Preparation method and application of cement-based material additive

A technology of cement-based materials and additives, applied in chemical instruments and methods, inorganic chemistry, calcium/strontium/barium compounds, etc., can solve problems such as high cost, difficult hardening of liquid binders, and inability to put into practical engineering applications, etc., to achieve Improve engineering durability and service life, improve mineralization efficiency, and reduce dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

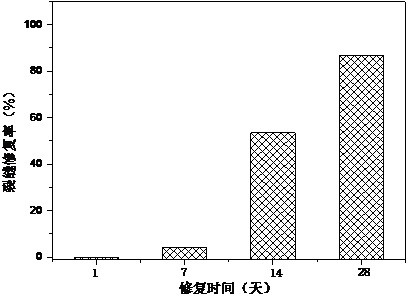

Embodiment 1

[0034] (1) Prepare equal quantities of calcium chloride solution and sodium bicarbonate solution, add organic template sodium dodecylsulfonate to the calcium chloride solution and sodium bicarbonate solution, the addition amount is 1g / L, and add magnetic particles Ferriferric oxide, the addition amount is 1g / L, the calcium chloride solution is slowly added dropwise to the sodium bicarbonate solution, the reaction temperature is 30°C, after standing for 2 hours, use centrifugal separation, wash the sediment with ethanol solution, and dry it Promptly obtain porous calcium carbonate microspheres;

[0035] (2) Inoculate Bacillus lysinus into the medium, the mass ratio of the inoculum to the medium is 1:100, the medium is deionized water 1000mL, peptone 8g, beef extract 2g, NaCl 1g, FeCl 2 0.4g, shake culture at constant temperature for 48 hours, add manganese chloride, a high-efficiency spore transformation agent, to the culture medium, and the addition amount is 1g / L, to obtain t...

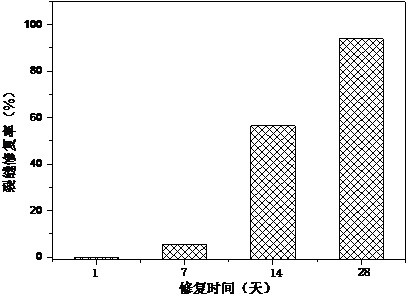

Embodiment 2

[0039] (1) Prepare calcium chloride solution and sodium bicarbonate solution in equivalent quantities, add organic template sodium dodecylsulfonate to calcium chloride solution and sodium bicarbonate solution respectively, the addition amount is 10g / L, add magnetic particles Ferriferric oxide, the addition amount is 5g / L, the calcium chloride solution is slowly added dropwise to the sodium bicarbonate solution, the reaction temperature is 30°C, after standing for 2 hours, centrifugal separation is used, and the ethanol solution is used to wash the sediment, and after drying Promptly obtain porous calcium carbonate microspheres;

[0040](2) Inoculate Bacillus lysinus into the medium, the mass ratio of the inoculum to the medium is 2:100, the medium is deionized water 1000mL, peptone 12g, beef extract 3g, NaCl 5g, FeCl 2 0.6g, shake culture at constant temperature for 48 hours, add manganese chloride, a high-efficiency spore transformation agent, to the culture medium, and the a...

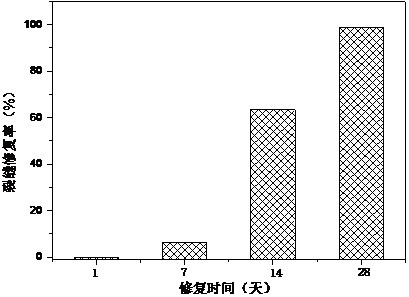

Embodiment 3

[0044] (1) Prepare calcium chloride solution and sodium bicarbonate solution in equivalent quantities, add organic template sodium dodecyl sulfonate to the calcium chloride solution and sodium bicarbonate solution, the addition amount is 5g / L, and add magnetic particles Ferriferric oxide, the addition amount is 2g / L, the calcium chloride solution is slowly added dropwise to the sodium bicarbonate solution, the reaction temperature is 30°C, after standing for 2 hours, the sediment is washed by centrifugation and ethanol solution, and dried Promptly obtain porous calcium carbonate microspheres;

[0045] (2) Inoculate Bacillus lysinus into the medium, the mass ratio of the inoculum to the medium is 1:100, the medium is deionized water 1000mL, peptone 10g, beef extract 2.5g, NaCl 2g, FeCl 2 0.5g, shake culture at constant temperature for 48 hours, add manganese chloride, a high-efficiency spore transformation agent, to the culture medium, and the addition amount is 2g / L, to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com