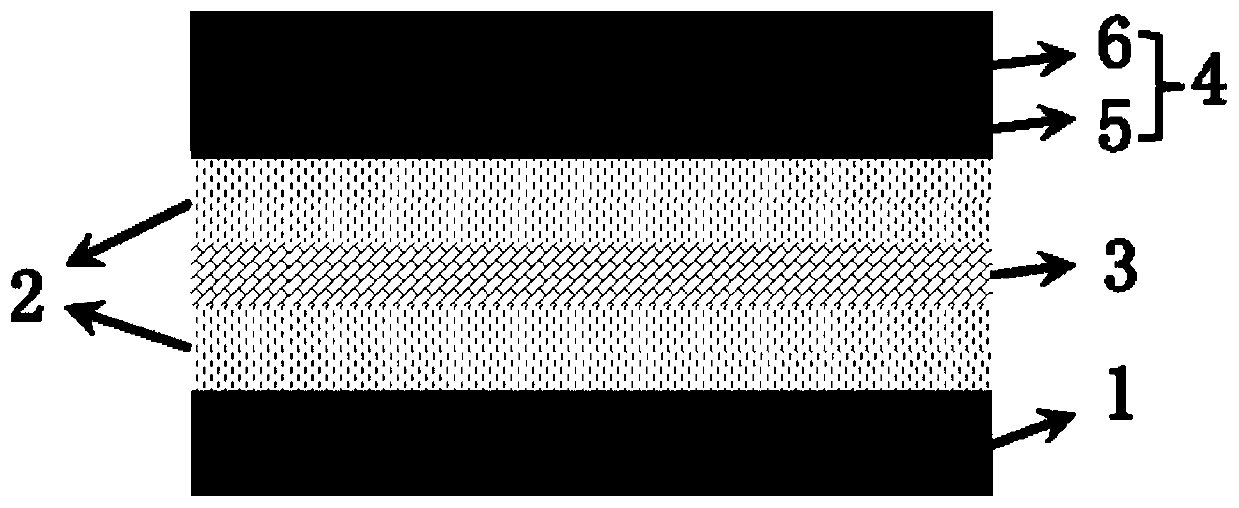

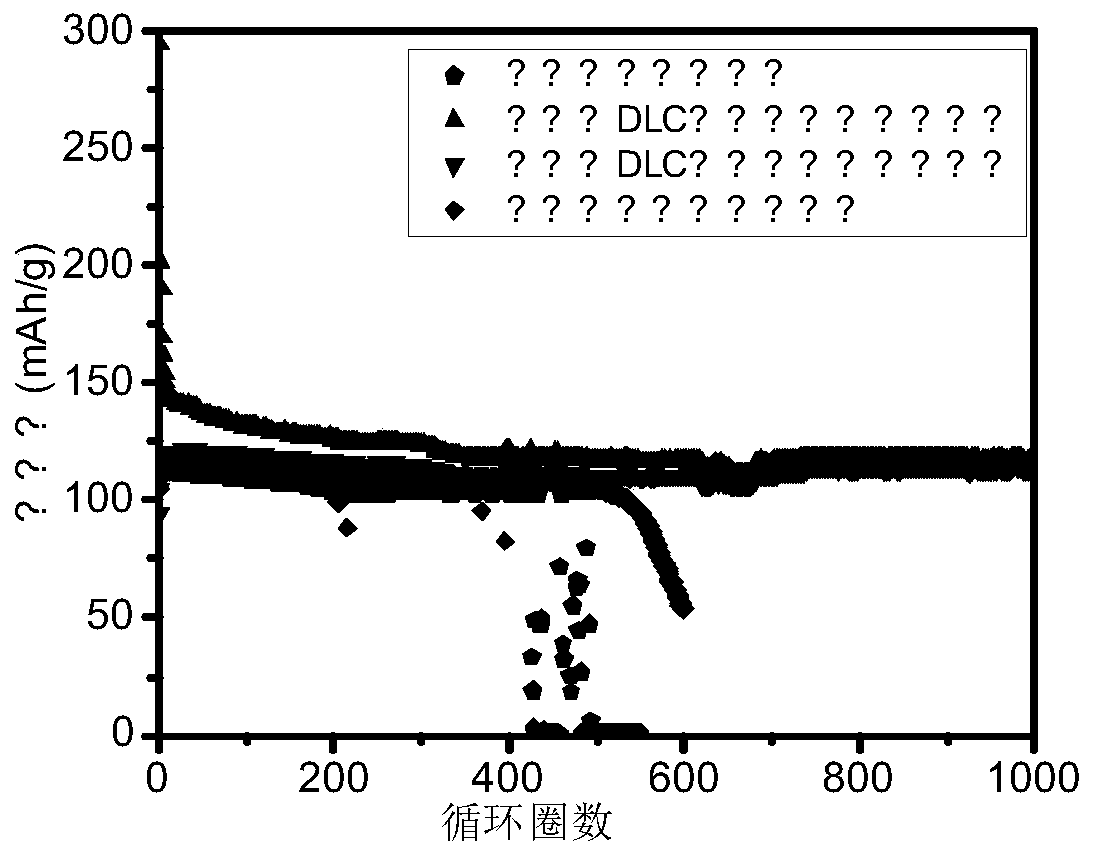

Element-doped diamond-like carbon film modified battery negative electrode and preparation method and application thereof

InactiveCN110896141AFix stability issuesSolve the problem of longevityElectrode manufacturing processesNegative electrodesCarbon filmMetal foil

The invention provides a battery negative electrode modified by an element-doped diamond-like carbon film. The battery negative electrode comprises a metal foil material and an element-doped diamond-like carbon film arranged on any surface of the metal foil material, and doped elements in the element-doped diamond-like carbon film are selected from at least one of F, N, P, Fe, Co, Ni and W; the metal foil material serves as a current collector and a negative electrode active material at the same time. The element-doped diamond-like carbon film is used for modifying the battery negative electrode, so that the problems that when a metal material is directly used as the battery negative electrode, the volume of the metal material is easy to expand, and the metal material is easy to react withelectrolyte at an interface to form an SEI film are solved, the stability of battery performance is improved, and the service life is prolonged.

Owner:SHENZHEN INST OF ADVANCED TECH

Preparation method of cadmium telluride

InactiveCN106495107AOvercome the defect of being easily oxidizedWell mixedMetal selenides/telluridesBinary selenium/tellurium compoundsMercury cadmium tellurideTe element

The invention discloses a preparation method of cadmium telluride. The preparation method is characterized by comprising the following steps: (1), firstly mixing a tellurium powder and a cadmium powder according to a ratio of 1:1.2 to 1.25; (2), grinding and stirring the mixed raw materials, so as to enable the tellurium powder and the cadmium powder to be uniformly mixed; (3), loading the uniformly mixed raw materials into a graphite boat, and then placing the graphite boat into a synthetic furnace to perform synthesis on the raw materials; (4), grinding and mixing a produced cadmium telluride material again; (5), adding the ground cadmium telluride material into a heating furnace, so as to perform annealing treatment on the material at the temperature to be 450 to 500 DEG C for 1 to 1.5 hour. The preparation method improves the purity of a synthetic product and the utilization factor of the raw materials.

Owner:乐山凯亚达光电科技有限公司

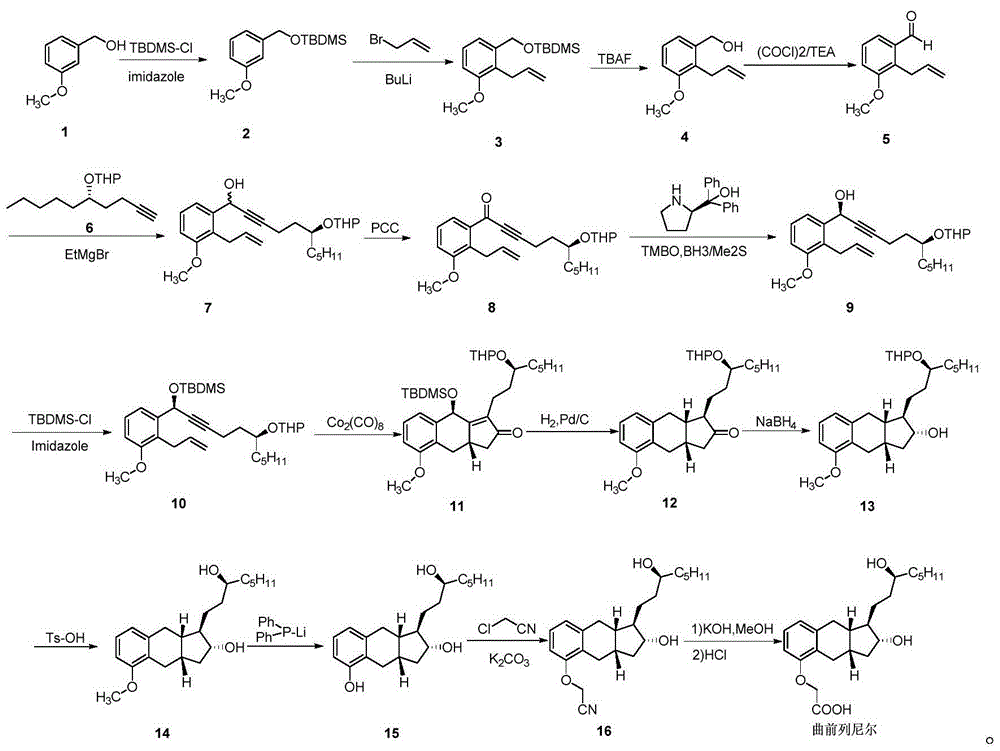

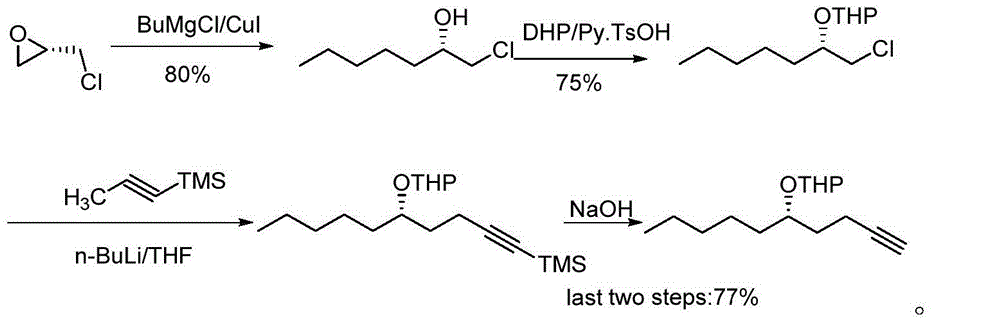

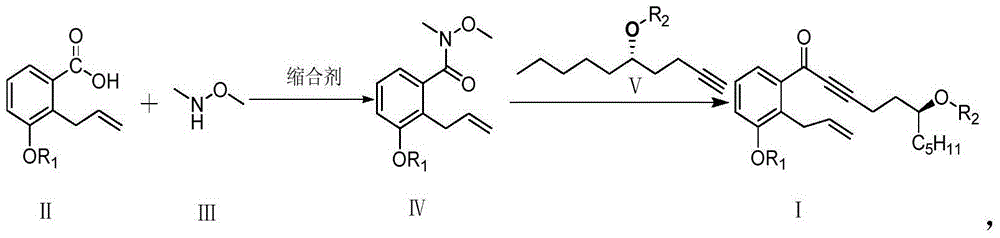

Preparation method for treprostinil intermediate

ActiveCN104892555AMild reaction conditionsEasy recrystallization purificationOrganic chemistryBulk chemical productionTreprostinilKetone

The invention relates to a preparation method for a treprostinil intermediate (I). The preparation method comprises the steps that: a compound of a formula (II) and a compound of a formula (III) or acidic salt thereof react in the presence of a condensing agent to obtain a compound of a formula (IV); the compound of the formula (IV) and a compound of a formula (V) react to obtain a compound of a formula (I). According to the preparation method for the treprostinil intermediate, weinreb amide and alkyne negative ions react to directly obtain a ketone compound (I), so that environment pollution caused by heavy metal (a PCC oxidant) is avoided, and the adoption of a butyl lithium low-temperature reaction method is also avoided. The preparation method for the treprostinil intermediate has the advantages that reaction conditions are mild, the yield is high, the purity of products is high, and the industrial application prospect is wide. (Formulae (I), (II), (III), (IV) and (V) are shown in the specification)

Owner:JIANGSU HANSOH PHARMA CO LTD +1

Biochemical landfill leachate treatment process

PendingCN110357344AAdd lessReduce processing costsWater treatment parameter controlWater contaminantsElectrolysisComposite electrolyte

The invention discloses a biochemical landfill leachate treatment process, which comprises: adjusting the pH value of landfill leachate with an ammonia nitrogen concentration of more than 2000 mg / L and B / C of less than 0.2 to 8-9, and filtering; precipitating the filtered landfill leachate in a coagulation pool; carrying out electrolysis treatment on the effluent of the coagulation pool for 20-30min in an electrolysis tank with a voltage of 3-5 V by using a titanium alloy electrode and a composite electrolyte, wherein the composite electrolyte comprises sodium hydroxide and hydrochloric acidfor adjusting the pH value of the effluent of the coagulation pool to 6-9, sodium chloride for adjusting the TDS value of the effluent of the coagulation pool to more than or equal to 6000 mg / L, and sodium hypochlorite for adjusting the redox potential of the effluent of the coagulation pool to more than -300 mV; and sequentially carrying out catalytic ozone oxidation treatment and biochemical treatment on the effluent of the electrolysis tank. According to the present invention, with the process, by adjusting the TDS value and the redox potential, the direct oxidation effect and the indirectoxidation effect in the electrolysis reaction are optimally balanced so as to obtain the optimal ammonia nitrogen and COD removal effect at low energy consumption.

Owner:章俭

Preparation method of silk fibroin lyophilized powder

InactiveCN110698556AHigh activityEasy to useCosmetic preparationsToilet preparationsPolymer sciencePolyethylene glycol

The invention provides a preparation method of silk fibroin lyophilized powder. The preparation method includes that small molecular silk fibroin is formed after silk fibroin is enzymatically hydrolyzed, starch is introduced and enzymatically hydrolyzed, viscous small molecular substance is generated after starch enzymolysis and adhered to the surface of the small molecular silk fibroin, and induction action of alcohol, crosslinking action of polyethylene glycol diglycidyl ether and freeze-thawing action are combined to enable the silk fibroin lyophilized powder to be in nanoscale size, supportive of transdermal absorption and good in cosmetic effect. The silk fibroin lyophilized powder is a lyophilized powder product and is high in activity and convenient to use.

Owner:长沙凯泽工程设计有限公司

A kind of graphene/titanium dioxide composite material and its preparation method and application

ActiveCN108160064BSimplify the linkConducive to follow-up reactionsGas treatmentPhysical/chemical process catalystsGraphene flakeGraphite

The invention relates to a graphene / titanium dioxide composite material and its preparation method and application. Graphene / titanium dioxide composite materials include: graphene, and titanium dioxide particles closely adhered to the graphene sheets. The present invention selects graphene and titanium dioxide to be composited to obtain a high-efficiency photocatalyst that has the excellent properties of both graphene and titanium oxide.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Graphene composite material and preparation method and application thereof

InactiveCN111905697AImprove adsorption capacityFully utilizeOther chemical processesWater contaminantsOrganic solventOxide composite

The invention discloses a preparation method of a graphene composite material, and the method comprises the following steps: mixing an aqueous solution of gamma-Fe2O3 with at least one alkaline solution under a constant-temperature stirring condition to obtain a first mixed solution; dissolving chitosan in an acetic acid solution to obtain a second mixed solution; stirring and reacting the first mixed solution and the second mixed solution under a heating condition, performing cooling to room temperature after the reaction is completed, washing precipitated substances with an organic solvent and water in sequence, and performing drying to obtain chitosan-modified gamma-Fe2O3; and dissolving graphene oxide in water, carrying out ultrasonic dissolution to obtain a graphene oxide suspension,carrying out ultrasonic mixing treatment on chitosan-modified gamma-Fe2O3 and the graphene oxide suspension, adjusting the pH value to neutrality, and carrying out separation, washing and drying underthe condition of an external magnetic field to obtain the chitosan-modified gamma-Fe2O3 / graphene oxide composite material. The preparation method is simple, and the obtained composite material is good in adsorption performance and separability and low in cost and can be applied to the technical field of wastewater treatment.

Owner:ANYANG NORMAL UNIV

A kind of environment-friendly preparation method of fluorine-containing acrylate

ActiveCN108911983BNo potential risk of PFOAIn line with industrial policyOrganic compound preparationCarboxylic acid esters preparationIodideEthyl group

The invention relates to the technical field of preparation of new fluorine-containing materials, particularly to an environmentally friendly preparation method of fluorine-containing acrylate. The environmentally friendly preparation method comprises: carrying out a reaction on short-chain perfluoroiodoalkane and ethylene, separating, and purifying to obtain perfluoroalkylethyl iodide; carrying out hydrolysis on the perfluoroalkylethyl iodide, separating, and purifying to obtain perfluoroalkylethanol; and carrying out a reaction on the perfluoroalkylethanol and acrylic acid, separating, and purifying to obtain the product. According to the present invention, the perfluorooctyl-free product is synthesized, the potential risk of PFOA production cannot exist, and the obtained product is theenvironmentally friendly product, and meets the national industrial policy; the preparation method is simple, and is suitable for industrial production; and the reaction conversion rate is high, and the purity of the intermediate product is high, such that the subsequent reaction is easily performed, the yield is easily increased, and the cost is reduced.

Owner:济南齐氟新材料技术有限公司 +1

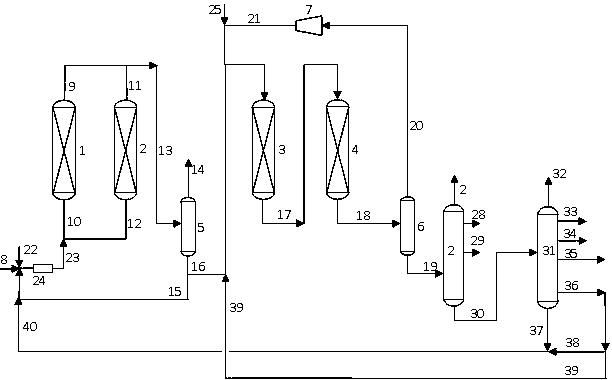

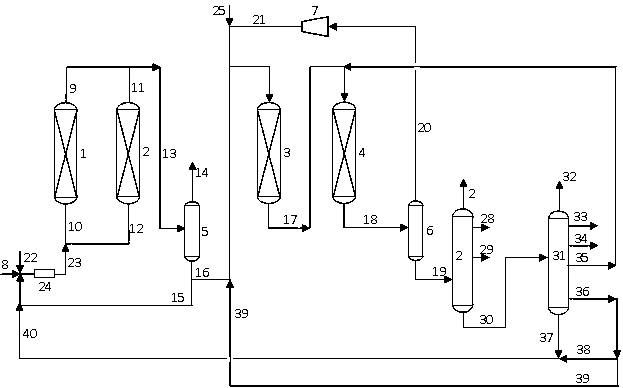

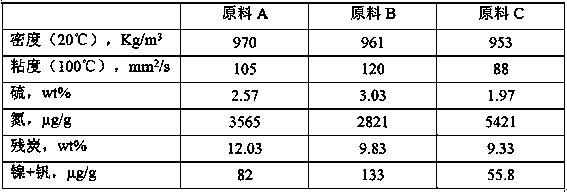

Method for treating inferior oil product by combined process

ActiveCN110408431AExtended operating cycleReduce poisonTreatment with hydrotreatment processesHydrogenReaction temperature

The invention discloses a method for treating an inferior oil product by a combined process. The method comprises the following steps: allowing an inferior oil raw material and hydrogen to enter a mixer for saturated hydrogen dissolution, and allowing an obtained mixture to pass through a hydropretreating zone; and separating a reaction effluent, allowing a separated reaction effluent and catalytic-cracked circulating oil to enter a hydrotreating reaction zone, separating an obtained reaction effluent, allowing obtained hydrotreated residual oil to undergo a catalytic cracking reaction, allowing obtained circulating oil and / or an oil slurry to be circulated to a hydropretreating reaction zone, and allowing a part of obtained circulating oil to be circulated to the hydrotreating reaction zone; wherein the reaction temperature t1 of the hydropretreating reaction zone is higher than the reaction temperature t2 of the hydrotreating reaction zone. The method provided by the invention can increase the utilization rate of a main hydrotreating catalyst, prolongs the operation cycle of a combined device, and increases the operation efficiency of a device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of high-purity cadmium telluride

InactiveCN106495106AOvercome the defect of being easily oxidizedWell mixedMetal selenides/telluridesBinary selenium/tellurium compoundsTe elementGraphite

The invention discloses a preparation method of high-purity cadmium telluride. The preparation method is characterized by sequentially including the steps of 1), firstly, mixing tellurium powder with cadmium powder according to proportion of 1:1.5-1.56; 2), grinding and stirring the mixed raw materials to have the tellurium powder and the cadmium powder mixed evenly; 3), feeding the evenly-mixed raw materials into a graphite boat and placing the graphite boat in a synthesis furnace for synthesizing; 4), grinding and mixing the generated cadmium telluride materials once more; 5), placing the ground cadmium telluride materials in a heating furnace for annealing treatment and controlling the temperature within 600-750DEG C and annealing time within 1-2 hours. With the method, purity of the qualified product is improved, and utilization of the raw materials is increased.

Owner:乐山凯亚达光电科技有限公司

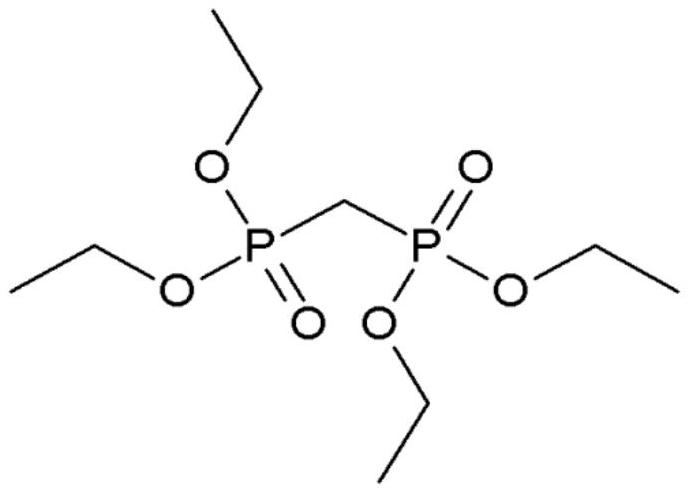

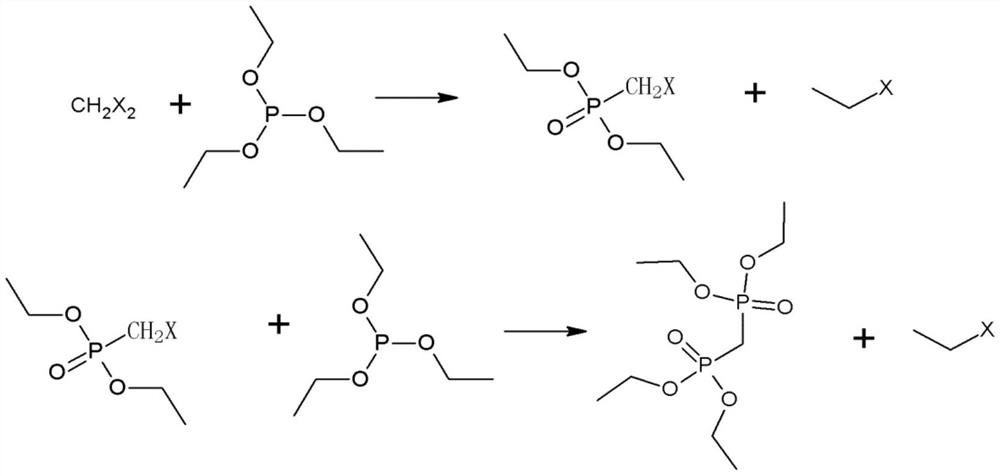

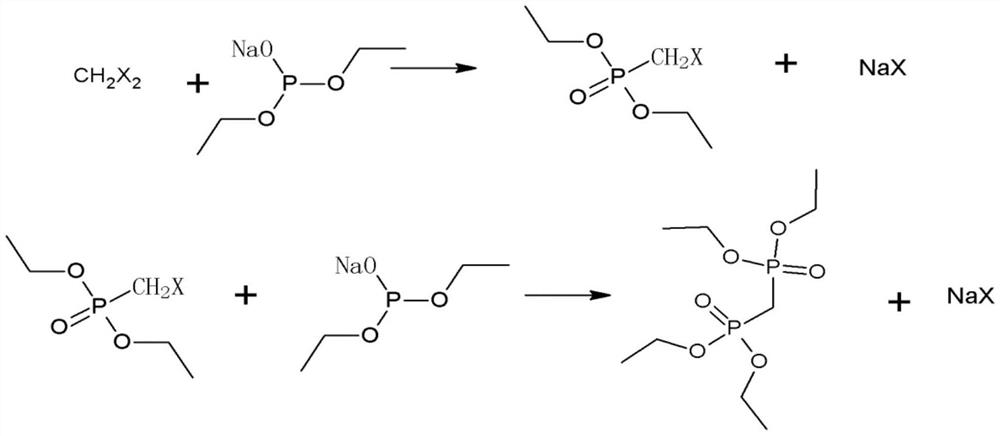

Preparation method for synthesizing vitamin A intermediate tetraethyl methylenediphosphonate

PendingCN112010893AReduce generationConducive to follow-up reactionsGroup 5/15 element organic compoundsPhosphorous acidPhosphite salt

The invention relates to a preparation method for synthesizing a vitamin A intermediate tetraethyl methylenediphosphonate. The preparation method comprises the following steps: adding an organic solvent into metallic sodium or a metallic sodium compound, uniformly stirring, dropwise adding diethyl phosphite at 10-60 DEG C, and keeping the temperature at 10-60 DEG C after the diethyl phosphite is dropwise added, so as to obtain a sodium diethyl phosphite solution; removing the organic solvent, and recovering the organic solvent to obtain a sodium diethyl phosphite solid; adding dichloromethaneinto the sodium diethyl phosphite salt for dissolving, and carrying out a substitution reaction at 20-55 DEG C, so as to obtain the tetraethyl methylenediphosphate. The method is simple and convenientto operate, short in process flow, less in involved solvent, simple and convenient to recycle, economic, environment-friendly, good in product quality and high in yield. Industrial production conditions can be met.

Owner:ZHEJIANG MEDICINE CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Crystal form of 6, 7-dihydro-6-mercapto-5H-pyrazolo[1,2-alpha][1,2,4] triazoliumchloride and preparation method thereof Crystal form of 6, 7-dihydro-6-mercapto-5H-pyrazolo[1,2-alpha][1,2,4] triazoliumchloride and preparation method thereof](https://images-eureka.patsnap.com/patent_img/18c1e736-fe04-47e4-bfc2-a858f5e0ca1e/H2008100797329E0000011.PNG)

![Crystal form of 6, 7-dihydro-6-mercapto-5H-pyrazolo[1,2-alpha][1,2,4] triazoliumchloride and preparation method thereof Crystal form of 6, 7-dihydro-6-mercapto-5H-pyrazolo[1,2-alpha][1,2,4] triazoliumchloride and preparation method thereof](https://images-eureka.patsnap.com/patent_img/18c1e736-fe04-47e4-bfc2-a858f5e0ca1e/H2008100797329E0000021.PNG)

![Crystal form of 6, 7-dihydro-6-mercapto-5H-pyrazolo[1,2-alpha][1,2,4] triazoliumchloride and preparation method thereof Crystal form of 6, 7-dihydro-6-mercapto-5H-pyrazolo[1,2-alpha][1,2,4] triazoliumchloride and preparation method thereof](https://images-eureka.patsnap.com/patent_img/18c1e736-fe04-47e4-bfc2-a858f5e0ca1e/H2008100797329E0000031.PNG)