High-density graphene/silver composite and preparation method thereof

A composite material, graphene technology, applied in graphene, metal material coating process, nanotechnology for materials and surface science, etc., can solve the problem of low mass percentage of silver or nano silver, low density, particle size problems such as low diameter, to avoid agglomeration and damage, simple preparation process, and prevent agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

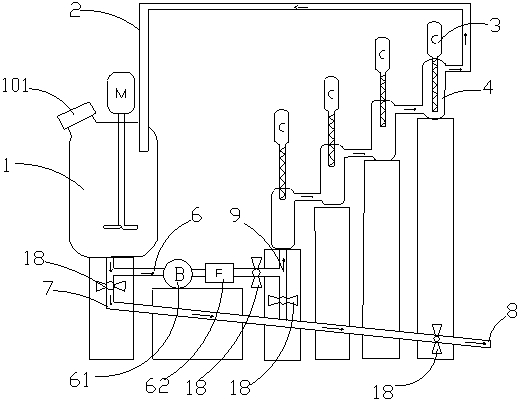

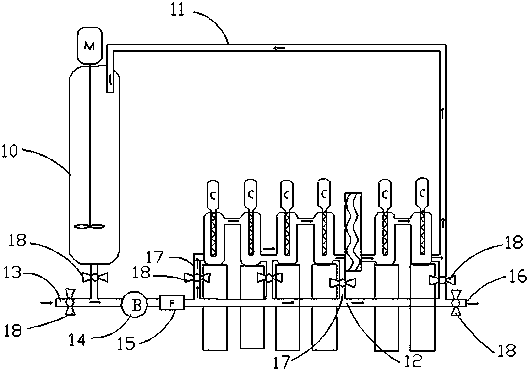

Image

Examples

Embodiment 1

[0036] The present embodiment provides a kind of high density graphene / silver composite material preparation method, comprises the following steps:

[0037] S1. Preparation of graphene oxide substrate: graphene oxide was prepared by the improved Hummers method, and then dissolved in water for secondary ultrasonic dispersion to obtain a monolayer graphene oxide aqueous solution with a concentration of 0.02g / L;

[0038] After cleaning and drying the silicon carbide or silicon oxide substrate, immerse it in APTS ethanol solution to complete the surface treatment, and then immerse it in the graphene oxide aqueous solution to obtain the graphene oxide substrate;

[0039] S2. Configure silver nitrate reducing solution: mix 0.1mol / L silver nitrate, 0.05mol / L sodium citrate and 0.1mol / L glucose to obtain silver nitrate reducing solution;

[0040] S3. Immerse the graphene oxide substrate prepared in step S1 in the silver nitrate reducing solution in step S2, the reaction temperature is...

Embodiment 2

[0050] The present embodiment provides a kind of high density graphene / silver composite material preparation method, comprises the following steps:

[0051] S1. Preparation of graphene oxide substrate: graphene oxide was prepared by the improved Hummers method, and then dissolved in water for secondary ultrasonic dispersion to obtain a monolayer graphene oxide aqueous solution with a concentration of 0.04g / L;

[0052] After cleaning and drying the silicon carbide or silicon oxide substrate, immerse it in APTS ethanol solution to complete the surface treatment, and then immerse it in the graphene oxide aqueous solution to obtain the graphene oxide substrate;

[0053] S2. Configure silver nitrate reducing solution: mix 0.3mol / L silver nitrate, 0.1mol / L sodium citrate and 0.3mol / L glucose to obtain silver nitrate reducing solution;

[0054] S3. Immerse the graphene oxide substrate prepared in step S1 in the silver nitrate reducing solution in step S2. The reaction temperature is ...

Embodiment 3

[0060] This embodiment is basically the same as Embodiment 1, except that in step S4, steps S2 to S4 are repeated three times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com