Nitrogen-doped carbon quantum dots and preparation method thereof, and reduced graphene oxide and preparation method and application thereof

A technology of carbon quantum dots and nitrogen doping, applied in electrolytic components, electrodes, electrolytic processes, etc., can solve the problems of limiting the large-scale production and application of carbon quantum dots, and the high cost of carbon quantum dot sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] In order to process vinegar residue waste more effectively and utilize it as a resource, the invention provides a method for preparing nitrogen-doped carbon quantum dots using vinegar residue, the method comprising the following steps:

[0043] (1) Dry the vinegar slag in an oven, the drying temperature is 200°C, and the drying time is 2h, take out part of the dried vinegar slag, put it into a muffle furnace for heating and carbonization treatment; the carbonization temperature is 400 ℃, the time is 6 hours, after the carbonization is completed, the carbonized product is taken out, and the carbonized product is ground into powder to obtain carbonized vinegar slag powder.

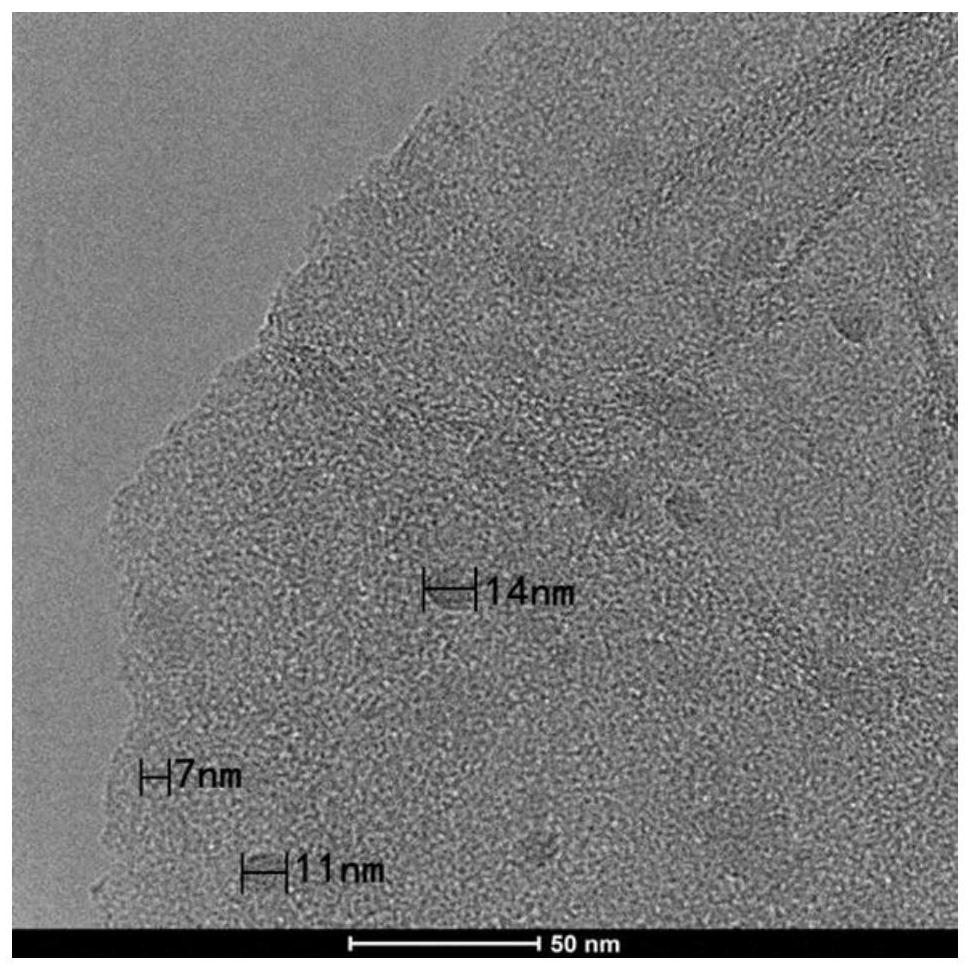

[0044] (2) In the carbonized vinegar residue powder obtained in step (1), add urea as a nitrogen source, and add water as a solvent simultaneously; when urea is a nitrogen source, the ratio of vinegar residue, urea and water is 0.1g:0.1g:10mL , put the mixture into an autoclave for hydrothermal reacti...

Embodiment 1

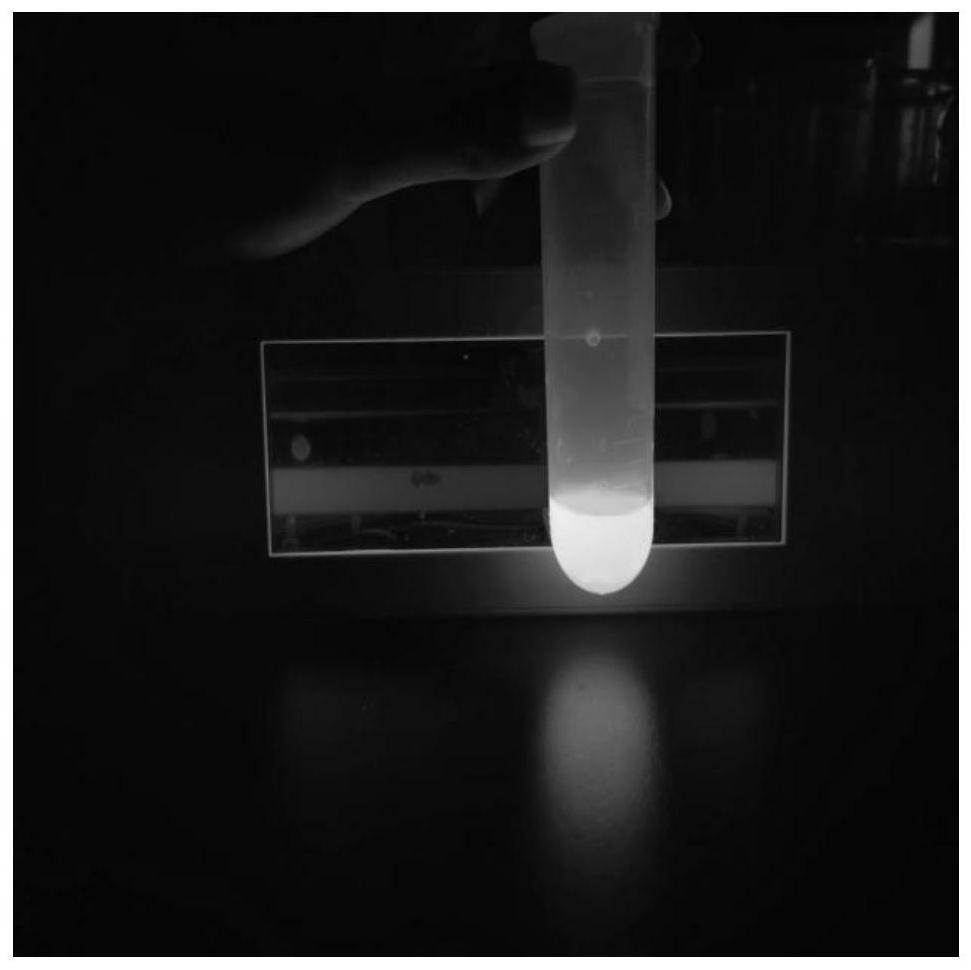

[0050] 1) Preparation of nitrogen-doped carbon quantum dots: Put the vinegar residue in an oven at 200°C for 2 hours to dry the moisture contained in the vinegar residue; then put the dried vinegar residue into a porcelain boat and place it on a horse In the Furnace, carbonize at 400°C for 6 hours, take it out after carbonization and grind it into powder; then use an analytical balance to weigh 0.1g of carbonized vinegar residue powder and 0.1g of urea, and measure 10mL of distilled water, mix them into The autoclave was placed in an oven, and reacted at 200° C. for 8 hours; finally, the nitrogen-doped carbon quantum dot solution was obtained by filtering through a 300 mm filter paper.

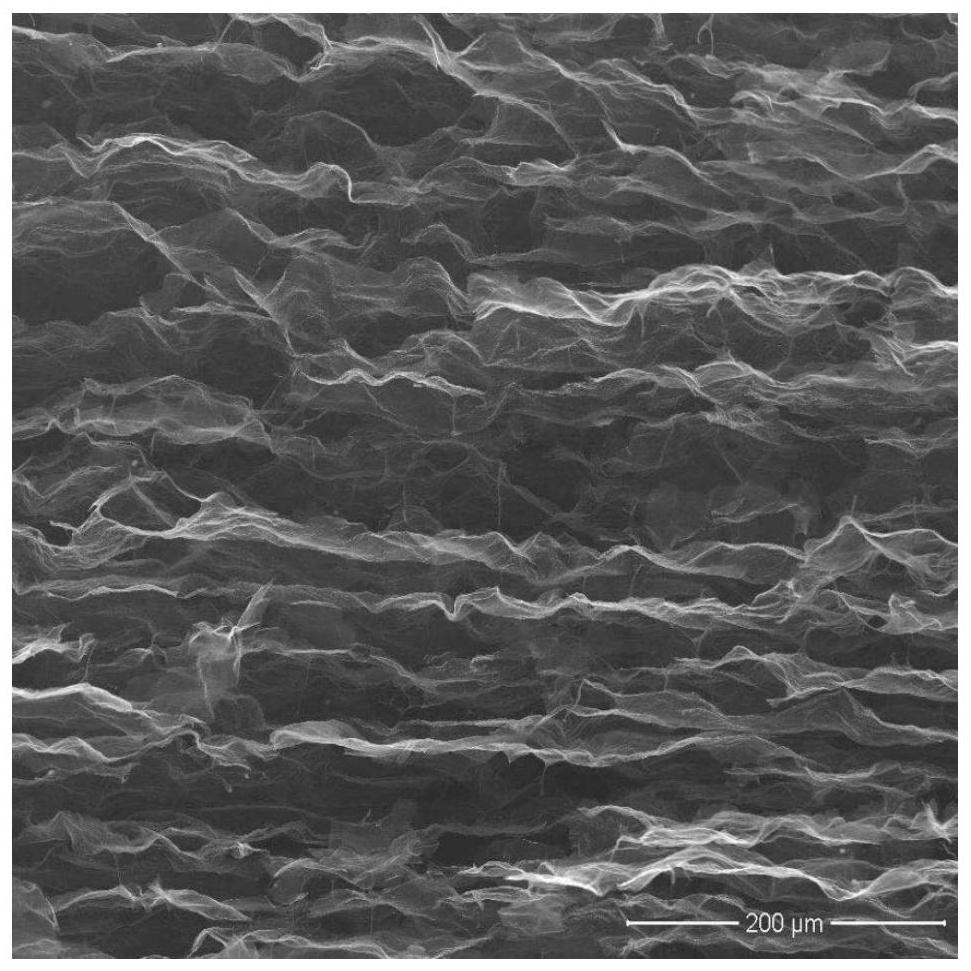

[0051] 2) Take 10ml of the filtered nitrogen-doped carbon quantum dot solution, 10ml of deionized water and 0.24g of graphene oxide and ultrasonically mix them, and after ultrasonic treatment for 2 hours, a uniformly dispersed mixed solution is formed. After being frozen with liquid nitrogen, ...

Embodiment 2

[0056] 1) Preparation of nitrogen-doped carbon quantum dots: Put the vinegar residue in an oven at 200°C for 2 hours to dry the moisture contained in the vinegar residue; then put the dried vinegar residue into a porcelain boat and place it on a horse In the Furnace, carbonize at 400°C for 6 hours, take it out after carbonization and grind it into powder; then use an analytical balance to weigh 0.1g of carbonized vinegar residue powder and 0.1g of urea, and measure 10mL of distilled water, mix them into The autoclave was placed in an oven, and reacted at 200° C. for 8 hours; finally, the nitrogen-doped carbon quantum dot solution was obtained by filtering through a 100 mm filter paper.

[0057] 2) Take 10ml of the filtered nitrogen-doped carbon quantum dot solution, 10ml of deionized water and 0.24g of graphene oxide and ultrasonically mix them, and after ultrasonic treatment for 1 hour, a uniformly dispersed mixed solution is formed. After being frozen with liquid nitrogen, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com