Patents

Literature

38results about How to "Fill pores" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing silicon carbide coating on graphite surface

The invention discloses a method for preparing a silicon carbide coating on a graphite surface. The method includes, firstly, placing a graphite crucible containing solid silicone materials in a high temperature graphitizing furnace and placing a graphite base body on a graphite support in the graphite crucible to generate a silicon carbide coating by means of direct reaction of silicon steam and carbon on the surface of the graphite base body; and secondly, placing the graphite base body which generates the silicon carbide coating on the surface in a chemical vapor deposition (CVD) furnace to be pyrolyzed on the surface of the silicon carbide coating which is located on the surface of the graphite base body to generate a CVD silicon carbide coating. According to the method for preparing the silicon carbide coating on the graphite surface, by means of the direct reaction of the silicon steam formed by heating the solid silicone materials and the carbon on the surface of the graphite base body, an in-situ formed chemical vapor reaction (CVR) silicon carbide coating is firmly combined on the graphite base body so that combination intensity is improved; and then a CVD process is used for pyrolyzing the CVR silicon carbide coating at high temperatures on the CVD silicon carbide coating so that pore space of the CVR silicon carbide coating is effectively filled, and combination strength is improved.

Owner:XIAN CHAOMA SCI TECH

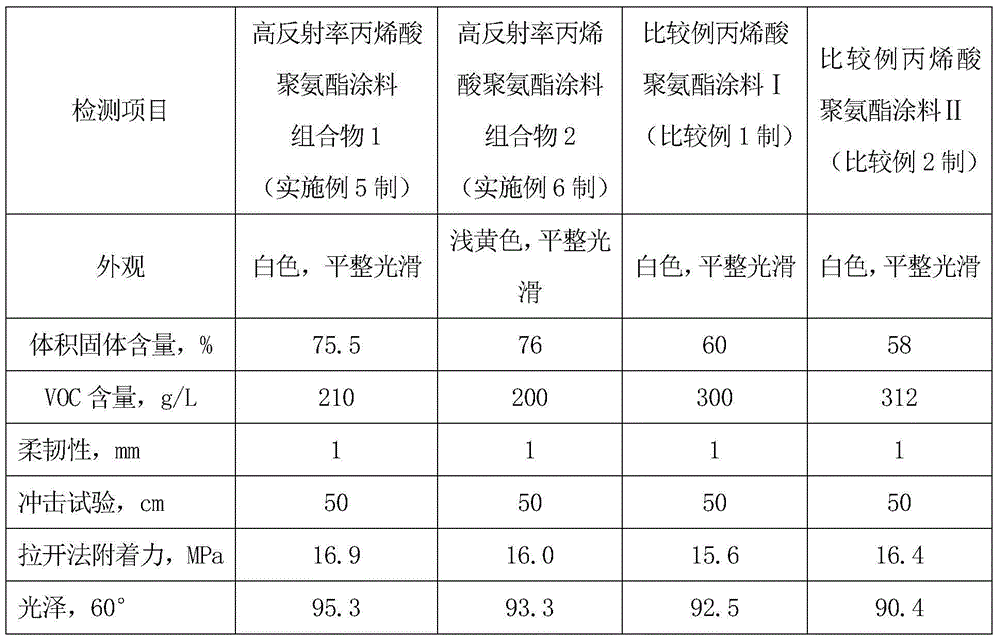

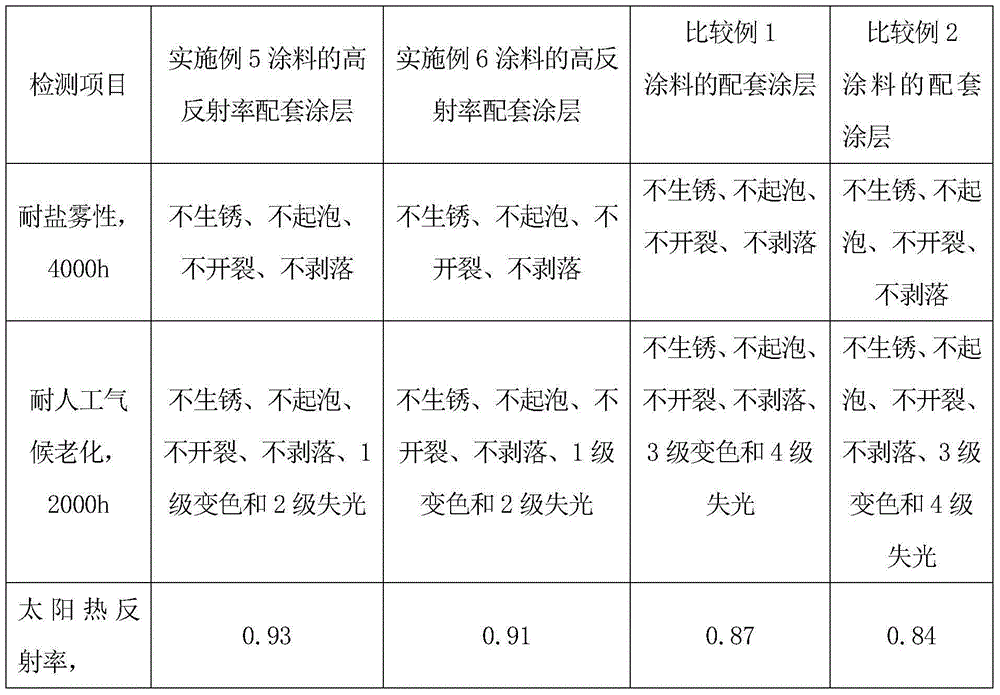

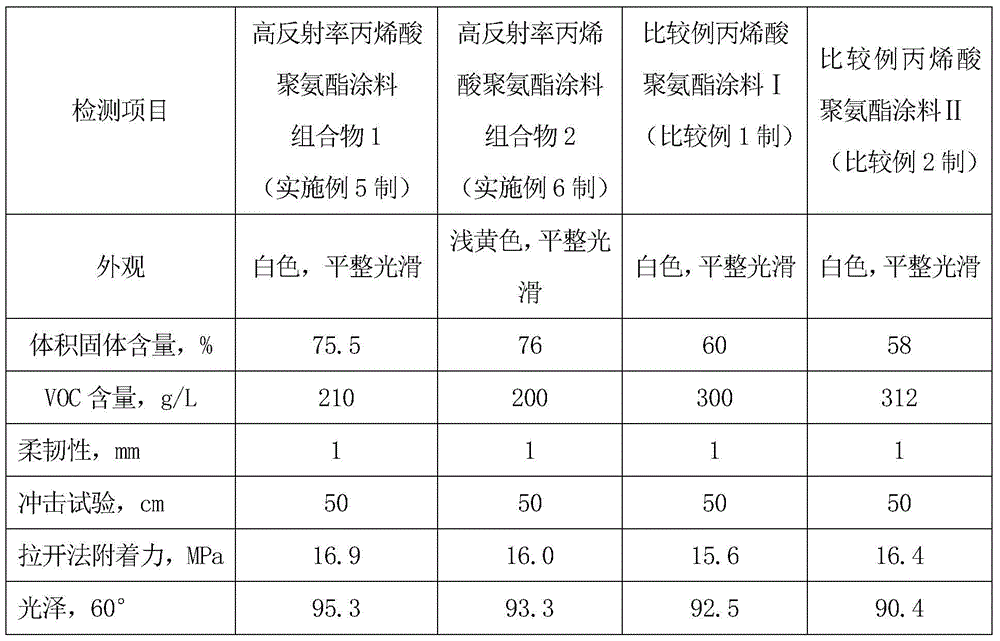

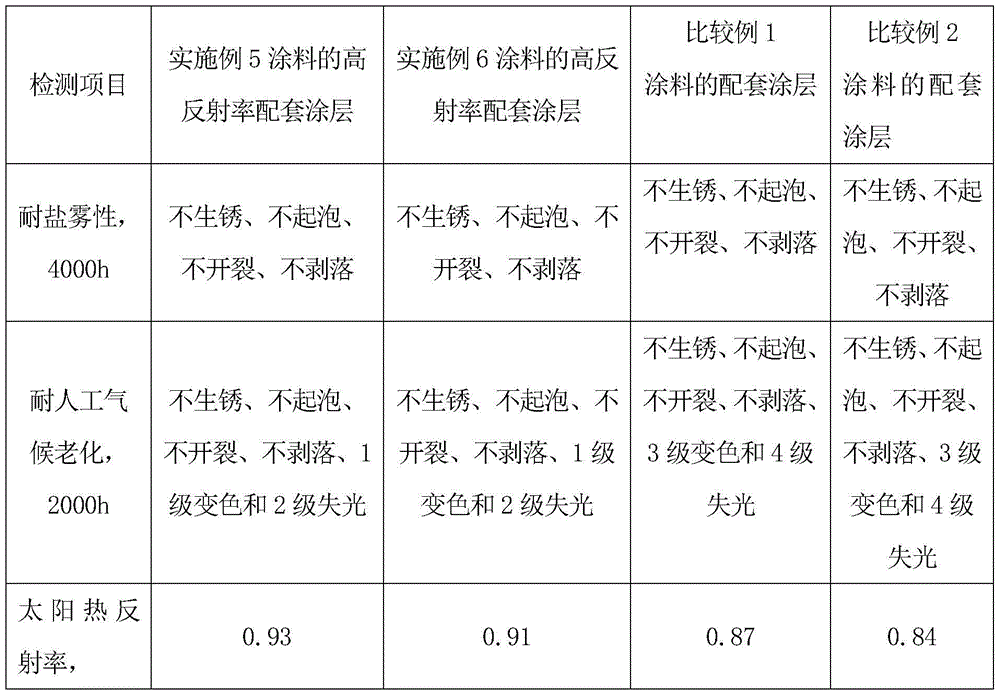

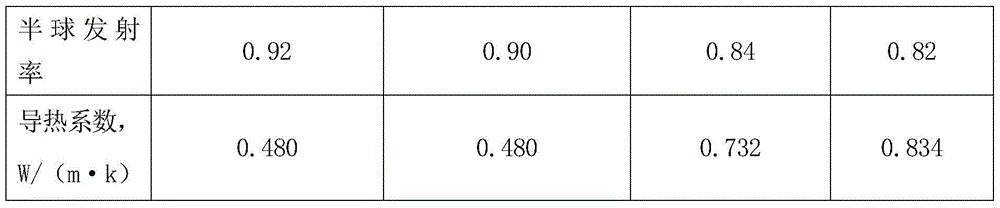

High-reflective acrylic polyurethane coating composition

ActiveCN104371531AHigh solid contentGood weather resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsAcrylic resinIsophorone diisocyanate

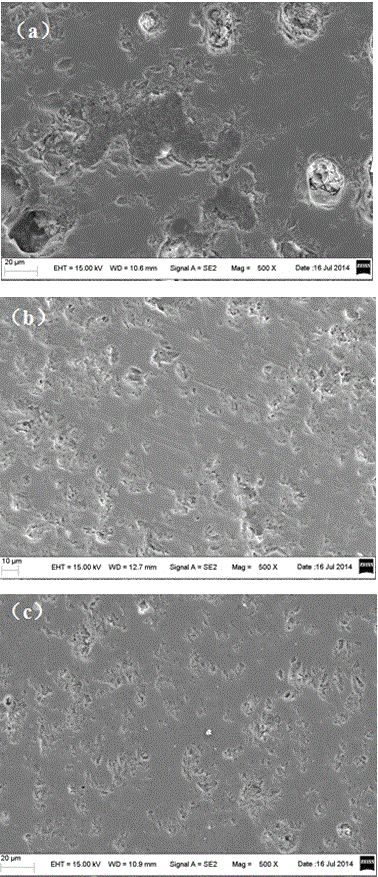

The invention relates to a high-reflective acrylic polyurethane coating composition which comprises a component A and a component B in a mass part ratio of 20;3. The component A in 100 parts by mass comprises the following materials in part by mass: 30-50 parts of modified hydroxyl acrylic resin, 2-6 parts of auxiliaries, 35-45 parts of heat reflective pigments, 4-8 parts of aerogel and 10-15 parts of organic solvent. The component B in 100 parts by mass comprises the following materials in part by mass: 75-90 parts of polyisocyanate and 10-25 parts of organic solvent. The modified hydroxyl acrylic resin is obtained by cold-blending modified resin and hydroxyl acrylic resin in a mass part ratio of 1-3: 1; the solid content of the modified hydroxyl acrylic resin is greater than or equals to 75wt%; the particle size of heat reflective pigments ranges from 0.55 micron to 1.2 microns; the particle size of the aerogel ranges from 1 micron to 80 microns; the pore size of the aerogel ranges from 10 nanometers to 20 nanometers; and the heat conductivity coefficient of the aerogel is less than or equals to 0.015W / (m k). The polyisocyanate is one or more of HDI (hexamethylene diisocyanate) biuret, HDI trimer and IPDI (isophorone diisocyanate) trimer curing agents. The high-reflective acrylic polyurethane coating composition is high in reflective insulation quality; and the quantity of VOC (volatile organic compounds) of the high-reflective acrylic polyurethane coating component is low.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

Vacuum heat insulating plate and preparation and application thereof

InactiveCN102587517ALow costSimple preparation processClimate change adaptationInsulation improvementFiberUltimate tensile strength

The invention provides a vacuum heat insulating plate and preparation and application of the vacuum heat insulating plate. The vacuum heat insulating plate comprises a heat insulating core material and a film material coating the heat insulating core material. The heat insulating core material comprises nanoscale silicon dioxide and is formed by mixing the nanoscale silicon dioxide with multi-scale expanded perlites and chopped fibers in the weight ratio of 10:5-30:1. The specific surface area of the nanoscale silicon dioxide is 100-400m<2> / g. The incompact stacking density of the multi-size expanded perlites is lower than 350kg / m<3>. The length of the chopped fibers is less than 10mm, and the diameter is less than 20mum. The vacuum heat insulating plate is obtained by uniformly mixing the raw materials, putting the uniformly mixed raw materials into a mold for pressing and molding, taking out the molded core materials, drying the molded core materials to constant weight, putting the core materials into a bag which is prepared from the film material in advance, vacuumizing till the vacuum degree is less than 0.1Pa, and then performing hot sealing. The vacuum heat insulating plate is high in strength and good in heat insulating effect. In this way, the vacuum heat insulating plate is applied to the heat insulation of building walls.

Owner:SOUTHEAST UNIV

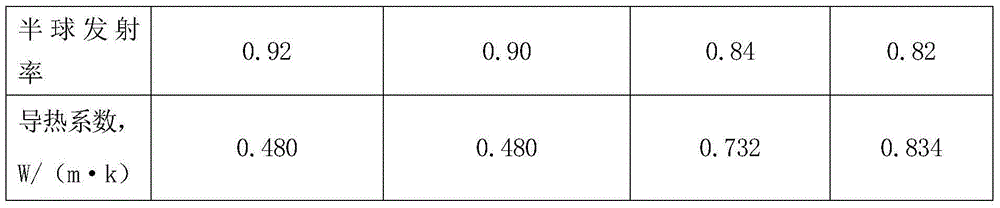

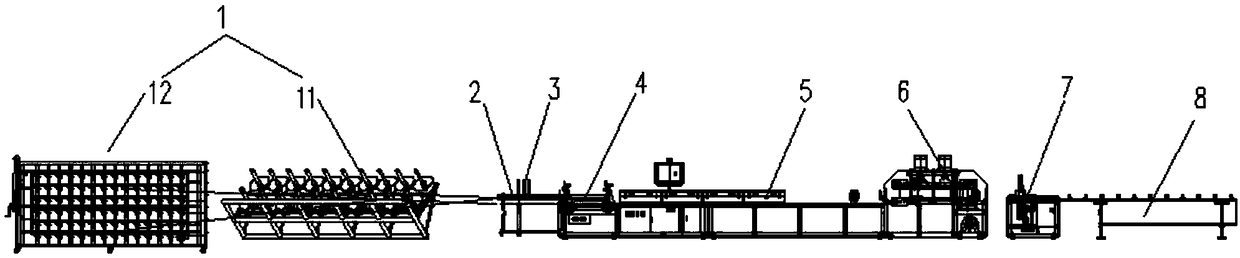

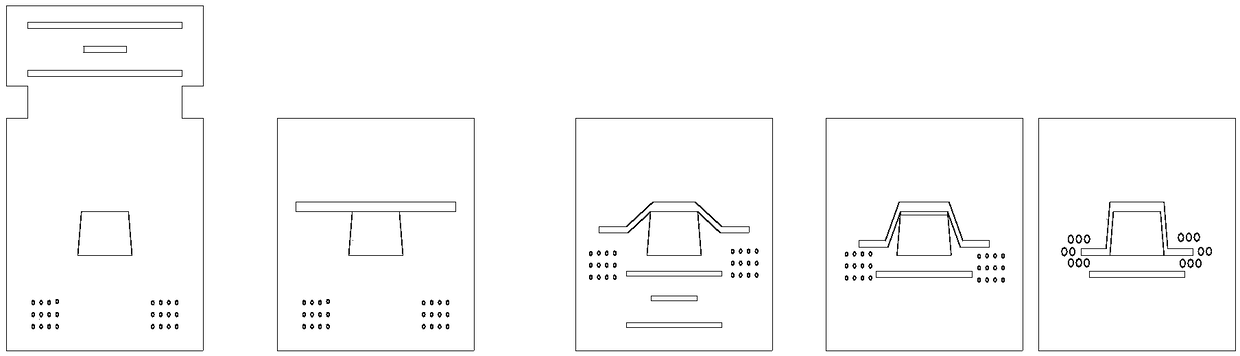

Equipment cabin pultrusion technology

The invention provides an equipment cabin pultrusion technology. The equipment cabin pultrusion technology comprises the steps that firstly, fiber yarn and fiber fabric are discharged at the same time, an equipment cabin body part is made of fiber fabric, and fiber yarn is adopted at the corner part or the thickened part; secondly, a pre-forming die is used for conducting pre-forming treatment onthe fiber yarn and the fiber fabric, the pre-forming die comprises a plurality of pre-forming plates, the pre-forming plates are provided with hollow grooves, the hollow grooves can gradually change,and finally the product shape is formed; thirdly, glue injection type pultrusion is conducted on the pre-formed fiber yarn and the pre-formed fiber fabric; fourthly, a curing die is used for conducting curing on the fiber yarn and the fiber fabric obtained after pultrusion; and fifthly, an automatic cutting machine is used for cutting the cured fiber yarn and the cured fiber fabric. Compared withthe prior art, the fiber fabric and fiber yarn mixed pultrusion manner is adopted, holes of the fiber fabric are filled, the fiber content reaches up to 80%, and the equipment cabin mass is further reduced.

Owner:NEWTRY COMPOSITE

Mildewproof treatment method for corn bran

InactiveCN106272779AFill poresPrevent shrinkageWood treatment detailsReed/straw treatmentBranBiology

The invention belongs to the technical field of weaving material deep processing and particularly relates to a mildewproof treatment method for corn bran. The mildewproof treatment method for corn bran comprises the steps of corn bran temporary storage, soaking treatment, suffocating treatment, drying and the like. Compared with the prior art, the mildewproof treatment method provided by the invention has the following advantages: a corresponding placement method is provided for collected corn bran, and raw material loss caused during storage can be reduced greatly; a soak solution is used for soaking, thereby not only playing a sterilizing and softening effect, but also filling gaps in corn bran, and effectively preventing shrinking and aging after the suffocating and during drying of the corn bran; after suffocating, the luster of the corn bran is enhanced, the corn bran is pure white and soft, the use ratio of the corn bran during a weaving process is improved, product quality is improved, the appearance retention rate is relatively high, the service life period is prolonged, and market requirements are met.

Owner:安徽宏润工艺品有限公司

Covering layer of sanitary landfill

The invention provides a covering layer of a sanitary landfill. The covering layer is formed by uniformly mixing and stirring three component materials consisting of 1-3 parts by weight of pre-treated garbage incinerated ash residues, 1-4 parts by weight of pre-treated sludge and 1-6 parts by weight of pre-treated cohesive soil. The covering layer of the sanitary landfill disclosed by the invention not only has lower anti-seepage coefficient but also provides a way for effectively disposing the garbage incinerated ash residues, sewage and the sludge while reducing the use amount of the cohesive soil.

Owner:福建优建建筑科技有限公司

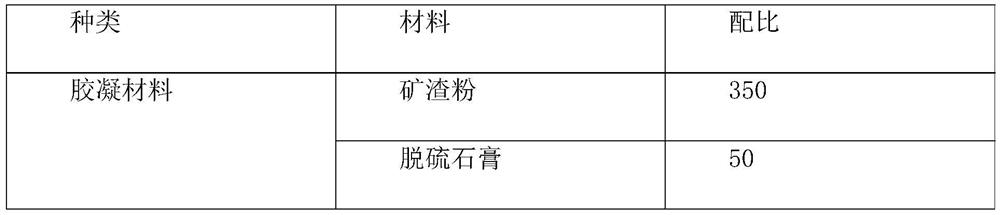

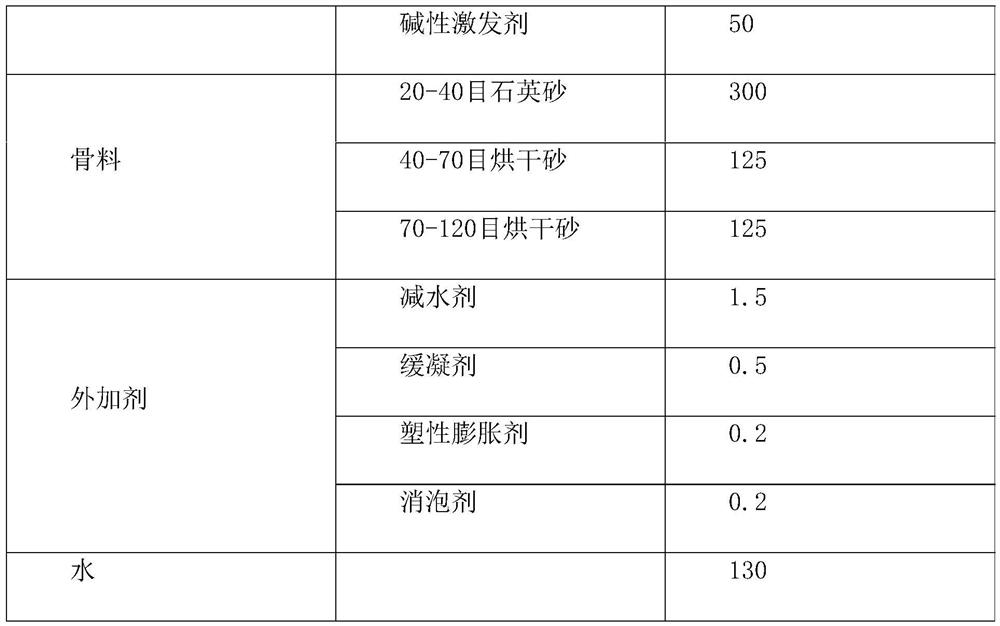

Ecological cement high-strength grouting material and preparation method thereof

The invention provides an ecological cement high-strength grouting material and a preparation method thereof. The ecological cement high-strength grouting material has the advantages of high flowability, favorable constructability, long operable time and smooth and flat surface after completion, and can perform self-remaining leveling. The ecological cement high-strength grouting material comprises a cementing material, aggregate and an additive, wherein the cementing material comprises slag powder, desulfurized gypsum and an alkaline activator; the aggregate is prepared from, by weight, 250-300 parts of 20-40-mesh quartz sand, 100-150 parts of 40-70-mesh dried sand and 100-150 parts of 70-120-mesh dried sand; and the additive comprises, by weight, 1-2 parts of a water reducing agent, 0.1-0.6 part of a retarder, 0.1-0.3 part of a plastic expanding agent and 0.1-0.3 part of a defoaming agent.

Owner:山东华迪建筑科技有限公司 +1

Novel nano-modified high-strength concrete

PendingCN111960769AImprove mechanical propertiesIncrease salt and frost resistanceHigh strength concreteFiber

The invention relates to novel nano-modified high-strength concrete which comprises the following components in parts by mass: 170-220 parts of water; 340 to 460 parts of Portland cement; 600 to 850 parts of aggregate; 13-28 parts of a nano porous material; 220 to 250 parts of nanometer fibers; 50 to 80 parts of silica fume; 65 to 95 parts of mineral powder; 3-5 parts of a water reducing agent; 15-30 parts of a filling reinforcing material; according to the nano-modified high-strength concrete disclosed by the invention, Portland cement and aggregate are used as main materials of the concrete;the nano porous material and the nano fiber are added to modify the concrete, so that the mechanical property, the salt resistance, the frost resistance and the high temperature resistance of the concrete are improved, meanwhile, the overall workability and the flowability are maintained, internal pores of the concrete are effectively filled, and the grain composition and the compactness are improved.

Owner:岑儒湛

Tertiary air duct curve prefabricated component for cement kiln

The present invention provides a with tertiary air duct curve prefabricated component for a cement kiln, and aims to resolve the problem of poor anti-erosion performance of the tertiary air duct curve of the prior art. The tertiary air duct curve prefabricated component for the cement kiln comprises the following components by weight parts of: 15-25 parts of 5-8mm black corundum, 15-20 parts of 3-5mm black corundum, 10-15 parts of 1-3mm black corundum, 10-15 parts of 0-1mm black corundum, 10-20 parts by 0-1mm of silicon carbide, 6-10 parts of silicon carbide powder not larger than 200 mesh, 5-10 parts of brown alumina powder not larger than 200 mesh, 4-7 parts of calcium aluminate cement, 3-5 parts of alumina powder, 4-6 parts of silica powder, 0.10-0.15 part of a water reducing agent, 0.01-0.02 part of explosion-proof fiber and 0.5-1 part of heat-resistant steel fiber. The invention uses black corundum and silicon carbide as the main materials for the tertiary air duct curve prefabricated component, and the black corundum can make the matrix and aggregate fully connect and cement at high temperature, effectively fill the pores of aggregate and significantly improve the high temperature properties of the material, thereby increasing the abrasion resistance and alkali erosion resistance of the tertiary air duct curve inner liner.

Owner:ZHEJIANG KINGCRED NEW MATERIAL CO LTD

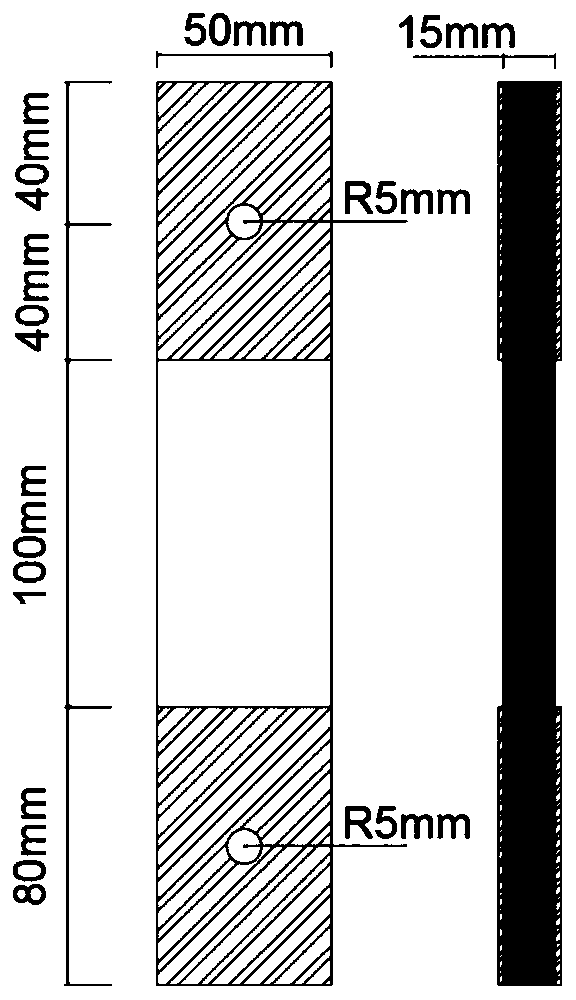

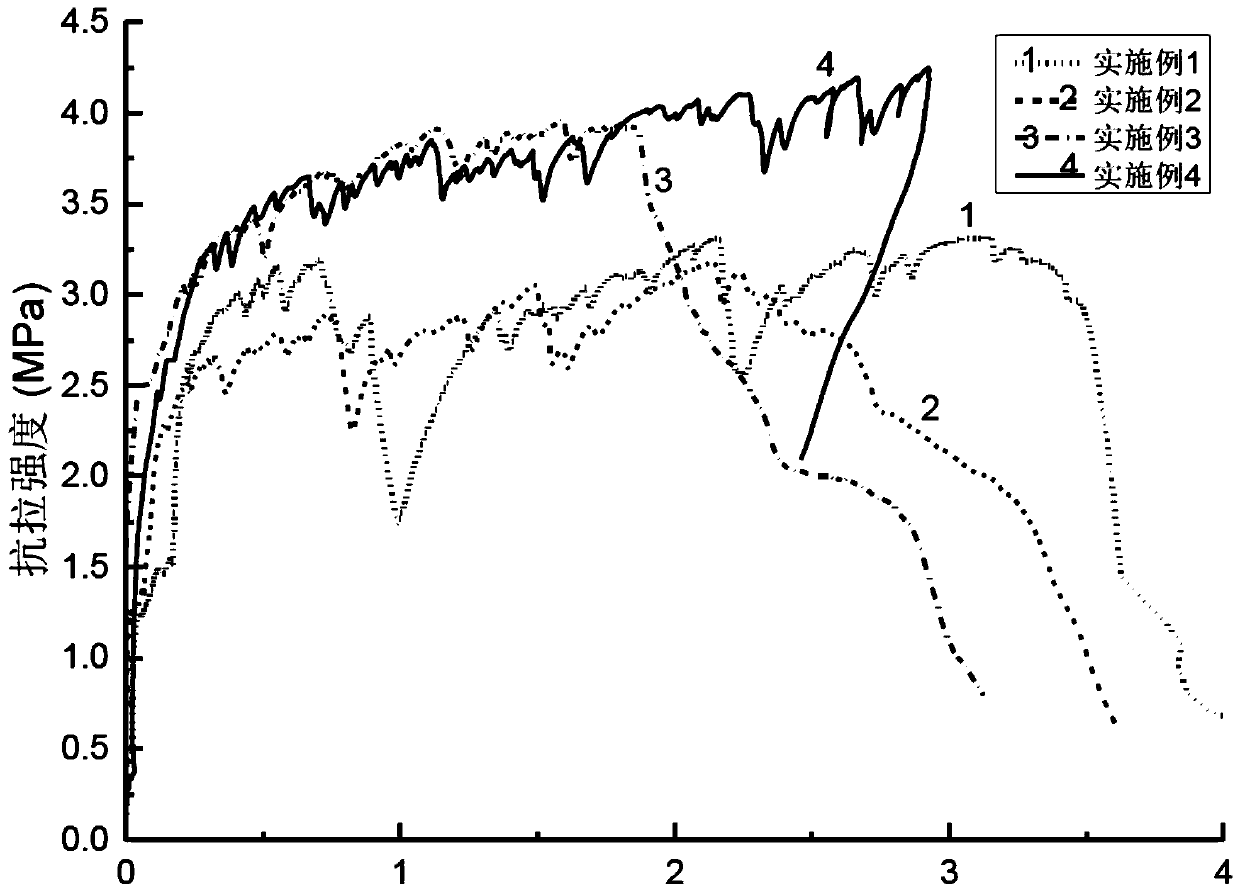

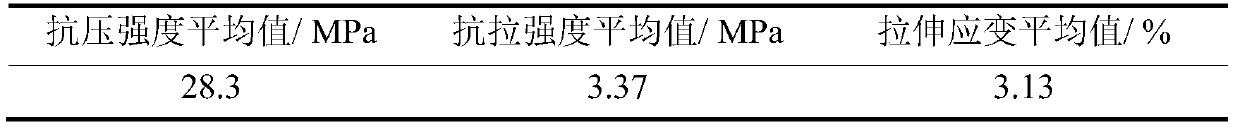

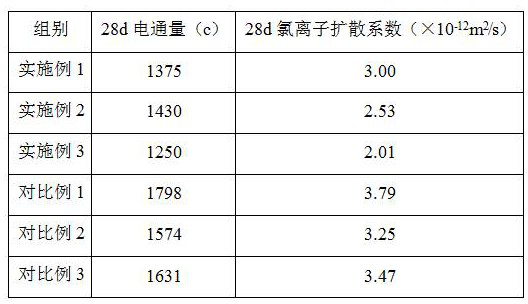

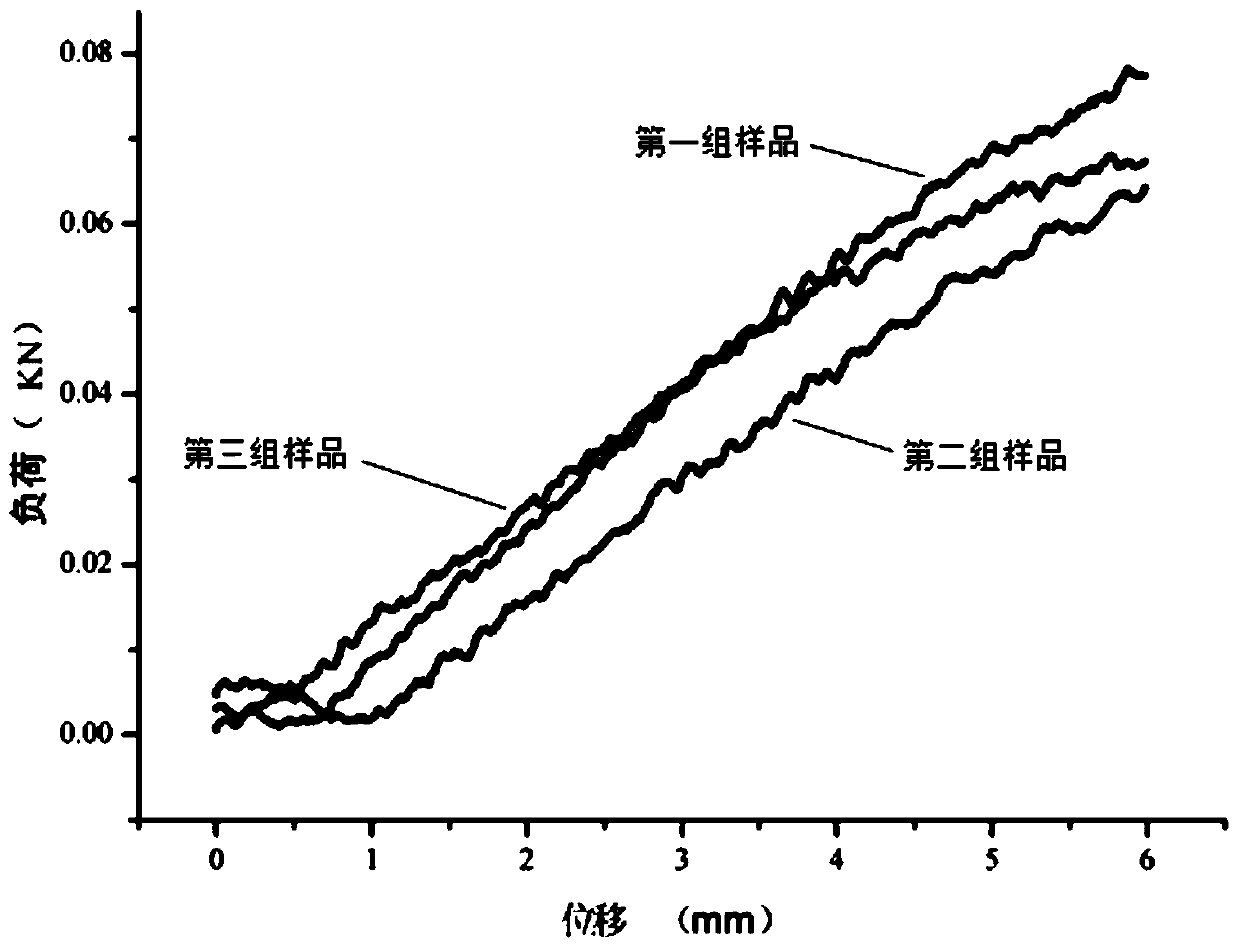

Calcium sulfate-doped high-performance fiber cement-based composite material and preparation method thereof

InactiveCN109942256AEmission reductionImprove mechanical propertiesMechanical propertyToxic industrial waste

The invention discloses a calcium sulfate-doped high-performance fiber cement-based composite material and a preparation method thereof, and belongs to the technical field of cement materials. The calcium sulfate-doped high-performance fiber cement-based composite material consists of cement, fly ash, silica fume, quartz sand, calcium sulfate, water, a water reducing agent, a thickening agent andPVA fibers. The preparation method comprises the following steps of: mixing and pouring the cement, the fly ash, the silica fume, the quartz sand, the calcium sulfate and the thickening agent into a stirrer for dry stirring for two minutes; pouring the water reducing agent into the water, and pouring the mixture of the water reducing agent and the water into the stirrer for stirring for four minutes after being fully and uniformly mixed; and then adding the PVA fibers into a stirring pot for stirring for three minutes at the speed of 90-100 revolutions per minute and for one minute at the speed of 180-190 revolutions per minute. According to the composite material and the preparation method thereof, the raw materials are convenient to obtain, the preparation process is simple, and the strength of a test piece is improved while the good tensile mechanical property of the test piece is maintained by adding the calcium sulfate. Meanwhile, the fly ash is adopted to replace the cement in the cementing material, so that an industrial waste residue is consumed, and the carbon emission is reduced.

Owner:BEIJING UNIV OF TECH

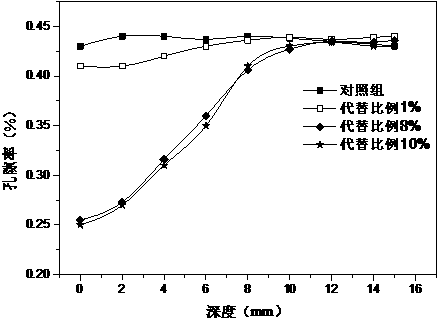

Marine concrete reinforcing material as well as preparation method and application thereof

InactiveCN111592258ARealize intelligent crackingReduce dosageCalcium/strontium/barium carbonatesSodium bicarbonateMicrosphere

The invention discloses a marine concrete reinforcing material as well as a preparation method and application thereof. The preparation method comprises the following steps: preparing a calcium chloride solution and a sodium bicarbonate solution with equal mole to prepare porous calcium carbonate microspheres; inoculating lysinibacillus sp. into a culture medium, and adding a spore efficient transforming agent into a culture solution; putting the calcium carbonate microspheres into the lysinibacillus sp. spore culture solution, and fully standing until the concentration of the spore culture solution tends to be stable, so as to obtain calcium carbonate microspheres loaded with microbial spores; dissolving the calcium carbonate microspheres loaded with the microbial spores into a mixed solution of sodium alginate and a barium-silver compound, uniformly stirring, and coating the surface layers of the calcium carbonate microspheres through spray drying. Results show that the material canachieve concrete surface pore filling and plugging, improve compactness, prevent invasion of corrosive substances, improve engineering durability and prolong the service lifetime.

Owner:JIANGSU UNIV OF SCI & TECH

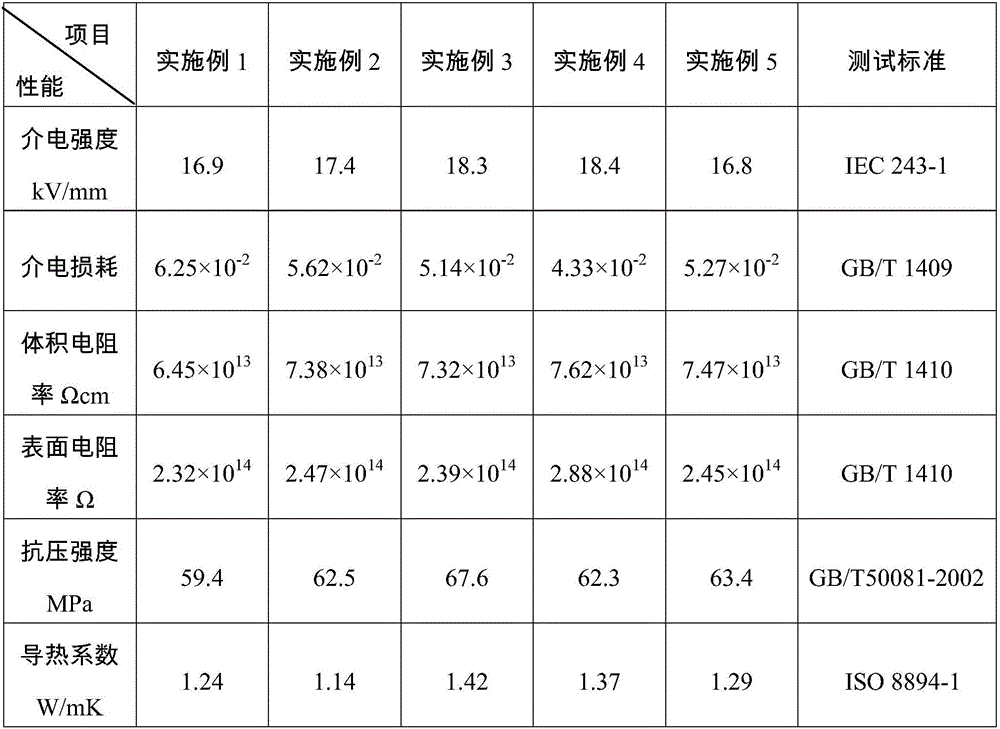

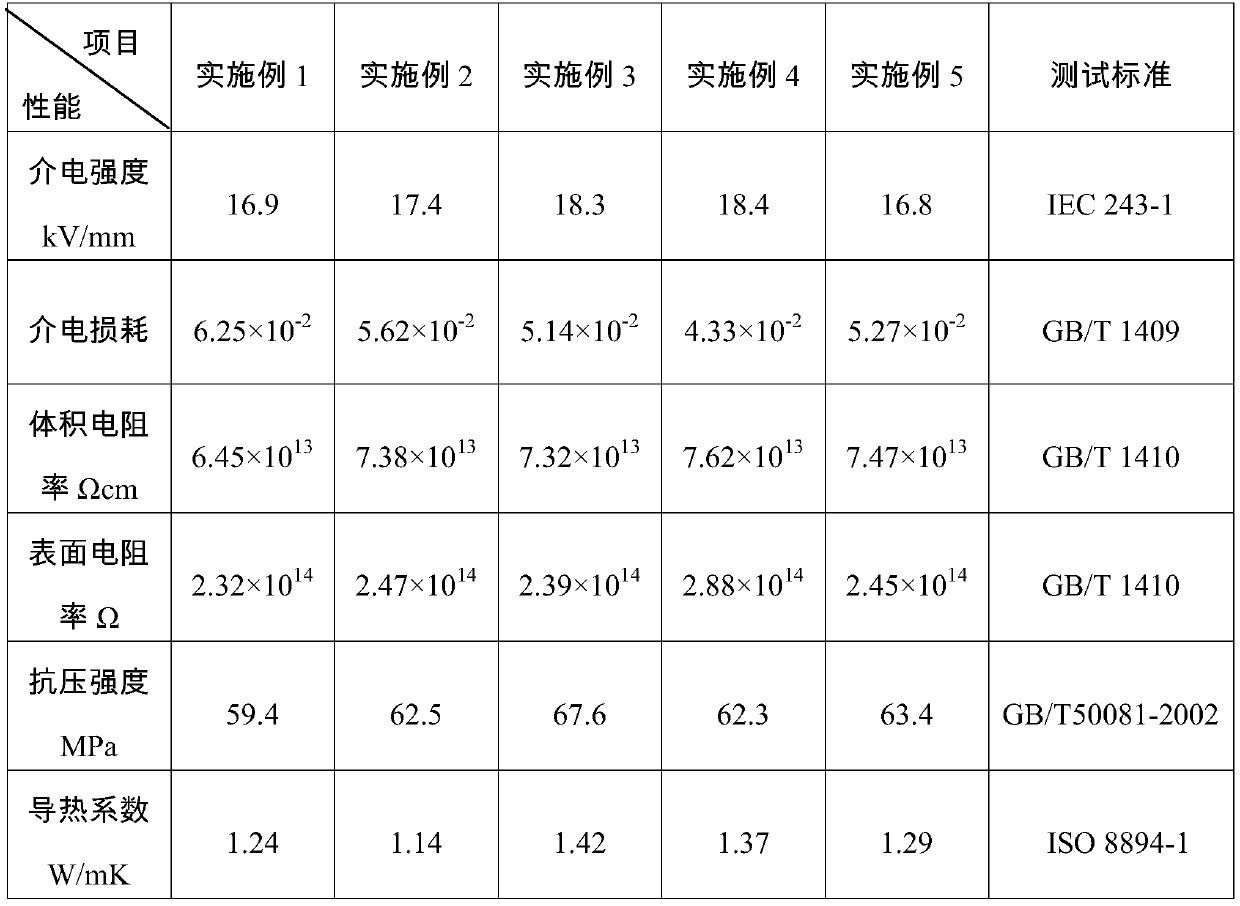

High insulating property dense polymer concrete as well as preparation method and application thereof

The invention provides high insulating property dense polymer concrete as well as a preparation method and application thereof. The concrete comprises the following components in parts by mass: 120 parts of cement, 10-50 parts of emulsion, 30-60 parts of water, 10-30 parts of wollastonite, 5-30 parts of mica, 10-20 parts of silica, 0.1 part of a water reducing agent and 0.01 part of an antifoaming agent. The concrete is processed by the steps of stirring in vacuum, molding, curing, drying and the like. The concrete can be applied to electrical insulating pipelines, brackets and transformer bases. The polymer serves as an electrical insulating material, and the prepared concrete has the advantages of high insulating property, compactness, strength and durability and is simple in preparation process, low in cost, convenient in construction and suitable for large-scale industrial production.

Owner:WUHAN NARI LIABILITY OF STATE GRID ELECTRIC POWER RES INST +3

Vacuum heat insulating plate and preparation and application thereof

InactiveCN102587517BLow thermal conductivityLow bulk densityClimate change adaptationInsulation improvementFiberSilicon dioxide

The invention provides a vacuum heat insulating plate and preparation and application of the vacuum heat insulating plate. The vacuum heat insulating plate comprises a heat insulating core material and a film material coating the heat insulating core material. The heat insulating core material comprises nanoscale silicon dioxide and is formed by mixing the nanoscale silicon dioxide with multi-scale expanded perlites and chopped fibers in the weight ratio of 10:5-30:1. The specific surface area of the nanoscale silicon dioxide is 100-400m<2> / g. The incompact stacking density of the multi-size expanded perlites is lower than 350kg / m<3>. The length of the chopped fibers is less than 10mm, and the diameter is less than 20mum. The vacuum heat insulating plate is obtained by uniformly mixing the raw materials, putting the uniformly mixed raw materials into a mold for pressing and molding, taking out the molded core materials, drying the molded core materials to constant weight, putting the core materials into a bag which is prepared from the film material in advance, vacuumizing till the vacuum degree is less than 0.1Pa, and then performing hot sealing. The vacuum heat insulating plate is high in strength and good in heat insulating effect. In this way, the vacuum heat insulating plate is applied to the heat insulation of building walls.

Owner:SOUTHEAST UNIV

Preparation method of modified fluorgypsum powder

The invention discloses a preparation method of modified fluorgypsum powder. Fluorgypsum waste residues after production of hydrofluoric acid are cooled through a horizontal cooling converter, saponification slag and quicklime are added, the mixture is uniformly mixed, the mixture, alums and fly ash are jointly subjected to ball milling, and the modified fluorgypsum powder is prepared. According to the preparation method of the modified fluorgypsum powder, the preparation process is simple, a few procedures are adopted, generation of pungent smell is effectively reduced in the preparation process, the cost is low, and the prepared modified fluorgypsum powder is wide in application range.

Owner:UNIV OF JINAN

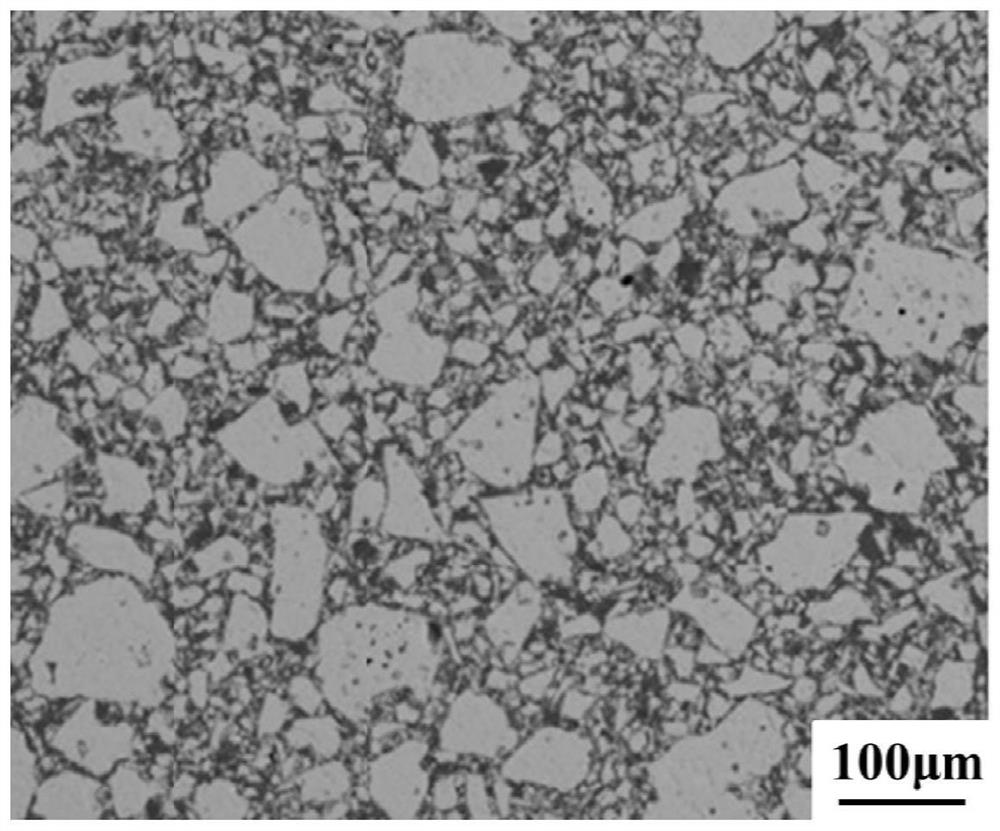

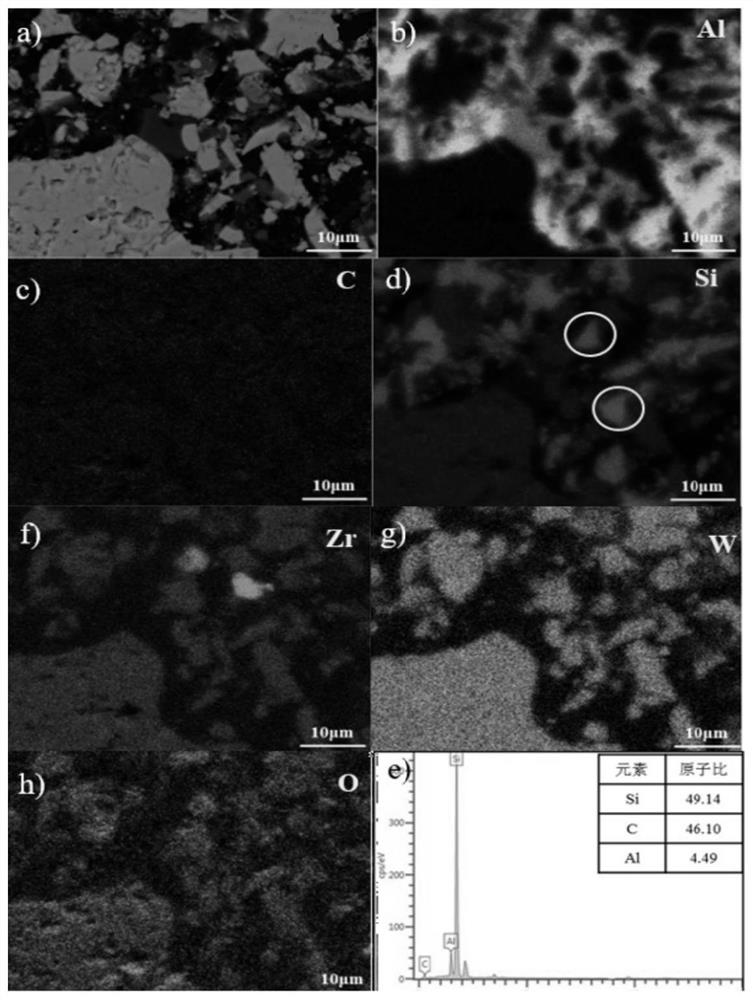

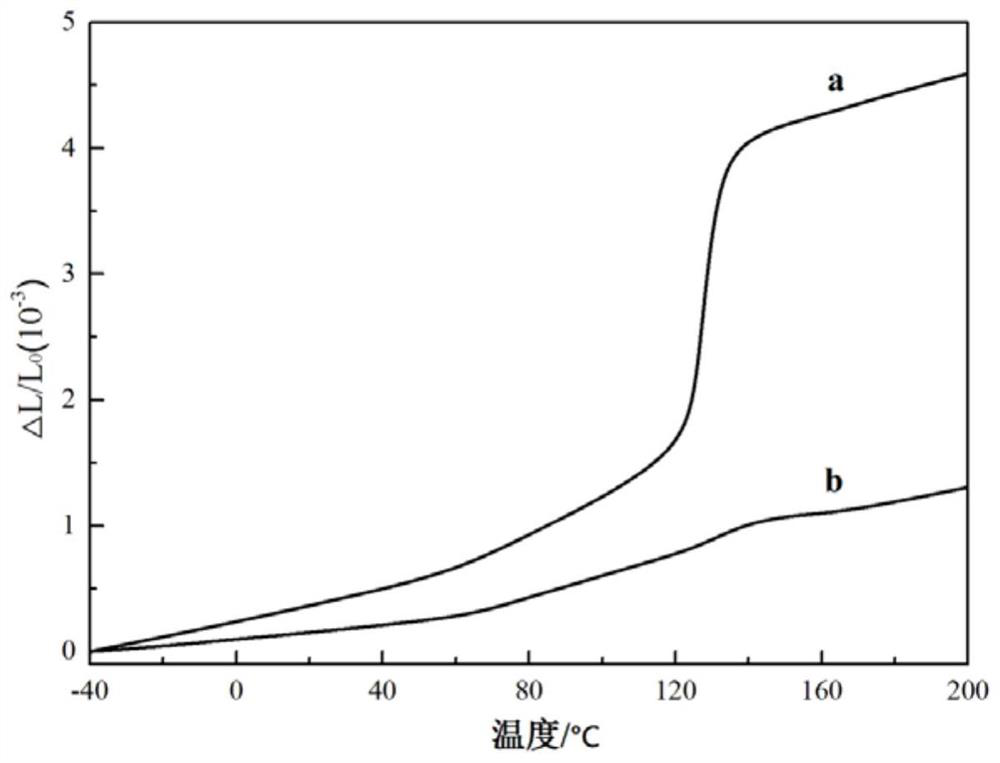

Preparation method of zirconium tungstate-containing aluminum-based composite material with high comprehensive performance

The invention discloses a preparation method of a zirconium tungstate-containing aluminum-based composite material with high comprehensive performance, and relates to a preparation method of a ZrW2O8 aluminum-based composite material. The problems that an existing ZrW2O8 / Al composite material is low in strength, and the thermal expansion coefficient of the composite material is large due to the fact that the content of gamma-ZrW2O8 is too high are solved. The method comprises the following steps: weighing ZrW2O8 powder, high-strength ceramic powder and an aluminum matrix as raw materials; the preparation method comprises the following steps: mixing high-strength ceramic powder and ZrW2O8 powder, carrying out ball milling, pre-pressing to obtain a reinforcement preform, preheating, preparing a molten metal matrix, carrying out liquid aluminum infiltration, and carrying out annealing treatment on the composite material. The volume fraction of a reinforcement is increased by adopting a mixing ratio of various particle sizes, internal stress is reduced through stress relief annealing treatment, so that the thermal expansion coefficient of the composite material is reduced, and the comprehensive performance of the composite material is improved.

Owner:HARBIN INST OF TECH

A way to add srb 4 o 7 Electric porcelain of seed crystal and preparation method thereof

Owner:FUZHOU UNIV

Durable emulsified asphalt mixture prepared from waste tire rubber powder and preparation method

The invention discloses a durable emulsified asphalt mixture prepared from waste tire rubber powder. The durable emulsified asphalt mixture is prepared from epoxy resin modified emulsified asphalt, aggregate, a curing agent and tire rubber powder, wherein the epoxy resin modified emulsified asphalt accounts for 8-10% of the aggregate in percentage by mass; the curing agent accounts for 3-4% of themass of the epoxy resin modified emulsified asphalt; and the tire rubber powder is obtained by shearing and crushing waste tires, and the mass of the tire rubber powder accounts for 1-3% of the massof the aggregate. According to the durable emulsified asphalt mixture, the tire rubber powder is added, so that the durability and the wear resistance of a pavement can be kept for a long time, the service life of the pavement is greatly prolonged, and meanwhile, reutilization of rubber resources and environmental protection are facilitated.

Owner:郑州市路通公路建设有限公司

A kind of dense polymer concrete with high insulation and its preparation method and application

The invention provides high insulating property dense polymer concrete as well as a preparation method and application thereof. The concrete comprises the following components in parts by mass: 120 parts of cement, 10-50 parts of emulsion, 30-60 parts of water, 10-30 parts of wollastonite, 5-30 parts of mica, 10-20 parts of silica, 0.1 part of a water reducing agent and 0.01 part of an antifoaming agent. The concrete is processed by the steps of stirring in vacuum, molding, curing, drying and the like. The concrete can be applied to electrical insulating pipelines, brackets and transformer bases. The polymer serves as an electrical insulating material, and the prepared concrete has the advantages of high insulating property, compactness, strength and durability and is simple in preparation process, low in cost, convenient in construction and suitable for large-scale industrial production.

Owner:WUHAN NARI LIABILITY OF STATE GRID ELECTRIC POWER RES INST +3

Bonding mortar capable of being used for bonding large boards and preparation method of bonding mortar

ActiveCN114591051AImprove performanceImproves tensile bond strengthSolid waste managementAluminateMicroorganism

The invention discloses adhesive mortar capable of being used for large board bonding, which is prepared from the following components in parts by weight: 70 to 80 parts of Portland cement, 20 to 30 parts of sulphoaluminate cement, 8 to 10 parts of hydroxyethyl methyl cellulose, 2 to 3 parts of modified silicon oxide aerogel and 80 to 100 parts of quartz sand, the modified silicon oxide aerogel is prepared by the following steps: firstly, carrying out surface silanization treatment on superfine silicon oxide aerogel by adopting 3-(methacryloyloxy) propyltrimethoxysilane, and then inducing carbonate precipitation by adopting microorganisms to carry out modification. The invention also discloses a preparation method of the adhesive mortar, and the adhesive mortar prepared by the invention not only has good tensile adhesive strength, but also has good mechanical properties, excellent sagging resistance and good volume stability.

Owner:临海市忠信新型建材有限公司

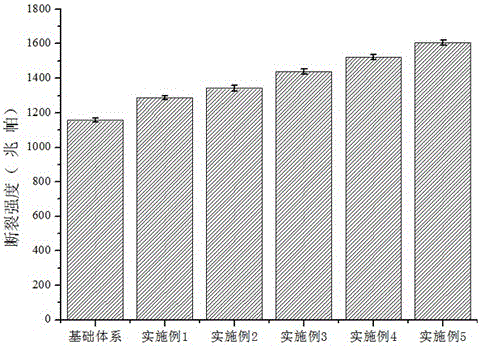

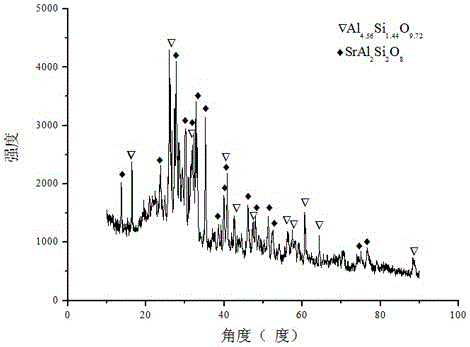

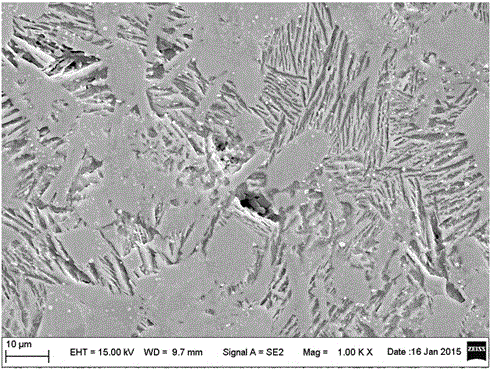

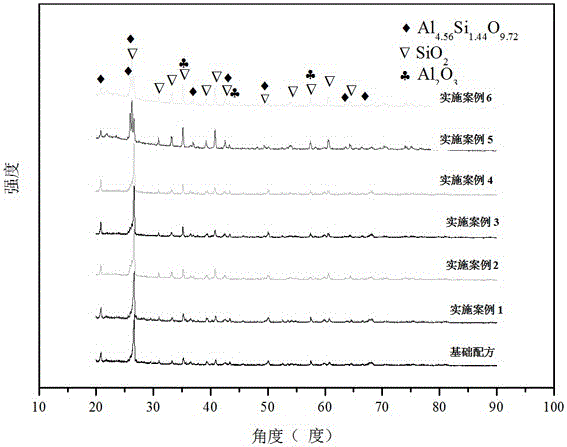

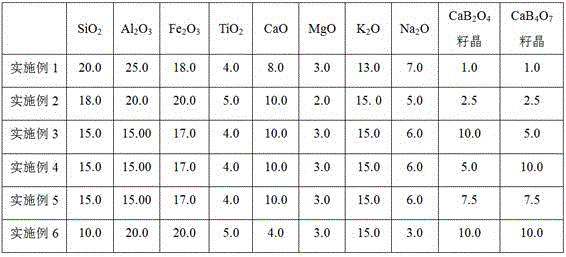

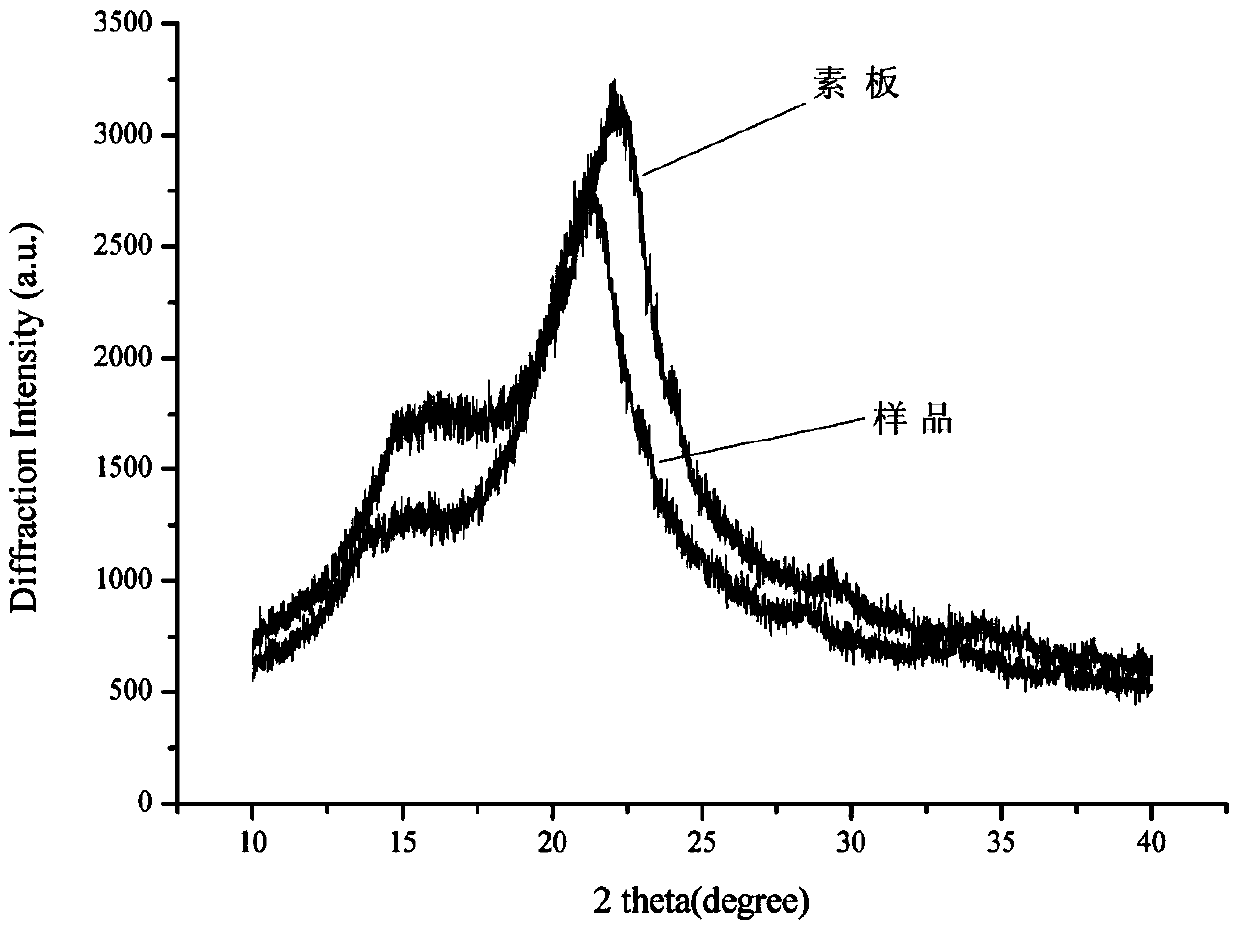

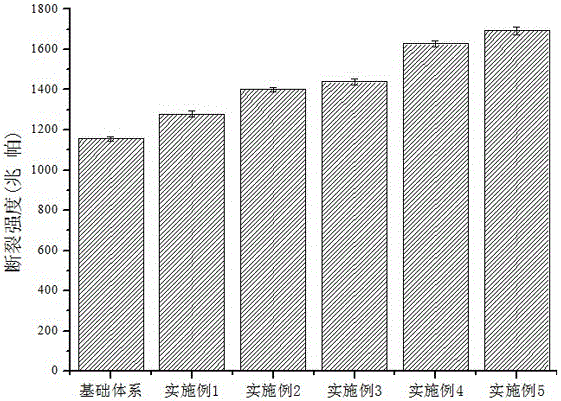

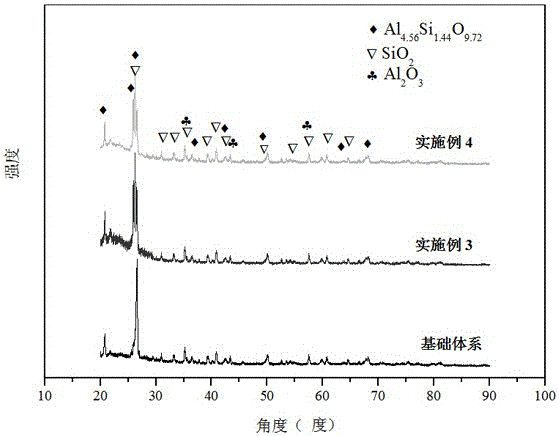

Compound amorphous seed added electrical porcelain and preparation method thereof

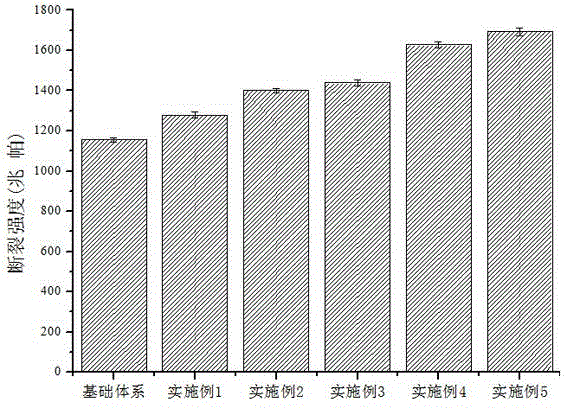

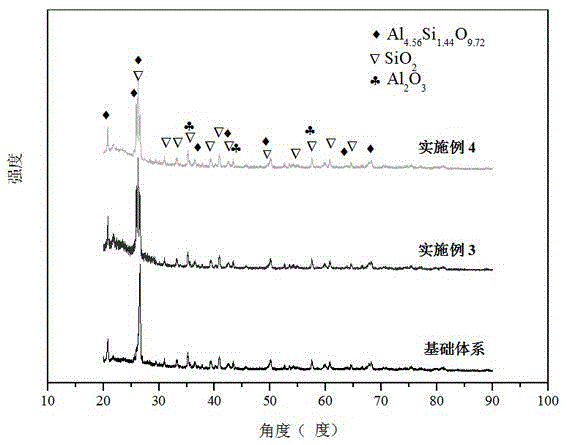

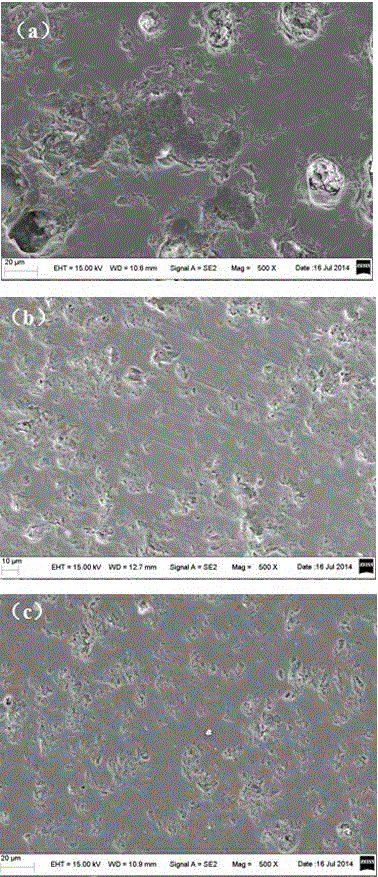

InactiveCN104803668AIncreased elastic strain energyEasy to prepare ingredientsBreaking strengthMullite

The invention discloses compound amorphous seed added electrical porcelain and a preparation method thereof. The compound amorphous seed added electrical porcelain is prepared from the following raw materials in weight percent: 10-20% of SiO2, 10-25% of Al2O3, 10-20% of Fe2O3, 1-5% of TiO2, 2-10% of CaO, 0-3% of MgO, 5-15% of K2O, 3-8% of Na2O, and 5-20% of compound amorphous seeds. According to the compound amorphous seed added electrical porcelain and the preparation method thereof disclosed by the invention, the compound amorphous seeds (CaB2O4 amorphous seed and CaB4O7 amorphous seed) are added, so that the softening characteristic of the amorphous seeds can be exerted, and the sintering process of the electrical porcelain can be promoted; in the temperature raising process, the compound amorphous seeds can be converted into compound seed crystals (CaB2O4 seed crystal and CaB4O7 seed crystal), and the seed crystals are molten to form a liquid phase, so that the sintering process of the electrical porcelain can be further promoted, the density of the electric porcelain can be improved, and the breaking strength of the electrical porcelain is obviously enhanced; in addition, the addition of the compound amorphous seeds can effectively facilitate crystallization of mullite phase, and furthermore the mechanical strength of the electrical porcelain is obviously improved. The preparation method disclosed by the invention is simple and accessible in raw materials, stable and mature in process, and capable of meeting the requirements of practicability and industrialization.

Owner:FUZHOU UNIV

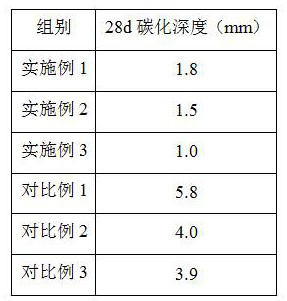

High durability concrete and preparation method thereof

ActiveCN114230243BCompact and stable structureImprove microstructureSolid waste managementFiberSuperplasticizer

The invention discloses a high-durability concrete. The high-durability concrete comprises the following raw materials in parts by weight: 200-260 parts of cement, 50-80 parts of mineral powder, 40-50 parts of limestone grinding fine powder, 900-970 parts of mechanism Sand, 900-980 parts of limestone crushed stone, 7-10 parts of polycarboxylate superplasticizer, 160-170 parts of water, 1-2 parts of magnesium borate-carbon nanotube composite material, 0.3-0.5 parts of diamond micropowder, 0.4-0.7 parts of fiber material. The invention can effectively improve the anti-chloride ion erosion performance and anti-carbonation performance of concrete.

Owner:柳州市大星混凝土有限公司

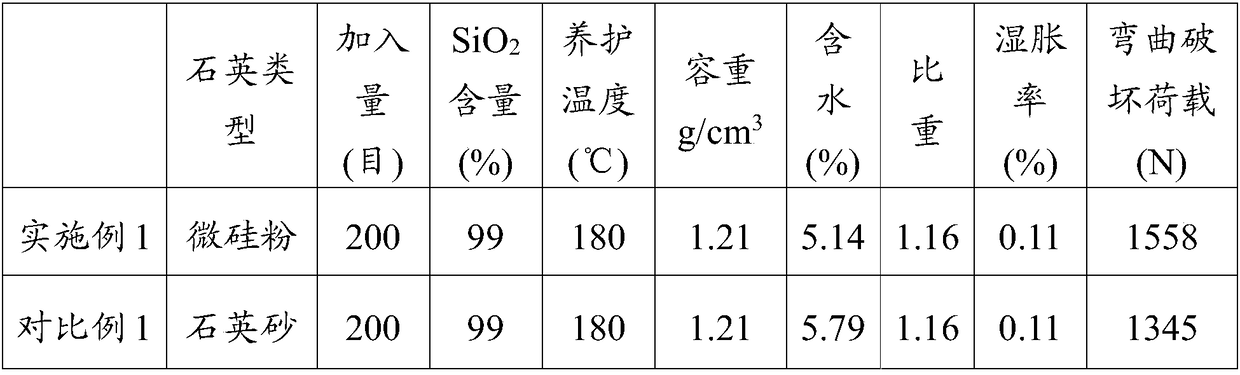

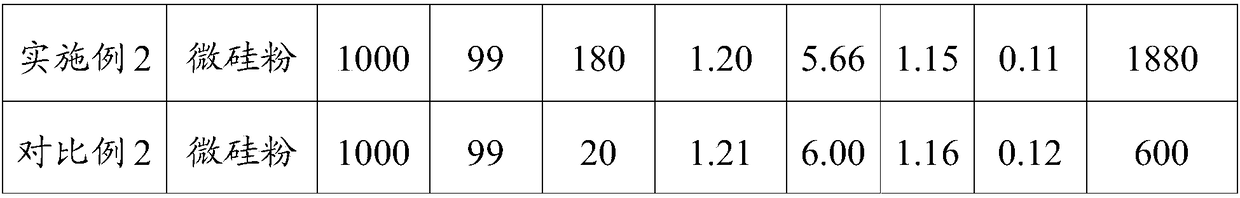

Fiber cement external wall board and preparation method thereof

The invention provides a fiber cement external wall board and a preparation method thereof. The fiber cement external wall board comprises the following components in parts by weight: 80-120 parts ofcement, 22-27 parts of silicon micropowder, 43-58 parts of closed-pore vitrified microbeads, 20-29 parts of talcum powder, 12-18 parts of mica, 20-28 parts of wood fiber and 27-34.5 parts of fly ash,wherein the silicon micropowder has the particle size of 10-20 microns and has the silicon dioxide content of 99% or above. Through addition of a certain proportion of silicon micropowder into a production formula, pores of a cement substrate can be effectively filled, the compactness of the board is improved, and the water absorbing rate is reduced; meanwhile, through production of a gel by virtue of a hydration reaction of the silicon micropowder and the cement, adhesion between the fiber and the cement is strengthened and the flexural strength of the board is effectively improved.

Owner:BEIJING NEW BUILDING MATERIALS PLC +1

A kind of electric porcelain with composite seed crystal added and its preparation method

The invention discloses an electroceramic added with compound seed crystal and a preparation method of the electroceramic. The electroceramic is prepared from such raw materials in percentage by weight as 10-20% of SiO2, 10-25% of Al2O3, 10-20% of Fe2O3, 1-5% of TiO2, 2-10% of CaO, 0-3% of MgO, 5-15% of K2O, 3-8% of Na2O and 2-20% of compound seed crystal. As the compound seed crystal (CaB2O4 seed crystal and CaB4O7 seed crystal) is added, the sintering process of the electroceramic can be accelerated, the density of the electroceramic can be increased and the breaking strength of the electroceramic can be remarkably enhanced; besides, due to the addition of the compound seed crystal, the crystallization of the mullite phase also can be effectively promoted, and therefore, the mechanical strength of the electroceramic can be remarkably improved. The preparation raw materials of the electroceramic are simple and easily available, and the process is stable and mature, and satisfies the practical and industrial conditions.

Owner:FUZHOU UNIV

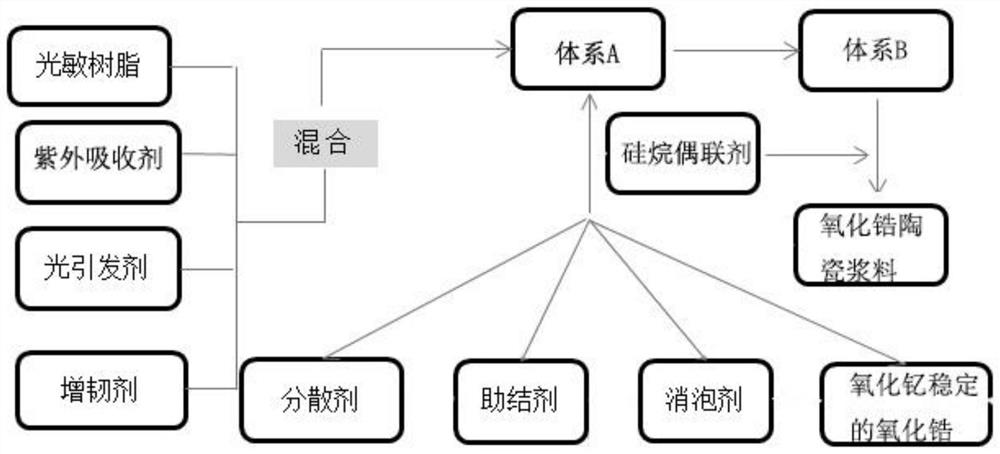

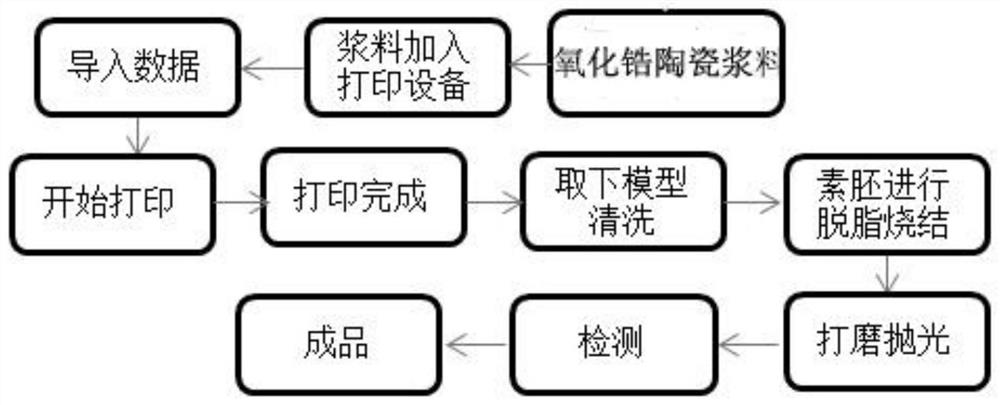

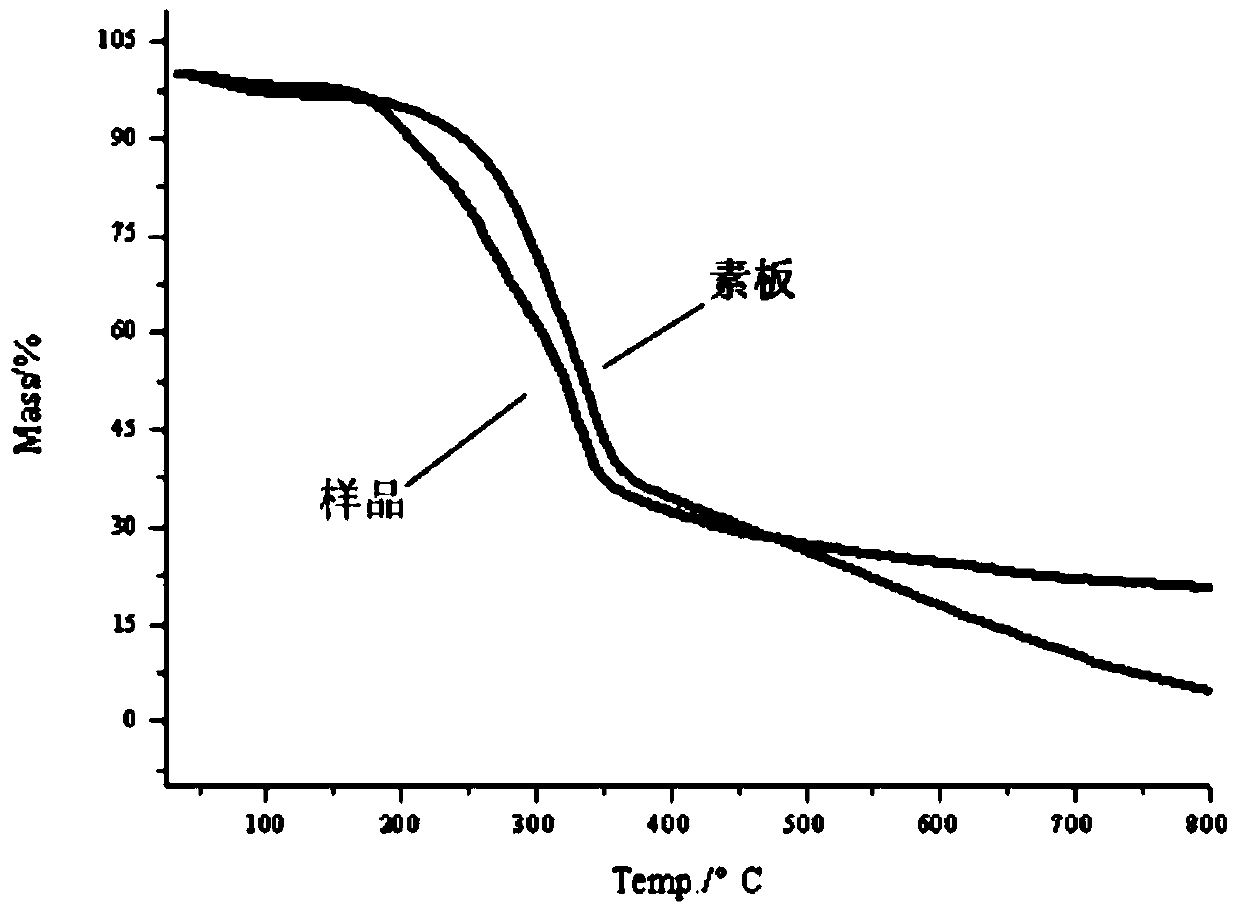

Zirconia ceramic slurry, preparation method thereof, false tooth and false tooth preparation method

PendingCN114621006ASolve the defect that it is easy to settle for a long timeSolve the defect of easy settlementImpression capsAdditive manufacturing apparatusUv absorbanceTooth Preparations

The invention discloses zirconia ceramic slurry, a preparation method thereof, a false tooth and a false tooth preparation method. The zirconia ceramic slurry is prepared from the following raw materials: yttria-stabilized zirconia, a dispersing agent, an ultraviolet absorbent, a photoinitiator, photosensitive resin, a toughening agent, a bonding aid, a defoaming agent and a silane coupling agent, the invention relates to a light-sensitive ceramic material, which is prepared from the following components in parts by weight: 60 to 75 parts of yttria-stabilized zirconia, 2 to 4 parts of dispersing agent, 1 to 3 parts of ultraviolet absorbent, 3 to 5.2 parts of photoinitiator, 18 to 26 parts of photosensitive resin, 3 to 6 parts of toughening agent, 5 to 11.4 parts of bonding aid and 2 to 2.6 parts of defoaming agent, wherein the yttria-stabilized zirconia is prepared from the following components in parts by weight: 60 to 75 parts of yttria-stabilized zirconia, 2 to 4 parts of dispersing agent, 1 to 3 parts of ultraviolet absorbent, 3 to 5.2 parts of photoinitiator, 18 to 26 parts of photosensitive resin, 3 to 6 parts of toughening agent, 5 to 11.4 parts of bonding aid and 2 to 2.6 parts of defoaming agent; the weight part of the silane coupling agent is 1-3 parts; and the particle size of the yttrium oxide-stabilized zirconium oxide is 50-100 nm. The slurry can effectively overcome the defect that traditional zirconium oxide slurry is easy to settle after being placed for a long time.

Owner:西安优梨数字科技有限公司

A kind of thin flame-retardant medium density fiberboard and its preparation method

ActiveCN105751346BThermoplasticEffectively fills poresDomestic articlesFlat articlesFiberSingle type

The invention discloses a thin flame-retardant medium-density fiberboard which comprises the following raw materials: a fiber raw material, urea resin accounting for 8-16 weight percent of the fiber raw material, a flame retardant accounting for 8-20 weight percent of the fiber raw material, ammonia chloride accounting for 0.12-0.24 weight percent of the fiber raw material and emulsion paraffin accounting for 0.6-1.2 weight percent of the fiber raw material, wherein the flame retardant comprises a solid flame retardant and a liquid flame retardant. The thin flame-retardant medium-density fiberboard disclosed by the invention adopts the two types of flame retardants, namely the solid flame retardant and the liquid flame retardant, and can solve the problem that the structure is simple due to the addition of the single type of flame retardant, so that the mechanical property is reduced; by the collaborative use of the solid flame retardant and the liquid flame retardant, pores inside the fiberboard can be effectively filled; the liquid flame retardant can form a good connecting link between two solid matters; meanwhile, the liquid flame retardant has a certain thermal plasticity, so that the adverse effect of the flame-retardant on the mechanical properties of the board can be reduced to a certain extent.

Owner:文安县和民木业有限公司

A kind of electric porcelain with added composite seed amorphous and its preparation method

The invention discloses compound amorphous seed added electrical porcelain and a preparation method thereof. The compound amorphous seed added electrical porcelain is prepared from the following raw materials in weight percent: 10-20% of SiO2, 10-25% of Al2O3, 10-20% of Fe2O3, 1-5% of TiO2, 2-10% of CaO, 0-3% of MgO, 5-15% of K2O, 3-8% of Na2O, and 5-20% of compound amorphous seeds. According to the compound amorphous seed added electrical porcelain and the preparation method thereof disclosed by the invention, the compound amorphous seeds (CaB2O4 amorphous seed and CaB4O7 amorphous seed) are added, so that the softening characteristic of the amorphous seeds can be exerted, and the sintering process of the electrical porcelain can be promoted; in the temperature raising process, the compound amorphous seeds can be converted into compound seed crystals (CaB2O4 seed crystal and CaB4O7 seed crystal), and the seed crystals are molten to form a liquid phase, so that the sintering process of the electrical porcelain can be further promoted, the density of the electric porcelain can be improved, and the breaking strength of the electrical porcelain is obviously enhanced; in addition, the addition of the compound amorphous seeds can effectively facilitate crystallization of mullite phase, and furthermore the mechanical strength of the electrical porcelain is obviously improved. The preparation method disclosed by the invention is simple and accessible in raw materials, stable and mature in process, and capable of meeting the requirements of practicability and industrialization.

Owner:FUZHOU UNIV

Aerogel heat insulation sleeve for battery and preparation method of aerogel heat insulation sleeve

PendingCN113443890AUniform shapeAvoid uneven dippingCell component detailsCeramicwareMicrofiberSilicon oxide

The invention discloses an aerogel heat insulation sleeve for a battery. The aerogel heat insulation sleeve for the battery comprises a cylindrical sleeve body with one end sealed, wherein grooves are formed in the sleeve body in an axis direction, and the number of the grooves is 1-4, and the grooves are evenly distributed in the circumferential direction. The preparation method comprises the following steps: (1) continuously pumping uniform superfine fiber slurry into a hollow special-shaped mold, allowing fibers to be stacked in the mold and to be automatically woven and formed, and then carrying out drying and demolding to obtain a superfine fiber sleeve; (2) preparing a silicon dioxide micelle particle solution; (3) adding the silicon dioxide micellar particle solution into the superfine fiber sleeve, and then conducting treatment by using a mechanical wave dispersion method to obtain a heat insulation sleeve gel preform; (4) putting the heat insulation sleeve gel preform into an alcoholic solution of a water repellent for modification; and (5) prefabricating the modified heat insulation sleeve gel, and conducting drying and demolding to obtain the aerogel heat insulation sleeve for the battery. The sleeve is uniformly formed, and the defects of non-uniform gum dipping, bending, cavities and the like are effectively avoided.

Owner:GUIZHOU AEROSPACE WUJIANG MACHINERY & ELECTRICITYEQUIP

A kind of high reflectance acrylic polyurethane coating composition

ActiveCN104371531BHigh solid contentGood weather resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsAcrylic resinHigh reflectivity

The invention relates to a high-reflective acrylic polyurethane coating composition which comprises a component A and a component B in a mass part ratio of 20;3. The component A in 100 parts by mass comprises the following materials in part by mass: 30-50 parts of modified hydroxyl acrylic resin, 2-6 parts of auxiliaries, 35-45 parts of heat reflective pigments, 4-8 parts of aerogel and 10-15 parts of organic solvent. The component B in 100 parts by mass comprises the following materials in part by mass: 75-90 parts of polyisocyanate and 10-25 parts of organic solvent. The modified hydroxyl acrylic resin is obtained by cold-blending modified resin and hydroxyl acrylic resin in a mass part ratio of 1-3: 1; the solid content of the modified hydroxyl acrylic resin is greater than or equals to 75wt%; the particle size of heat reflective pigments ranges from 0.55 micron to 1.2 microns; the particle size of the aerogel ranges from 1 micron to 80 microns; the pore size of the aerogel ranges from 10 nanometers to 20 nanometers; and the heat conductivity coefficient of the aerogel is less than or equals to 0.015W / (m k). The polyisocyanate is one or more of HDI (hexamethylene diisocyanate) biuret, HDI trimer and IPDI (isophorone diisocyanate) trimer curing agents. The high-reflective acrylic polyurethane coating composition is high in reflective insulation quality; and the quantity of VOC (volatile organic compounds) of the high-reflective acrylic polyurethane coating component is low.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

A sulfate-resistant concrete

The invention discloses a sulfate-resistant concrete, which belongs to the technical field of concrete. The main points of the technical scheme are, in parts by weight, 260-330 parts of cement, 160-180 parts of water, 60-100 parts of fly ash, and 90 parts of mineral powder. ‑120 parts, 720‑870 parts of fine aggregate, 900‑1200 parts of coarse aggregate, 7‑11 parts of calcined hydrotalcite powder, 1‑2 parts of sodium benzoate, 1‑2 parts of barium nitrate, 10‑20 parts of nano silicon dioxide Parts, 7‑13 parts of polycarboxylate superplasticizer, calcined hydrotalcite powder is obtained by calcining hydrotalcite at 500°C for 2 hours, to improve the sulfate corrosion resistance of concrete.

Owner:中建西部建设北方有限公司 +1

A method for preparing silicon carbide coating on graphite surface

The invention discloses a method for preparing a silicon carbide coating on a graphite surface. The method includes, firstly, placing a graphite crucible containing solid silicone materials in a high temperature graphitizing furnace and placing a graphite base body on a graphite support in the graphite crucible to generate a silicon carbide coating by means of direct reaction of silicon steam and carbon on the surface of the graphite base body; and secondly, placing the graphite base body which generates the silicon carbide coating on the surface in a chemical vapor deposition (CVD) furnace to be pyrolyzed on the surface of the silicon carbide coating which is located on the surface of the graphite base body to generate a CVD silicon carbide coating. According to the method for preparing the silicon carbide coating on the graphite surface, by means of the direct reaction of the silicon steam formed by heating the solid silicone materials and the carbon on the surface of the graphite base body, an in-situ formed chemical vapor reaction (CVR) silicon carbide coating is firmly combined on the graphite base body so that combination intensity is improved; and then a CVD process is used for pyrolyzing the CVR silicon carbide coating at high temperatures on the CVD silicon carbide coating so that pore space of the CVR silicon carbide coating is effectively filled, and combination strength is improved.

Owner:XIAN CHAOMA SCI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com