A method for forming a silicon germanium source/drain structure

A silicon germanium and silicon germanium layer technology, applied in semiconductor devices and other directions, can solve problems such as device performance deterioration, and achieve the effects of performance improvement, compressive stress assurance, and lattice mismatch reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

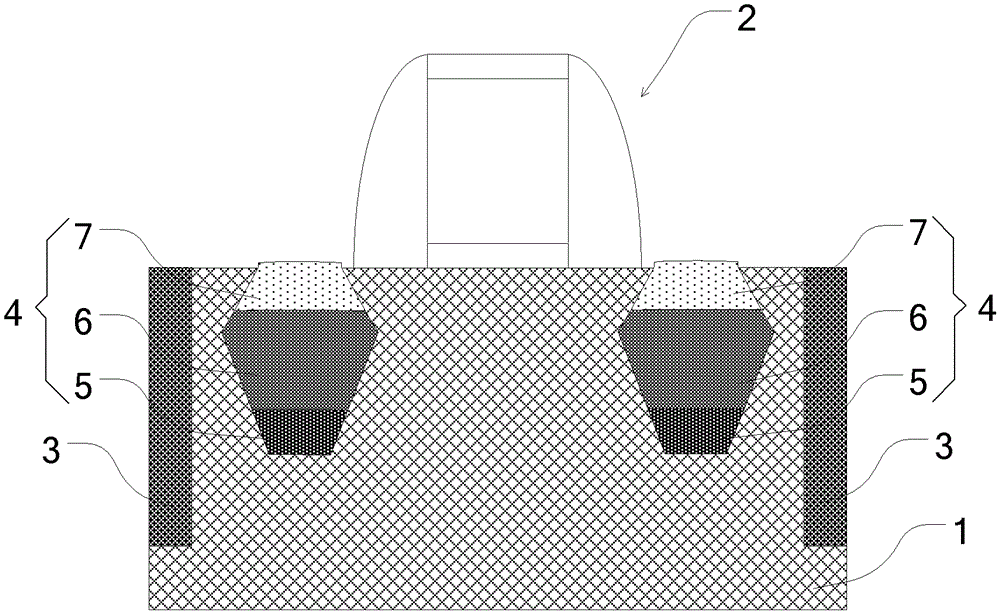

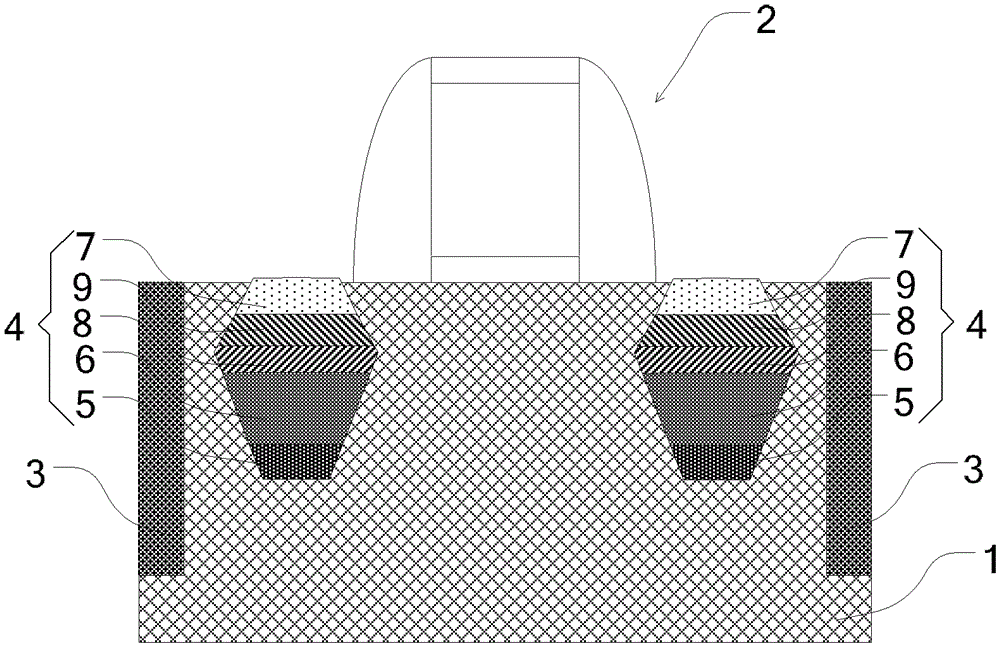

[0050] Please refer to Figure 2a , a formation process of a silicon germanium source / drain structure, providing a substrate 1, such as a silicon substrate, etc., forming a gate structure 2 on the substrate 1, forming an isolation structure 3 in the substrate, etching The substrate 1 forms recesses on both sides of the gate structure 2, and a source / drain region 4 is formed in the recess, wherein the forming of the source / drain region 4 includes: forming a seed layer 5, and the seed layer 5 is A silicon germanium layer, a bulk layer 6 is formed on the seed layer 5, the bulk layer 6 is a silicon germanium layer or a silicon germanium boron layer, a first transition layer 8 is formed on the bulk layer, and the first transition layer 8 A second transition layer 9 is formed on it, and an upper cladding layer 7 is formed on the second transition layer 9 .

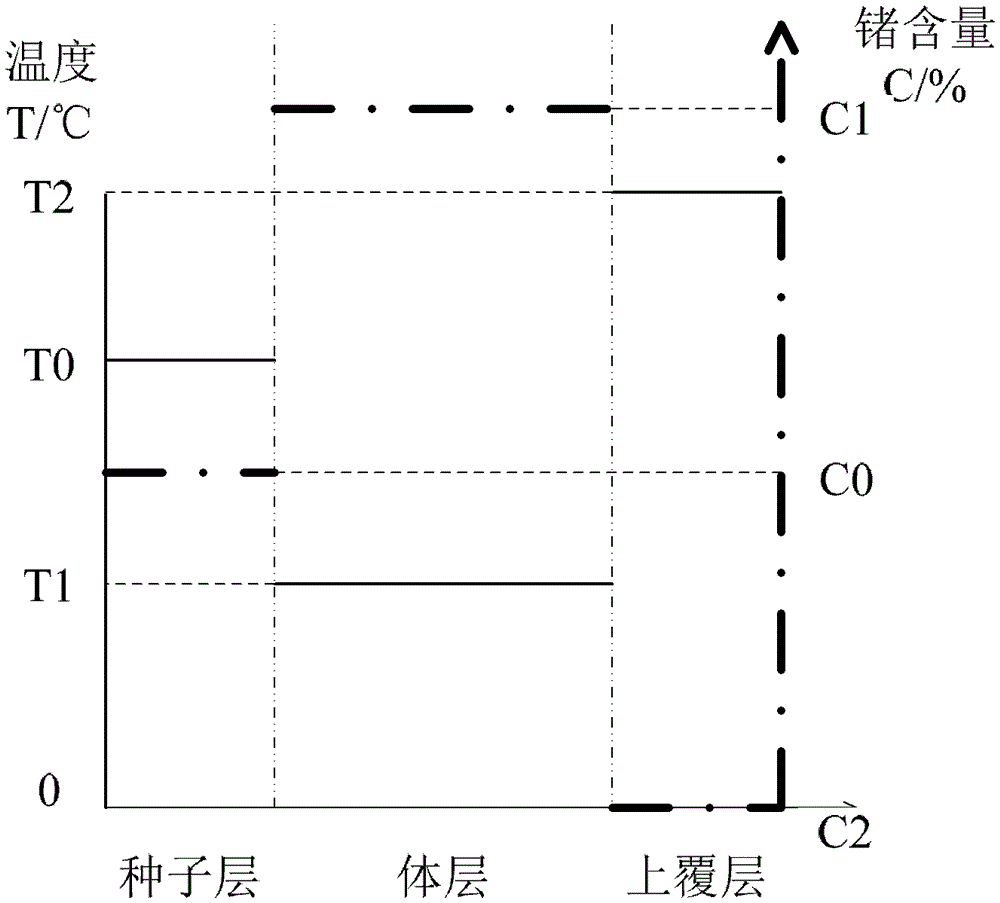

[0051] Specifically, please combine Figure 2b , the content of germanium in the growth process of the first transition laye...

Embodiment 2

[0053] Please refer to Figure 3a , a formation process of a silicon germanium source / drain structure, providing a substrate 1, such as a silicon substrate, etc., forming a gate structure 2 on the substrate 1, forming an isolation structure 3 in the substrate, etching The substrate 1 forms recesses on both sides of the gate structure 2, and a source / drain region 4 is formed in the recess, wherein the forming of the source / drain region 4 includes: forming a seed layer 5, and the seed layer 5 is A silicon germanium layer, a bulk layer 6 is formed on the seed layer 5, the bulk layer 6 is a silicon germanium layer or a silicon germanium boron layer, a transition layer 10 is formed on the bulk layer 6, and an upper layer is formed on the transition layer 10 Cladding 7.

[0054] Specifically, please combine Figure 3b , the transition layer 10 satisfies the following two conditions: 1. The germanium content decreases linearly during the growth process, that is, from the same germa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com