Marine concrete reinforcing material as well as preparation method and application thereof

A technology for marine concrete and reinforced materials, applied in chemical instruments and methods, inorganic chemistry, calcium/strontium/barium compounds, etc., can solve problems such as aggregate denudation and steel bar corrosion, reduce consumption, improve engineering durability, The effect of preventing the intrusion of corrosive ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

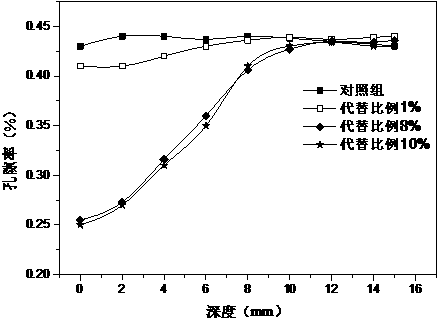

Embodiment 1

[0019] A marine concrete strengthening material, comprising porous microspheres, Bacillus lysinus, sodium alginate, soluble barium silver salt, the porous microspheres are composed of calcium carbonate, sodium dodecylsulfonate and ferric oxide particles Composition, calcium carbonate is used as the main body of porous microspheres, sodium dodecyl sulfonate and ferric oxide particles are uniformly distributed in calcium carbonate porous microspheres; lysine is loaded in the pores of the porous microspheres and on their surfaces Bacillus; the surface of the porous microsphere is coated with a shell made of sodium alginate and soluble barium silver salt. Use the above materials to replace the aggregate in the concrete, and the replacement ratio is 1%.

Embodiment 2

[0021] A marine concrete strengthening material, comprising porous microspheres, Bacillus lysinus, sodium alginate, soluble barium silver salt, the porous microspheres are composed of calcium carbonate, sodium dodecylsulfonate and ferric oxide particles Composition, calcium carbonate is used as the main body of porous microspheres, sodium dodecylsulfonate and chromium dioxide particles are evenly distributed in calcium carbonate porous microspheres; lysine spores are loaded in the pores of the porous microspheres and on their surfaces Bacillus; the surface of the porous microsphere is coated with a shell made of sodium alginate and soluble barium silver salt. Use the above materials to replace the aggregate in the concrete, and the replacement ratio is 8%.

Embodiment 3

[0023] A marine concrete strengthening material, comprising porous microspheres, Bacillus lysinus, sodium alginate, soluble barium silver salt, the porous microspheres are composed of calcium carbonate, sodium dodecylsulfonate and ferric oxide particles Composition, calcium carbonate is used as the main body of porous microspheres, sodium dodecyl sulfonate and ferric oxide particles are uniformly distributed in calcium carbonate porous microspheres; lysine is loaded in the pores of the porous microspheres and on their surfaces Bacillus; the surface of the porous microsphere is coated with a shell made of sodium alginate and soluble barium silver salt. Use the above materials to replace the aggregate in the concrete, and the replacement ratio is 10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com