Multi-size mixed nano-particle paste and preparation method thereof

A technology of nano particles and nano metal particles is applied in the field of preparation of metal paste, which can solve the problems of development limitation, large porosity and high price of silver materials, and achieve the effects of reducing cost, easy assembly and improving reliability performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

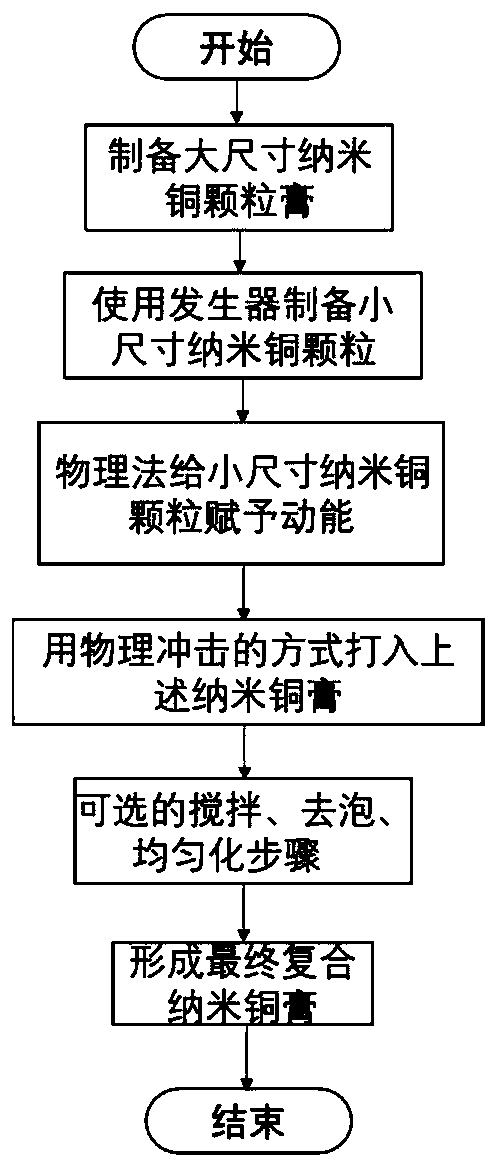

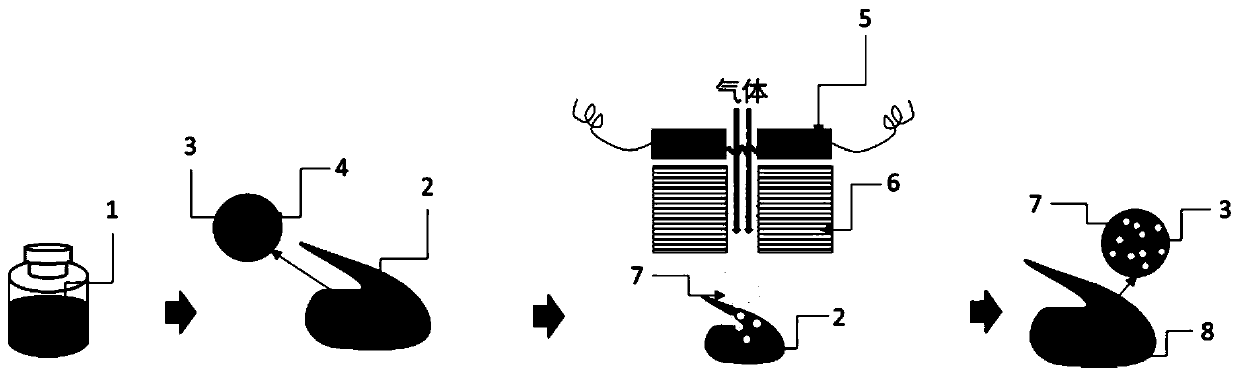

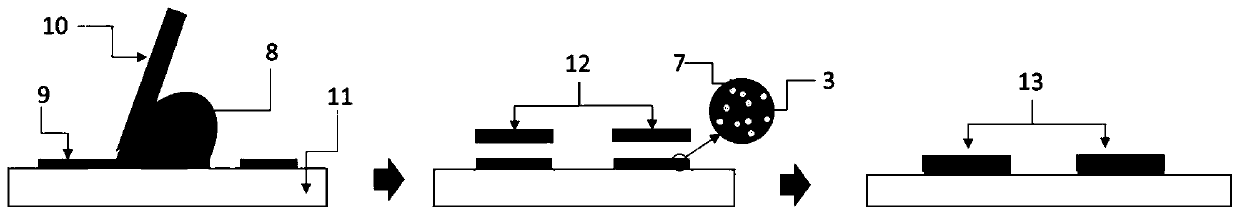

[0047] This embodiment provides a multi-size mixed nano-particle paste. A large-sized nano-copper paste is prepared by a chemical method, and then the prepared small-sized nano-metal particles are abraded by a specific physical method (such as physical spark ablation, etc.). Add large-size nano-copper paste, and configure nano-metal composite paste with mixed sizes. When the paste is used in the sintering process, the small-sized nano-metal particles will fill in the gaps of the large-sized nano-metal particles, which is conducive to realizing the connection of nano-copper without pressure assistance and improving the compactness of the metal layer after sintering .

[0048] The invention provides a multi-size mixed nanoparticle paste, comprising:

[0049] A first material paste, the first material paste containing nano metal particles of the first size;

[0050] second size nano metal particles;

[0051] The second-size metal nano-particles fill the gap between the first-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com