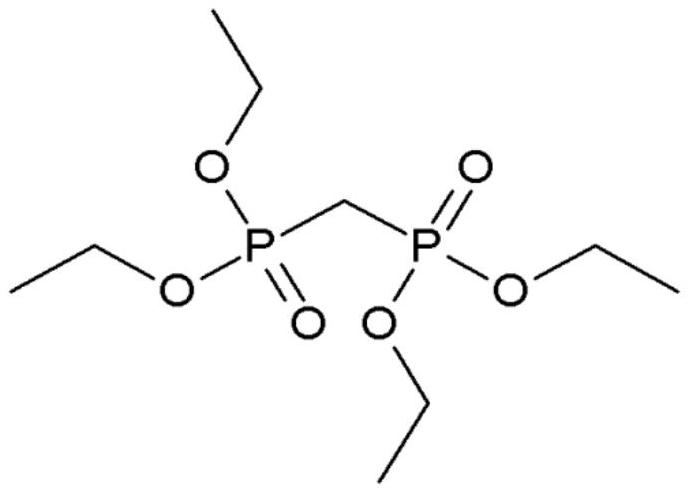

Preparation method for synthesizing vitamin A intermediate tetraethyl methylenediphosphonate

A technology of tetraethyl methylene diphosphonate and diethyl phosphite, which is applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., and can solve problems that are not suitable for industrial production , Difficult waste water treatment, difficulty in mechanical application, etc., to achieve the effect of facilitating recycling, shortening reaction time, and facilitating follow-up reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

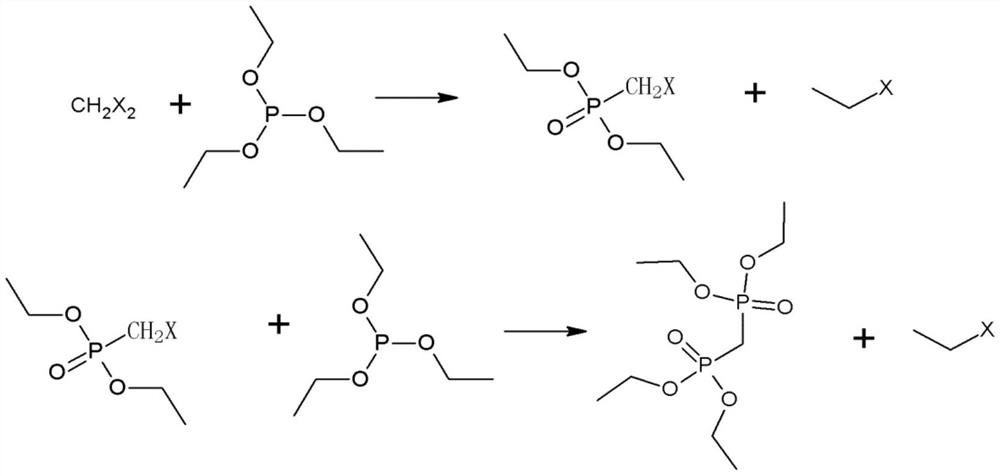

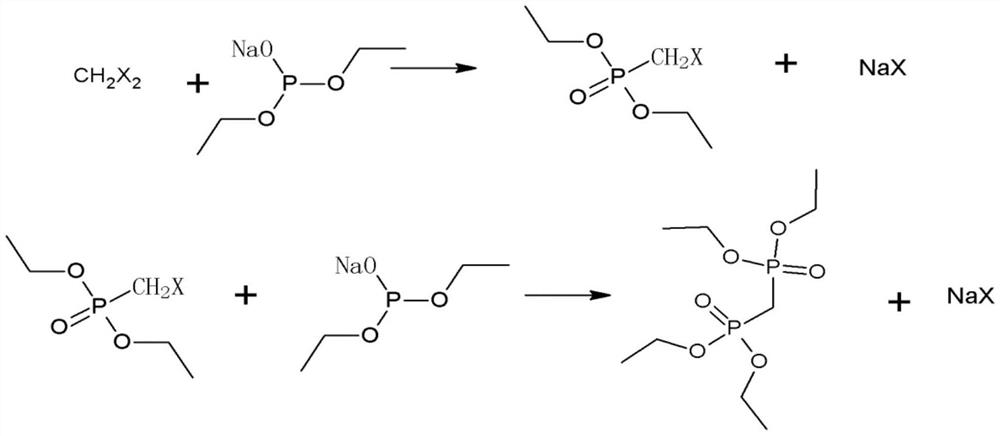

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: the preparation of tetraethyl methylene diphosphate

[0031] (1) Under the condition of nitrogen protection, accurately weigh the solid sodium metal (23.69 g, 1.03 mol) and place it in a 500 ml four-neck flask.

[0032] (2) In step (1), put the four-necked flask in the sodium metal solid, add 100 ~ 150ml tetrahydrofuran, dropwise add diethyl phosphite (138.1g, 1.0mol) to control the reaction temperature at 15 ~ 25 ° C, drop After adding for 2 hours, after dropping, keep warm at 20-25°C for 10 hours to obtain a sodium diethyl phosphite solution, and precipitate to obtain a solid sodium diethyl phosphite.

[0033] (3) Dissolve the diethyl phosphite sodium salt in step (2) with 425g methylene chloride (5.0mol). React at a temperature of 25-30°C for 42-50 hours, add 200ml of water to terminate the reaction, and separate the liquids. The upper aqueous phase was extracted twice, the organic phases were combined, and distilled under reduced pressure to obtain t...

Embodiment 2

[0035] The operating steps are the same as in Example 1, except that the type of alkali in step (1) is changed, and sodium hydride is used as the alkali to prepare sodium diethyl phosphite, which is then reacted with dichloromethane to prepare tetramethylene diphosphonate ethyl ester. The fine GC content is 97.5%, and the yield is 80.5%.

Embodiment 3

[0037] The operation steps are the same as in Example 1, the difference is that the type of alkali in step (1) is changed, and sodium ethylate is used as alkali to prepare sodium diethyl phosphite, which is then reacted with dichloromethane to prepare tetramethylene diphosphonate ethyl ester. The fine GC content is 97.0%, and the yield is 76.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com