Graphene/titanium dioxide composite material, preparation method and application thereof

A technology of titanium dioxide and composite materials, which is applied in the field of air purification, can solve the problems of reducing the photocatalytic efficiency of composite materials, not being able to fully exert the adsorption performance, and less research on adsorption and degradation, so as to improve photocatalytic activity and inhibit composite materials. The effect of increasing the local gas concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

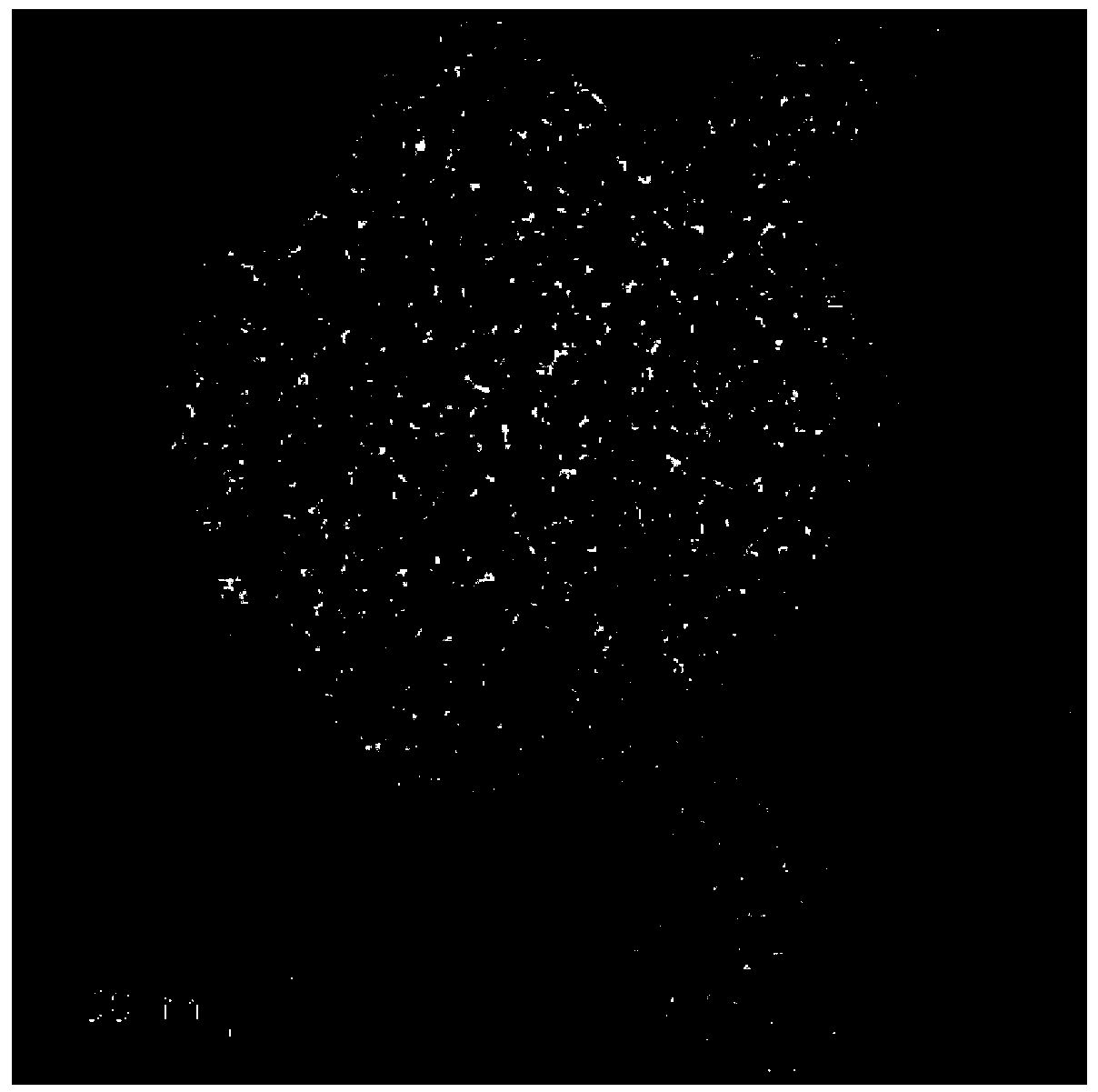

[0058] Preparation of Amorphous Titanium Oxide. In one example, amorphous titanium oxide is prepared by liquid phase hydrolysis. Dissolve the organic titanium source in a mixed solution of absolute ethanol and water (preferably deionized water), mix well and continue to react at a certain temperature for a period of time, and then undergo solid-liquid separation (such as centrifugation), washing, and drying to obtain amorphous Titanium oxide particles. The organic titanium source can be at least one of titanium isopropoxide and tetrabutyl titanate. Compared with inorganic titanium sources, the experimental conditions of organic titanium sources are mild, and the experiment safety is high. The mass ratio of the organic titanium source, absolute ethanol and water can be (1-5): (300-500): (3-10). Under this reaction ratio, the hydrolysis rate of the titanium source is moderate, which helps to obtain granular Titanium oxide particles with a diameter of 3 to 50 nm. The reaction...

Embodiment 5

[0065] In one example, the above-mentioned coating was tested for photocatalytic degradation of low-concentration flowing adjacent xylene and acetaldehyde gas under low-power ultraviolet light. The concentrations of o-xylene and acetaldehyde gas are both 25ppm. The ultraviolet light illumination condition can be 250W xenon lamp. The distance between the xenon lamp and the composite material is 35 cm. The ultraviolet photodegradation efficiency of the graphene / titanium dioxide composite material prepared by the invention can be 20% to 90% for o-xylene gas. The ultraviolet light degradation efficiency of acetaldehyde gas can be 20% to 90%. See respectively Figure 5 with Image 6 It can be seen that for the graphene / titanium dioxide composite material obtained by the above method, for the degradation of low-concentration gaseous acetaldehyde under the condition of 250W xenon lamp, the photocatalytic activity of Example 6 (rGO wt%=0.5%) is relatively higher than that of other...

Embodiment 1

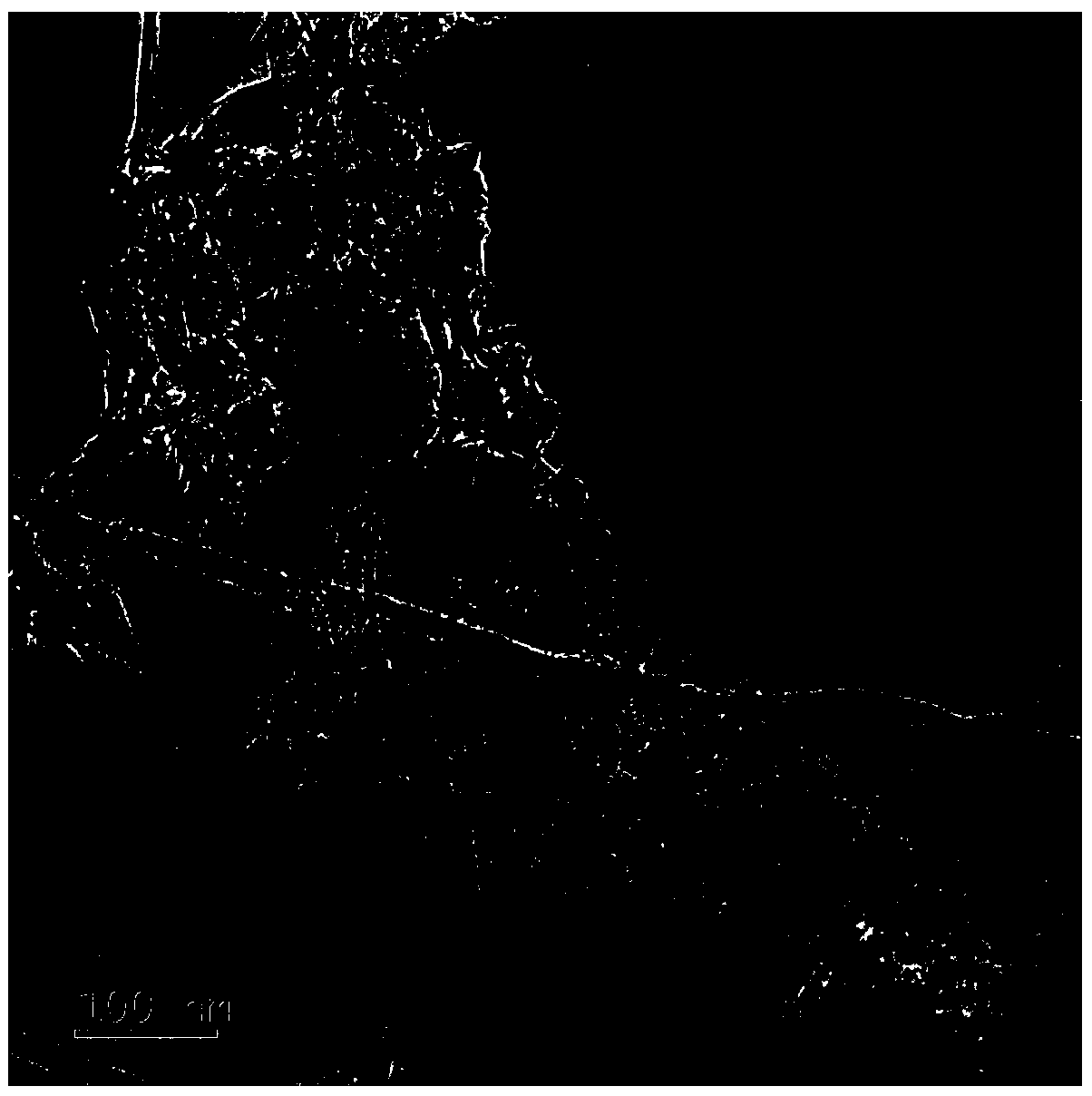

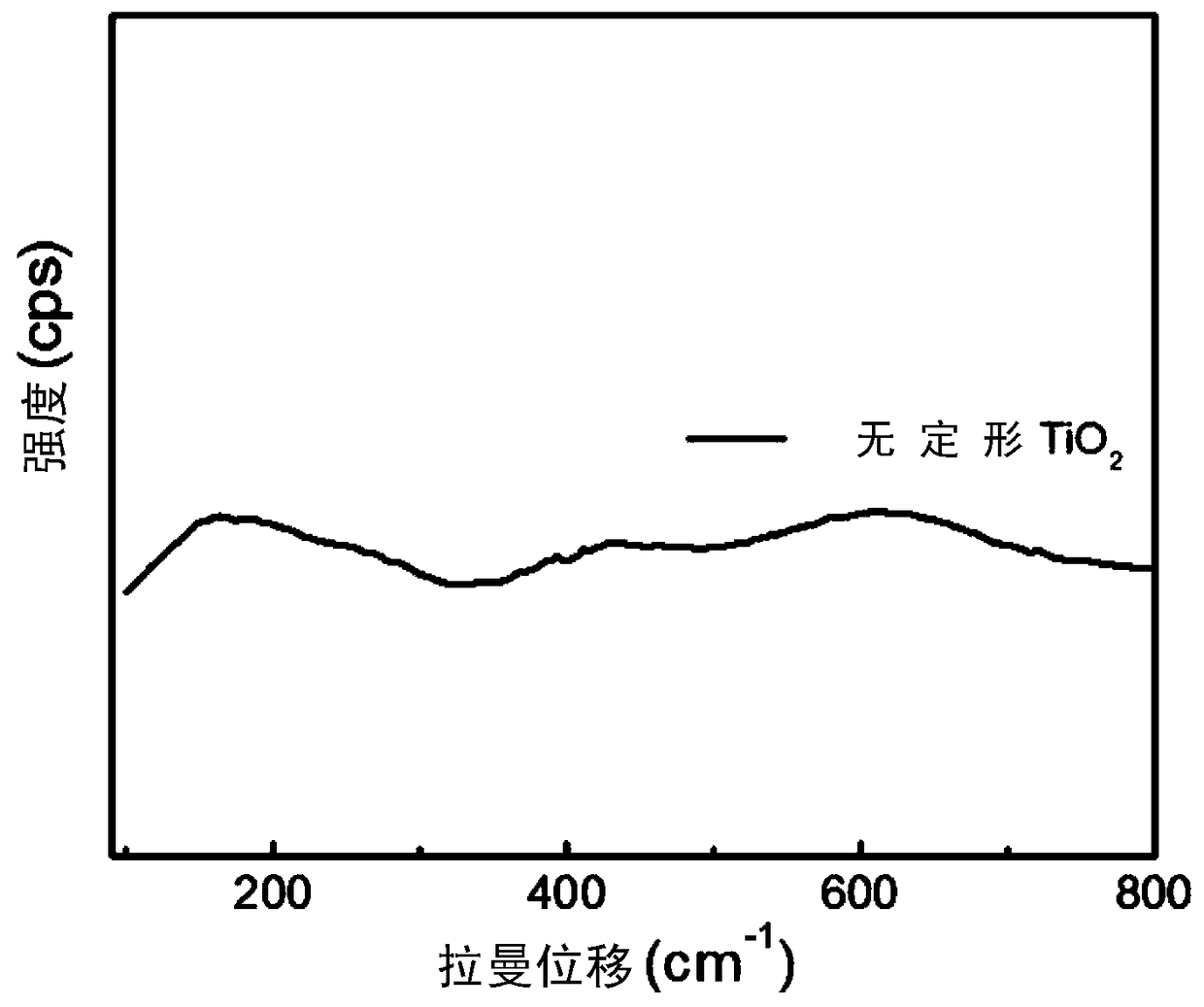

[0070] First, 5 g of tetrabutyl titanate was dissolved in 500 g of absolute ethanol, and 4 g of deionized water was added dropwise while stirring, and then placed in an 80°C oil bath to reflux for 5 hours. After the resulting product was centrifuged, it was washed three times with ethanol and three times with distilled water to obtain amorphous titanium oxide, which was obtained from the Raman spectrum image 3 It can be seen that titanium oxide is not crystallized and is in an amorphous state. Then above-mentioned product is dispersed in 50ml H together with 1.46mg graphene oxide 2 Dilute sulfuric acid was added dropwise to the mixed solution of O and 25ml of ethanol to adjust the pH to 4. After ultrasonication for 1 hour and stirring for 5 hours, the solution was placed in a hydrothermal kettle for hydrothermal reaction at 150°C for 6 hours. The final product was washed with deionized water and then dried at 50°C for 2 hours to obtain a graphene / titanium dioxide composite m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com