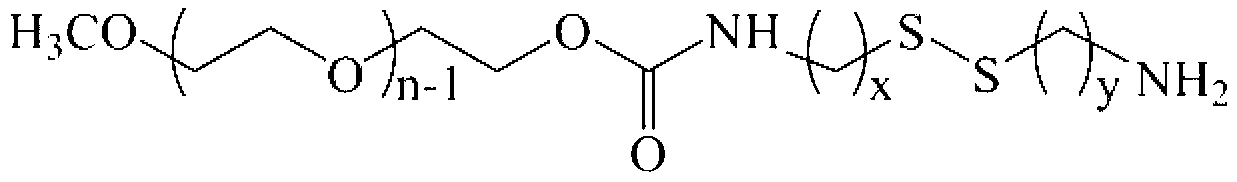

Bi-functional polyethylene glycol derivative and preparation method thereof

A polyethylene glycol and bifunctional technology, which is applied in the field of bifunctional polyethylene glycol derivatives and their preparation, can solve the cumbersome protection and deprotection of functional groups, the high price of polyethylene glycol derivatives, the Problems such as the decrease of the molecular weight of alcohols, etc., to achieve the effects of mass production, mild reaction conditions, high yield and product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

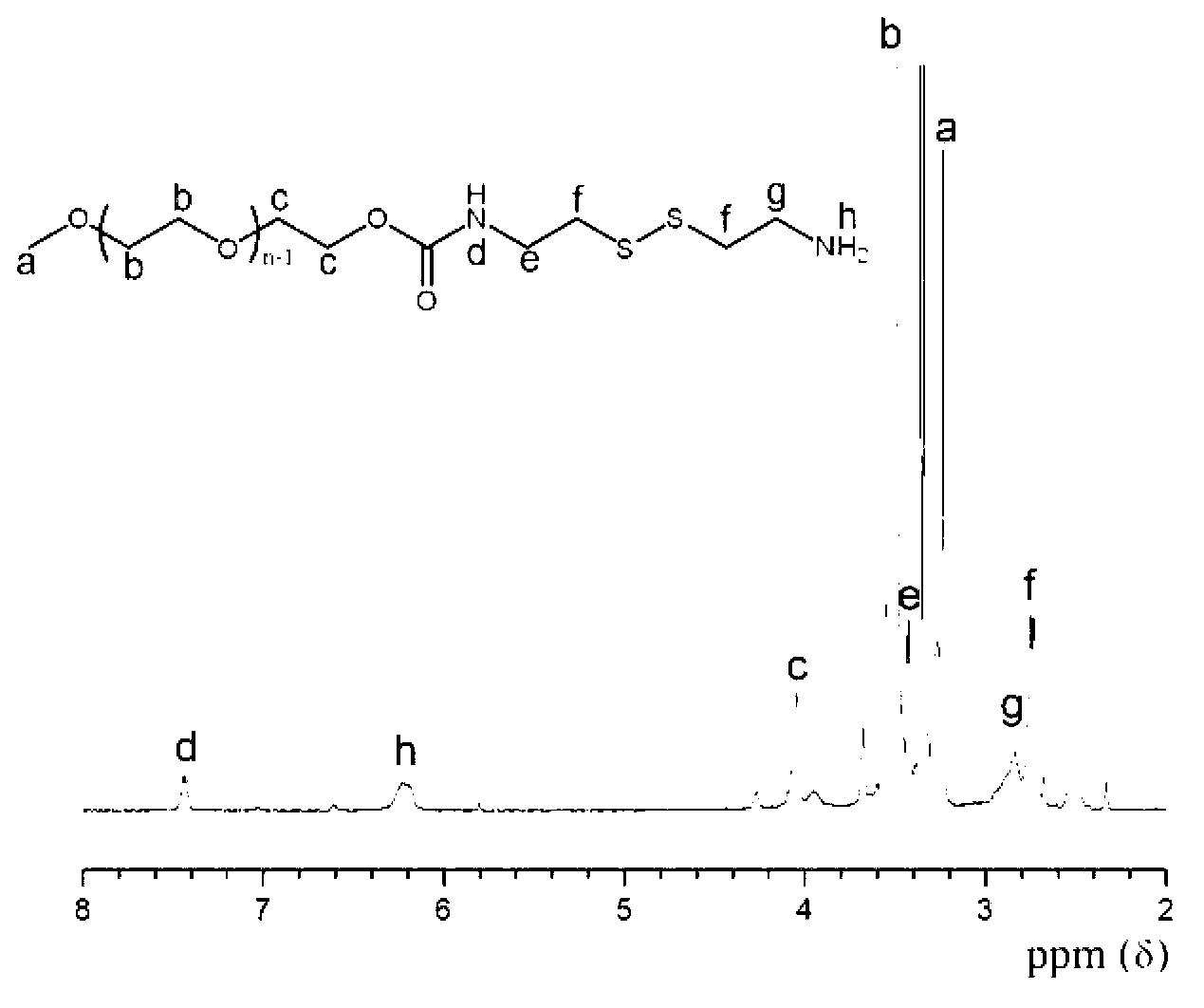

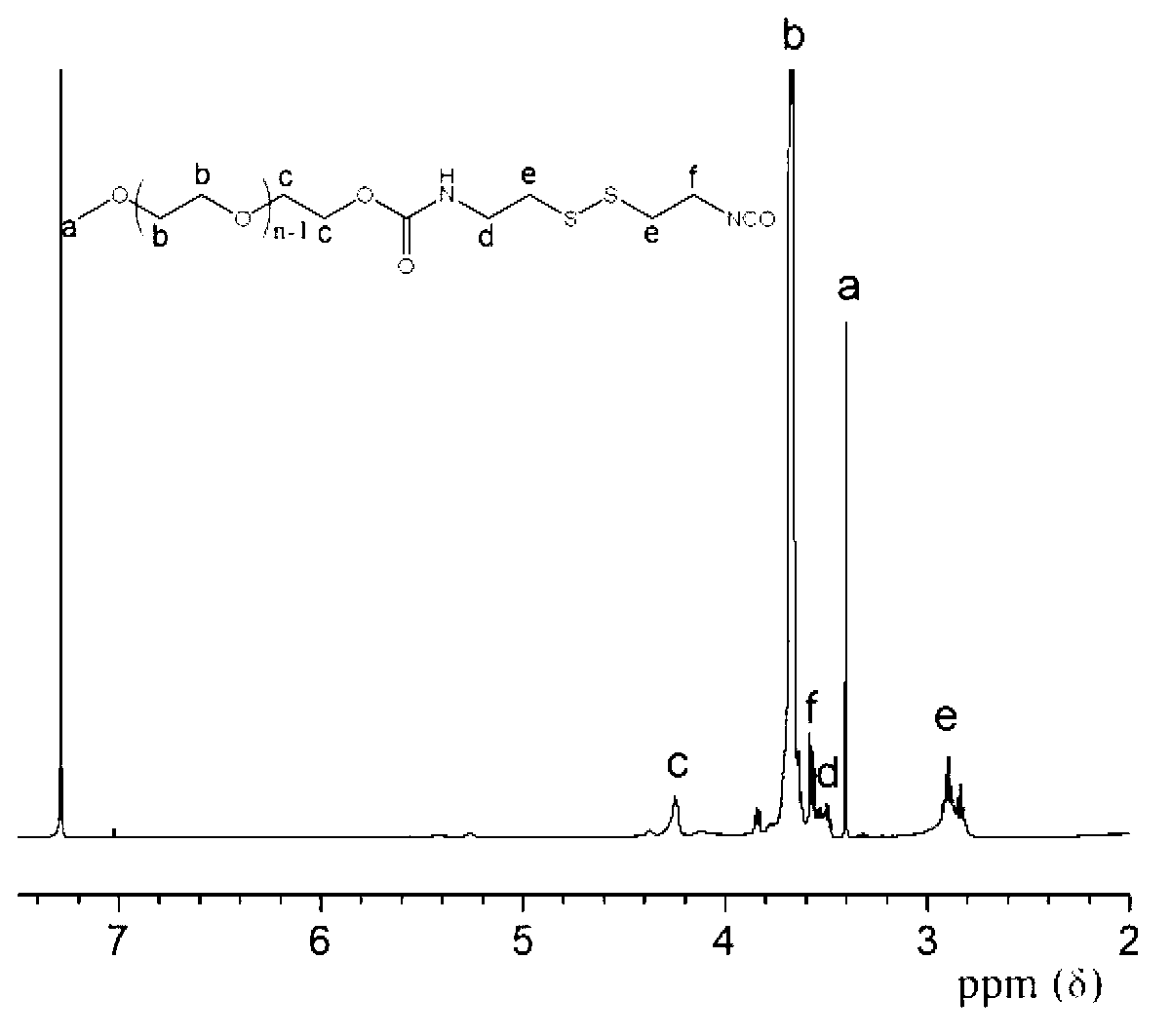

Image

Examples

Embodiment 1

[0043] 1) Synthesis of 3,3'-dithiodipropionylhydrazide:

[0044] Add 3,3'-dithiodipropionic acid and ethanol to a reactor containing toluene and p-toluenesulfonic acid, reflux for 10 hours, remove the solvent in a vacuum, and then add a mass concentration of 50% hydrazine hydrate aqueous solution, reflux reaction for 3 hours, and then recrystallized with a solvent mixed with water and ethanol at a volume ratio of 3:7 to obtain 3,3'-dithiodipropionyl hydrazide; wherein, the The molar ratio of added 3,3'-dithiodipropionic acid to ethanol is 1:15, and the molar ratio of 3,3'-dithiodipropionic acid to hydrazine hydrate in aqueous solution is 1:20; 3 , The molar ratio of 3'-dithiodipropionic acid to p-toluenesulfonic acid is 1:0.005; add 0.6mol of 3,3'-dithiodipropionic acid per liter of toluene;

[0045] 2) Synthesis of 2,2'-dithiodiethylisocyanate:

[0046] Dissolve 3,3'-dithiodipropionylhydrazide in hydrochloric acid with a concentration of 3mol / L, add dropwise an aqueous solu...

Embodiment 2

[0054] 1) Synthesis of 2,2'-dithiodiacetylhydrazide:

[0055] Add 2,2'-dithiodiacetic acid and methanol into a reactor containing toluene and p-toluenesulfonic acid, reflux for 8 hours, remove the solvent in a vacuum, and then add a mass concentration of 65 to the residue in the reactor % hydrazine hydrate aqueous solution, reflux reaction for 5 hours, and then recrystallized with a solvent mixed with water and ethanol at a volume ratio of 2:8 to obtain 2,2'-dithiodiacethydrazide; wherein, the added 2 , The molar ratio of 2'-dithiodiacetic acid to methanol is 1:15, the molar ratio of 2,2'-dithiodiacetic acid to hydrazine hydrate in aqueous solution is 1:30, 2,2'-di The molar ratio of thiodiacetic acid to p-toluenesulfonic acid is 1:0.01; add 1mol of 2,2'-dithiodiacetic acid to every liter of toluene;

[0056] 2) Synthesis of dithiodimethylisocyanate:

[0057] Dissolve 2,2'-dithiodiacetylhydrazide in hydrochloric acid with a concentration of 3mol / L, add dropwise sodium nitrit...

Embodiment 3

[0063] 1) Synthesis of 4,4'-dithiodibutyrhydrazide:

[0064] Add 4,4'-dithiodibutyric acid and methanol into a reactor filled with toluene and concentrated sulfuric acid with a mass concentration greater than 95%, reflux for 6 hours, remove the solvent in a vacuum, and add to the residue in the reactor Add an aqueous solution of hydrazine hydrate with a mass concentration of 85%, and then reflux for 6 hours, and then recrystallize with a solvent mixed with water and ethanol at a volume ratio of 1:9 to obtain 4,4'-dithiodibutyric hydrazide ; Wherein, the molar ratio of added 4,4'-dithiodibutyric acid to methanol is 1:25, and the molar ratio of 4,4'-dithiodibutyric acid to hydrazine hydrate in aqueous solution is 1 :25,4,4'-dithiodibutyric acid and the mol ratio of concentrated sulfuric acid are 1:0.015; Add 1.5mol of 4,4'-dithiodibutyric acid in every liter of toluene;

[0065] 2) Synthesis of 3,3'-dithiodipropylisocyanate:

[0066] Dissolve 4,4'-dithiodibutyric acid hydrazide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com