A kind of thin flame-retardant medium density fiberboard and its preparation method

A medium-density, fiberboard technology, applied in the field of thin flame-retardant medium-density fiberboard and its preparation, can solve problems such as reducing the mechanical properties of the board, achieve excellent thermal insulation performance, simple preparation method, and reduce the effect of water absorption thickness expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

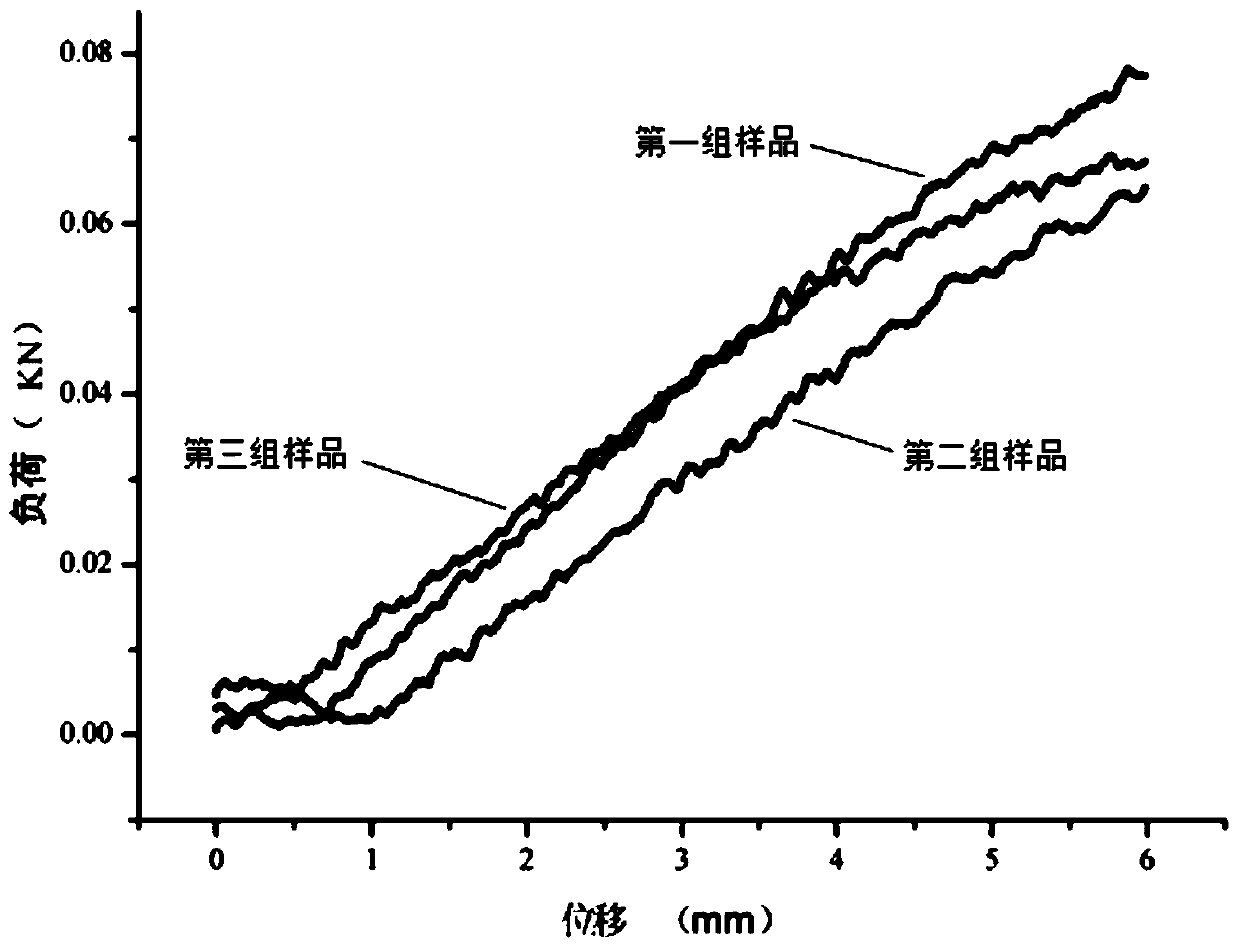

Embodiment 1

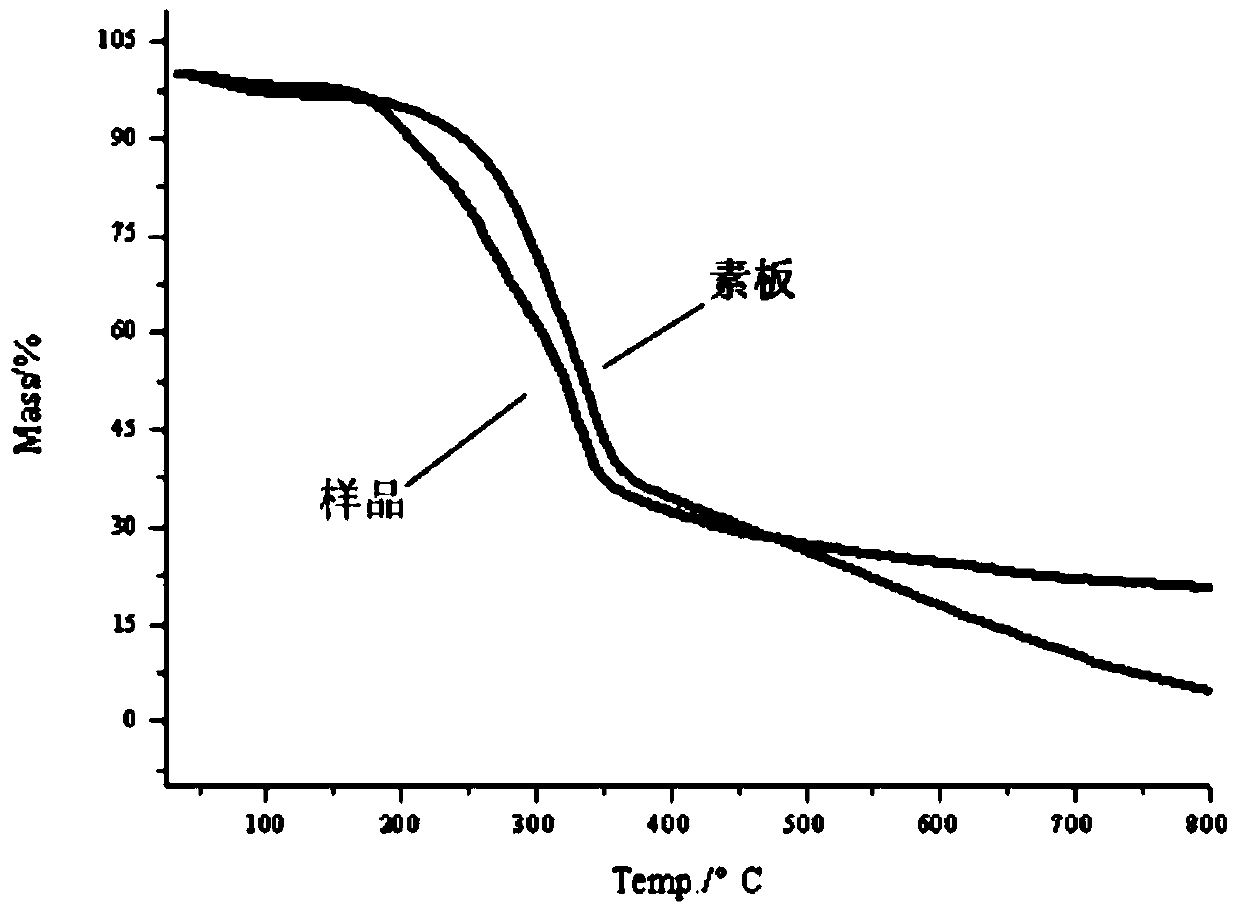

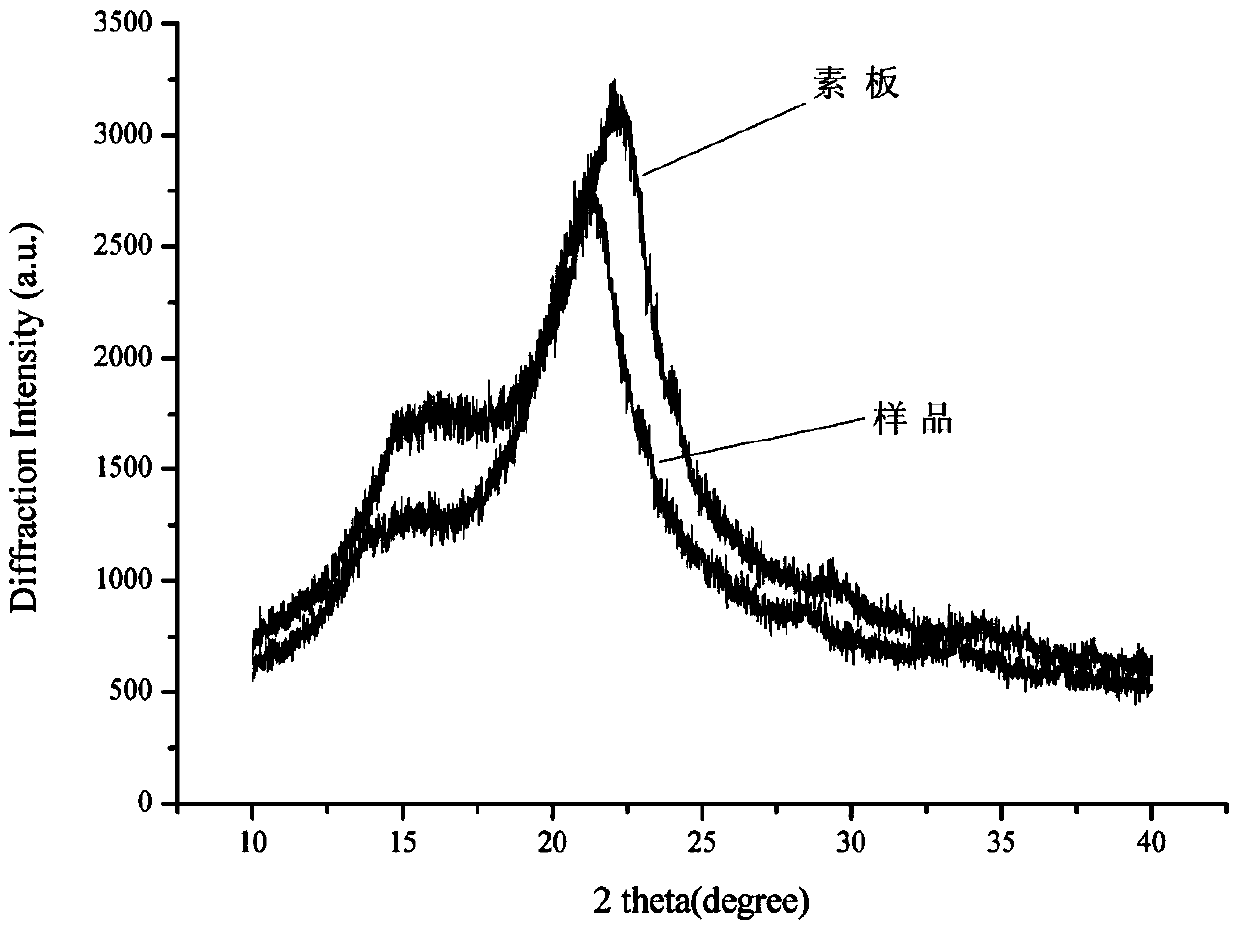

[0030] A thin flame-retardant medium density fiberboard, comprising the following raw materials: fiber raw materials, urea-formaldehyde resin accounting for 12% by weight of fiber raw materials, flame retardant accounting for 14% by weight of fiber raw materials, ammonium chloride accounting for 0.18% by weight of fiber raw materials and 0.9% by weight of raw material emulsified paraffin, the density of thin flame retardant medium density fiberboard is 0.84g / cm 3 , the thickness is 3.0mm;

[0031] The flame retardant includes a solid flame retardant and a liquid flame retardant, and the mass ratio of the solid flame retardant to the liquid flame retardant is 1:1; the raw material of the solid flame retardant includes ammonium polyphosphate and zinc borate, wherein The mass ratio of ammonium polyphosphate and zinc borate is 1:0.3, the raw material of the liquid flame retardant includes phosphoric acid solution, urea and ammonia water, the molar ratio of phosphoric acid, urea an...

Embodiment 2

[0039] A thin flame-retardant medium-density fiberboard, comprising the following raw materials: fiber raw materials, urea-formaldehyde resin accounting for 8% by weight of fiber raw materials, flame retardant accounting for 8% by weight of fiber raw materials, ammonium chloride accounting for 0.12% by weight of fiber raw materials and fiber 0.6% emulsified paraffin wax by raw material weight, and the density of thin flame-retardant MDF is 0.84g / cm 3 , the thickness is 2.8mm;

[0040] The flame retardant includes a solid flame retardant and a liquid flame retardant, and the mass ratio of the solid flame retardant to the liquid flame retardant is 1:0.7; the raw material of the solid flame retardant includes ammonium polyphosphate and zinc borate, wherein The mass ratio of ammonium polyphosphate and zinc borate is 1:0.3, the raw material of the liquid flame retardant includes phosphoric acid solution, urea and ammonia water, the molar ratio of phosphoric acid, urea and ammonia i...

Embodiment 3

[0048] A thin flame-retardant medium density fiberboard, comprising the following raw materials: fiber raw materials, urea-formaldehyde resin accounting for 16% by weight of fiber raw materials, flame retardant accounting for 20% by weight of fiber raw materials, ammonium chloride accounting for 0.24% by weight of fiber raw materials and 1.2% emulsified paraffin wax by raw material weight, the density of thin flame retardant medium density fiberboard is 0.84g / cm 3 , the thickness is 3.2mm;

[0049] The flame retardant includes a solid flame retardant and a liquid flame retardant, and the mass ratio of the solid flame retardant to the liquid flame retardant is 1:1.2; the raw material of the solid flame retardant includes ammonium polyphosphate and zinc borate, wherein The mass ratio of ammonium polyphosphate and zinc borate is 1:0.3, the raw material of the liquid flame retardant includes phosphoric acid solution, urea and ammonia water, the molar ratio of phosphoric acid, urea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com